Method and structure for fixing communication pipe of water extraction pump station water absorption pond

A fixing method and technology of connecting pipes, which are applied in pumping stations, water supply devices, drinking water devices, etc., can solve the problems of falling off of connecting pipes and unsatisfactory fixing methods of connecting pipes in suction pools, etc., and achieve reliable connection and fixing, simple structure, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the drawings and embodiments.

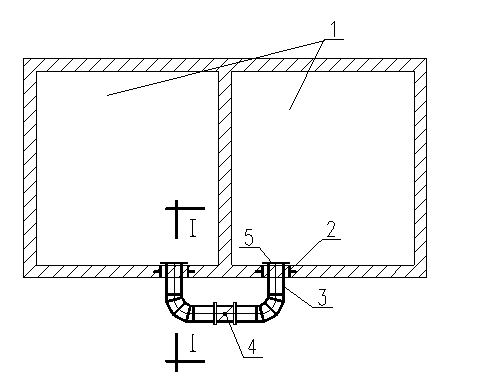

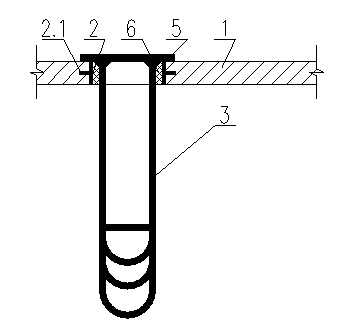

[0014] Embodiments of the present invention: The method for fixing the connecting pipe of the suction pool of a water intake pumping station of the present invention can be implemented on the suction pool of an existing water intake pumping station. When implemented, the two nozzles of the connecting pipe 3 are respectively connected When fixing on two suction basins 1, a waterproof casing 2 is pre-embedded and fixed at the connection hole of the two suction basins 1, and then the two nozzles of the connecting pipe 3 are inserted into the waterproof casing 2. After the two nozzle end faces of the connecting pipe 3 are passed through the waterproof casing 2 respectively, a flange piece 5 is welded to the two nozzle end faces of the connecting pipe 3 so that the inner diameter of the flange piece 5 is the same as that of the connecting pipe 3. The inner diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com