Preparation method of boron nitride nano tube with controllable dimension

A boron nitride nanotube and size technology, which is applied in nanostructure manufacturing, chemical instruments and methods, nitrogen compounds, etc., can solve the problems of attenuation of preparation efficiency, high preparation cost, equipment corrosion, etc., and achieve shortening of ball milling time and preparation process Simple, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Put the raw materials boron and ferrous chloride in a plastic bottle at a weight ratio of 1:0.02, add zirconia balls and dimethylformamide, raw materials (boron and ferrous chloride), zirconia balls and dimethylformamide The weight ratio of formamide is 1:5:5, ball milled for 8 hours, and after drying, pass through a 100-mesh sieve;

[0020] 2) Put the mixture sieved in step 1) into an alumina porcelain boat and place it in the constant temperature zone of a horizontal tube furnace, feed 50 sccm of argon gas, start to heat up, when the temperature reaches 1000°C, turn off the argon gas and Pass into 100sccm nitrogen, constant temperature 5 hours;

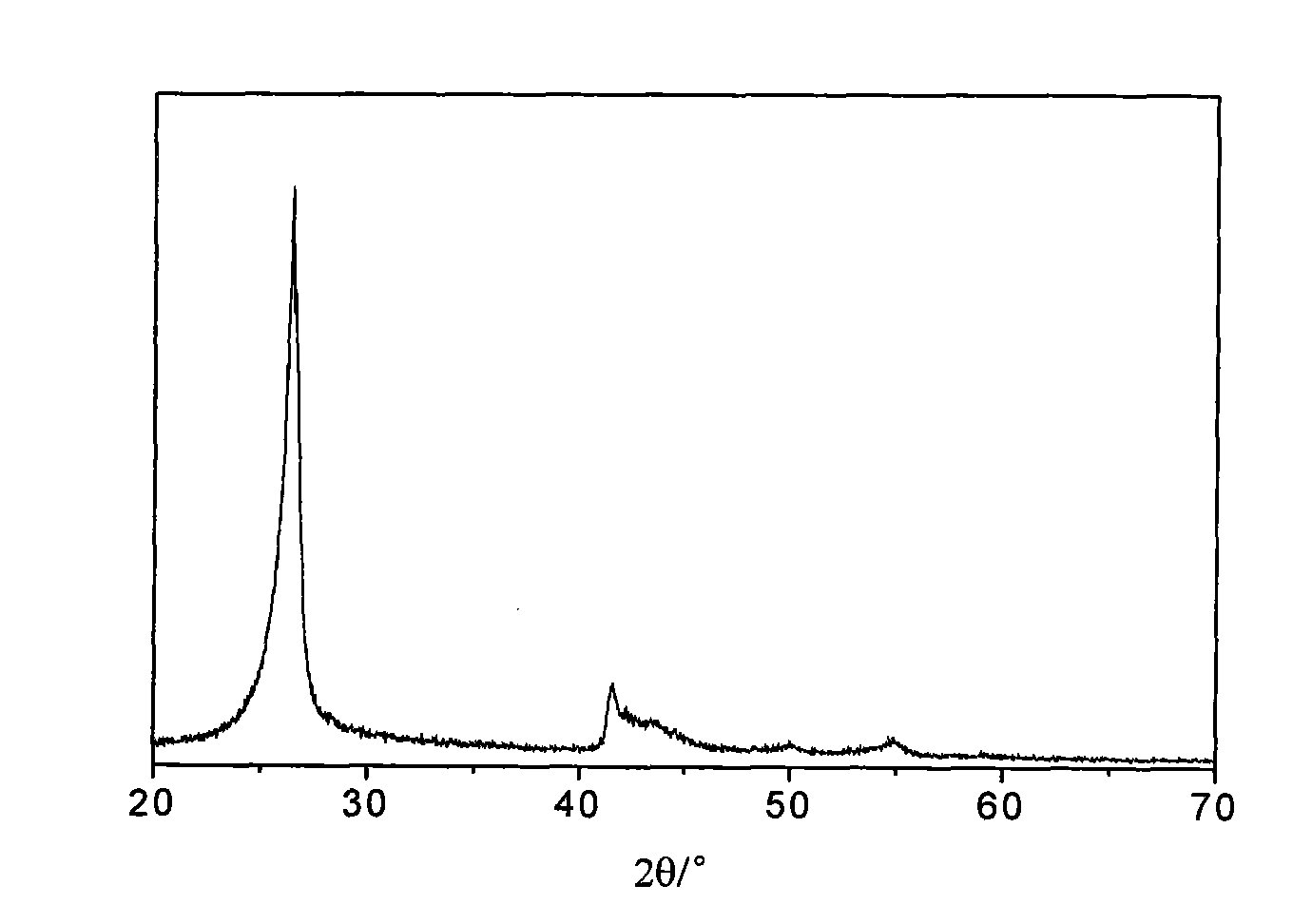

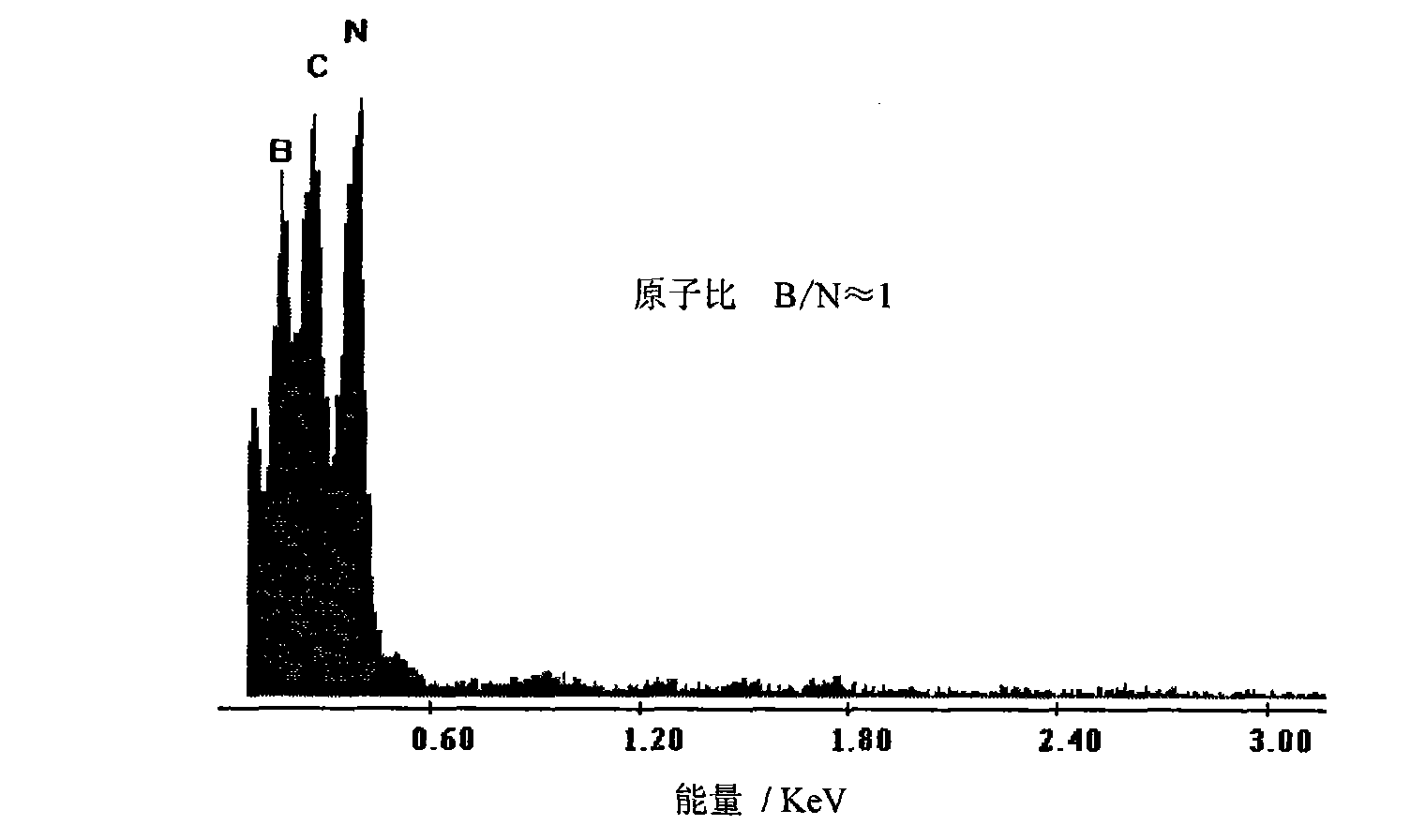

