Preparation method of quasi one-dimensional boron nitride nanostructure

A nanostructure and boron nitride technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of low output, poor crystallinity, and low purity of boron nitride tubes, and achieve easy control of process parameters, Large product output and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

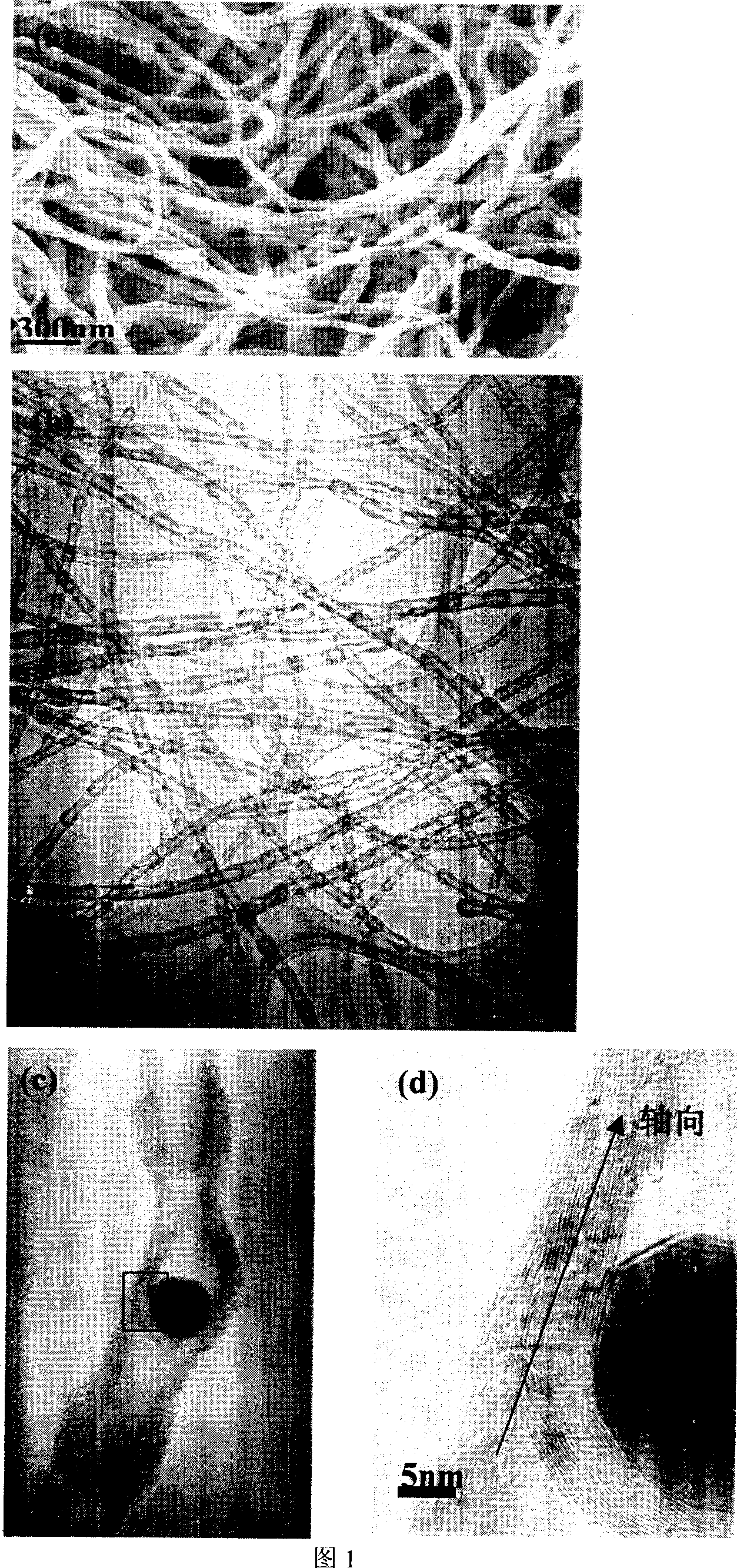

[0024] The floating catalyst is ferrocene, the weight ratio relationship between the amount used and the sum of the reactants (boron powder, boron oxide) is 0.1, the evaporation temperature is 150°C, the flow rate of ammonia gas is 100 sccm, the flow rate of nitrogen gas is 300 sccm, boron powder and boron oxide The weight ratio is 1:4, the reaction temperature is 1300°C, the heating rate is 25°C / min, and the reaction time is 1 hour. Bamboo-shaped boron nitride nanotubes with a diameter of about 50 nanometers and a length of tens of micrometers were obtained, as shown in FIG. 1 . From the high-resolution image, it can be clearly seen that (0002) is arranged parallel to the axial direction, and its purity is 95%.

