Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Asbestos cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asbestos cement, genericized as fibro or fibrolite - short for "fibrous (or fibre) cement sheet" - and AC sheet, is a building material in which asbestos fibres are used to reinforce thin rigid cement sheets.

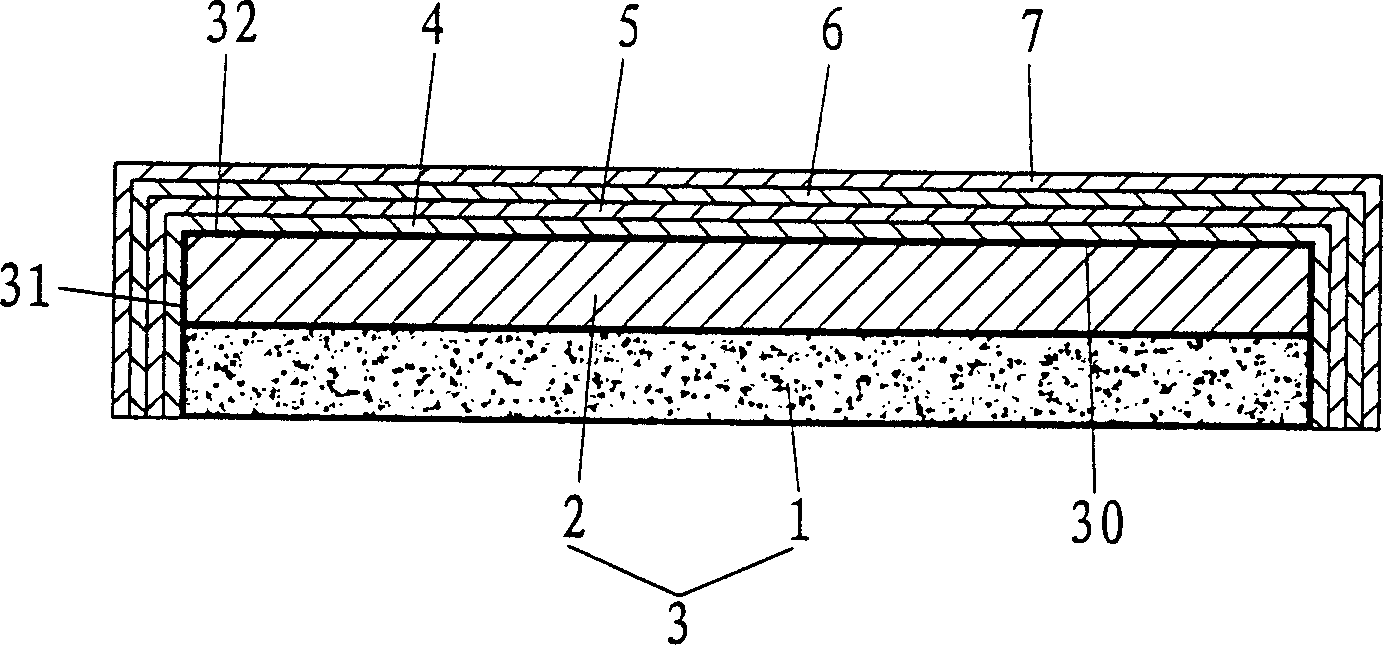

Wall surface decoration plate and its producing method

The present invention discloses a kind of coated metal-imitating wall decorating plate and its production process. Foamed polystyrene plate is adhered with asbestos cement plate to form composite plate, and the periphery of the composite plate is coated and fixed by adhesive, and the outside surface and lateral surfaces are coated successively with putty layer, closing primer layer, intermediate paint layer and facing paint layer to form the decoration plate product. The decoration plate has low cost and simple operation, and is suitable for industrial production.

Owner:谢日清

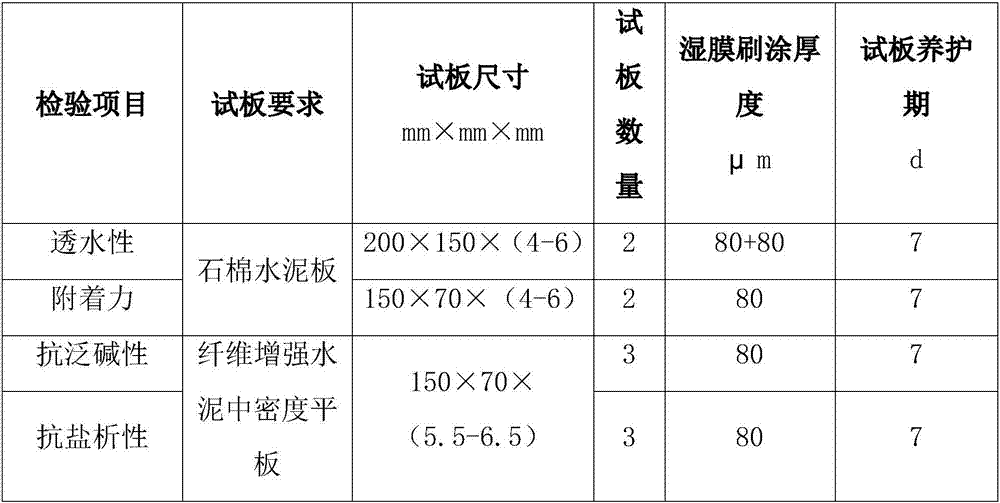

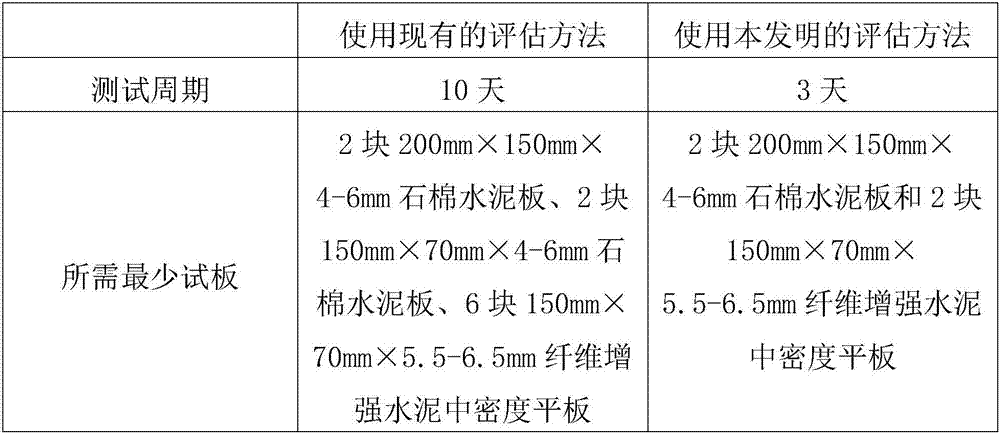

Performance testing method of water sensitive humidity-controlling coating

InactiveCN105388105AImprove performance testing efficiencySimple methodWeather/light/corrosion resistanceScattering properties measurementsCoated surfaceTest efficiency

The invention relates to a performance testing method of a water sensitive humidity-controlling coating. The method comprises the following steps: sampling a coating according to the GB3186 method, according to the requirements of GB9152-88 construction paint / coating test plate preparation, painting the coating on an asbestos cement plate, making the coated surface be upward, horizontally placing the test plate on an experiment table, allowing the test plate to stand still for 7d under adjusted states, humidity, and temperature, which are defined in GB9278-88, and finally testing. The provided method is simple, the cost is low, the measuring is rapid and precise, the measurement period is short, and the efficiency of tests on the performance of water sensitive humidity-controlling coating is effectively improved.

Owner:CHONGQING SANLINGSAN TECH CO LTD

Method for manufacturing tile by rice/wheat straw

InactiveCN1843719AHigh yieldEasy to shapeDomestic articlesFlat articlesLand resourcesAfter treatment

The invention relates to a method for producing rice / wheat straw tile, which comprises: the raw material treatment; the gluing step; the spreading and demoulding step; the thermal compress step; and after-treatment step. The invention can be used to replace traditional tile, with lower weight and saved land resource. The used straw can be decomposed; therefore, the detached building will not be waste. And it has lower cost, better social and economic benefits, while the water adsorption rate of straw tile can reach 21% which is lower than asbestos cement tile, and its anti-bend strength is significantly higher than the support strengths of sinter tile and asbestos cement tile; and the longitudinal anti-bend strength is reduced to 1400N, and the transverse one is reduced to 2200N.

