Post-planting installation method for rubber waterstop

A technology of a rubber waterstop and an installation method, which are used in protection devices, shaft equipment, earth-moving drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

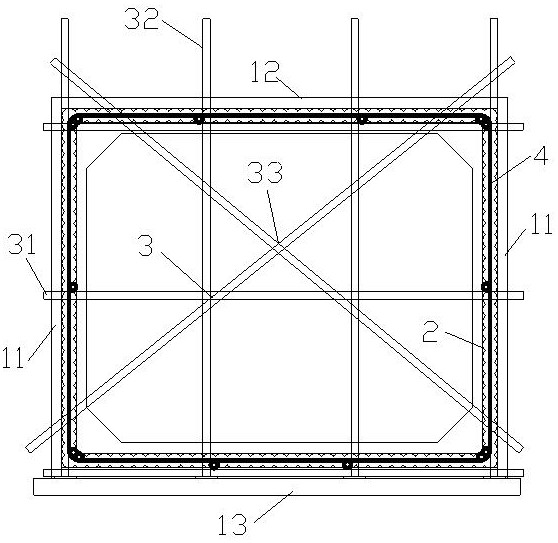

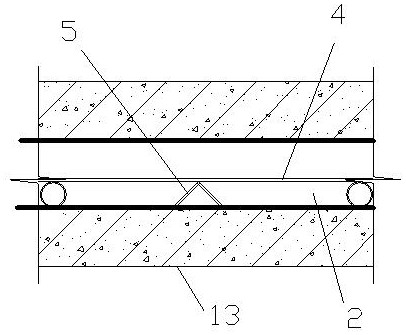

[0023] Example figure 1 and figure 2 The post-planting installation method for rubber waterstop of the present invention comprises the following steps:

[0024] Step 1. Groove 2 at the positions where rubber waterstops are installed on both sides 11, top 12 and bottom 13 of the wall, pop up and install the centerline of the rubber waterstop, and use a Φ100 drill to drill holes along the centerline at intervals. The hole overlap is 20mm, and the hole depth is 150mm;

[0025] Step 2. After drilling, remove the hole cores one by one with steel brazing to form the installation groove 2. Some hole cores are broken in the middle, and use steel brazing to probe into the installation groove 2 to remove the hole cores from the root until the bottom of the groove is flat and has no protrusions;

[0026] Step 3. Cut off the rubber waterstop according to the sum of the lengths of the installation grooves 2 on both sides, top and bottom of the wall plus 300mm lap length, and cut out the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com