Preparation method of boron nitride nanotube-intensified silicon oxide ceramic

A technology of boron nitride nanotubes and silicon dioxide, which is applied in the field of preparation of silicon dioxide ceramics, can solve problems such as difficulty in ensuring uniform dispersion, poor uniformity of mixed powder, and complicated operation engineering, so as to facilitate large-scale production, Improved bending strength and good process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

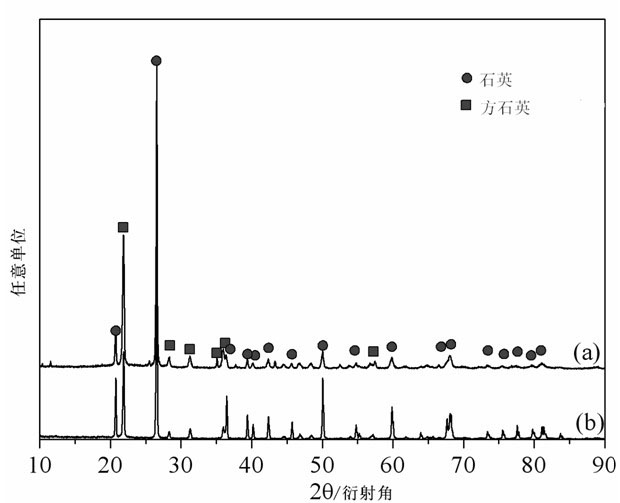

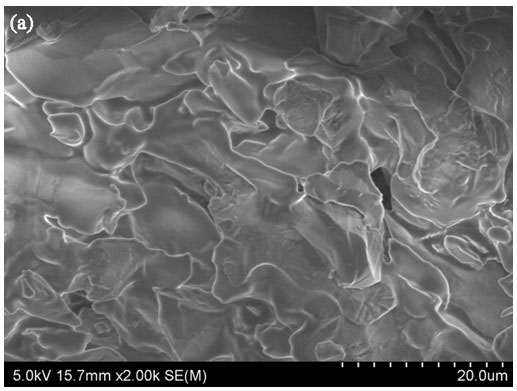

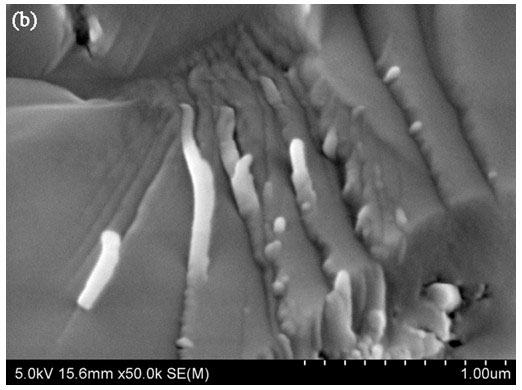

[0034] Example 1: Boron nitride nanotubes are used as reinforcing phase, and nano-sized silicon dioxide and micron-sized silicon dioxide are used as substrates to prepare silicon dioxide ceramics by hot pressing and sintering.

[0035] First, the boron nitride nanotubes were washed three times with analytically pure hydrochloric acid, then three times with deionized water, and then put into a drying oven at 45° C. for 23 h.

[0036] Then use an electronic balance to weigh 1g of boron nitride nanotubes, 3g of nano-sized silicon dioxide and 16g of micron-sized silicon dioxide, pretreat the boron nitride nanotubes and use ultrasonic dispersion, and the surfactant is hexadecyltrimethyl Ammonium bromide, and cetyltrimethylammonium bromide mass is 0.0416g, the dispersion medium is ethanol, and the volume is 100ml. Silica is dispersed by stirring, the surfactant is sodium dodecylsulfonate, and the quality of sodium dodecylsulfonate is 0.7917g, the dispersion medium is ethanol, and th...

Embodiment 2

[0037] Example 2: Boron nitride nanotubes were used as reinforcing phase, and nano-sized silicon dioxide and micron-sized silicon dioxide were used as substrates to prepare silicon dioxide ceramics by hot pressing and sintering.

[0038] First, the boron nitride nanotubes were washed three times with analytically pure hydrochloric acid, then three times with deionized water, and then put into a drying oven to dry at 50° C. for 24 h.

[0039]Weigh 0.8g of boron nitride nanotubes, 2.8g of nano-scale silicon dioxide and 16.4g of micron-scale silicon dioxide with an electronic balance, pretreat the boron nitride nanotubes and disperse them ultrasonically, and the surfactant is hexadecane trimethylammonium bromide, and the mass ratio of hexadecyltrimethylammonium bromide to boron nitride nanotubes is 0.0333g, the dispersion medium is ethanol, and the volume is 90ml. Silica is dispersed by stirring, the surfactant is sodium dodecylsulfonate, and the quality of sodium dodecylsulfonat...

Embodiment 3

[0040] Example 3: Boron nitride nanotubes were used as reinforcing phases, and nano-sized silicon dioxide and micron-sized silicon dioxide were used as substrates to prepare silicon dioxide ceramics by hot pressing and sintering.

[0041] Firstly, the boron nitride nanotubes were washed three times with analytically pure hydrochloric acid, then washed three times with deionized water, and then put into a drying oven to dry at 55° C. for 25 h.

[0042] Weigh 0.9g of boron nitride nanotubes, 3g of nano-sized silicon dioxide and 16.1g of micron-sized silicon dioxide with an electronic balance, pretreat the boron nitride nanotubes and disperse them ultrasonically, and the surfactant is hexadecyl Trimethylammonium bromide, and the mass ratio of hexadecyltrimethylammonium bromide to boron nitride nanotubes is 0.0625g, the dispersion medium is ethanol, and the volume is 110ml. Silica is dispersed by stirring, the surfactant is sodium dodecylsulfonate, and the quality of sodium dodecy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com