Owner:NANJING FORESTRY UNIV

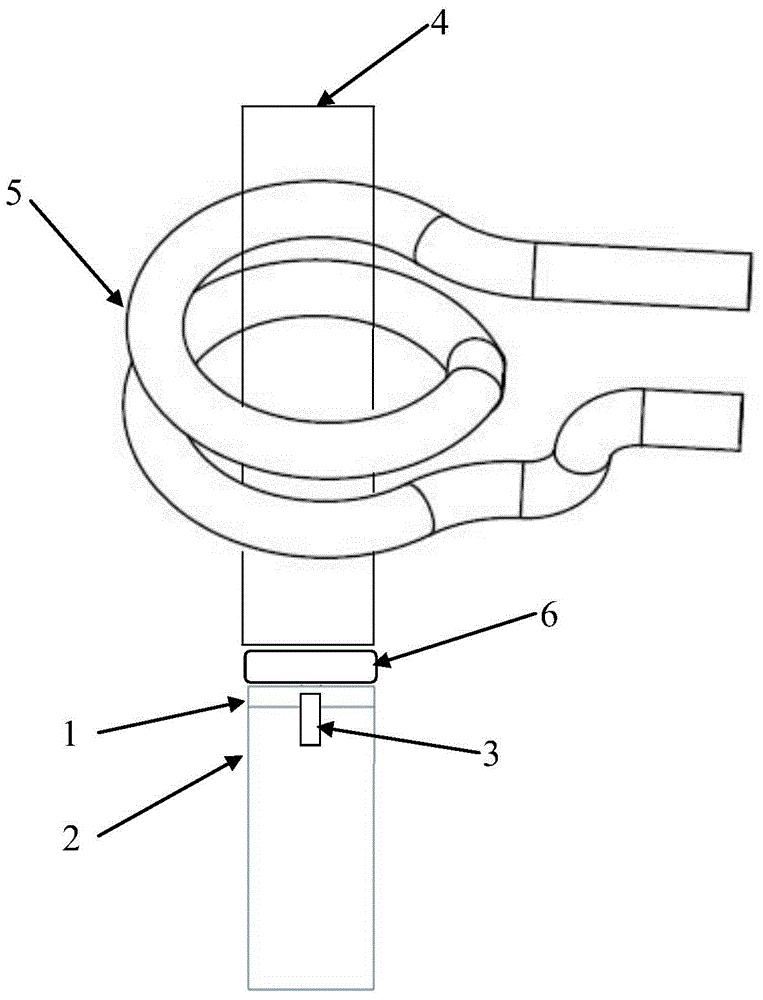

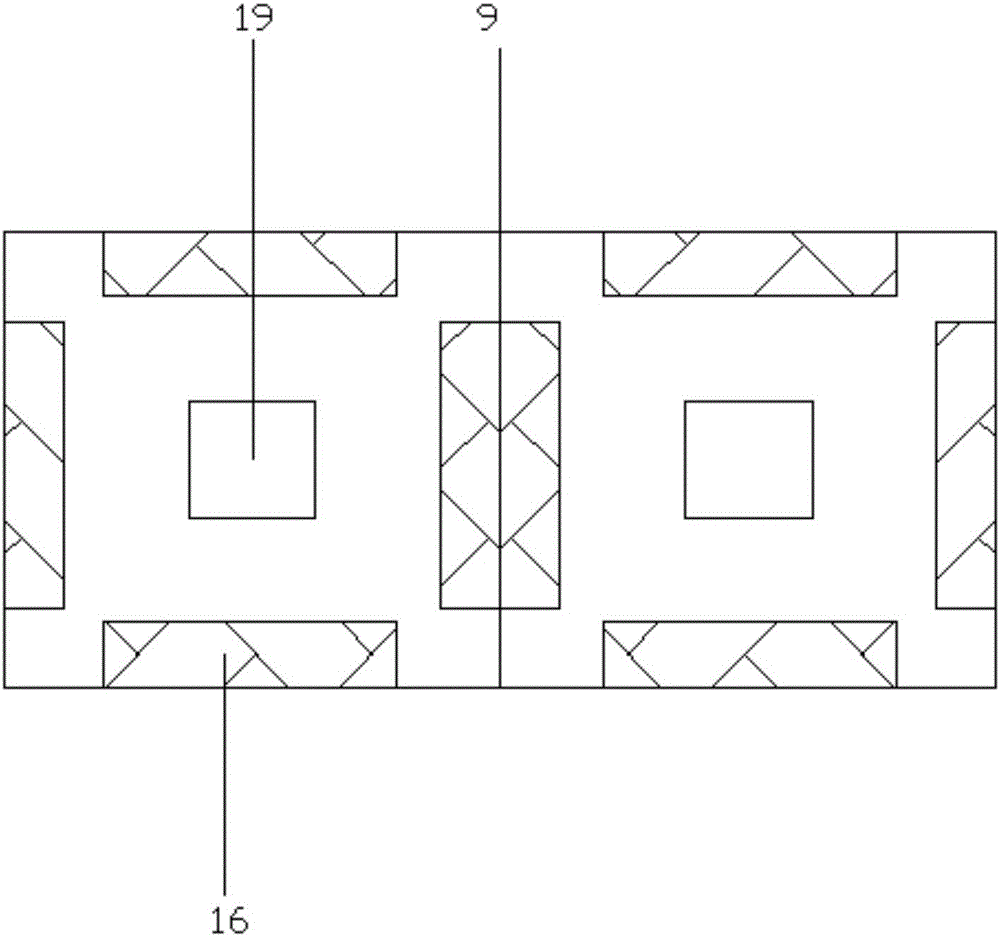

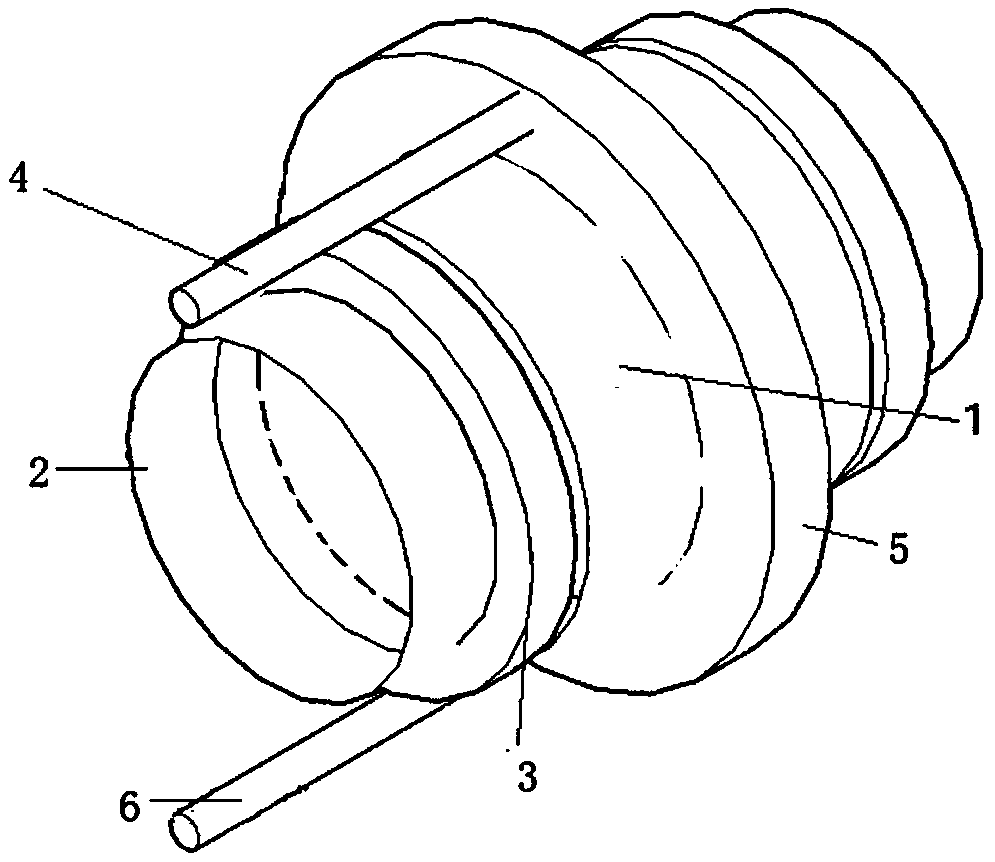

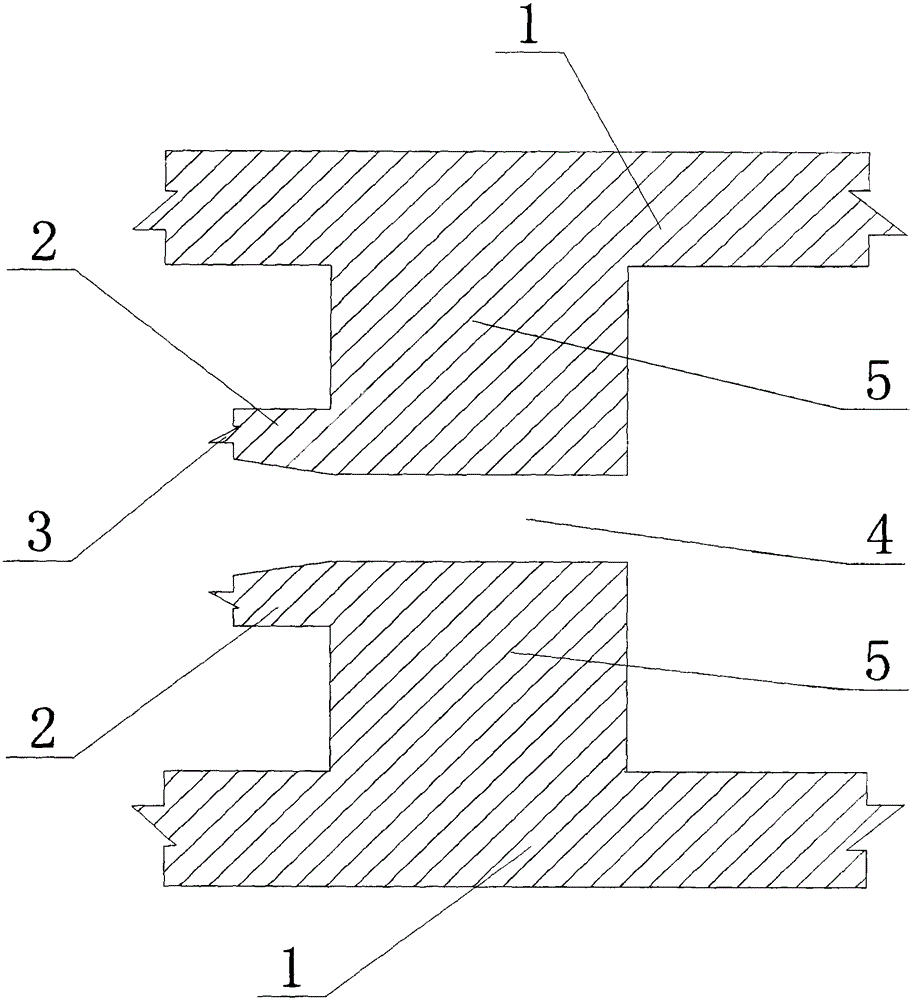

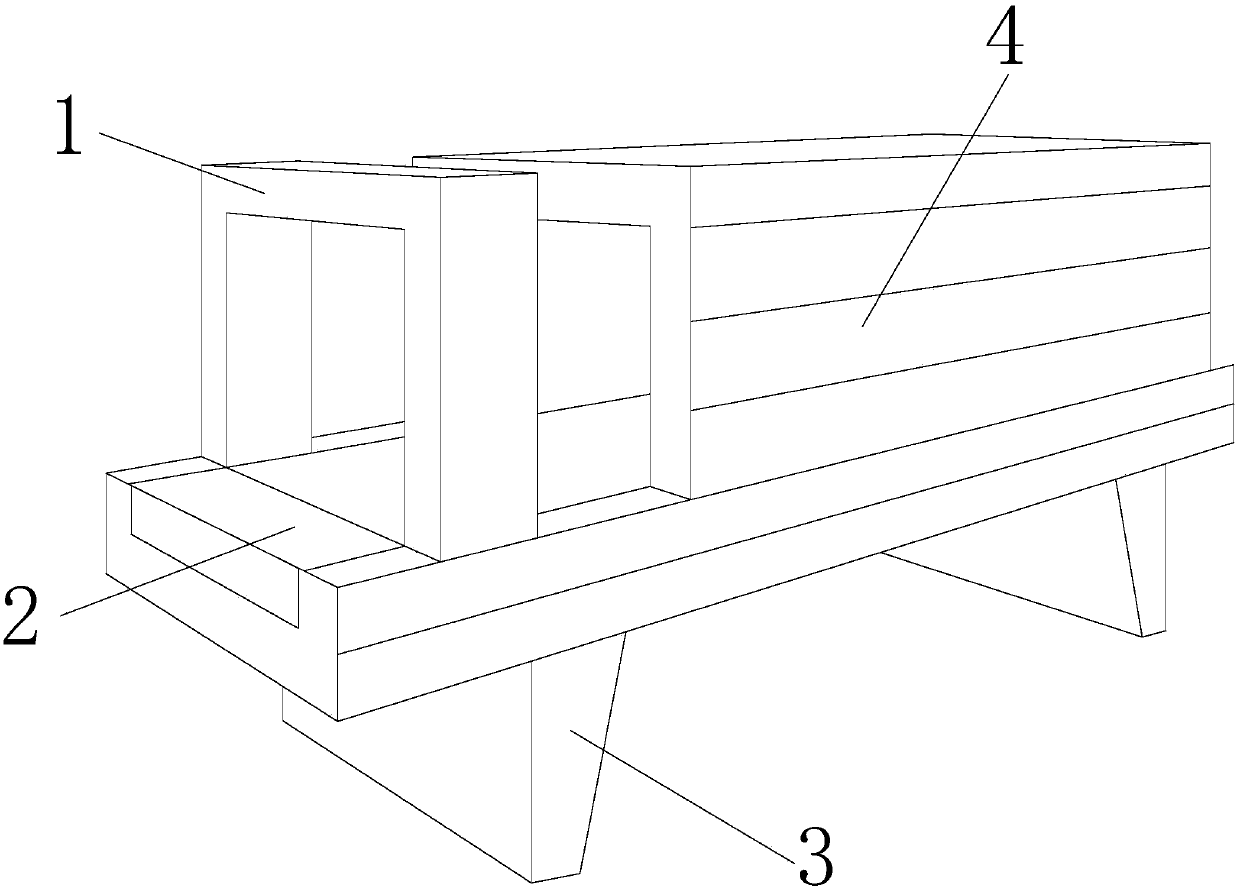

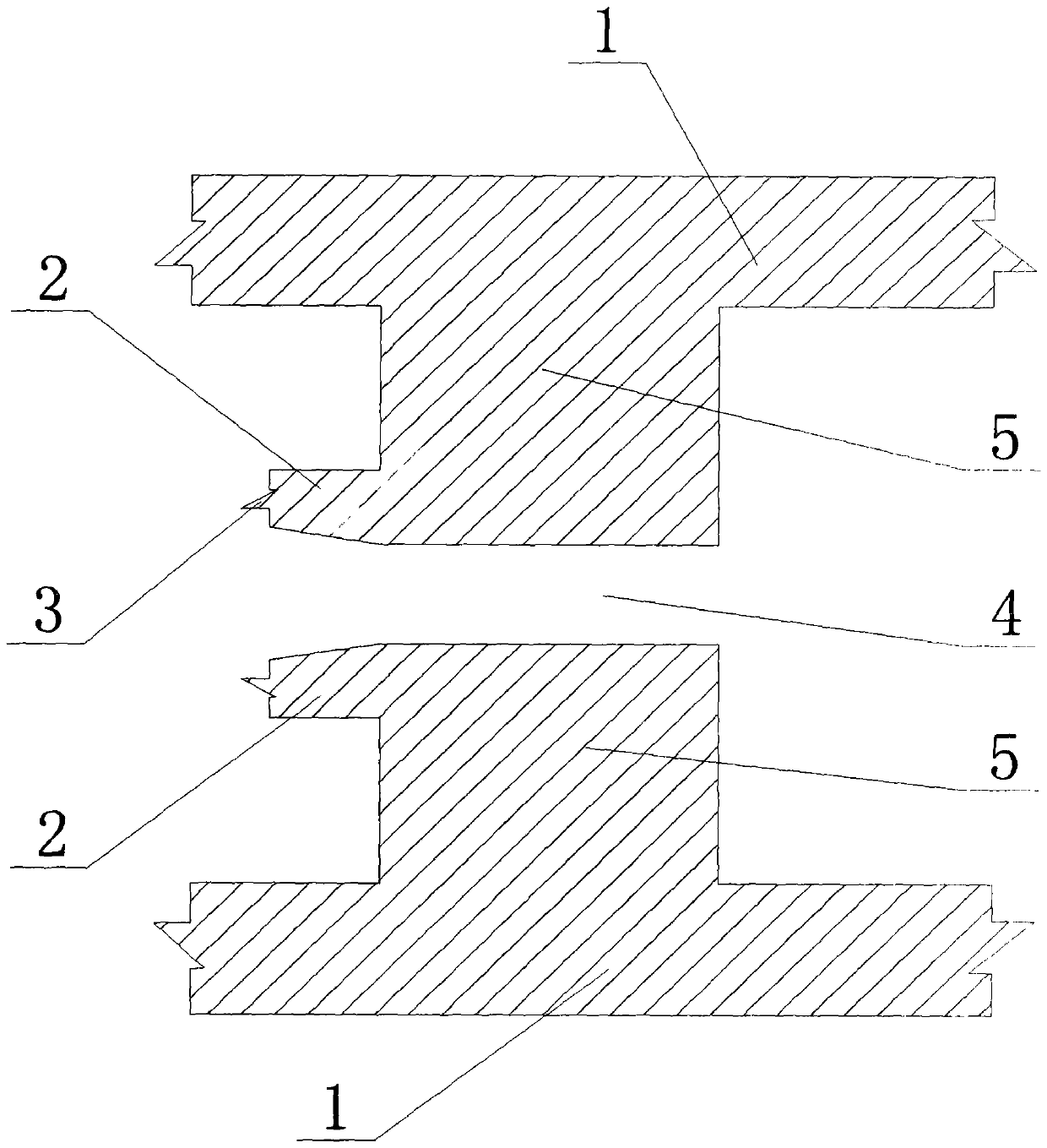

Tool and processing method used for precise induction brazing of annular thin-walled part

InactiveCN105643043AMeet the positioning accuracy requirements of precision induction brazingMeet positioning accuracy requirementsSoldering auxillary devicesInduction weldingCarbon steel

The invention discloses a tool and processing method used for precise induction brazing of an annular thin-walled part and relates to the field of induction welding. The tool used for precise induction brazing of the annular thin-walled part comprises a combination tool body of asbestos cement and carbon steel and a heating rod. An asbestos cement tool body directly makes contact with the to-be-welded surface of the part without precision requirements, a carbon steel tool body directly makes contact with the non-welded portion of the part, and the positioning precision is ensured. The heating rod is placed in an induction coil, and one end of the heating rod makes contact with the part. After induction heating of the heating rod is conducted, heat is uniformly and gently input into the to-be-welded annular thin-walled part through heat conduction to complete welding. According to the tool and processing method used for precise induction brazing of the annular thin-walled part, reliable and high-frequency induction welding of the annular thin-walled part is achieved, the problem that a traditional nonmetal tool is low in positioning precision is solved, and the problem that the annular thin-walled part is prone to oversintering and partial fusing through high-frequency brazing is solved. The processing method is simple, low in cost, easy to achieve and capable of providing a new method for machining of other similar parts.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

Protective sleeve of buried-type medium-voltage power cable

InactiveCN103779822ACorrosion resistanceHigh strengthCable installations in underground tubesThreaded pipeWear resistant

The invention discloses a protective sleeve of a buried-type medium-voltage power cable which includes a protective sleeve and a threaded pipe. The protective sleeve and the threaded pipe are integrally connected. The material of the protective sleeve and the threaded pipe is a hard polyvinyl chloride. A reinforcement layer is arranged on the surface of the protective sleeve. Two faces of the reinforcement layer are connected with an inflaming retarding layer and a wear resistant layer respectively. Through the above-mentioned method, the protective sleeve of the buried-type medium-voltage power cable undergoes high-temperature extrusion and sizing through a plastic extruder and has the properties of being corrosion resistant, high in strength and high-temperature resistant and can withstand voltages below 2000V and overcomes critical defects of asbestos cement pipes and is mainly used for pipe laying for power cables of 26 / 35 kV and below.

