Patents

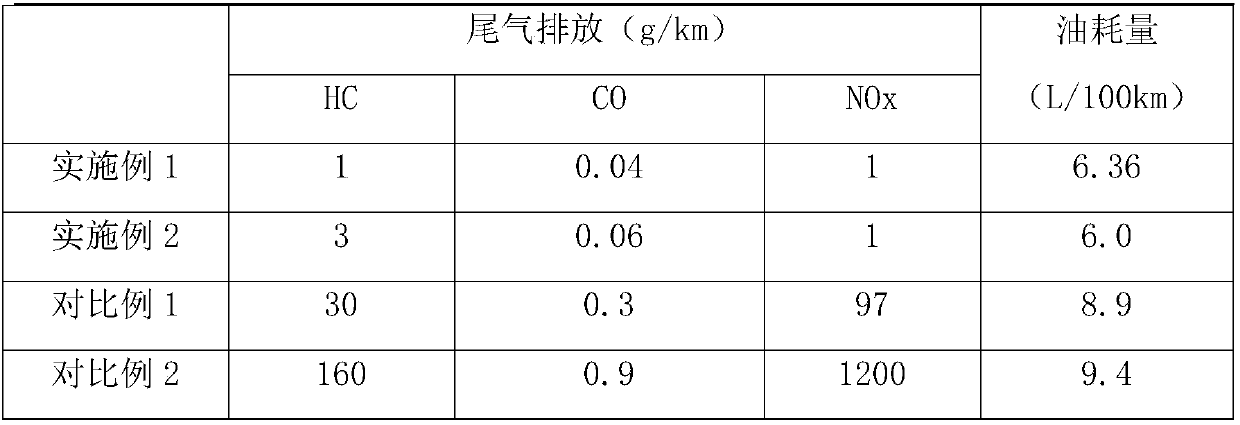

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Will not spontaneously combust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of sulfuration method of hydrogenation catalyst and its application

ActiveCN102284299AGood vulcanization rateNo abnormal smellCatalyst regeneration/reactivationCatalyst activation/preparationPtru catalystHydrogenation reaction

The invention relates to a method for pre-vulcanizing a hydrogenation catalyst outside a hydrogenation reactor and activating the hydrogenation catalyst in the hydrogenation reactor. The method comprises the following steps of: (1) pre-vulcanizing the catalyst outside the hydrogenation reactor; (2) passivating the catalyst; and (3) reactivating the catalyst. A vulcanization method for the hydrogenation catalyst provided by the invention can guarantee high vulcanization rate of the catalyst; the passivated catalyst does not have abnormal odor and does not release hydrogen sulfide gas when being in contact with air or vapor; and the catalyst does not spontaneously combust and is not required to be protected by inert gas. Storage, transportation and filling methods and the like of the catalyst are simple and convenient. The catalyst can reach an activated state in a few hours during reactivation of an atmosphere containing a vulcanizing agent and hydrogen, is short in processing time, convenient to operate and has high catalytic performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polymer composition for air purification

Disclosed herein are a polymer composition for air purification and a filter manufactured using the polymer composition. The polymer composition comprises a peroxide or superoxide and silicone (i.e. an organopolysiloxane). Since the silicone has a high gas permeability, the polymer composition comprising the peroxide or superoxide as an air purifier rapidly absorbs harmful gases and is highly stable even when in contact with water, allowing the polymer composition to show superior characteristics. Particularly, since the polymer composition comprises a stabilizer, it is highly stable and thus is not spontaneously ignited even at very high temperatures. Accordingly, the polymer composition can be manufactured into filters having various shapes by common rubber processing.

