Boron nitride nanotube fibrils and yarns

a boron nitride and nanotube technology, applied in the field of nanostructure production, can solve the problems of not reporting the same progress for bnnts, not showing the production of boron nitride fibrils that can be bunched and spun into yarns, and little progress in the scale-up of their synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

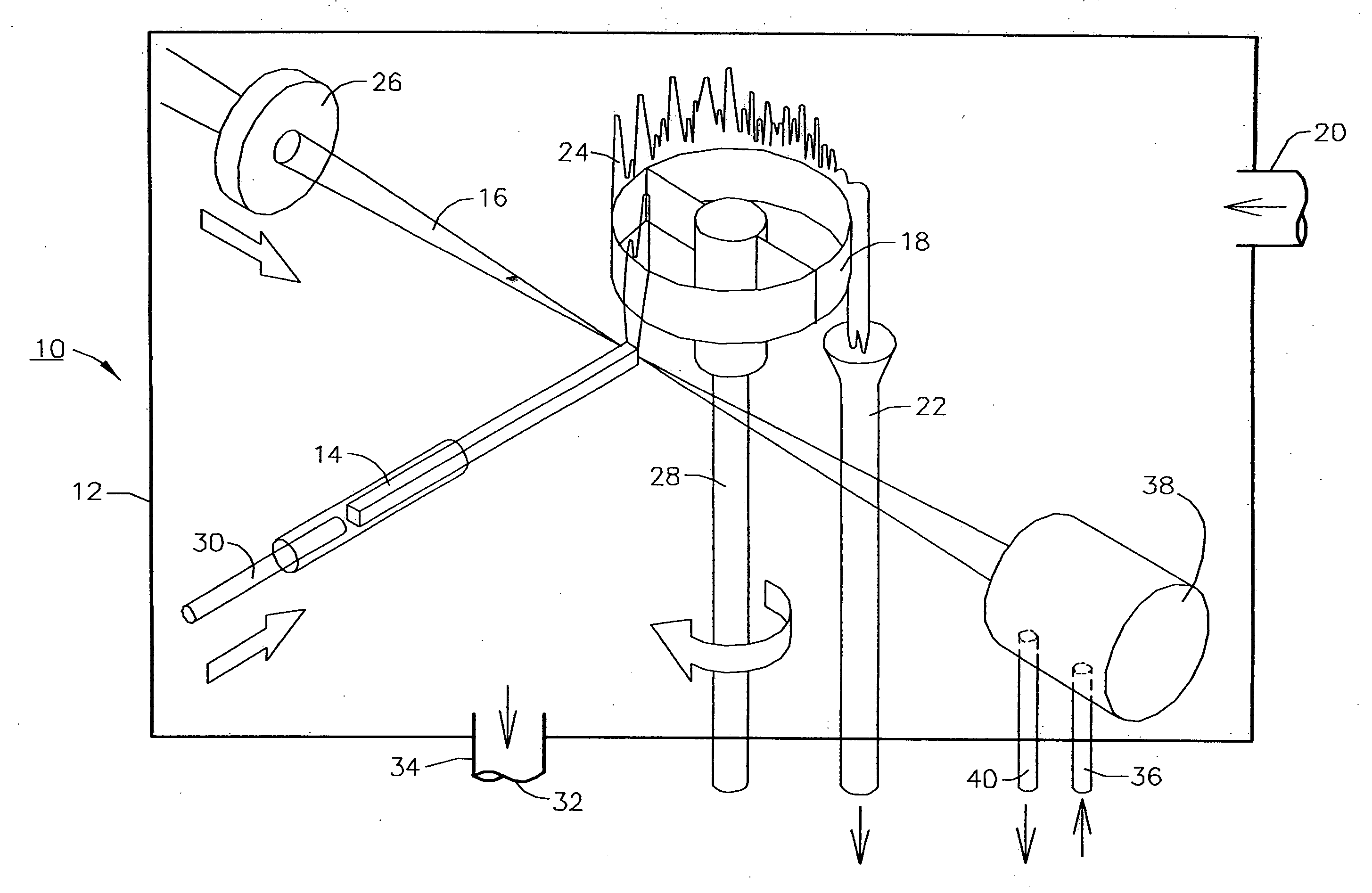

[0017]The benefits of the present invention are achieved by providing a process for producing boron nitride nanotubes and nanostructures, which comprises:[0018](a) providing a boron-containing target in a chamber under nitrogen pressure which is elevated above atmospheric; and[0019](b) thermally exciting a boron-containing target.

[0020]Especially advantageous results are obtained if the boron-containing target is thermally excited by means of a laser, such as a free electron laser or a carbon dioxide laser.

[0021]Beneficial results are obtained if the boron-containing target is made of compressed boron powder or compressed boron nitride powder.

[0022]The target is advantageously cylindrical, rotating, and illuminated on the radius, or cylindrical, rotating, and illuminated on one face. However, the target may also be stationary. Further preferred target orientation and illuminations are described in greater detail below.

[0023]Highly desirable and very advantageous results are obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com