Owner:CHANGZHOU TUOYUAN CABLE ASSEMBLY

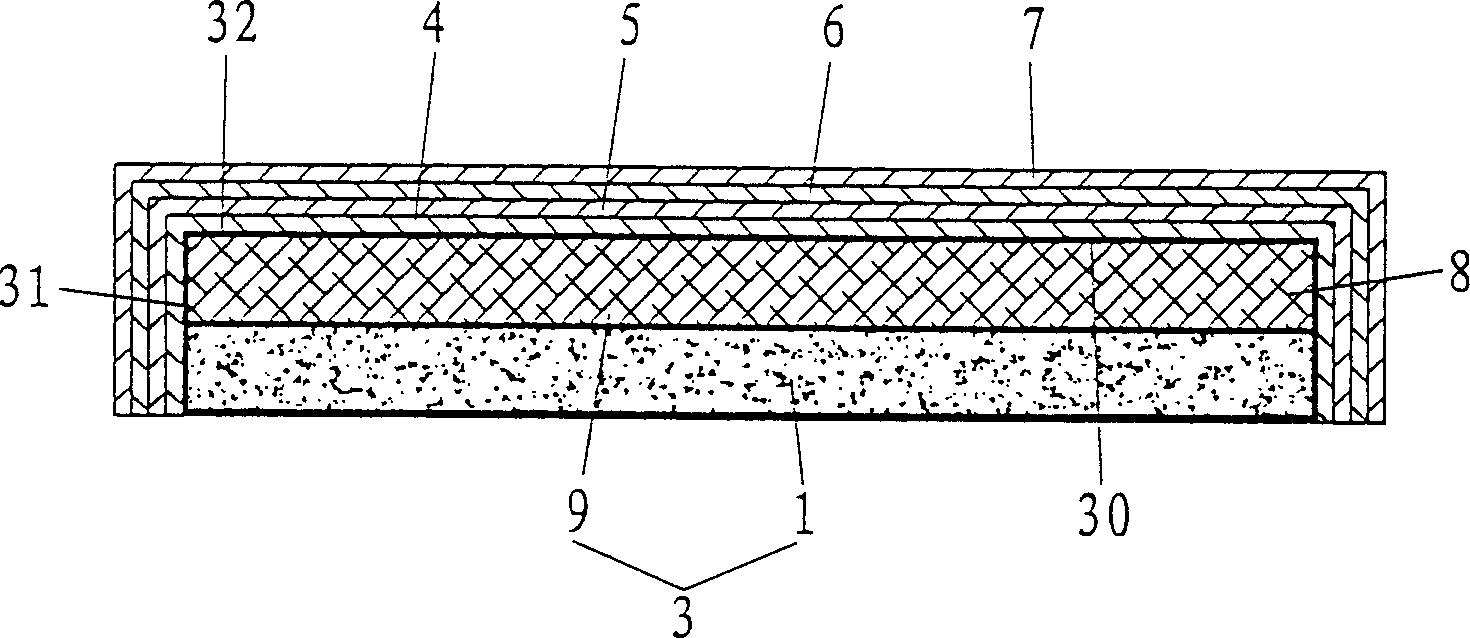

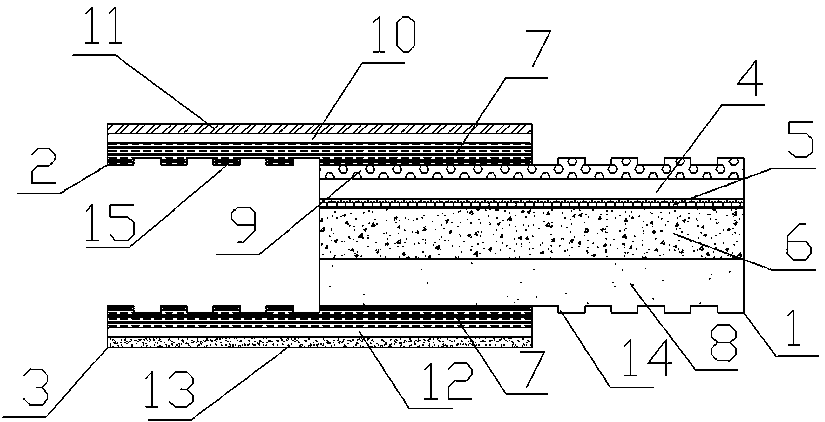

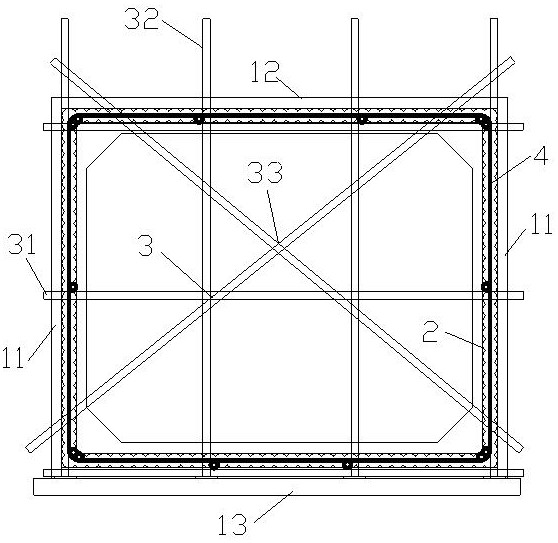

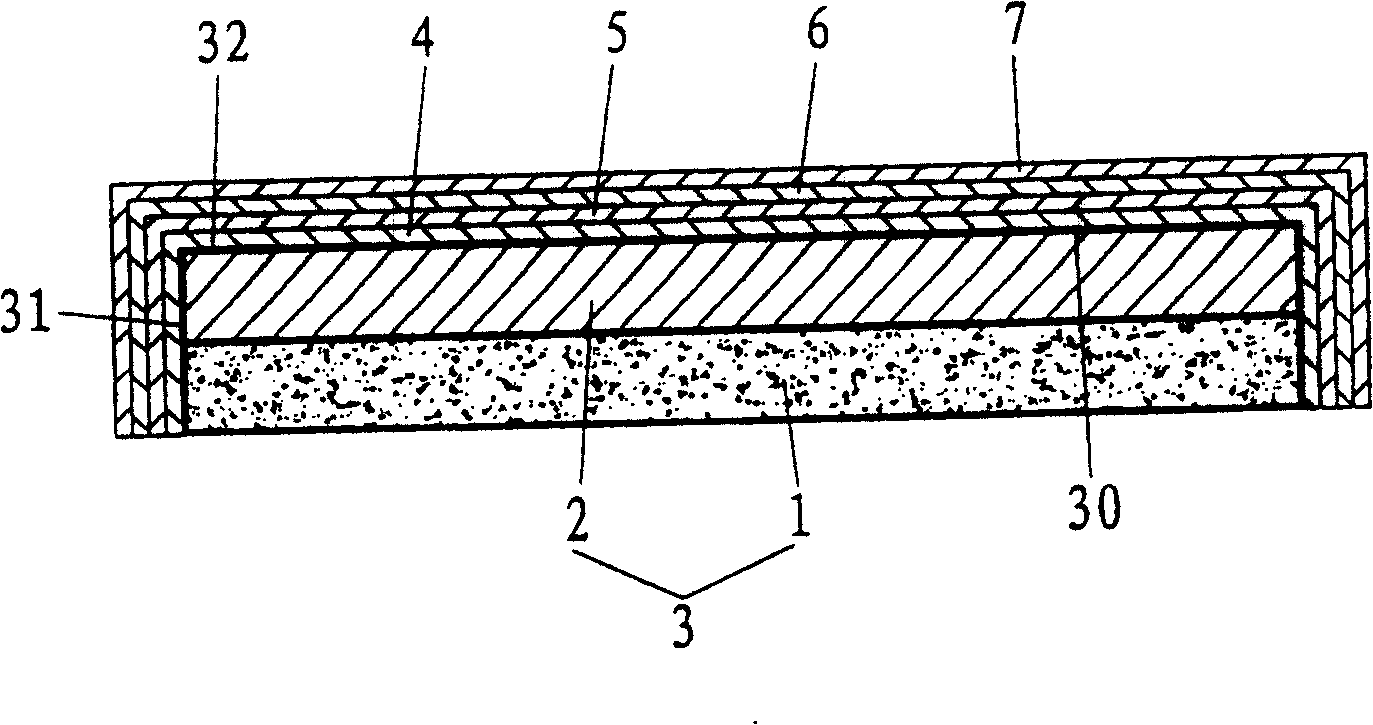

Novel building energy-saving wallboard

InactiveCN107938936AThe installation fits firmlyEasy to installSynthetic resin layered productsBuilding componentsBuilding energyEngineering

A new building energy-saving wall panel, which includes: a casing, a main wall panel and an attached wall panel, the attached wall panel includes an inner wall panel and an outer wall panel, the inner surface of the main wall panel and the inner The outer part of the wallboard is connected, the outer part of the main wallboard is connected with the inner part of the outer wallboard, the inner surface and the outer surface of the main wallboard are provided with a main wallboard engagement structure, and the inner wallboard Both the outer surface and the inner surface of the exterior wall panels are provided with a wall panel interlocking structure matched with the main wall panel interlocking structure, and the main wall panel includes a sound insulation layer, a hot-dip galvanized steel mesh layer and an asbestos cement layer , both the inner wall board and the outer wall board are set as buffer boards. Compared with the prior art, the present invention has a relatively simple structure, and the wallboards are firmly installed and fitted, easy to install, have better thermal insulation performance, good fireproof performance, and have excellent characteristics such as shock resistance, anti-corrosion, insulation, sound insulation, and long life.

Owner:河南恒华科技有限公司

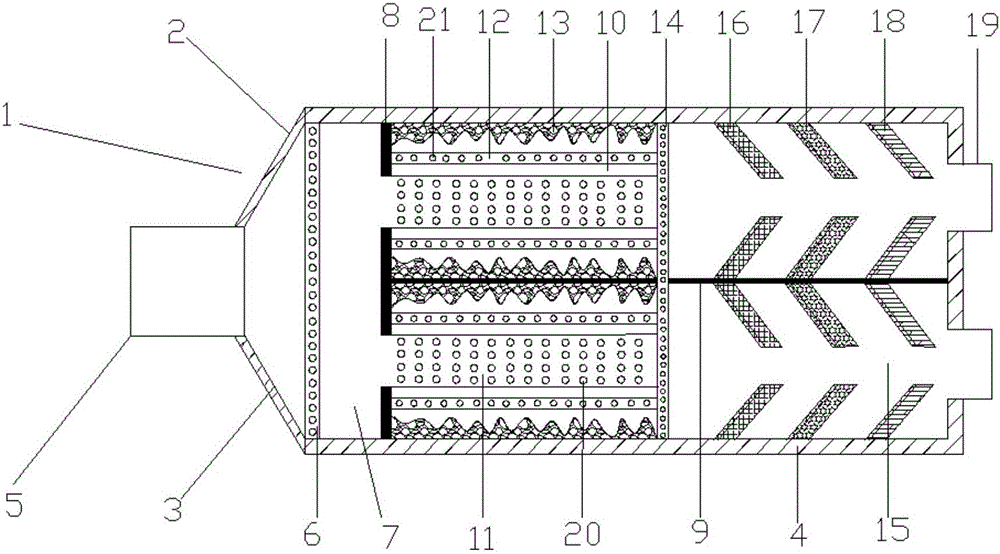

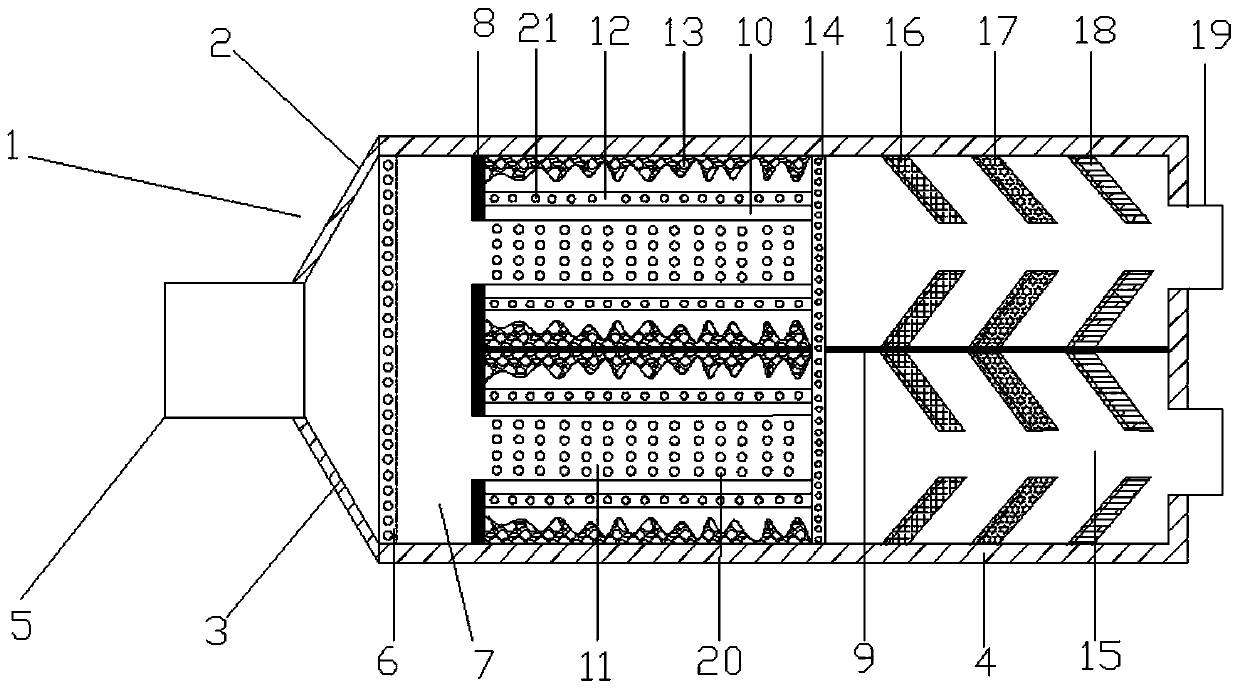

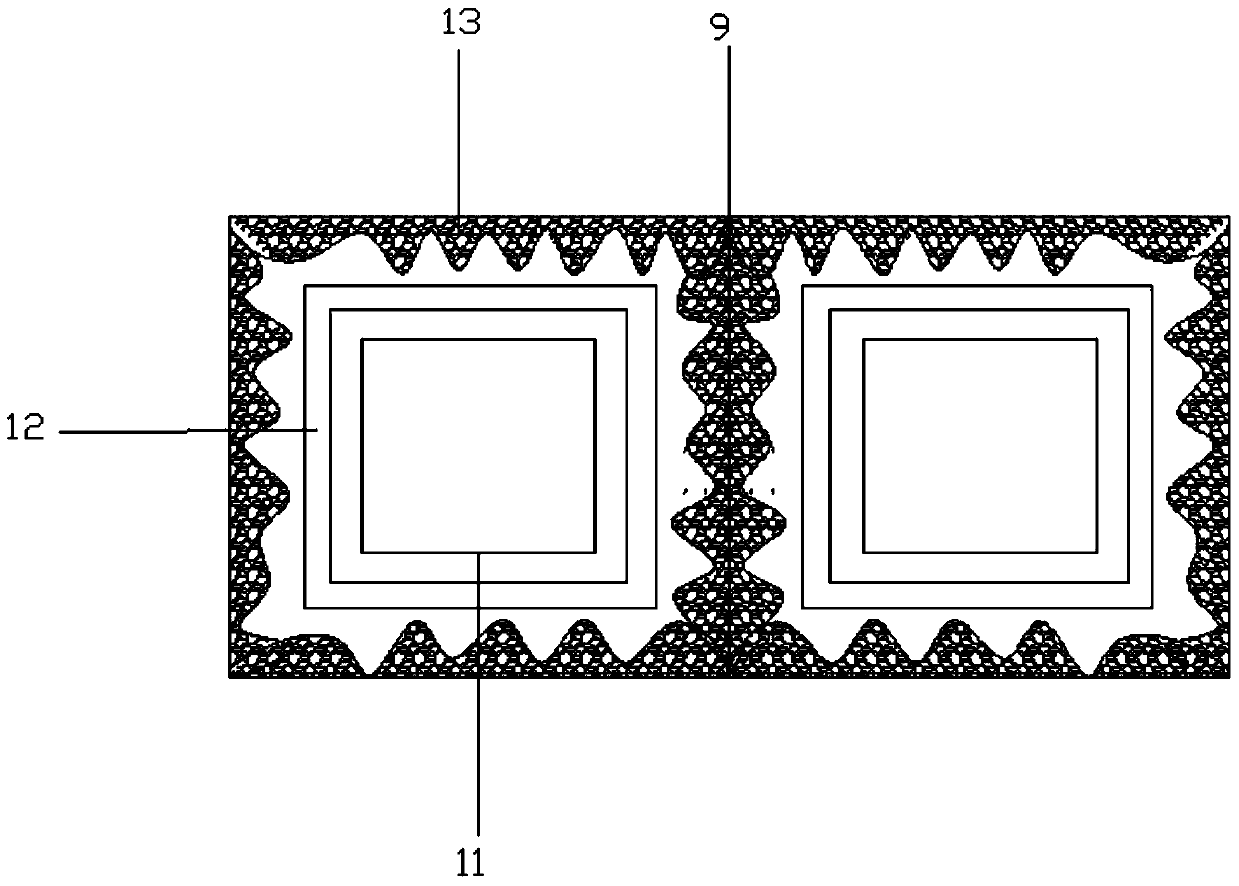

Novel silencer for engine

ActiveCN106014545AReduce mid and high frequency noiseReduce mid and low frequency noiseSilencing apparatusMachines/enginesIntermediate frequencyEngineering

The invention discloses a novel silencer for an engine. The novel silencer comprises a cavity, an outer shell, an inner wall, glass fiber cotton, an air inlet pipe, a damping hole plate, a first cavity, a first partition, a center partition, a second cavity, an air guiding pipe, a micro perforated plate, wave crest sound absorption sponge, a second partition, a third cavity, a porous expansion perlite layer, a closed hole type foam plastic layer, a porous asbestos cement plate layer, an air outlet pipe, micro through holes and micro small holes. The cavity comprises the outer shell and the inner wall. The cavity is internally provided with the damping hole plate, the first partition, the second partition, the first cavity, the second cavity and the third cavity. According to the novel silencer for the engine, simplicity of the noise reduction theory and method adopted by existing noise reduction equipment is changed, the beneficial effects of damping noise reduction, resistance noise reduction, micro perforated plate noise reduction and small hole noise reduction are integrated, the low frequency sound wave, the intermediate frequency sound wave, the high frequency sound wave and the ultrahigh frequency sound wave in noise can be effectively absorbed, pollution caused by noise is reduced to the maximum degree, and the health of the human body is protected.