Owner:卢万均

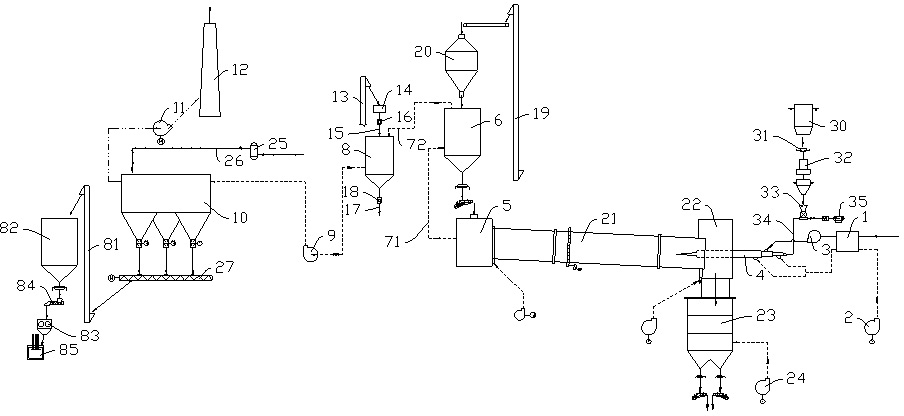

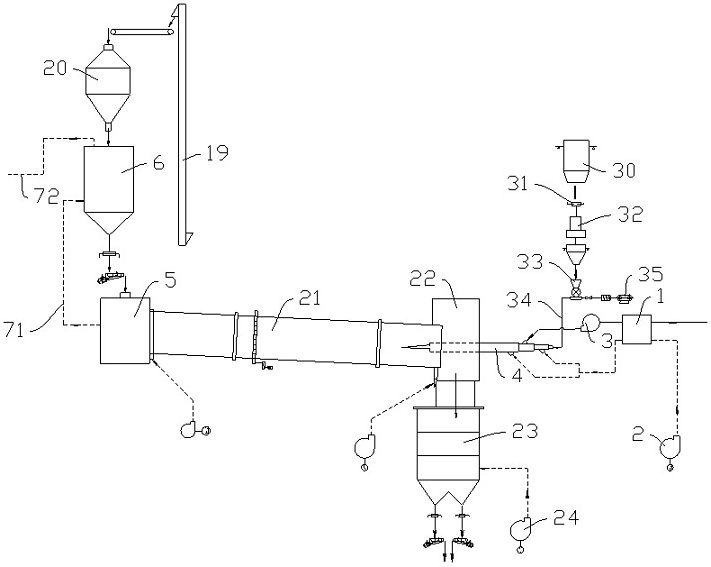

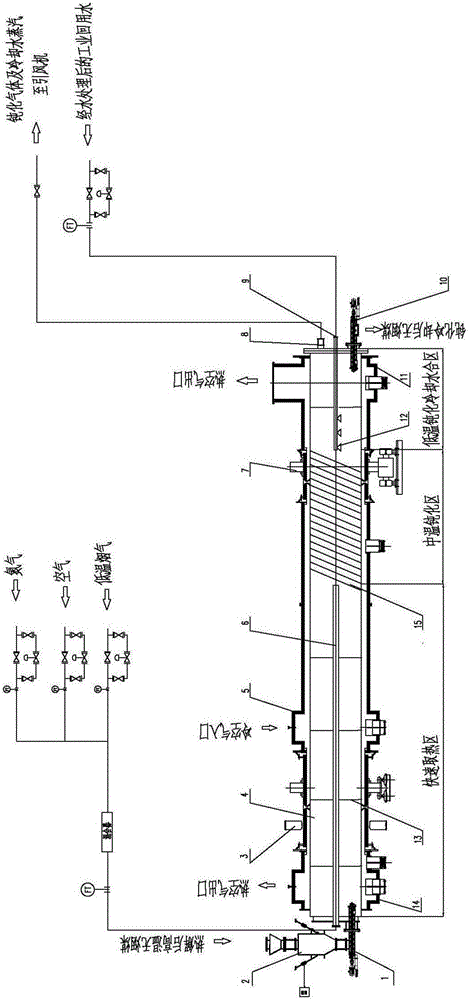

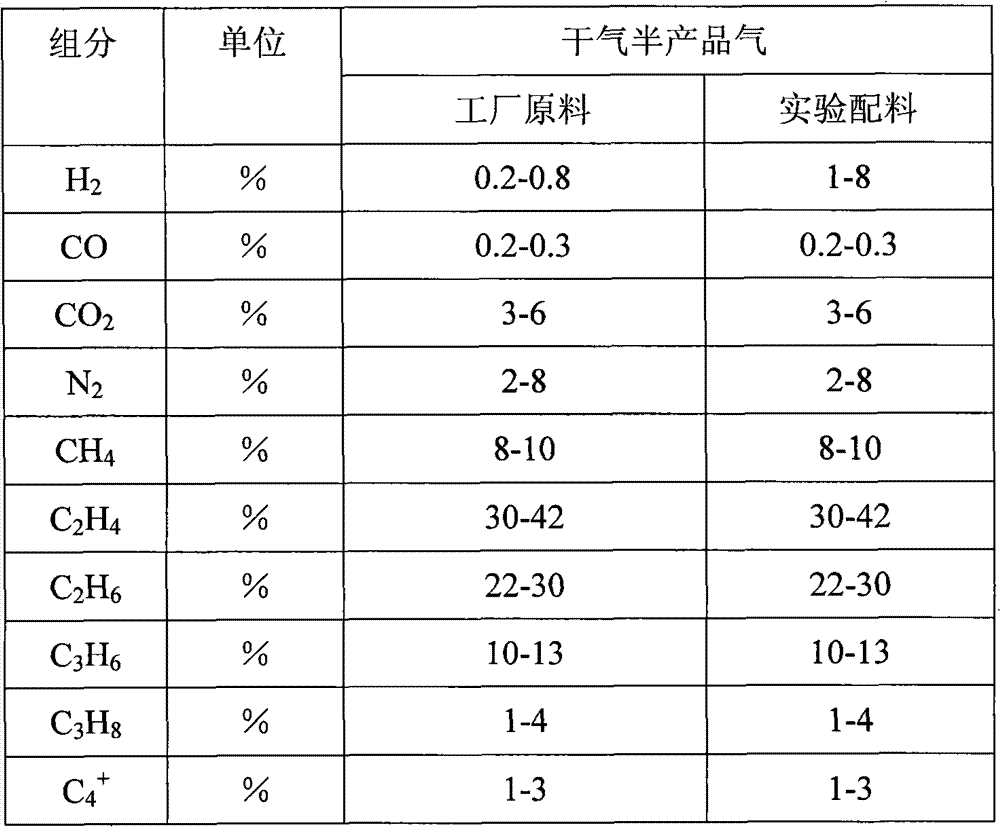

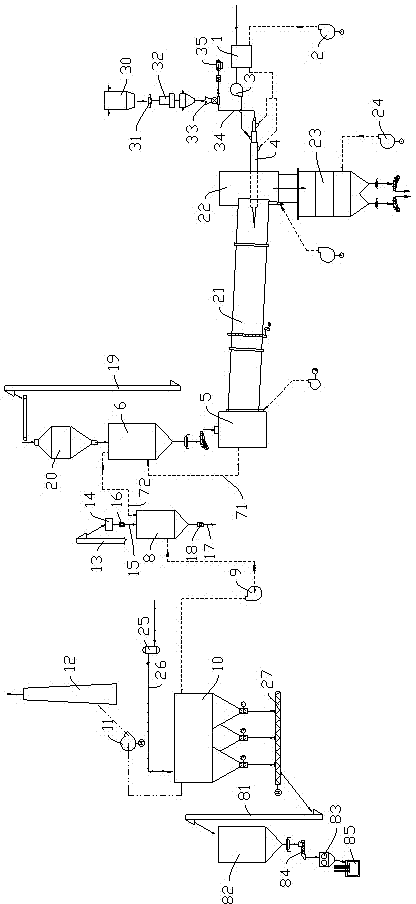

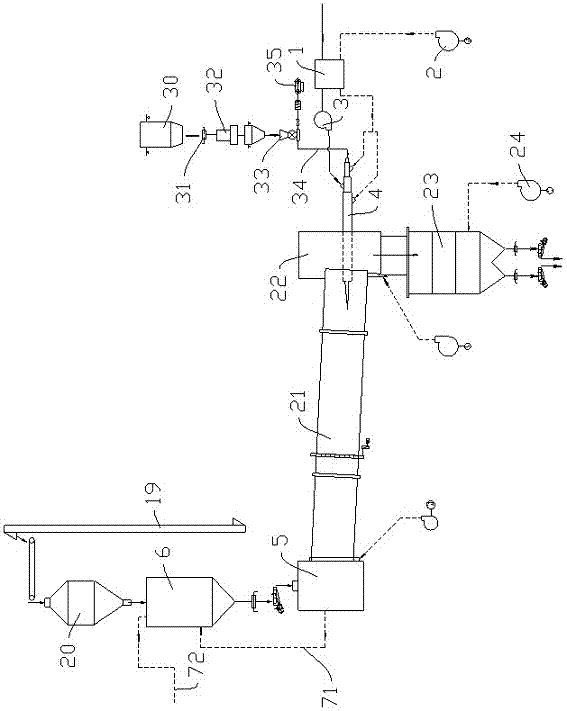

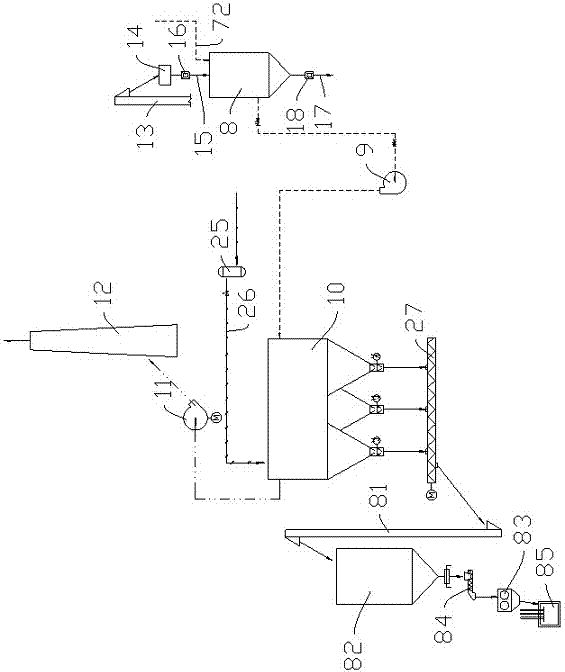

Utilization method and system for tail gas of calcium carbide furnace

InactiveCN102620573AEliminate potential safety hazardsLess investmentWaste heat treatmentHigh concentrationCombustor

The invention provides a utilization system for the tail gas of a calcium carbide furnace. By the system, without purification treatment, the tail gas of the calcium carbide furnace is directly conveyed into a burner and then burnt, investment to the purification treatment of the tail gas of the calcium carbide furnace is eliminated, and hidden danger in the purification treatment of the tail gas of the calcium carbide furnace, which contains high-concentration carbon oxide (CO), is eliminated. The utilization system for the tail gas of the calcium carbide furnace comprises a heat exchanger, a pressurizing conveying fan and a lime rotary kiln, wherein the heat exchanger cools the tail gas of the calcium carbide furnace; the lime rotary kiln is provided with the burner; and a calcium carbide furnace tail gas discharge pipe, the heat exchanger, the pressurizing conveying fan and the burner are sequentially connected in series. The invention also provides a utilization method for the tail gas of the calcium carbide furnace. The method comprises the following steps of: reducing the temperature of the tail gas of the calcium carbide furnace to 200 