Tool and processing method used for precise induction brazing of annular thin-walled part

A technology for induction brazing of thin-walled parts, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as deformed structures, welding failures, scrapped parts, etc., and achieve the effects of small deformation, reliable quality, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] When welding the feedback assembly of the jet pipe valve, the position of the feedback wire and the sleeve is required to be within 0.2mm. Pure asbestos cement tooling is used. The tooling accuracy is low and some positioning structures cannot be processed, and the technological requirements of the position of 0.2mm cannot be guaranteed; only Carbon steel metal tooling is used, the parts and tooling are easy to stick, and it is easy to be scrapped; the parts are directly placed in the coil for induction heating, and the thin-walled annular area is easy to be burned and scrapped due to the small heat capacity and fast heating speed.

[0023] Use this tool:

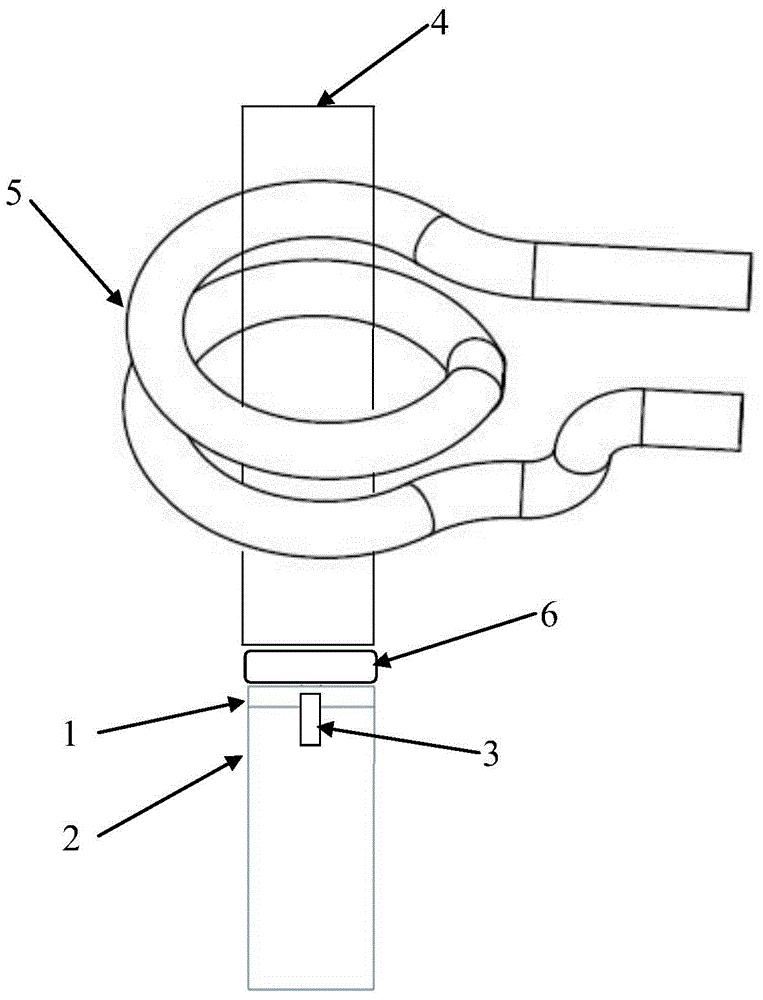

[0024] (1) The annular thin-walled part 6 to be welded is bonded to one side of the cement tooling 1, and the other side of the cement tooling 1 is bonded to the carbon steel tooling 2; the cement tooling 1 and the carbon steel tooling 2 are fixed by the connecting pin 3.

[0025] (2) Place the heat conducting rod 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com