Owner:泉州市知产茂业工业设计有限公司

Manufacture and construction method for nano paint

InactiveCN101117480AIncrease profitFunctionalLiquid surface applicatorsCoatingsCellulosePolyvinyl alcohol

The invention provides a manufacture and construction method of a nanometer coating. Composite nanometer powder is weighed and inputted into deionized water, and then ultrasonic dispersed. Water-soluble polyvinyl alcohol solution and film former silica sol are added and ultrasonic dispersed to obtain the A component. Deionized defoamer, wetting agent, dispersant, antifreeze propanediol and pH regulator are added in a stirrer, and then rutile titanium dioxide, calcined kaolin, heavy calcium and talcum powder are added and sand milled, and then 4.0 percent of light ethyl cellulose solution is added and sand milled. The pigment and filler slurry is transferred to a paint blending tank and stirred, and then styrene-acrylic emulsion, alcohol ester-12, thickener SN612, defoamer CF-16 are added and stirred to obtain the B component which is coated on an asbestos cement plate and cured. The A component is sprayed on the surface of a template and cured. The invention has advantages of simple manufacture and construction, high utilization of nanometer material, low cost and good practicality.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

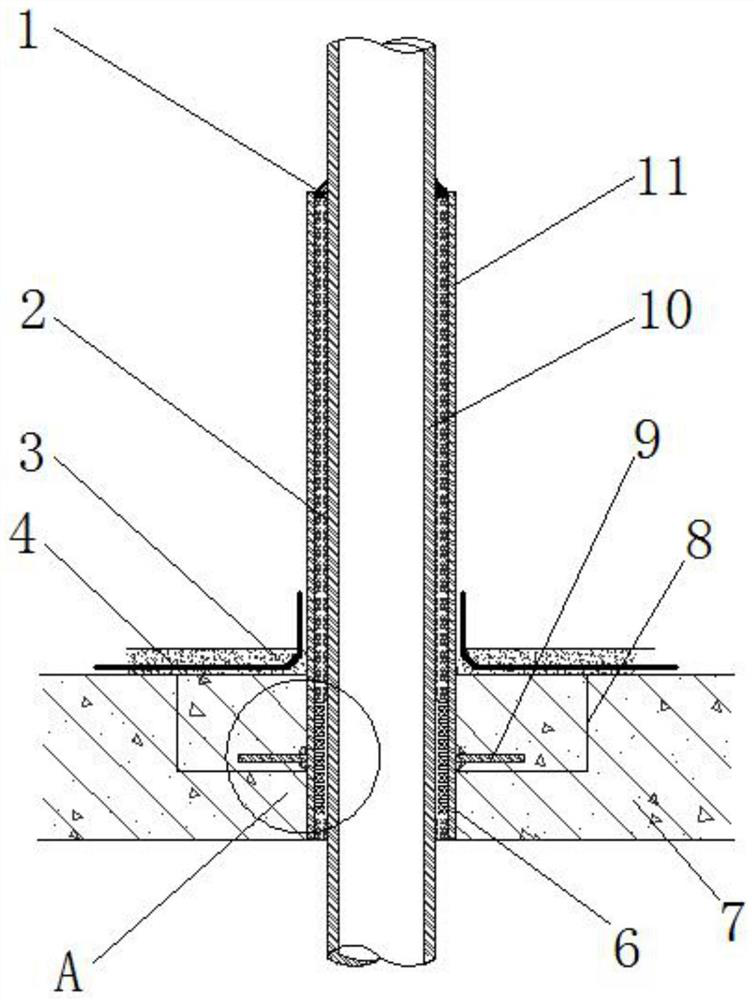

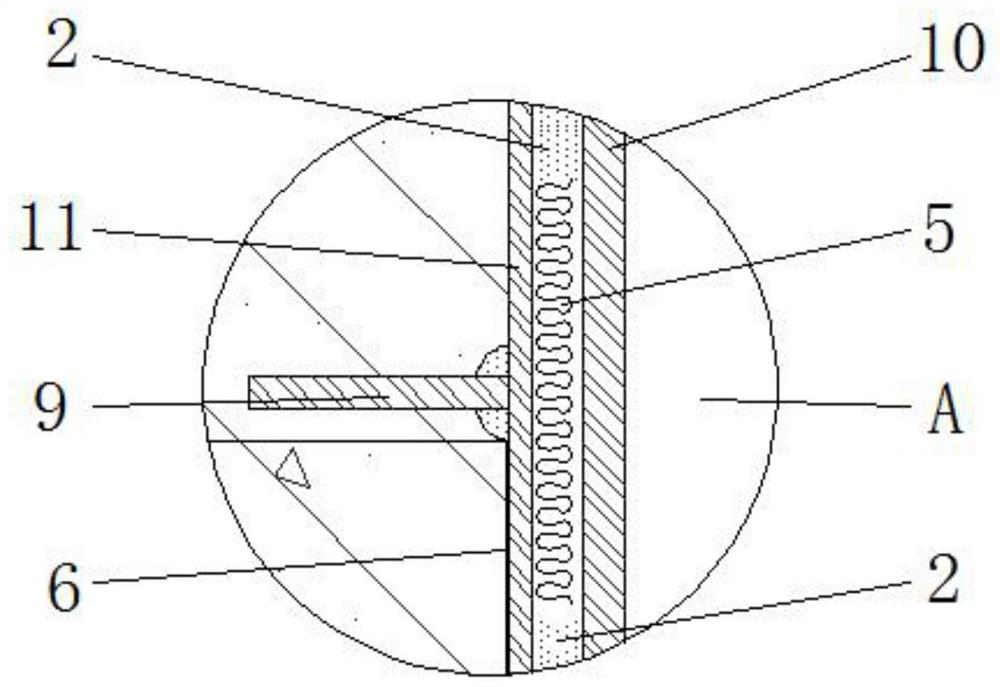

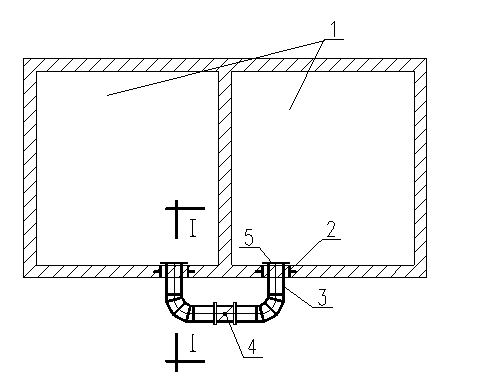

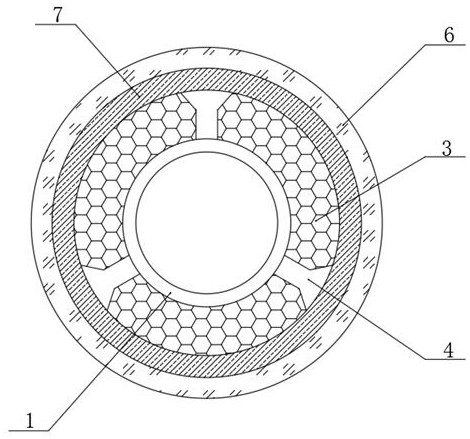

High-waterproofness wall bushing easy to construct

The invention provides a high-waterproofness wall bushing easy to construct. The wall bushing comprises a bushing body and a hollow wing ring. The bushing body is provided with a hollow cavity allowing a penetrating pipe to penetrate out, and the outer wall of the bushing body is sleeved with the hollow wing ring. An inner cavity of the hollow wing ring communicates with the hollow cavity, and thehollow wing ring is provided with a grouting device and an exhaust device in a communicating manner. The high-waterproofness wall bushing easy to construct has the beneficial effects that the outer side seepage path of the bushing body is additionally arranged, the waterproofness of the inner side of the bushing body is enhanced through grouting, a grouting manner is used for replacing asbestos cement, sealant, batched jute filling and beating and other tedious waterproof work, and high waterproof performance is guaranteed while operation is simplified.

Owner:NANJING HYDRAULIC RES INST +1

Novel connecting method for pipelines with different pipe diameters and made of different materials

The invention discloses a novel connecting method for pipelines with different pipe diameters and made of materials. The novel connecting method is characterized by comprising the following steps that firstly, a blocking plate with the thickness of 2 m is arranged at the position, 5 m away from a water return branch hole, in the water return branch hole, the blocking plate, a connecting pipe made of concrete and branch hole linings at the position of the water return branch hole are poured at a time, no construction seam is reserved, during blocking plate pouring, rigid waterproof casing pipes are buried in the position, at the end of a connecting steel pipe, in the middle portion of the blocking plate, and due to the fact that the waterproof casing pipes are provided with wing rings, it can be ensured that the rigid waterproof casing pipes and the blocking plate are closely combined without water leakage; and secondly, a section of phi 630 steel pipe with a flange is installed at the end of the steel pipe in advance, the length of the phi 630 steel pipe is 300 mm, and sealing water preventing is conducted between the steel pipe and the casing pipes through baffle rings, batched jute and asbestos cement. By means of the novel connecting method, pipeline cracks, caused by differential settlement between a mountain and a soil layer, at the positions of the mountain and a dredging tank are avoided, the dredging work of the dredging tank is avoided, the labor force is saved, leakage of sewage containing toxic metal is prevented, and safety is high.