to 400 DEG C; pressurizing the tail gas of the calcium carbide furnace to be over 3,000 Pa by using the pressurizing conveying fan; conveying the tail gas of the calcium carbide furnace into the burner of the lime rotary kiln; and burning the tail gas of the calcium carbide furnace.

Owner:NANJING SUYE CALCIUM IND TECH

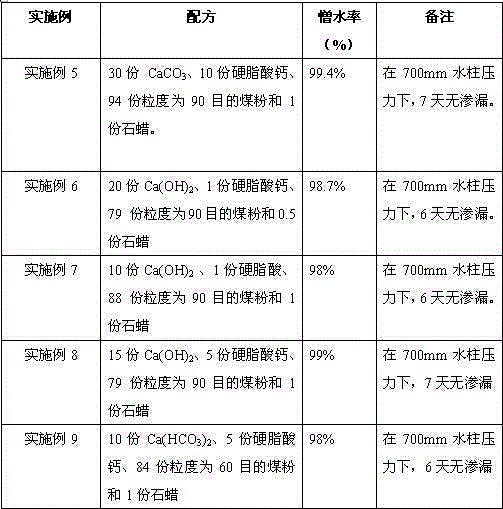

Waterproof pulverized coal and preparation method thereof

The invention discloses a waterproof pulverized coal and a preparation method thereof, wherein the waterproof pulverized coal comprises components with parts by weight: calcium salt or calcium hydroxide (Ca(OH)2) 5-30 parts, stearic acid or stearate 1-10 parts or pulverized coal 60-94 parts. The method for preparing the waterproof pulverized coal comprises steps: firstly, the components with parts by weight are weighted, are added into a roller type reaction kettle to be kept to heat for 20-60 min after being heated to 110-140 DEG C, thereby obtaining the waterproof pulverized coal. The method for preparing the waterproof pulverized coal can convert pulverized coal to be a hydrophobic substance from a hydrotropic substance, greatly reduces hydrophilic performance of the pulverized coal, and can prevent volatile components in the pulverized coal from volatilizing, thereby preventing the autoignition problem of the pulverized coal during storing, prolonging service life, improving safety during storage and transportation, and having excellent application prospect.

Owner:重庆四季金标科技有限公司

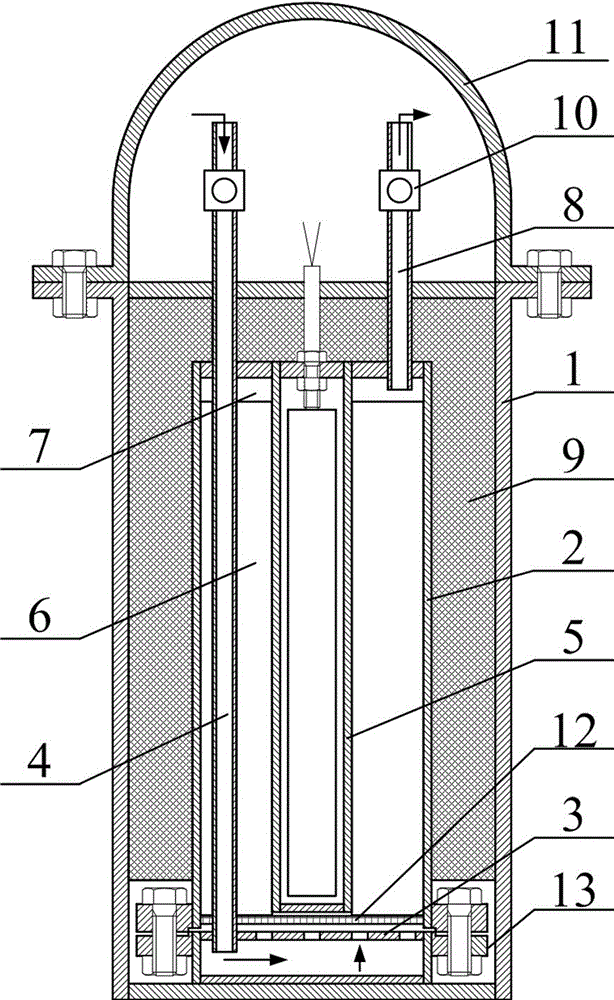

Tritium trap device used for removing tritium in helium-3 gas, and tritium-removing method

