Original roof pipeline waterproof structure of reconstruction project and construction method thereof

A waterproof structure and pipeline technology, applied in building construction, roof insulation materials, buildings, etc., can solve problems such as easy to cause water seepage, and achieve the effect of reducing changes, good waterproof performance, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

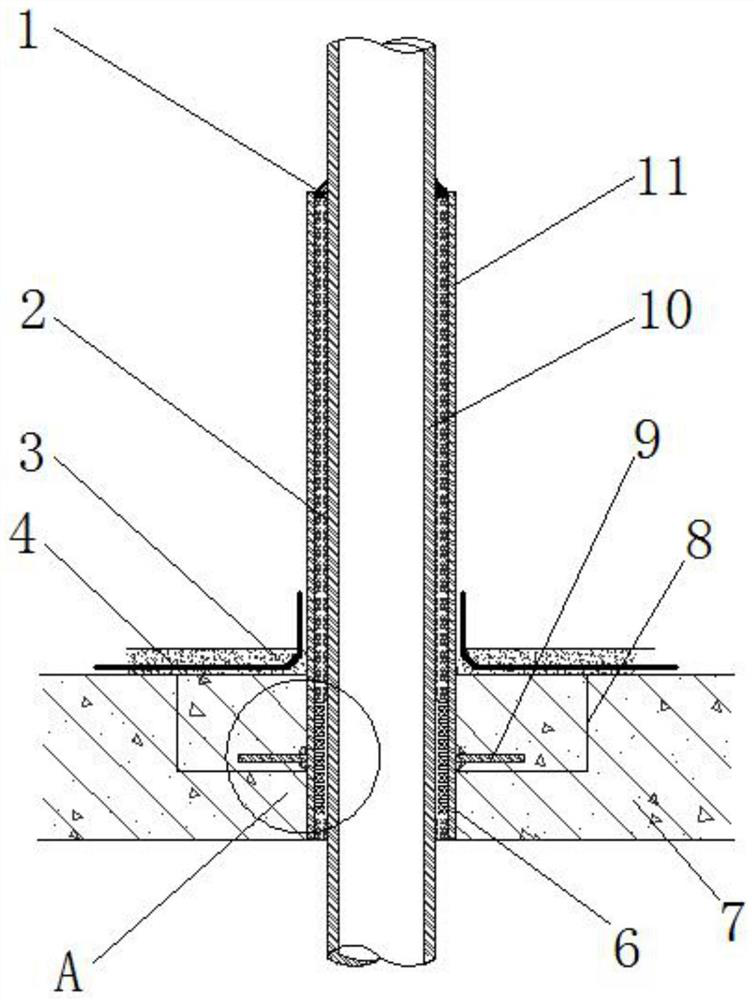

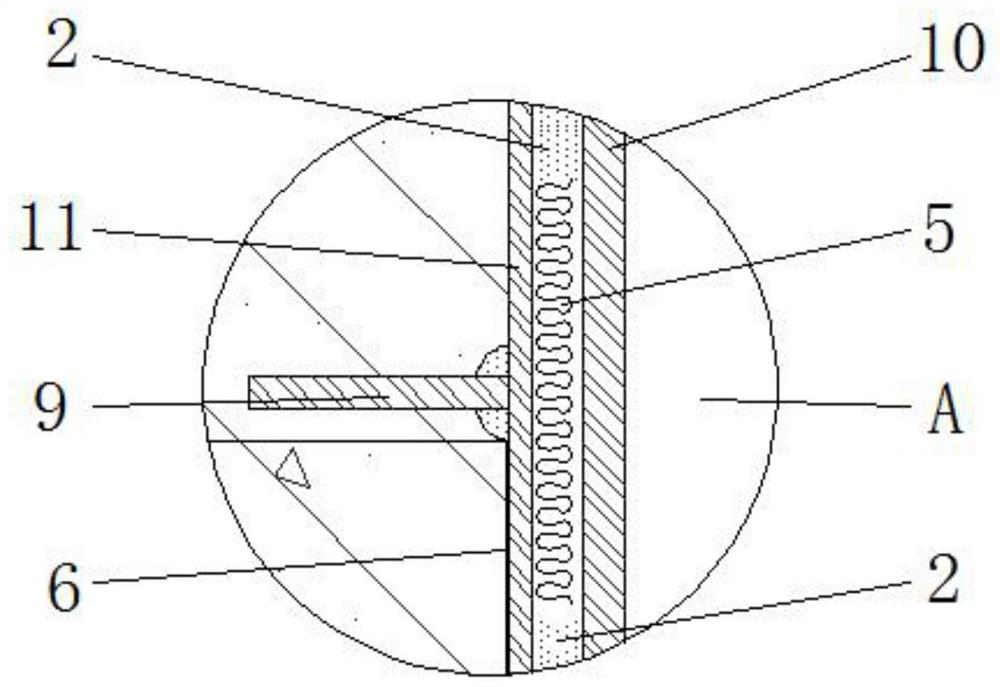

[0030] like figure 1 The original roof pipeline waterproof structure of a renovation project shown includes a pipeline 10 passing through the roof panel 7, the pipeline 10 is provided with a waterproof casing 11, and the roof panel 7 is provided with a waterproof casing just for the 11 through the installation through hole 6 at the lower end, the upper end surface of the roof panel 7 is provided with a fine stone concrete layer 3 surrounding the waterproof sleeve 11; the lower end of the waterproof sleeve 11 is fixedly sleeved with a wing plate 9, the upper part of the roof panel 7 corresponding to the installation through hole 6 is widened to the peripheral side to form an outer edge groove 8 for the placement of the wing plate 9, and the outer edge groove 8 is filled with concrete materials for burying the wing plate 9; There is a gap between the pipeline 10 and the waterproof sleeve 11, and an asbestos cement twist 2 and a linoleum filling layer 5 are filled in the gap, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com