Owner:NORTH CHINA METALLURGICAL CONSTR ENG CONSTR +1

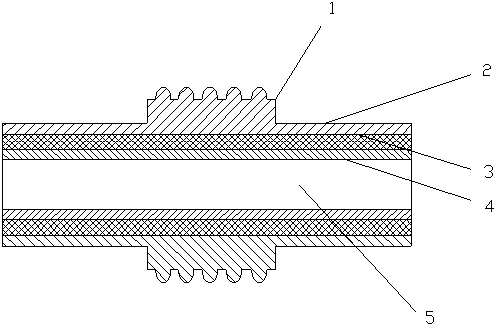

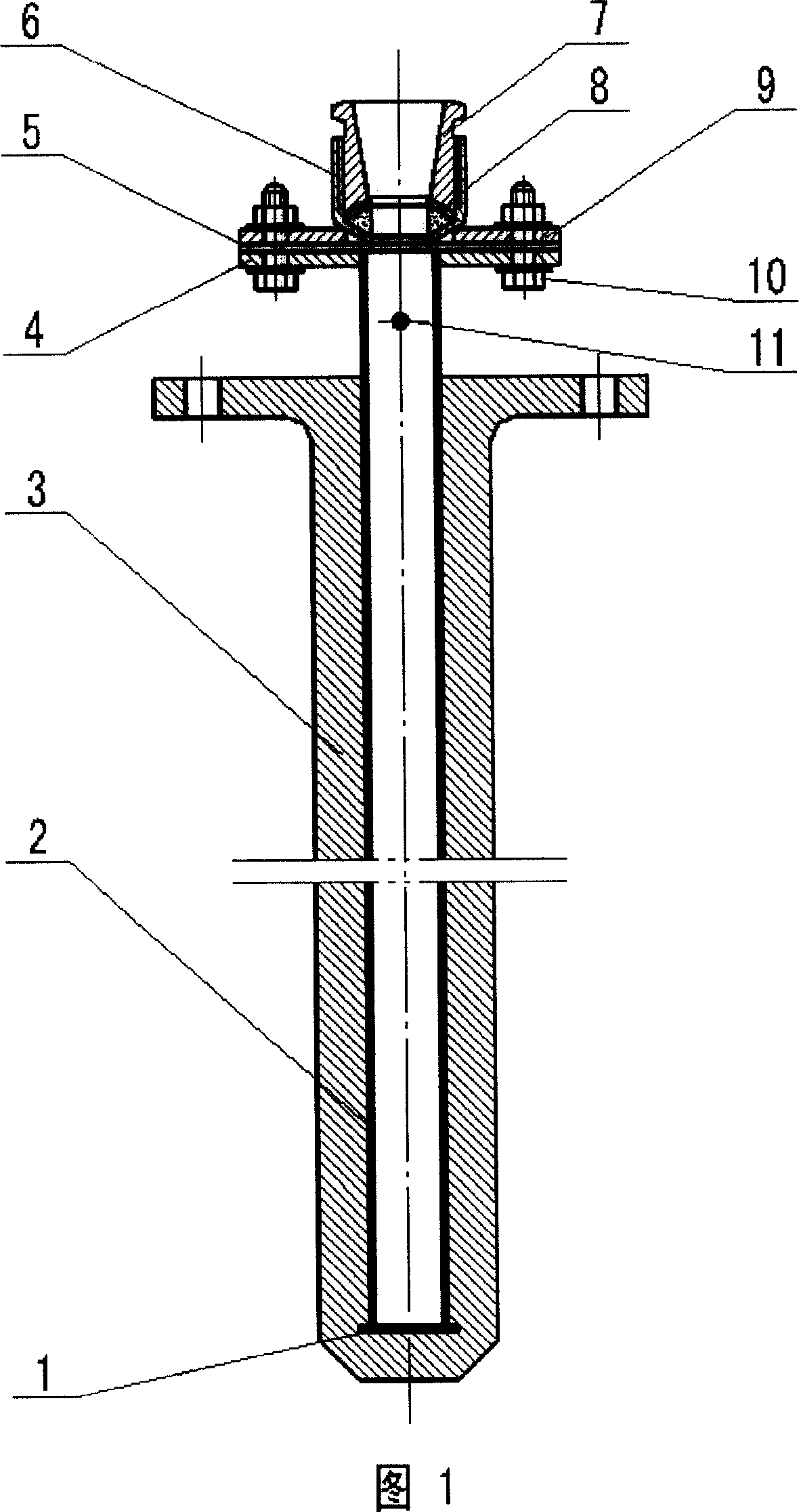

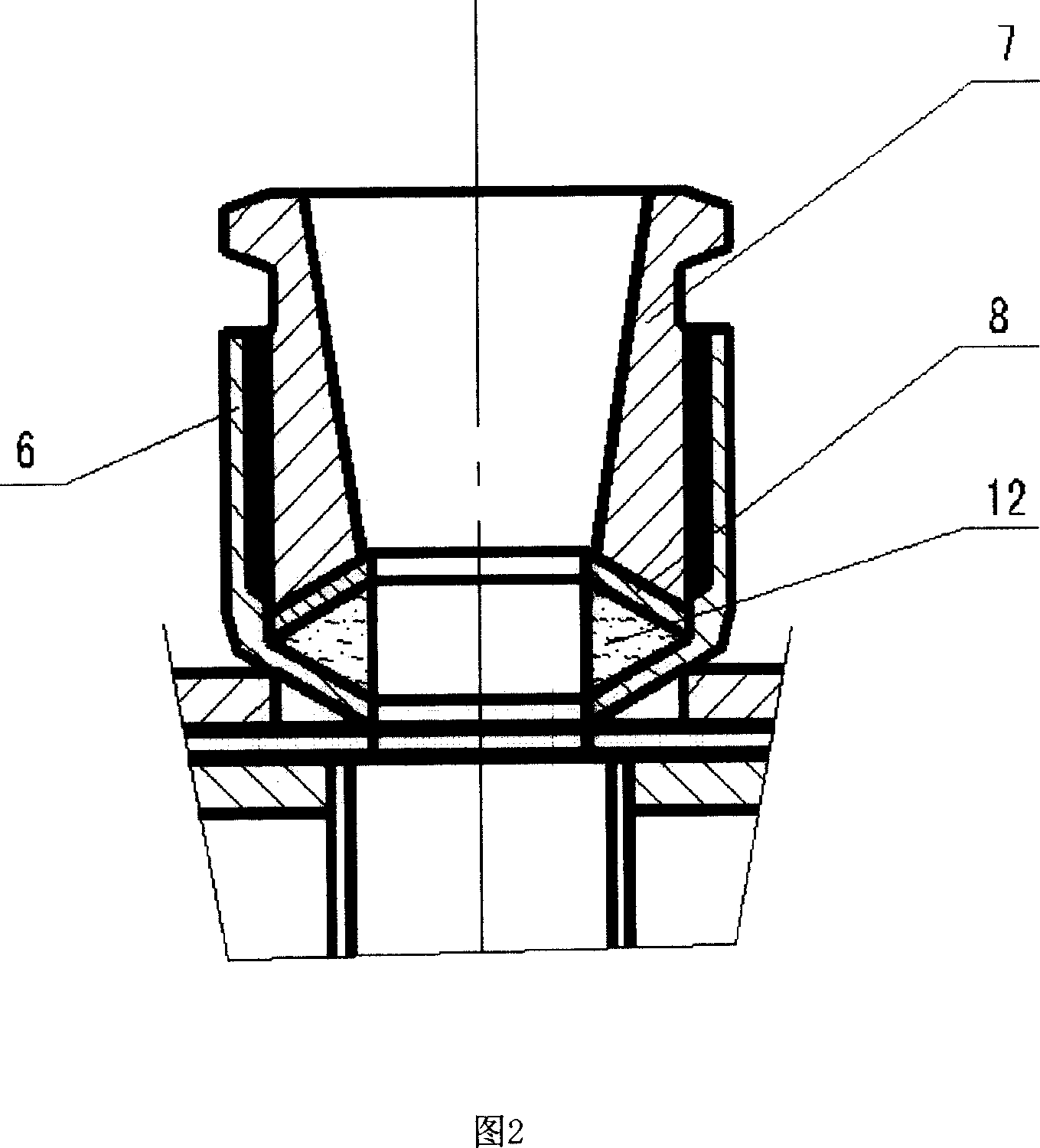

Impregnating furnace electric thermo-couple protector

InactiveCN1932459AThickness is easy to controlImprove thermal conductivityThermometer detailsThermometers using electric/magnetic elementsWaddingEngineering

The invention discloses a thermo element protector for the impregnating furnace. The motherboard (1) is in the bottom of the protector tube (2) which the outside is the reinforced covering layer (3) founded by the heat-resistant steel material. The flange (4) is on the top of the protector tube which is connected by the bolt units (10); also it has the rubber blanket (5) between the flanges; the outside of the connecting groove (6) is connected with the flange and the inside is connected with the connecting cap (7) by the screw thread; the junk ring (8) and the asbestos-cement filler (12) are between the underside of the connecting cap and the connecting groove; the constant hole (11) is in the protector tube; the upper end of the reinforced protecting layer has the flange and hole. The invention can prolong the life of the use in the high temperature and the corrosive liquid and ensure the temperature measuring precision.

Owner:GUIYANG AL-MG DESIGN & RES INST

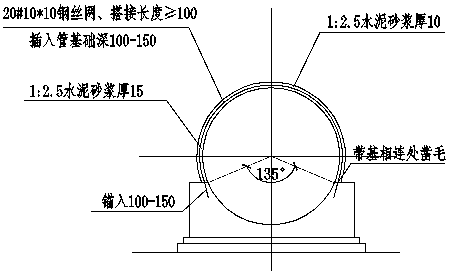

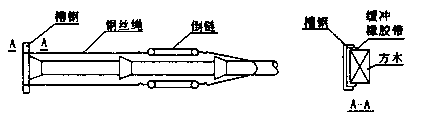

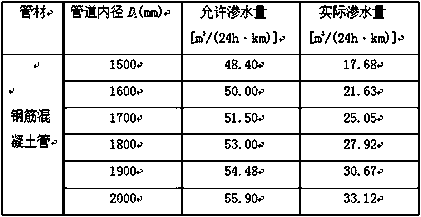

Impermeable technology for ultra-large-caliber concrete rainwater pipeline joint

InactiveCN111305355AImprove anti-seepage performanceReduce water seepageSewer pipelinesStructural engineeringCement mortar

The invention discloses an impermeable technology for an ultra-large-caliber concrete rainwater pipeline joint. The impermeable technology comprises the following steps that: after concrete pipelinesare independently hoisted section by section, putting the concrete pipelines in a groove to be assembled, laying a pipeline foundation below, putting a rubber sealing rubber gasket in a pipeline tongue-and-groove groove, adopting a chain fall pulling-into method to connect the pipelines, filling the inner and outer gaps of a pipeline joint with asbestos cement, and carrying out first impermeable processing; smearing a belt on the outer wall of the pipeline joint by cement mortar, and putting a steel wire net in the belt so as to carry out second impermeable processing; and before the pipelineis backfilled, coating the pipeline joint and a connection hole of the pipeline and an inspection well with nonwoven geotechnical cloth so as to isolate external soil from the inside of the pipeline,and carrying out third impermeable processing. The impermeable technology has a good effect and high reliability, a water seepage amount of the processed pipeline is far below a water seepage amount allowed by a specification, the impermeable technology has a low cost, is convenient to construct and has a short construction period, and the construction quality of a large-caliber rainwater pipelineis improved.