InactiveCN104538074AGuaranteed purityEfficient captureRadioactive decontaminationNuclear engineeringHeat losses

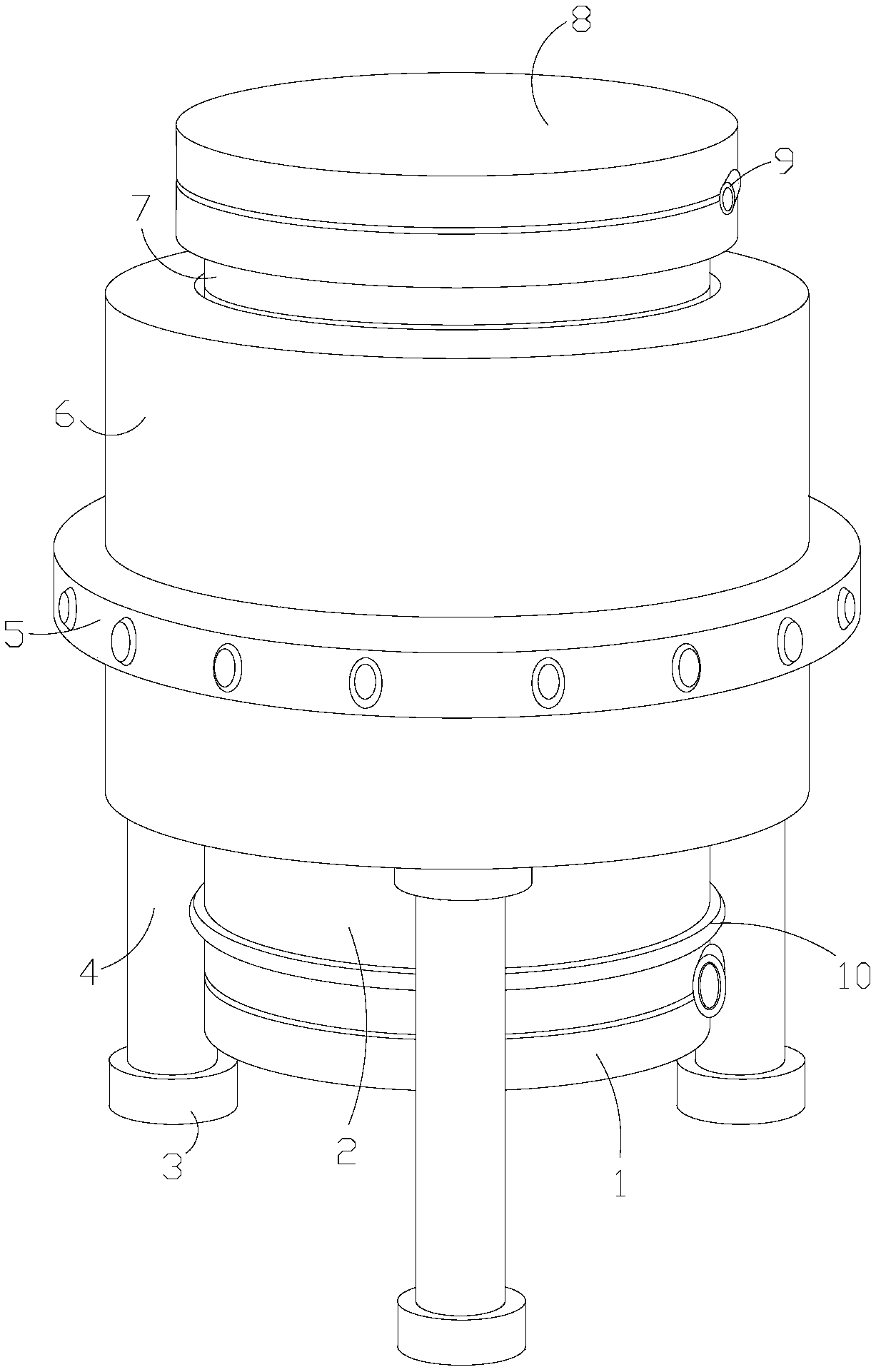

The invention discloses a tritium trap device used for removing tritium in helium-3 gas, and a tritium-removing method. The tritium trap device comprises an outer housing, an inner housing positioned inside the outer housing, a gas inlet pipe with a gas outlet port positioned in a lower part inside the inner housing, a heating chamber fixed inside the inner housing, a titanium sponge arranged above the gas outlet port of the gas inlet pipe and filled between the heating chamber and the inner housing, an expansion reserved space arranged inside the inner housing and positioned above the titanium sponge, and a gas outlet pipe with a gas inlet port positioned in the expansion reserved space. The invention also comprises a method for removing tritium with the tritium trap device. The device is suitable for removing tritium in a high-temperature high-pressure helium-3 loop, and has the advantages of reliable performance and compact structure. Also, with the device, heat loss and tritium permeation amount can be reduced. The device and the method have important significance in ensuring the safety and successful running of a power sharp-increase test.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

