Method for preparing boron nitride nanotube by magnesium reduction

A boron nitride nanotube and magnesium heating technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of large size span of nanotubes, affecting the service life of equipment, unstable chemical properties, etc. The effect of no structure, low preparation cost and easy purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Under the protection of argon, place boron oxide, magnesium and ferrous chloride in a molar ratio of 1:1:0.1 in an agate mortar and thoroughly grind to completely mix the reactants, then pass through a 300-mesh sieve;

[0018] 2) Put the mixture sieved in step 1) into an aluminum oxide porcelain boat and place it in the constant temperature zone of a horizontal tube furnace, feed 50 sccm of argon gas, start to heat up, and when the temperature reaches 900°C, turn off the argon Gas and feed 50sccm ammonia gas to continue to heat up, when it reaches 1200°C, keep the temperature constant for 5 hours;

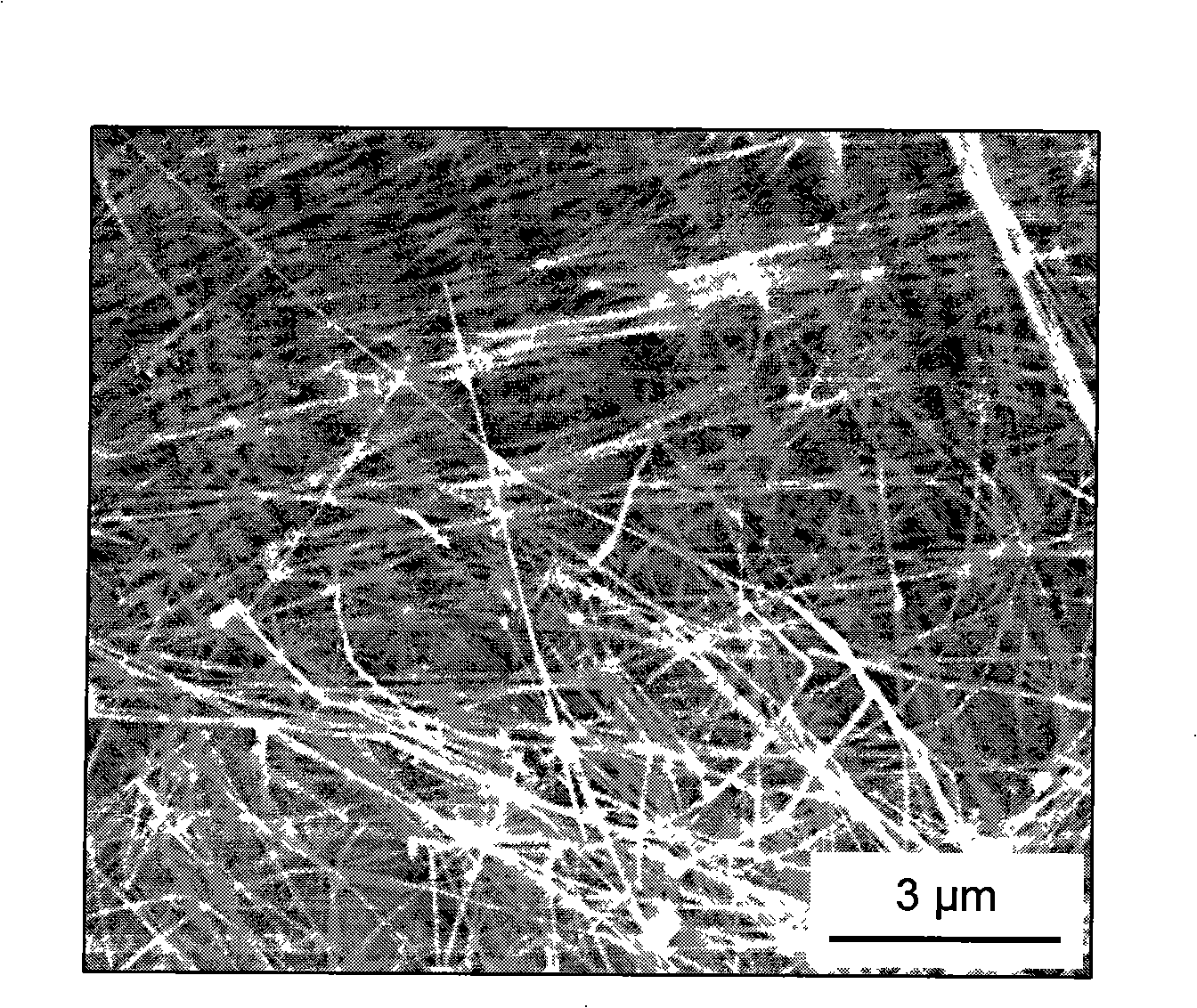

[0019] 3) At the end of the constant temperature, close the air inlet and exhaust port at the same time, and cool down to room temperature with the furnace. The product in the porcelain boat is a white spongy block, which is full of elasticity. After washing away impurities containing magnesium and iron with nitric acid, the product is uniform. White powder with no signif...

Embodiment 2

[0021] 1) Under the protection of argon, place boron oxide, magnesium and ferrous sulfate in a molar ratio of 1:2:0.05 in an agate mortar and thoroughly grind to completely mix the reactants, then pass through a 300-mesh sieve;

[0022] 2) Put the mixture sieved in step 1) into an aluminum oxide porcelain boat and place it in the constant temperature zone of a horizontal tube furnace, feed 100 sccm of argon gas, start to heat up, and when the temperature reaches 1100°C, turn off the argon Gas and feed 100sccm ammonia gas to continue heating up, when it reaches 1400°C, keep the temperature constant for 2 hours;

[0023] 3) At the end of the constant temperature, close the air inlet and exhaust port at the same time, and cool down to room temperature with the furnace. The product in the porcelain boat is a white spongy block, which is full of elasticity. After washing away impurities containing magnesium and iron with nitric acid, the product is uniform. White powder with no sig...

Embodiment 3

[0025] 1) Under the protection of argon, place boron oxide, magnesium and ferrous oxalate in a molar ratio of 1:3:0.01 in an agate mortar and thoroughly grind to mix the reactants completely, then pass through a 300-mesh screen;

[0026] 2) Put the mixture sieved in step 1) into an aluminum oxide porcelain boat and place it in the constant temperature zone of a horizontal tube furnace, feed 200 sccm of argon gas, start to heat up, and when the temperature reaches 1200°C, turn off the argon Gas and feed 200sccm ammonia gas to continue heating, when it reaches 1600°C, keep the temperature constant for 1 hour;

[0027] 3) At the end of the constant temperature, close the air inlet and exhaust port at the same time, and cool down to room temperature with the furnace. The product in the porcelain boat is a white spongy block, which is full of elasticity. After washing away impurities containing magnesium and iron with nitric acid, the product is uniform. White powder with no signif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com