Owner:CCCC THIRD HARBOR ENG +1

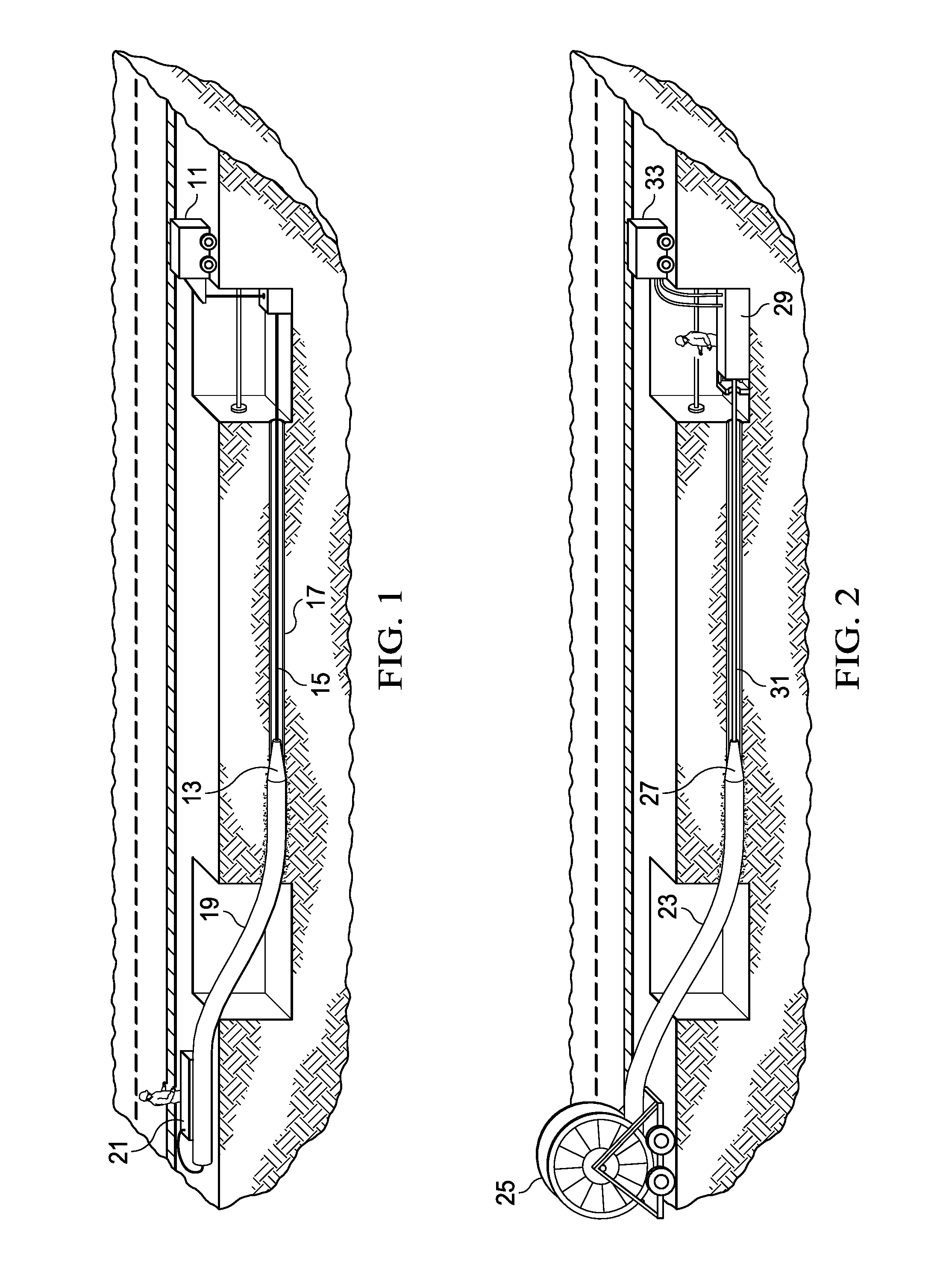

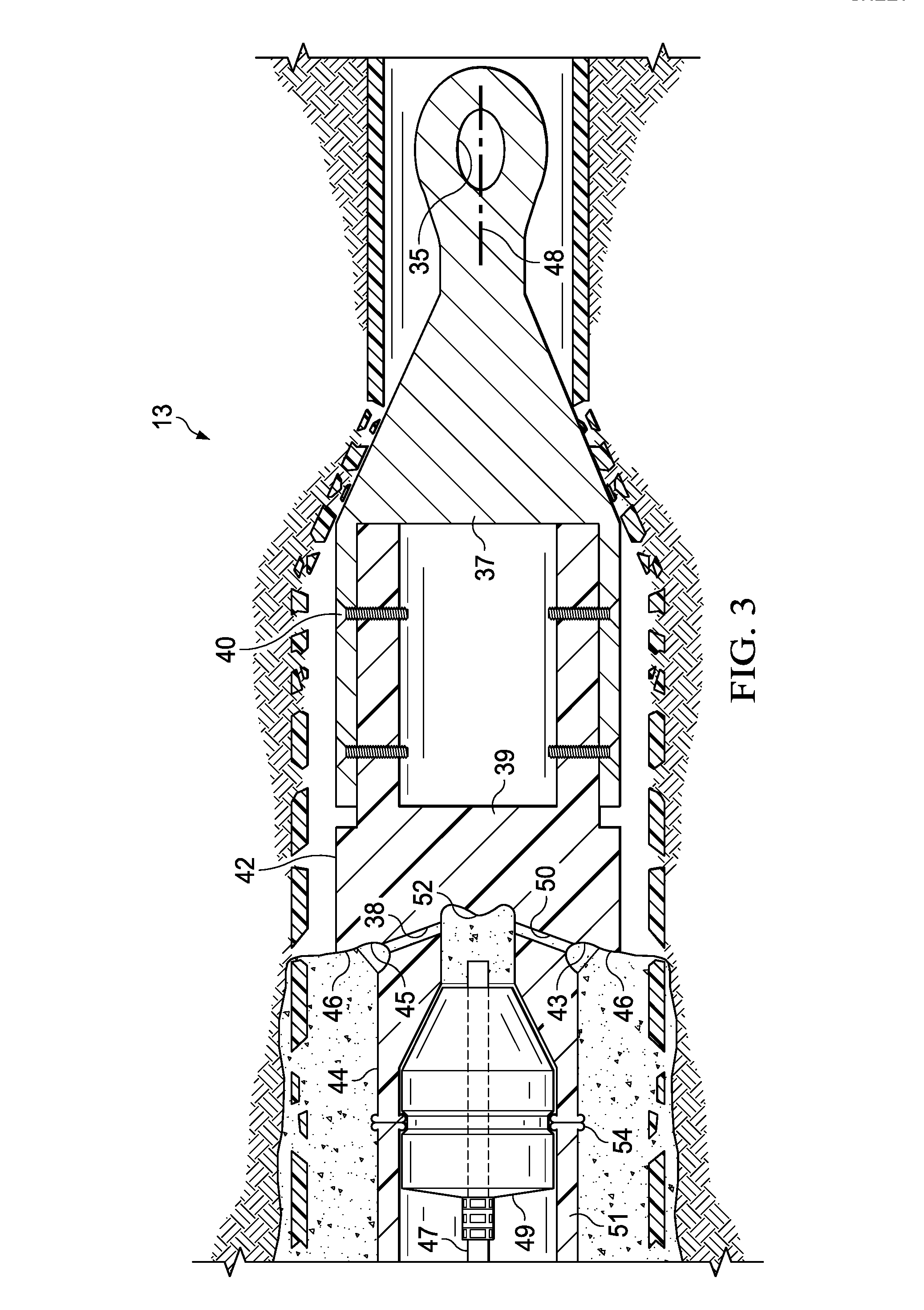

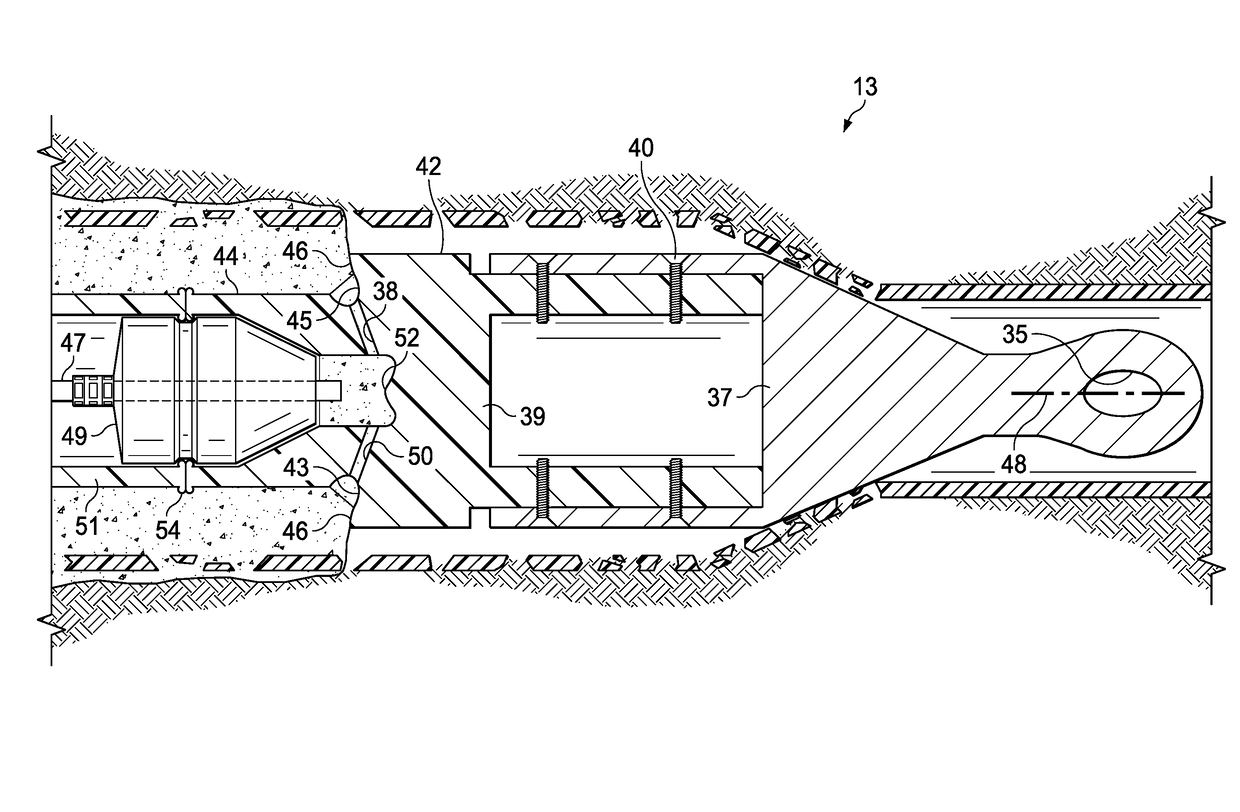

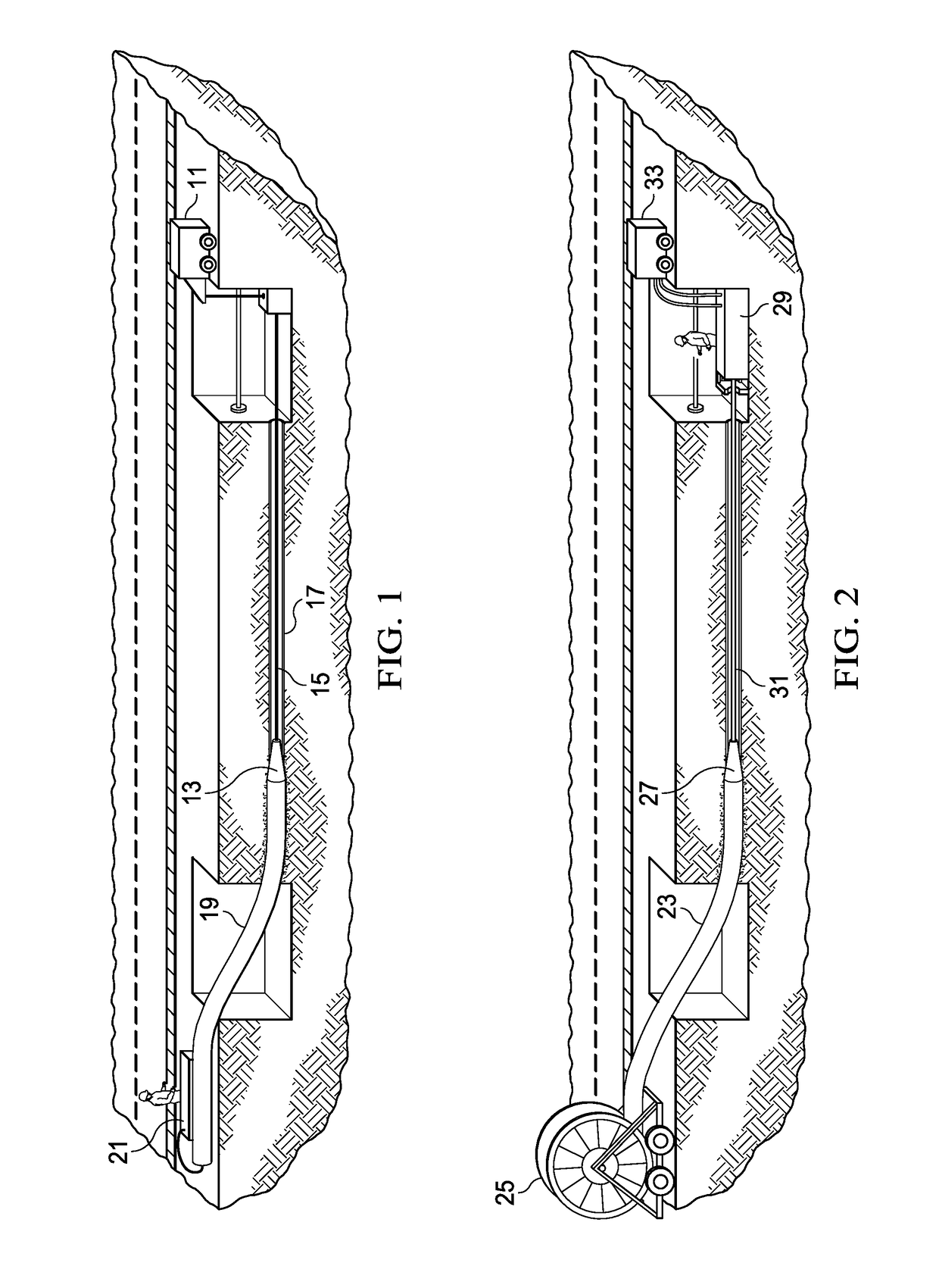

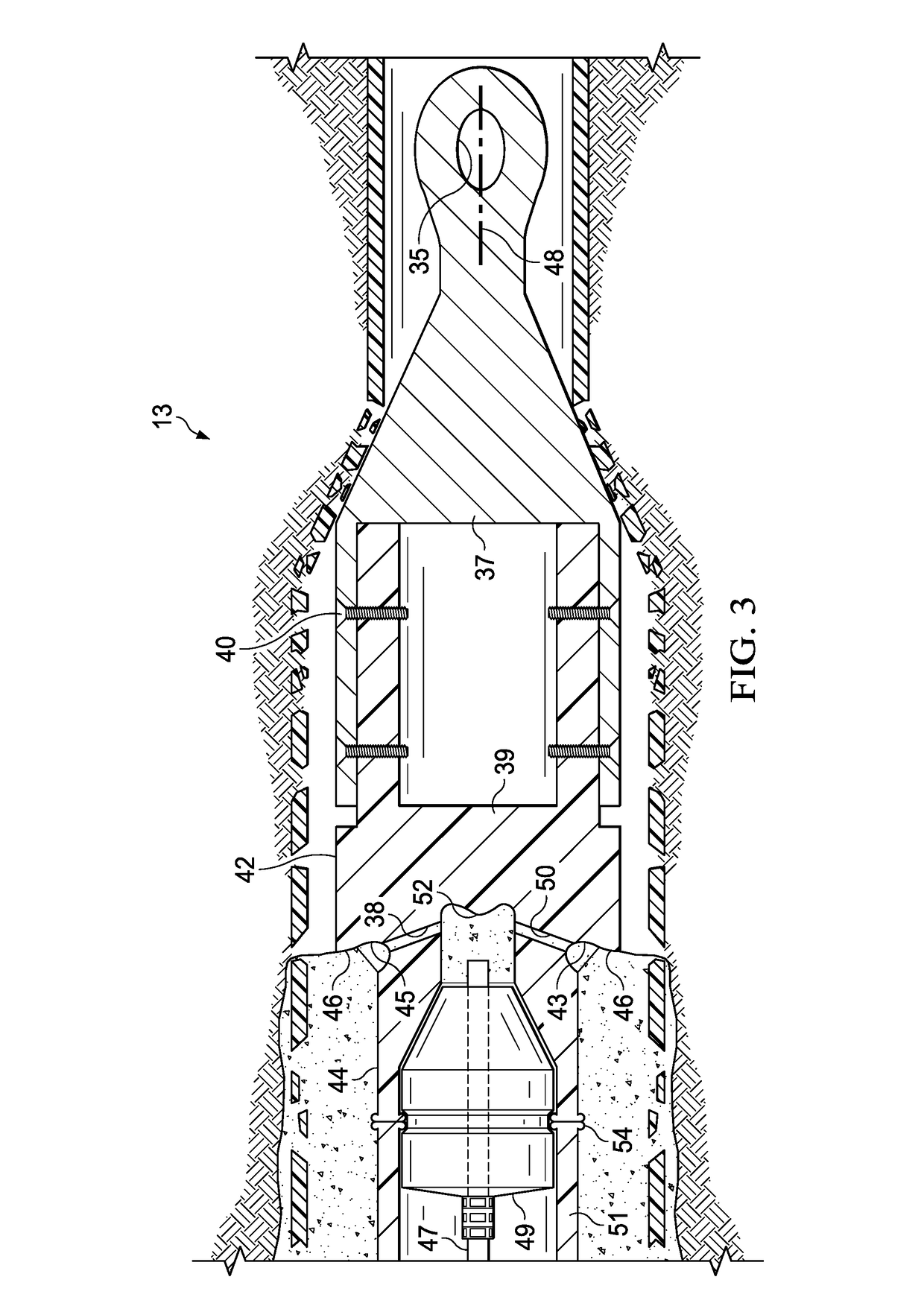

Compositions and Methods for In-Situ Macro-Encapsulation Treatment of Friable Asbestos Fibers Generated by Trenchless Pipe Bursting of Asbestos Cement Pipe

ActiveUS20160334047A1High viscosityTransportation and packagingSolid waste disposalFiberPipe bursting

Equipment, process and techniques are shown for rehabilitating old underground pipelines, particularly asbestos pipelines, in which an old underground pipeline is replaced, as by drawing a bursting head through the old pipe to burst it and simultaneously pulling a new pipe through behind the bursting head. The invention has particular applicability to the rehabilitation of old asbestos pipelines in which the burst up debris must be contained or encapsulated in some manner. The macro-encapsulation materials shown form an in-situ layer of a temporarily fluid macro-encapsulating material which absorbs and immobilizes asbestos fibers and pipe fragments, the macro-encapsulating material being applied simultaneously as the pipe bursting operation proceeds.

Owner:AMBLER EDWARD ALAN

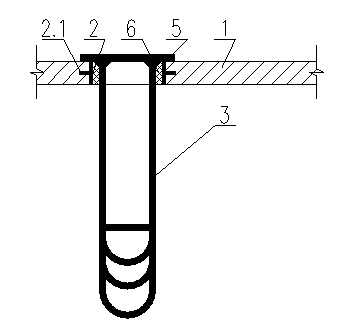

Original roof pipeline waterproof structure of reconstruction project and construction method thereof

PendingCN111927013AImprove waterproof performanceEnsure structural stabilityRoof covering insulationsBuilding material handlingWater storageArchitectural engineering

The invention discloses an original roof pipeline waterproof structure of a reconstruction project and a construction method thereof, and belongs to the technical field of roof waterproofing. The original roof pipeline waterproof structure of the reconstruction project comprises a pipeline passing through a roof sheathing; the pipeline is sleeved with a waterproof sleeve, and the roof sheathing isprovided with a mounting through hole just allowing the lower end of the waterproof sleeve to pass through; a fine aggregate concrete layer surrounding the periphery of the waterproof sleeve is arranged on the upper end face of the roof sheathing; the lower end side of the waterproof sleeve is fixedly sleeved with a wing plate, an outer edge groove is formed in the upper portion, corresponding tothe mounting through hole, of the roof sheathing, and an outer edge groove of the roof sheathing is filled with concrete materials used for burying the wing plate; an asbestos cement joint and linenfilling layer is filled between the pipeline and the waterproof sleeve, and a sealing element is arranged between the upper end of the waterproof sleeve and the pipeline. The construction method comprises the following steps of manufacturing the waterproof sleeve, punching, mounting the waterproof sleeve, arranging the fine aggregate concrete layer, performing a water storage test and then mounting the pipeline. The waterproof structure has good waterproof performance, and the stability of the waterproof structure can be well guaranteed.

Owner:中建五局安装工程有限公司

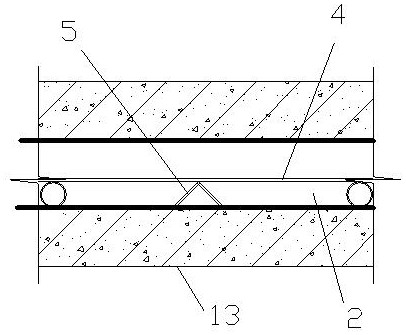

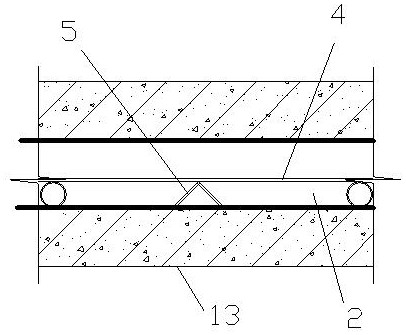

Water proofing method for situation that pipeline penetrates hydraulic structure settlement joint

InactiveCN105697887ATaking into account the waterproof problemEliminate destructionPipesHydraulic structureRigid wall

The invention discloses a waterproof method for a pipeline passing through a settlement joint of a hydraulic structure, which specifically includes installing a rigid waterproof casing, a rigid wall-penetrating pipeline, and filling with linseed and asbestos cement. The invention adopts a rigid-flexible combination connection The method takes into account the waterproof problem between the wall-penetrating pipe and the wall to be penetrated and eliminates the damage to the structure due to uneven settlement. It has the characteristics of good waterproof effect, convenient construction and maintenance, and strong applicability.

Owner:BEIJING MUNICIPAL CONSTR

Post-planting installation method for rubber waterstop

ActiveCN112695807AEasy to useIncreased durabilityArtificial islandsUnderground chambersAgricultural engineeringLap joint

The invention discloses a post-planting installation method for a rubber waterstop. The method comprises the following steps that the position where the rubber waterstop is installed is slotted, the rubber waterstop is cut out according to the sum of the lengths of mounting grooves and the lap joint length of 300 mm, and the end of the rubber waterstop is processed and then is subjected to hot joint treatment; thick cement paste is brushed in the mounting grooves, and the rubber waterstop is pushed into the mounting grooves through an erected mounting support; asbestos cement is prepared, the two sides of the rubber waterstop in the mounting grooves are filled with the asbestos cement, and the asbestos cement is knocked through a special tool till the surface is flat and compact; and the asbestos cement is subjected to moisturizing maintenance, the mounting support is dismounted after maintenance, and post-planting mounting of the rubber waterstop is completed. The post-planting installation method overcomes the defects of traditional rubber waterstop adding, operation is easy, materials are convenient to obtain, the post-planted rubber waterstop is firm and reliable, the using effect is good, durability is high, and the leakage problem of the added rubber waterstop is effectively solved.

Owner:CHINA MCC20 GRP CORP

Method and structure for fixing communication pipe of water extraction pump station water absorption pond

InactiveCN103572800AOvercoming water pressureNo loosenessPumping plantsDrinking water installationFiberEngineering

The invention discloses a method and a structure for fixing a communication pipe of a water extraction pump station water absorption pond. The method comprises the following steps of preliminarily respectively embedding and fixing a waterproof bushing in connection holes on the wall of two water absorption ponds, then inserting two pipe orifices of the communication pipe into the waterproof bushings, ensuring the end surfaces of two pipe orifices of the communication pipe to respectively penetrate through the waterproof bushings, respectively welding a flange piece on the end surfaces of the two pipe orifices of the communication pipe, wherein the inner diameter of the flange piece is identical to that of the communication pipe, the outer diameter of the flange piece is greater than the outer diameter of the waterproof bushing, and adopting a mixed material of fibers and asbestos cement to fill a seam between the communication pipe and the embedded waterproof bushings after the flange pieces are closely attached to the wall of the water absorption pond. By adopting the method, not only can the advantages such as reliability in connection and fixation and safety in use be realized, but also the advantages such as simplicity in structure, convenience in construction and long service life can be realized.