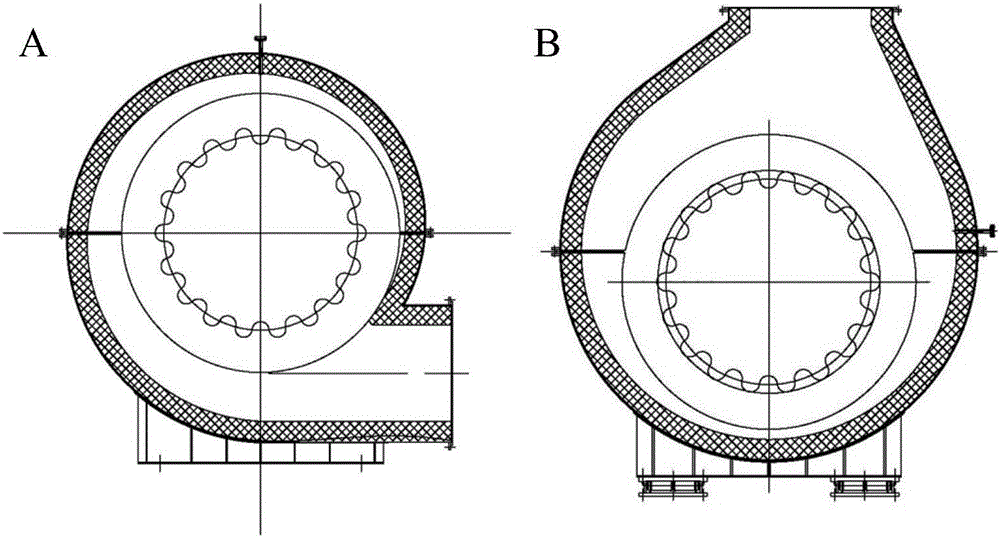

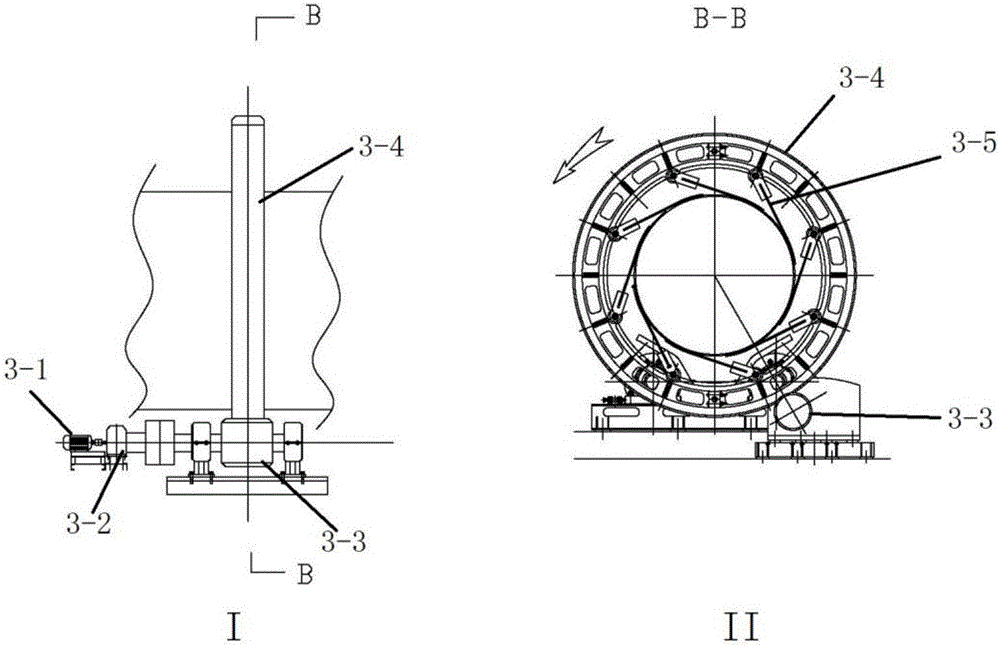

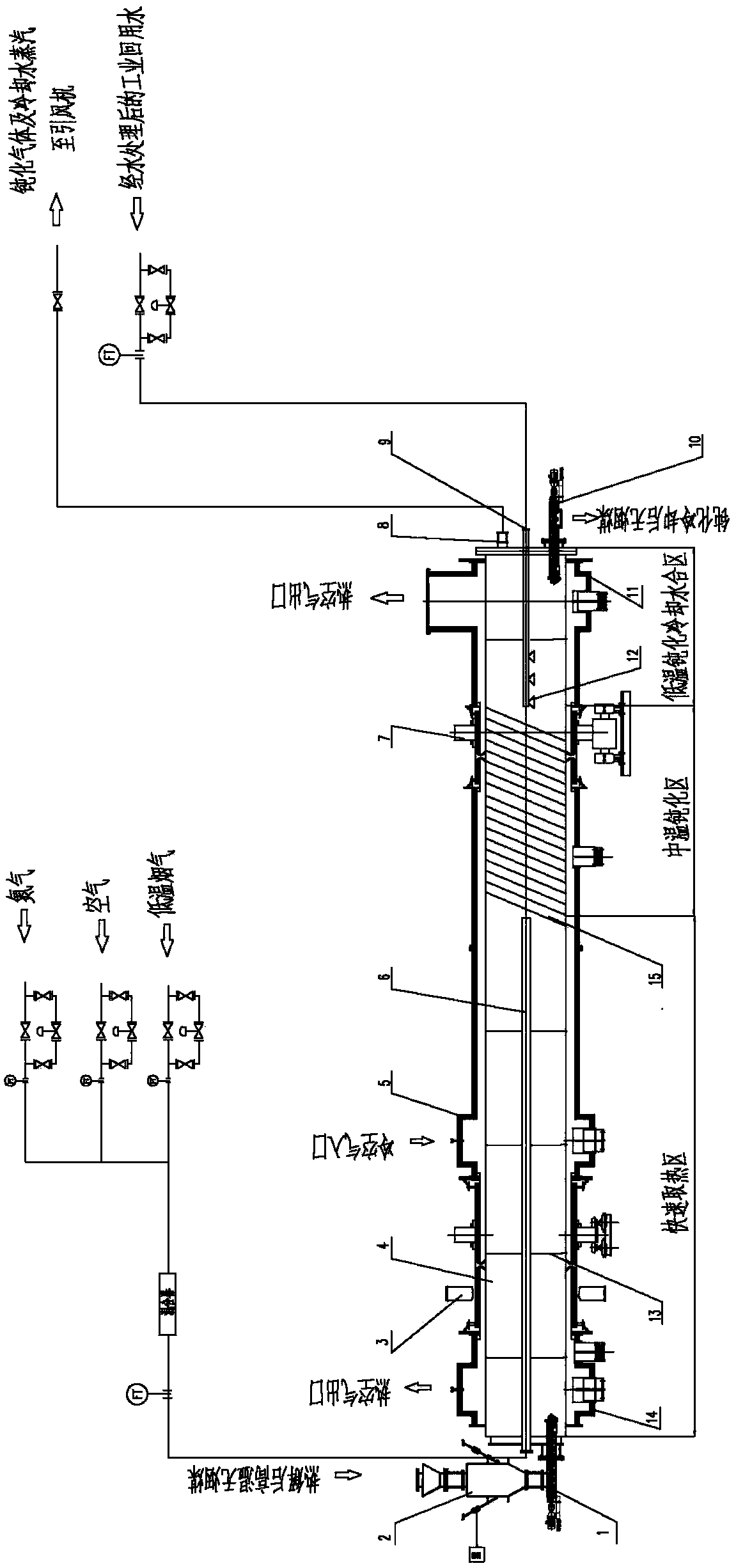

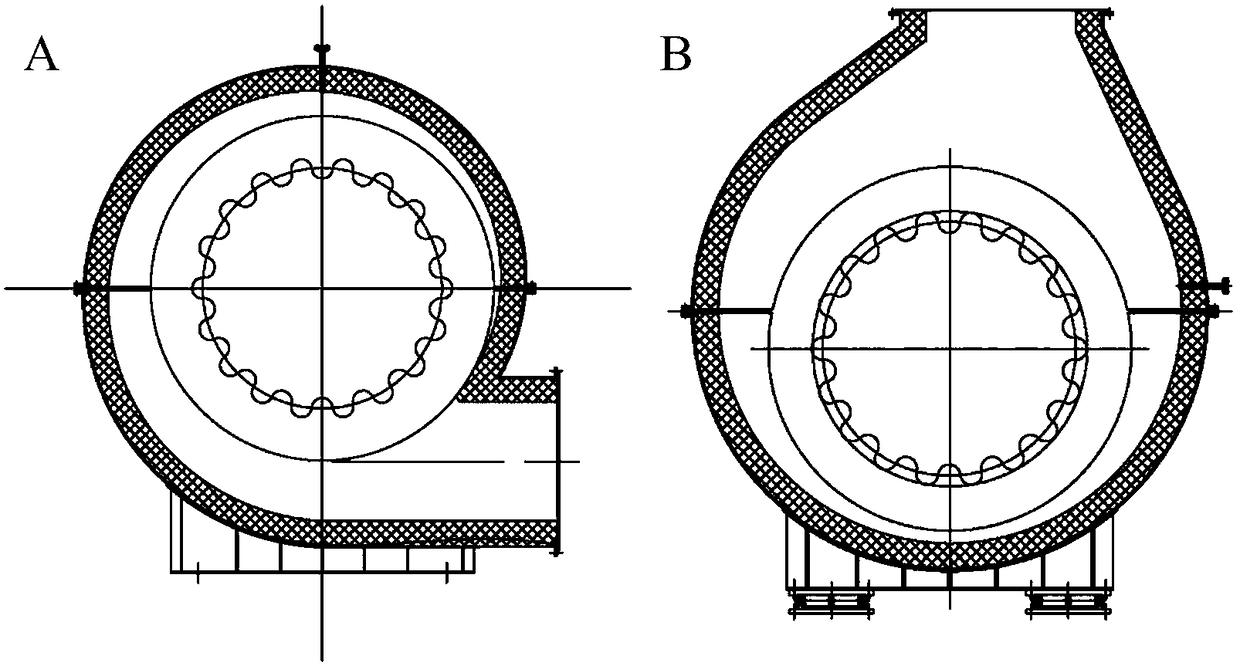

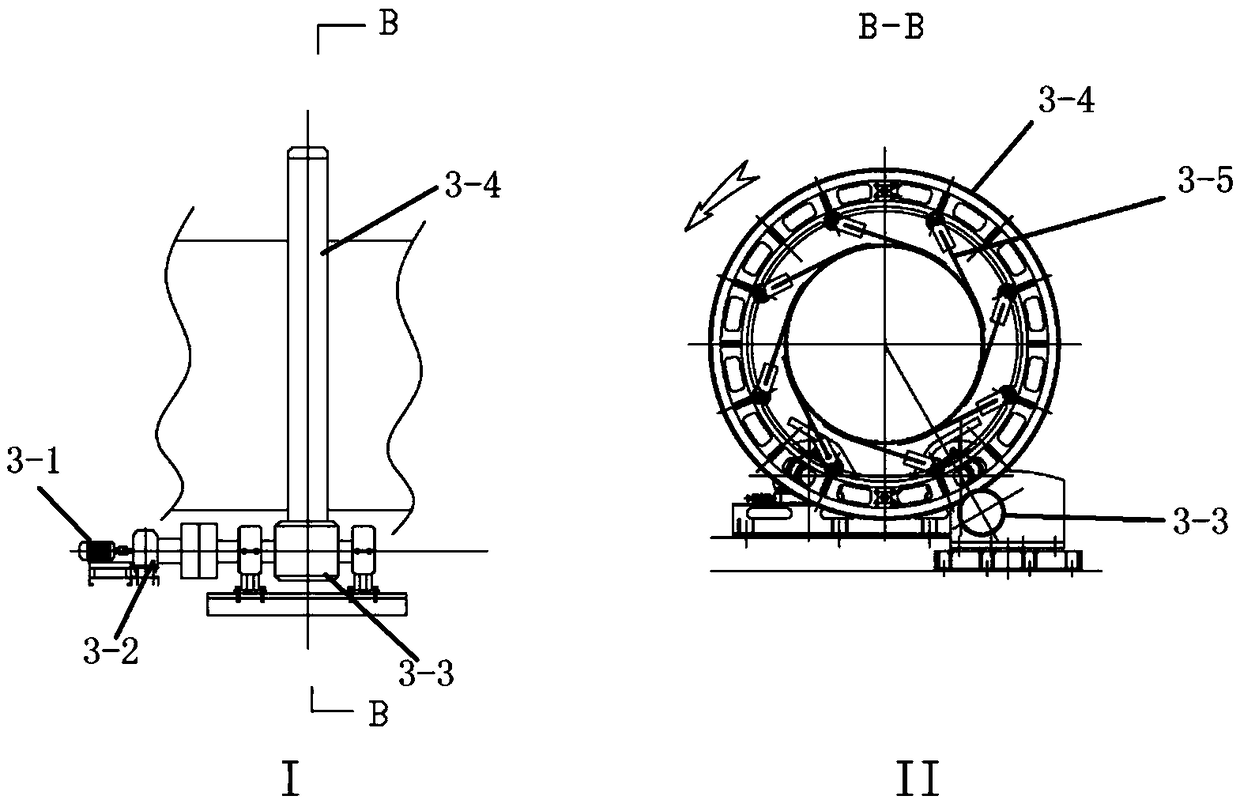

Method for passivating and cooling anthracite and integrated device thereof

ActiveCN105885903AAvoid overheatingHigh thermal efficiencyCoke quenchingSolid fuelsHydration reactionAnthracite