Embodiment 2

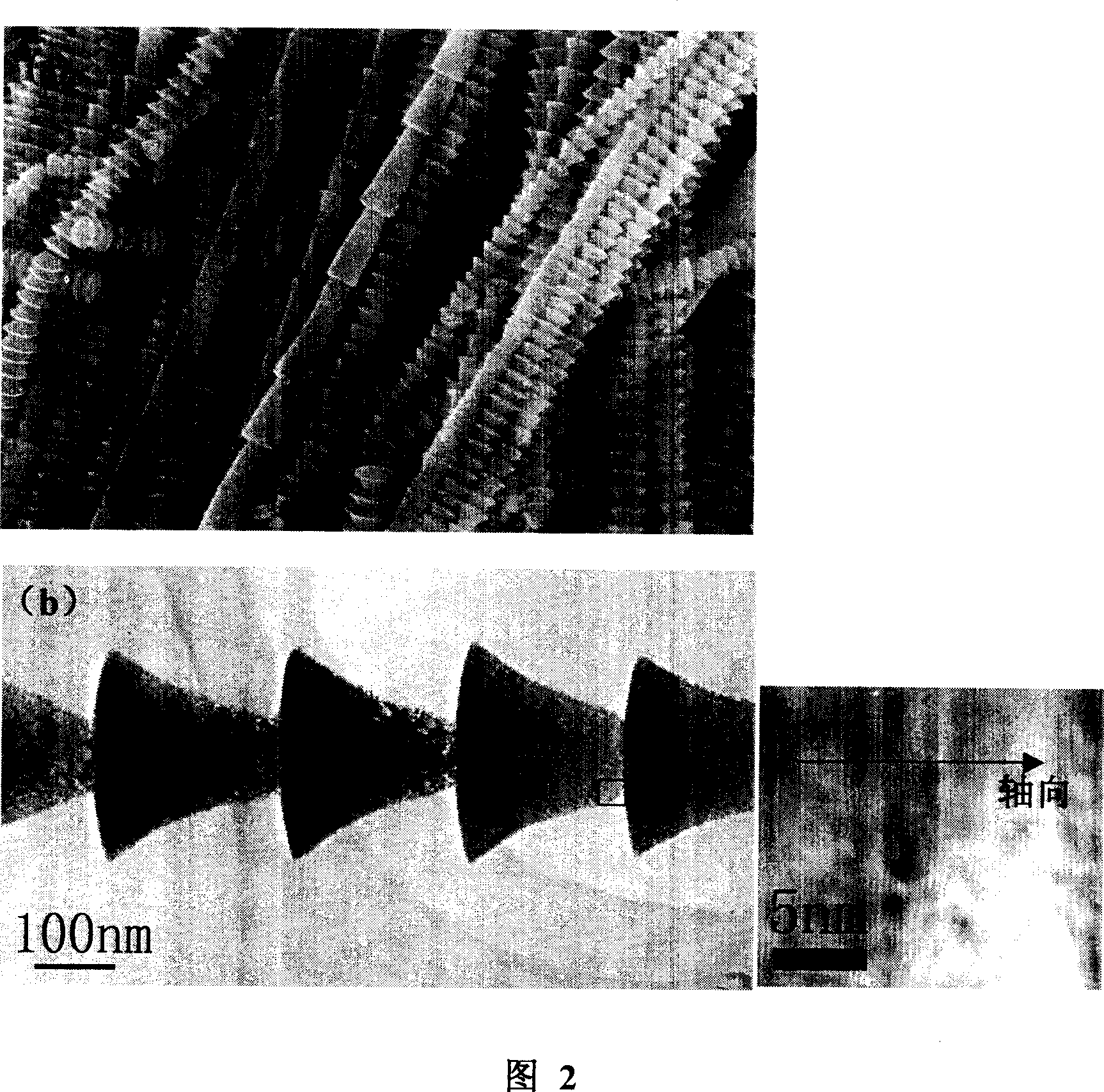

[0026] The floating catalyst is nickelocene, the weight ratio relationship between the amount used and the sum of reactants (boron powder, boron oxide) is 0.2, the evaporation temperature is 200°C, the flow rate of ammonia gas is 50 sccm, the flow rate of nitrogen gas is 150 sccm, boron powder and boron oxide The weight ratio is 1:4, the reaction temperature is 1400°C, the heating rate is 35°C / min, and the reaction time is 1 hour. A cup-stacked boron nitride nanowire with a diameter of about 100 nanometers and a length of tens of micrometers is obtained, as shown in FIG. 2 . From the high-resolution image, it can be clearly seen that the (0002) planes are arranged perpendicular to the axial direction, and the purity is 90%.

Embodiment 3

[0028] The floating catalyst is cobaltocene, the weight ratio relationship between the amount used and the sum of the reactants (boron powder, boron oxide) is 0.2, the evaporation temperature is 300°C, the flow rate of ammonia gas is 50 sccm, the flow rate of nitrogen gas is 200 sccm, boron powder and boron oxide The weight ratio is 1:7, the reaction temperature is 1380°C, the heating rate is 40°C / min, and the reaction time is 1 hour. The cup-stacked boron nitride nanowires with a diameter ranging from tens to two to three hundred nanometers and a length of tens of microns were obtained, and there were many secondarily grown sheets and small nanotubes on the surface, as shown in Figure 3. The arrangement of the (0002) vertical axis mentioned in Example 2 can be verified from selected area electron diffraction, and its purity is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com