Owner:GUIYANG AL-MG DESIGN & RES INST

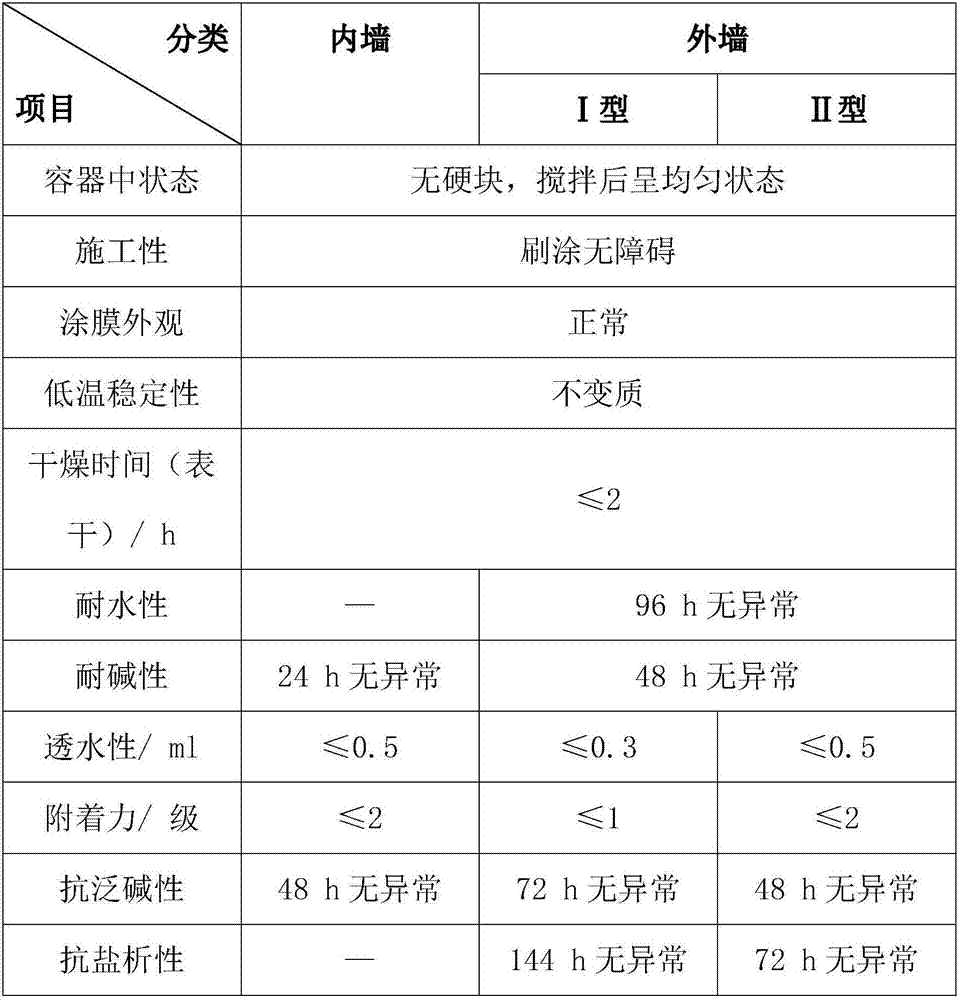

A Rapid Method for Evaluating Primer Performance

The invention relates to a method used for rapid evaluation of priming paint performance. The method comprises following steps: the surface of an asbestos cement plate and the surface of a fiber reinforced cement middle density flat board are coated with a priming paint to be tested respectively; the asbestos cement plate and the fiber reinforced cement middle density flat board are subjected to water permeability test, adhesion test, alkali burnout resistance test, and alkali burnout resistance and salting-out resistance test; if the water permeability, adhesive force, the alkali burnout resistance of inner wall priming paint, or alkali burnout resistance and salting-out resistance of outer priming paint are all qualified, the priming paint is qualified; if one parameter selected from the water permeability, adhesive force, the alkali burnout resistance of inner wall priming paint, or alkali burnout resistance and salting-out resistance of outer priming paint is not qualified, the priming paint is unqualified.

Owner:SKSHU PAINT

muffler for engine

ActiveCN106014545BReduce mid and high frequency noiseReduce mid and low frequency noiseSilencing apparatusMachines/enginesIntermediate frequencyEngineering

The invention discloses a novel silencer for an engine. The novel silencer comprises a cavity, an outer shell, an inner wall, glass fiber cotton, an air inlet pipe, a damping hole plate, a first cavity, a first partition, a center partition, a second cavity, an air guiding pipe, a micro perforated plate, wave crest sound absorption sponge, a second partition, a third cavity, a porous expansion perlite layer, a closed hole type foam plastic layer, a porous asbestos cement plate layer, an air outlet pipe, micro through holes and micro small holes. The cavity comprises the outer shell and the inner wall. The cavity is internally provided with the damping hole plate, the first partition, the second partition, the first cavity, the second cavity and the third cavity. According to the novel silencer for the engine, simplicity of the noise reduction theory and method adopted by existing noise reduction equipment is changed, the beneficial effects of damping noise reduction, resistance noise reduction, micro perforated plate noise reduction and small hole noise reduction are integrated, the low frequency sound wave, the intermediate frequency sound wave, the high frequency sound wave and the ultrahigh frequency sound wave in noise can be effectively absorbed, pollution caused by noise is reduced to the maximum degree, and the health of the human body is protected.

Owner:泉州市知产茂业工业设计有限公司

Asbestos cement and production process thereof

InactiveCN113443869AFully relaxStirring and mixing process is smoothHazardous substancePortland cement

The invention discloses asbestos cement which is prepared from the following raw materials in parts by weight: 30 to 40 parts of asbestos wool, 100 to 110 parts of Portland cement, 1200 to 1300 parts of clear water, 0.3 to 0.8 part of a defoaming agent and 15 to 25 parts of river sand aggregate; according to the asbestos cement, firstly, the defoaming agent and other auxiliary materials are added, the defoaming agent and asbestos wool are mixed in a container so that the asbestos wool can be sufficiently loosened and completely soaked, the defoaming agent plays a role in foam inhibition and foam breaking so as to facilitate smooth subsequent stirring and mixing procedures, 1200 parts of clear water with the water temperature of 20-30 DEG C are divided into three parts according to the proportion of 590 parts: 590 parts: 20 parts, the asbestos wool is soaked and bubbles are removed through two pieces of 590 parts of clear water, then harmful dust and impurities are filtered, 1200 parts of clear water are divided into three parts, the three parts of clear water are stored by three different stirring containers, the containers can be replaced to screen residues and harmful substances left in the previous stirring and mixing process, and the continuous residue in the formed asbestos cement is avoided.

Owner:罗安锰

Compositions and methods for in-situ macro-encapsulation treatment of friable asbestos fibers generated by trenchless pipe bursting of asbestos cement pipe

Equipment, process and techniques are shown for rehabilitating old underground pipelines, particularly asbestos pipelines, in which an old underground pipeline is replaced, as by drawing a bursting head through the old pipe to burst it and simultaneously pulling a new pipe through behind the bursting head. The invention has particular applicability to the rehabilitation of old asbestos pipelines in which the burst up debris must be contained or encapsulated in some manner. The macro-encapsulation materials shown form an in-situ layer of a temporarily fluid macro-encapsulating material which absorbs and immobilizes asbestos fibers and pipe fragments, the macro-encapsulating material being applied simultaneously as the pipe bursting operation proceeds.

Owner:AMBLER EDWARD ALAN

Grease for anti-weathering protection of stone

The invention relates to a grease for anti-weathering protection of stone, which is prepared from the following raw materials in percentage by weight: 40-45% of polyorganosiloxane, 35-40% of silane, 5-10% of organosilicon and 5-10% of refined quartz sand. The raw materials are proportionally mixed, and subjected to nano treatment in a reaction kettle until the particle size is 0.1-100nm. After the material is applied onto a substrate by dip coating, no trace can be left on the surface of the coated brick, ash mud, natural stone or concrete; and due to the non-drooping characteristic and the longer detention time on the substrate surface, the grease can permeate into the low-porosity building material more deeply. The grease has high acid / alkali resistance, high air permeability and favorable water resistance, and is applicable to adsorptive mineral substrates, such as natural hard laterite, glaze-free vitrified bricks, surface-protecting stone, asbestos cement boards, ash mud, glue mud, natural stone, prefabricated stone, concrete and the like.

Owner:候世益

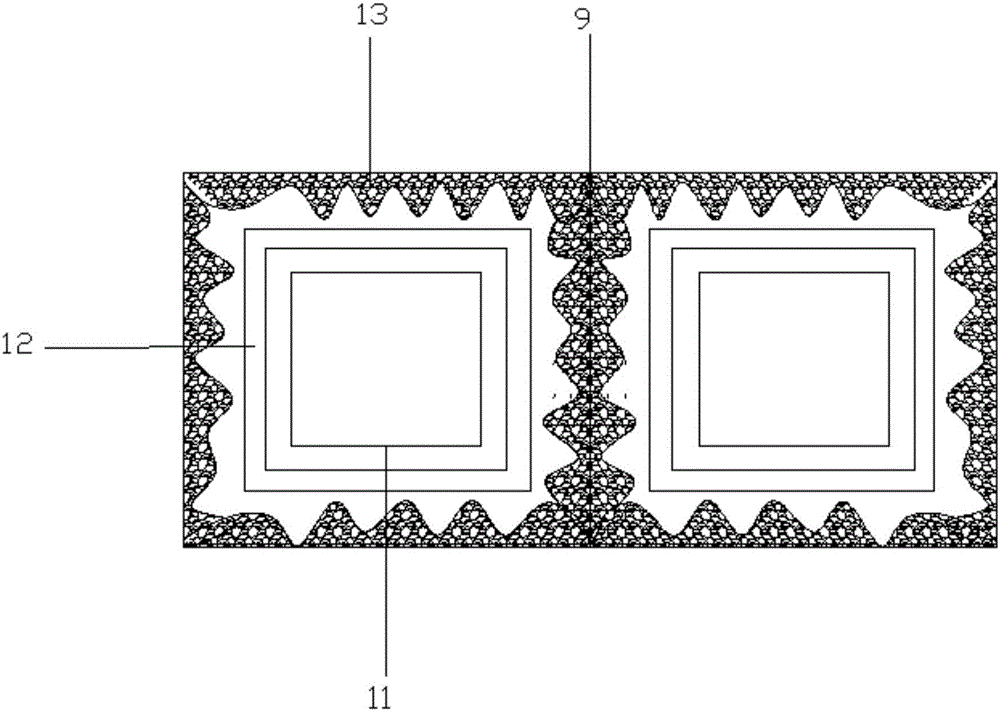

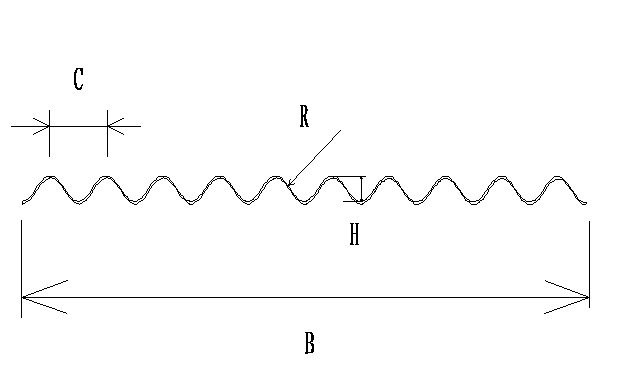

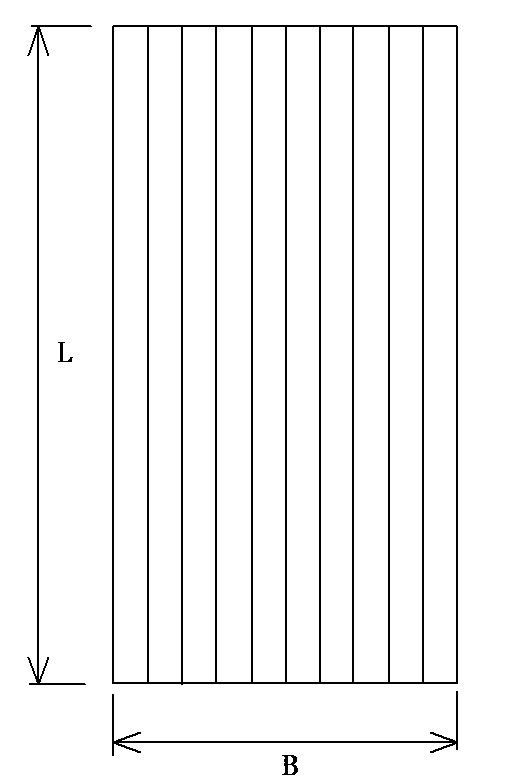

Novel fiber corrugated cement tile

InactiveCN107217793ASimple processing technologySimple production processRoof covering using tiles/slatesFiberWave shape

The invention discloses a novel fiber corrugated cement tile, the length of which is 800 mm to 1900 mm, and the width of the tile is 500 mm to 900 mm. , The arc distance is 65-130 mm, the wave height is 18-30 mm, the thickness is 4-8 mm, and the wave number is nine. The present invention has basically the same billet forming process as the common asbestos cement small wave tile in the existing market, the length, width and thickness are basically the same, there is no special requirement for the user's use conditions, and the advantages of the existing small wave tile are inherited. The wave type design is reasonable and comprehensive. The performance is good, the effective use area is increased by more than 10% compared with the small wave tile, and the production process can be simplified, energy saving and consumption reduction, and cost reduction. The invention only overlaps one wave to achieve the sealing effect of being able to withstand the strong rainfall in the south, makes the tiles closer to the purlins, is not easy to be damaged, makes the entire roof smoother, and increases the effective use area of the wave tiles.

Owner:颜笑宇

Asbestos cement tile

InactiveCN103469969ASimple processing technologySimple production processRoof covering using slabs/sheetsWave heightMaterials science

The invention relates to a roofing material, in particular to an asbestos cement tile. According to the asbestos cement tile, the arc radius (R) is 40 millimeters, the arc distance (C) is 140 millimeters, the wave height (H) is 40 millimeters, the thickness is 8 millimeters, and the wave number is 12. The asbestos cement tile has the advantages that the processing process is simple, the transverse breaking-resistant strength of a wavy tile is enhanced, and the effect use area of the wavy tile is increased.

Owner:郭馥生

Wall surface decoration plate and its producing method

The present invention discloses a kind of coated metal-imitating wall decorating plate and its production process. Foamed polystyrene plate is adhered with asbestos cement plate to form composite plate, and the periphery of the composite plate is coated and fixed by adhesive, and the outside surface and lateral surfaces are coated successively with putty layer, closing primer layer, intermediate paint layer and facing paint layer to form the decoration plate product. The decoration plate has low cost and simple operation, and is suitable for industrial production.