The invention discloses a method for passivating and cooling anthracite and an integrated device thereof. The method includes the steps that 1, the anthracite subjected to pyrolysis at the temperature of 550-600 DEG C is cooled to reach 220-250 DEG C, and pretreated anthracite is obtained; 2, the pretreated anthracite reacts with inert gas to conduct oxygen activation on the anthracite so as to obtain middle-temperature passivated anthracite of 150-220 DEG C; 3, cooling water is adopted to simultaneously conduct cooling and hydration reaction on the middle-temperature passivated anthracite in the step 2 to obtain low-temperature passivated anthracite of 40-60 DEG C. The device comprises a feeding bin, a feeding conveyor, a passivating and cooling rotary device and a discharging conveyor which are connected in sequence. Passivation, destructive distillation and pyrolysis of anthracite can be effectively performed and high-grade heat energy can be recovered by adopting the method and the device.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

Composite liquid fuel and its preparing method

InactiveCN1425744ANo pollution in the processNo harmLiquid carbonaceous fuelsLiquid fuelStearic acid

The composite liquid fuel consists of glycol, ethanol, propanol, propyl ether, ethyl acetate, stearic acid, petroleum ether and inorganic combustion improver KNO3 or NaNO3. The fuel of the present invention is used mainly for self-supporting hot pot and in field cooking and may be also used in household. The fuel of the present invention is non-toxic, smell-less, pollution-less, safe, high in heat value and stable in combustion and produces no carbon deposit to blacken kitchen ware.

Owner:SOUTH CHINA UNIV OF TECH

Vulcanization method for hydrogenation catalyst and application thereof

ActiveCN102284299BGood vulcanization rateNo abnormal smellCatalyst regeneration/reactivationCatalyst activation/preparationPtru catalystHydrogenation reaction

The invention relates to a method for pre-vulcanizing a hydrogenation catalyst outside a hydrogenation reactor and activating the hydrogenation catalyst in the hydrogenation reactor. The method comprises the following steps of: (1) pre-vulcanizing the catalyst outside the hydrogenation reactor; (2) passivating the catalyst; and (3) reactivating the catalyst. A vulcanization method for the hydrogenation catalyst provided by the invention can guarantee high vulcanization rate of the catalyst; the passivated catalyst does not have abnormal odor and does not release hydrogen sulfide gas when being in contact with air or vapor; and the catalyst does not spontaneously combust and is not required to be protected by inert gas. Storage, transportation and filling methods and the like of the catalyst are simple and convenient. The catalyst can reach an activated state in a few hours during reactivation of an atmosphere containing a vulcanizing agent and hydrogen, is short in processing time, convenient to operate and has high catalytic performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Radiation-free carbon fiber electric heating cable and heating device

PendingCN107750067AWill not spontaneously combustImprove securityHeating element shapesHeating element materialsFiberElectricity

The invention relates to the technical field of heating, and relates to a radiation-free carbon fiber electric heating cable and a heating device. The radiation-free carbon fiber electric heating cable includes a power line and a heating line. The heating line includes a carbon fiber line layer, an insulating layer, a modified PVC layer and a radiation shielding layer. The insulating layer wraps the outer wall of the carbon fiber line layer in order to prevent the current in the carbon fiber line layer from overflowing to cause danger to users. The modified PVC layer wraps the insulating layer. The modified PVC layer is resistant to high temperature, and can ensure that the radiation-free carbon fiber electric heating cable will not self-ignite when there is an accident such as short circuit. In order to avoid the damage of radiation to the human body, the radiation shielding layer is arranged outside the carbon fiber line layer. The radiation shielding layer can shield radiation inside the radiation shielding layer and prevent radiation from dispersing to cause harm to users. The heating device includes a modulator and the radiation-free carbon fiber electric heating cable, and has the above advantages compared with the prior art.