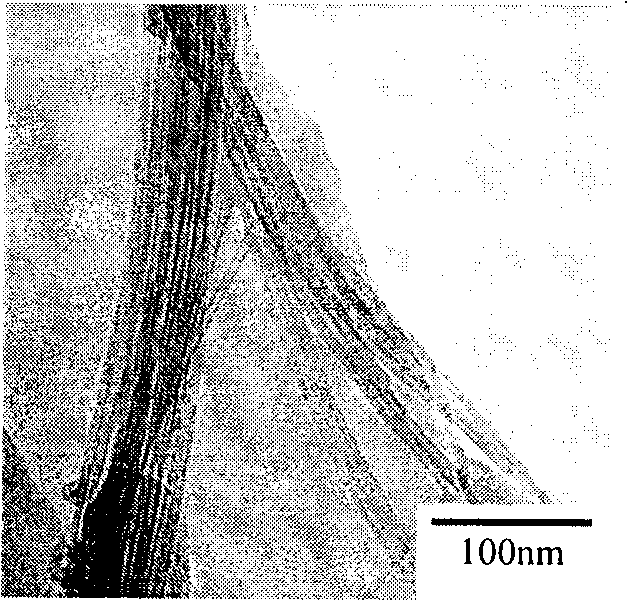

[0021] 3) Close the exhaust port and the air inlet successively at the end of the constant temperature, and cool down to room temperature with the furnace. The product in the porcelain boat is an off-white powder with static electricity. After ultrasonic washing with nitric acid to remove iron-containing impurities, the pr...

Embodiment 2

[0023] 1) Put the raw materials boron and ferrous chloride in a plastic bottle in a weight ratio of 1:0.01, add zirconia balls and dimethylformamide, raw materials (boron and ferrous chloride), zirconia balls and dimethylformamide The weight ratio of formamide is 1:5:5, ball milled for 8 hours, and after drying, pass through a 100-mesh sieve;

[0024] 2) Put the mixture sieved in step 1) into an alumina porcelain boat and place it in the constant temperature zone of a horizontal tube furnace, feed 50 sccm of argon gas, start to heat up, when the temperature reaches 1000°C, turn off the argon gas and Pass into 100sccm nitrogen and 10sccm ammonia gas, constant temperature 2 hours;

[0025] 3) Close the exhaust port and the air inlet successively at the end of the constant temperature, and cool down to room temperature with the furnace. The product in the porcelain boat is an off-white powder with static electricity. After ultrasonic washing with nitric acid to remove iron-contai...

Embodiment 3

[0027] 1) Put the raw materials boron and ferrous sulfate in a plastic bottle at a weight ratio of 1:0.03, add zirconia balls and hexane, the weight ratio of raw materials (boron and ferrous sulfate), zirconia balls and dimethylformamide is 1:5:5, ball mill for 12 hours, after drying, pass through a 100-mesh sieve;

[0028] 2) Put the mixture sieved in step 1) into an alumina porcelain boat and place it in the constant temperature zone of a horizontal tube furnace, feed 50 sccm of argon gas, start to heat up, when the temperature reaches 1150°C, turn off the argon gas and Pass into 100sccm nitrogen and 20sccm ammonia gas, constant temperature 3 hours;

[0029] 3) Close the exhaust port and the air inlet successively at the end of the constant temperature, and cool down to room temperature with the furnace. The product in the porcelain boat is an off-white powder with static electricity. After ultrasonic washing with nitric acid to remove iron-containing impurities, the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com