Owner:谢日清

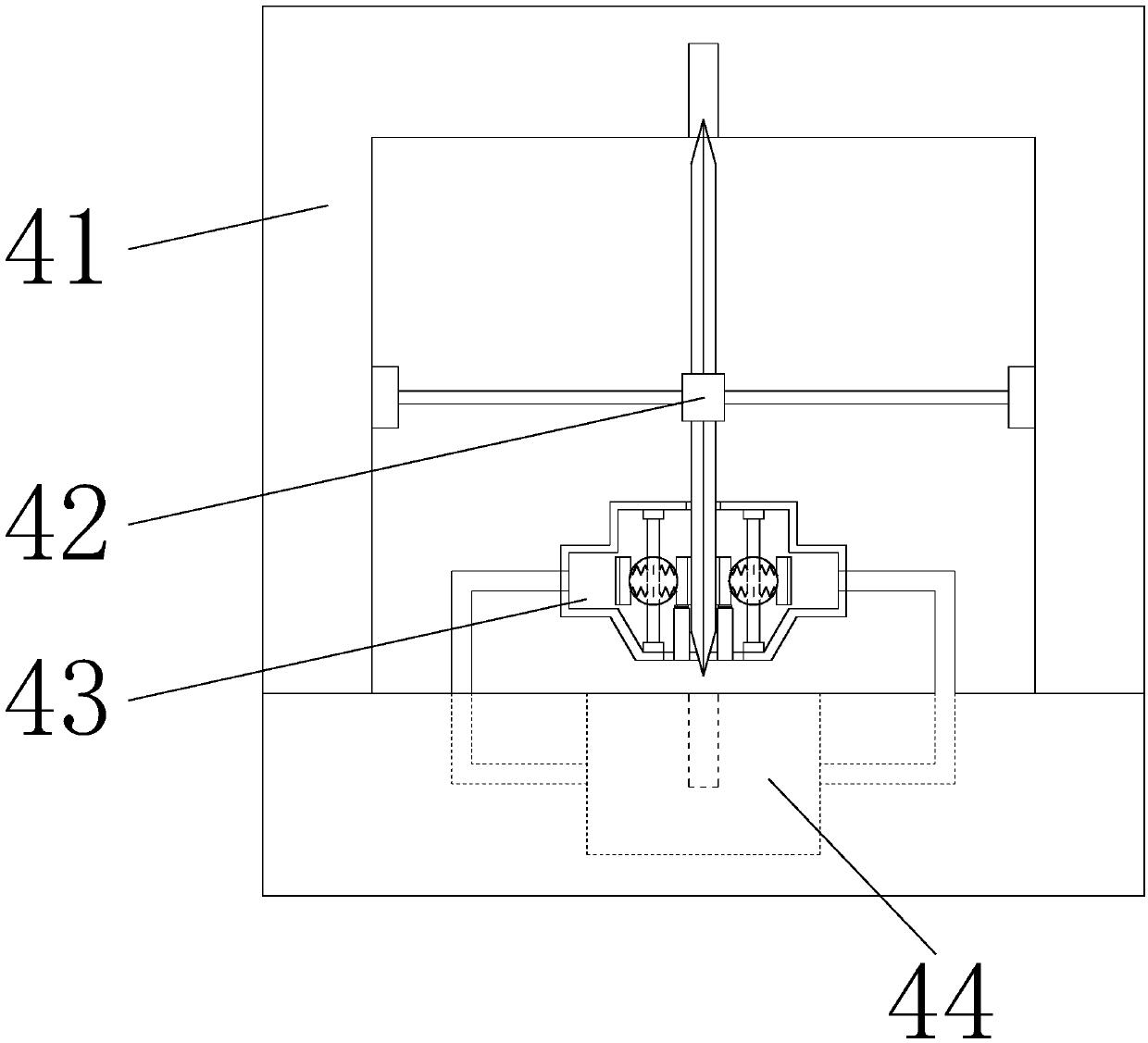

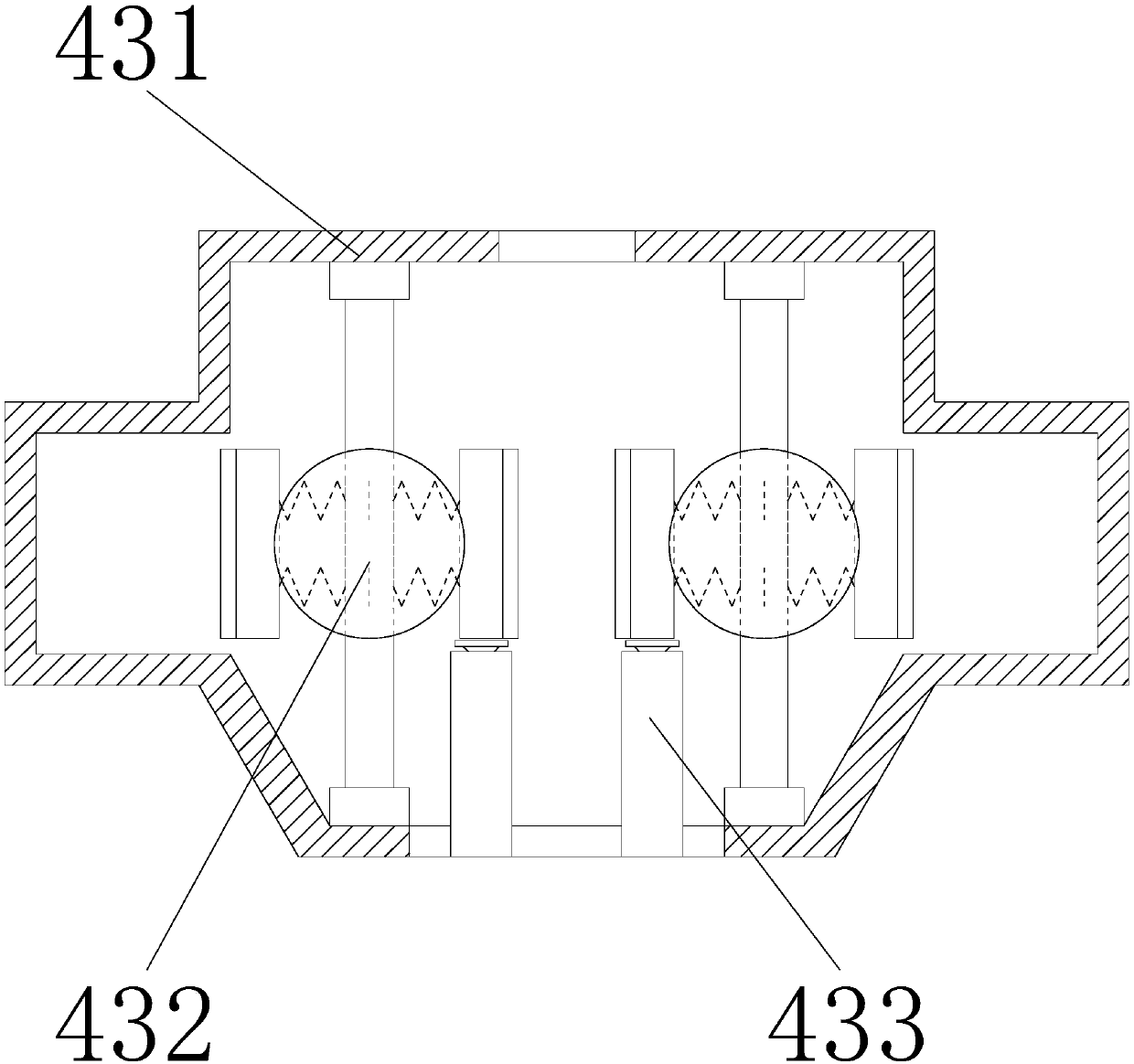

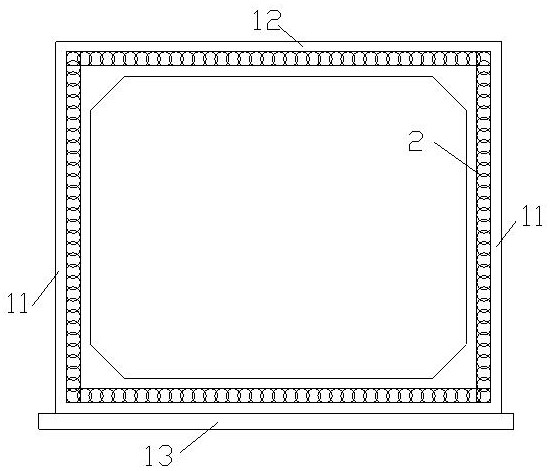

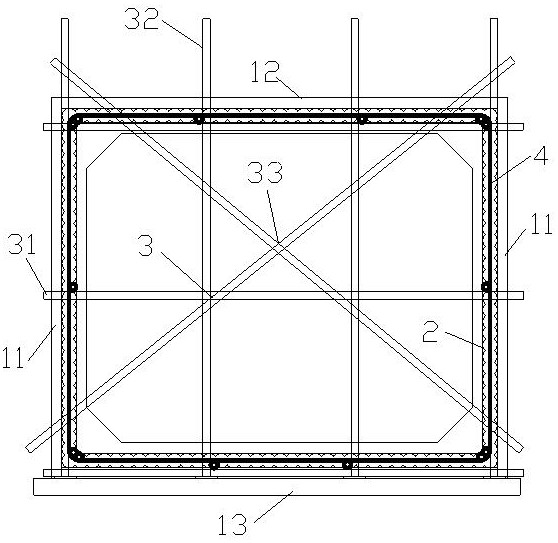

Vertical anti-dewatering cutting machine of asbestos cement plate

InactiveCN109571779AReduce the temperatureReduce breakageWorking accessoriesStone-like material working toolsStructural waterCement board

The invention discloses a vertical anti-dewatering cutting machine of an asbestos cement plate. The vertical anti-dewatering cutting machine structurally comprises a cement plate limiting frame, a cement plate transmission machine, two supporting feet and an asbestos cement plate cutting machine; and the cement plate limiting frame is fixedly mounted at the head end of the cement plate transmission machine, the two supporting feet are fixedly welded to the front end and the rear end of the cement plate transmission machine, the asbestos cement plate cutting machine is fixedly mounted at the tail end of the cement plate transmission machine, and the asbestos cement plate cutting machine and the cement plate limiting frame are parallel to each other. Heat energy generated during cutting of ahigh-speed cutting tool is absorbed through a heat transfer compression mechanism, thus the temperature of the high-speed cutting tool is decreased, the heat energy can further be utilized to work ona spiral cooling mechanism, structural water in asbestos fibers is absorbed to be injected onto a cutting opening, thus the asbestos fibers are protected, and cracks in the surface of the cement plate are reduced; and meanwhile, the heat energy generated during cutting is transferred to a cutting opening anti-fracture mechanism, thus the cutting opening anti-fracture mechanism tightens the cutting opening of the asbestos cement plate, impact force generated by the cutting opening of the asbestos cement plate and the high-speed cutting tool is lowered, and the situation of fracture of the cutting opening of the asbestos cement plate is reduced.

Owner:NANAN JIANQUAN MACHINERY TECH CO LTD

Post-planting installation method for rubber waterstop

ActiveCN112695807BEasy to useIncreased durabilityArtificial islandsUnderground chambersAgricultural engineeringCement slurry

The invention discloses a post-planting installation method for a rubber waterstop. In the method, a groove is made at the position where the rubber waterstop is installed, and the rubber waterstop is cut according to the sum of the lengths of the installation grooves plus a lap length of 300 mm, and the The end of the rubber water stop is thermally connected after treatment; the installation groove is painted with thick cement slurry, and the rubber water stop is pushed into the installation groove with the erected mounting bracket; asbestos cement is prepared and stuffed into the installation groove of the rubber water stop. On both sides, use special tools to tap the asbestos cement until the surface is flat and dense; moisturizing and curing the asbestos cement, remove the mounting bracket after curing, and complete the post-planting installation of the rubber waterstop. The method overcomes the defects of traditional rubber waterstop installation, has simple operation, convenient material acquisition, firm and reliable rubber waterstop after planting, good use effect and strong durability, and effectively solves the leakage problem of the installation of the rubber waterstop .

Owner:CHINA MCC20 GRP CORP

Pipeline through-wall culvert filling construction process

InactiveCN112856050AImprove protectionWaterproofNatural rubber adhesivesNon-macromolecular adhesive additivesArchitectural engineeringSealant

The invention relates to the technical field of pipeline through-wall culvert filling, in particular to a pipeline through-wall culvert filling construction process which comprises five steps. According to the pipeline through-wall culvert filling construction process provided by the invention, the design is ingenious, the materials are exquisite, the overall installation is simple and convenient, the construction difficulty is reduced, the construction progress is accelerated, a wall bushing is sleeved at the joint of a pipeline and a wall body, and a supporting steel plate is matched to play a better protection effect on a foaming filler, so that the leakage caused by the extrusion deformation of the foaming filler under the gravity action of the pipeline and the shaking of the pipeline is avoided; meanwhile, the foaming filler has waterproof, anti-aging and compression-resistant performance and is long in service life, asbestos cement has rigidity after being cured as a second waterproof seal, the position of the pipeline can be fixed, the situation that the foaming filler is extruded, deformed and torn due to displacement and shaking of the pipeline is prevented, and the protection performance is improved; and a weather-resistant sealant added with silicone has the advantages of good elasticity, strong binding power, aging resistance and strong sealing performance, and further improves the anti-leakage effect.

Owner:HUANENG QINGDAO THERMAL POWER CO LTD

Asbestos cement one-step formless building method

InactiveCN1200184CReduce processSimple structureCovering/liningsWallsReinforced concreteArchitectural engineering

Asbestos cement one-time formless construction method, including: 1. Use asbestos cement to make the outer wall of the wall component, fill the insulation material to make the inner wall, and finally decorate the outer decorative surface of the outer wall; 2. Use asbestos cement Make the outer surface of the column and beam components, and then decorate the decorative surface of the outer surface of the column and beam components; 3. Make floor panels with asbestos cement; 4. Make the above-mentioned walls, column beams and floors processed by the factory The panel components are transported to the construction site for combined installation, and finally the reinforced concrete pouring of the floor panels, columns and beam components is completed. The invention cancels the templates used in traditional building methods, and the procedures of plastering and making exterior decoration surfaces, and the walls, columns, beams, and panels can all be produced in factories, and only need to be combined during construction. The process is less, the structure is simple, the construction period is short, it meets the requirements of environmental protection, and the thermal insulation performance is good, and the construction cost is also low.

Owner:窦柏强 +2

A New Method for Connecting Pipes of Different Diameters and Materials

The invention discloses a novel connecting method for pipelines with different pipe diameters and made of materials. The novel connecting method is characterized by comprising the following steps that firstly, a blocking plate with the thickness of 2 m is arranged at the position, 5 m away from a water return branch hole, in the water return branch hole, the blocking plate, a connecting pipe made of concrete and branch hole linings at the position of the water return branch hole are poured at a time, no construction seam is reserved, during blocking plate pouring, rigid waterproof casing pipes are buried in the position, at the end of a connecting steel pipe, in the middle portion of the blocking plate, and due to the fact that the waterproof casing pipes are provided with wing rings, it can be ensured that the rigid waterproof casing pipes and the blocking plate are closely combined without water leakage; and secondly, a section of phi 630 steel pipe with a flange is installed at the end of the steel pipe in advance, the length of the phi 630 steel pipe is 300 mm, and sealing water preventing is conducted between the steel pipe and the casing pipes through baffle rings, batched jute and asbestos cement. By means of the novel connecting method, pipeline cracks, caused by differential settlement between a mountain and a soil layer, at the positions of the mountain and a dredging tank are avoided, the dredging work of the dredging tank is avoided, the labor force is saved, leakage of sewage containing toxic metal is prevented, and safety is high.

Owner:NORTH CHINA METALLURGICAL CONSTR ENG CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com