Owner:河北悦昌电子科技有限公司

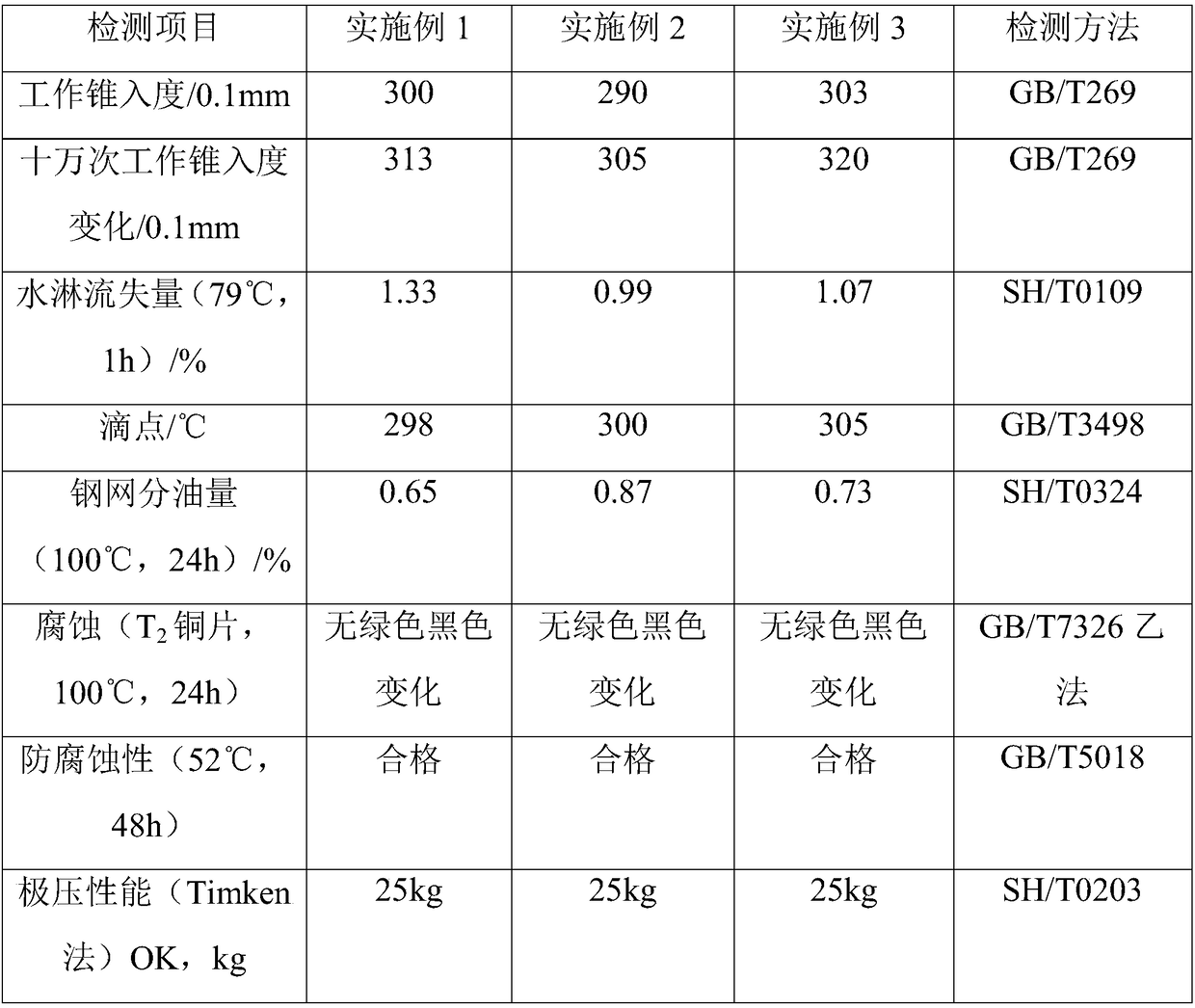

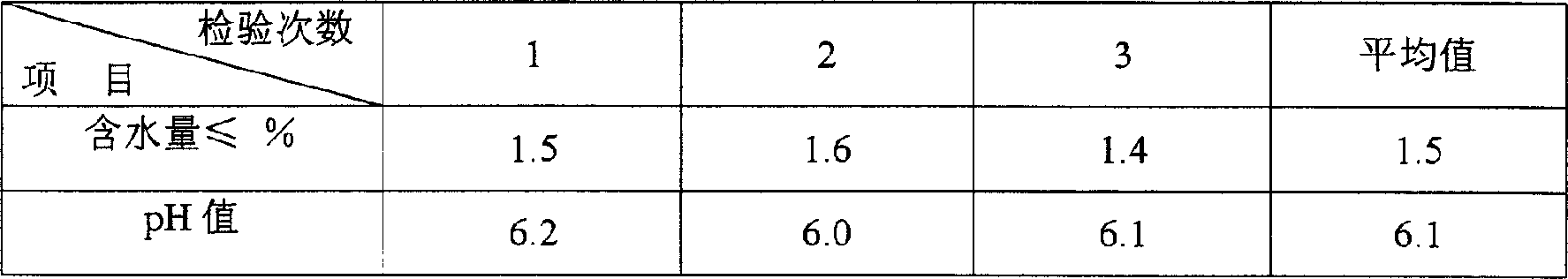

Preparation method of highly heatproof lubricating grease

InactiveCN109054945AReduce consumptionEasy to processLubricant compositionSpontaneous combustionOrganic acid

The invention discloses a preparation method of highly heatproof lubricating grease. The preparation method comprises the following steps that (1) organic acid is prepared and mixed; (2) a saponifiedsubstance is prepared, and rapidly cooled; (3) a mediate mixing agent is prepared; (4) preliminarily prepared lubricating grease is prepared; and (5) the highly heatproof lubricating grease is prepared. The invention provides the preparation method of the highly heatproof lubricating grease, the heatproof ability of the lubricating grease is greatly improved, the probability of spontaneous combustion of the lubricating grease in the using process is lowered, and the using safety of the lubricating grease is greatly enhanced.

Owner:四川新驱科为科技有限公司

Safe chlorothalonil smoke agent

InactiveCN1191012CImprove securityWill not spontaneously combustBiocideAnimal repellantsPotassium nitrateCombustion

The safe chlorothalonil smoke agent consists of chlorothalonil 25-45 weight portions, combustion promoter 25-35 weight portions and fuel 30-40 weight portions. The combustion promoter is one or several selected from ammonium nitrate, potassium nitrate, sodium nitrate, potassium perchlorate and potassium permanganate; and the fuel is one or several selected from corn cob, cow manure powder, straw and bagasse. The said agent is bagged, and thus safe without self combustion, low in cost and favorable to environment protection, and its package isolates moisture effectively.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI

Safe chlorothalonil smoke agent

The safe chlorothalonil smoke agent consists of chlorothalonil 25-45 weight portions, combustion promoter 25-35 weight portions and fuel 30-40 weight portions. The combustion promoter is one or several selected from ammonium nitrate, potassium nitrate, sodium nitrate, potassium perchlorate and potassium permanganate; and the fuel is one or several selected from corn cob, cow manure powder, straw and bagasse. The said agent is bagged, and thus safe without self combustion, low in cost and favorable to environment protection, and its package isolates moisture effectively.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI

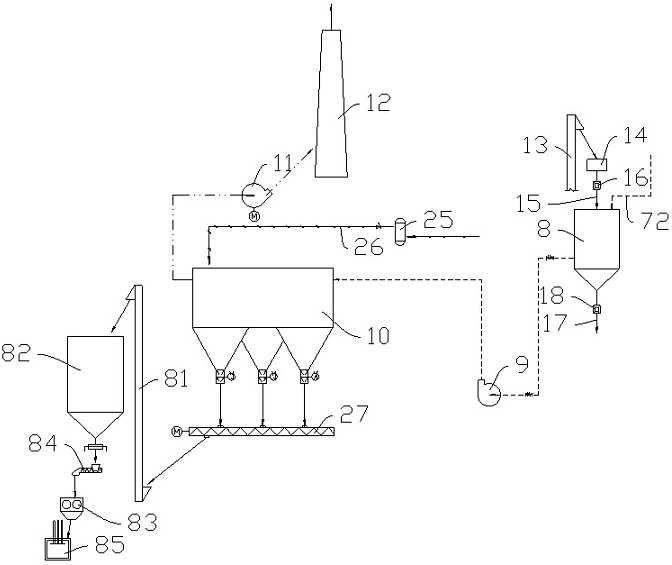

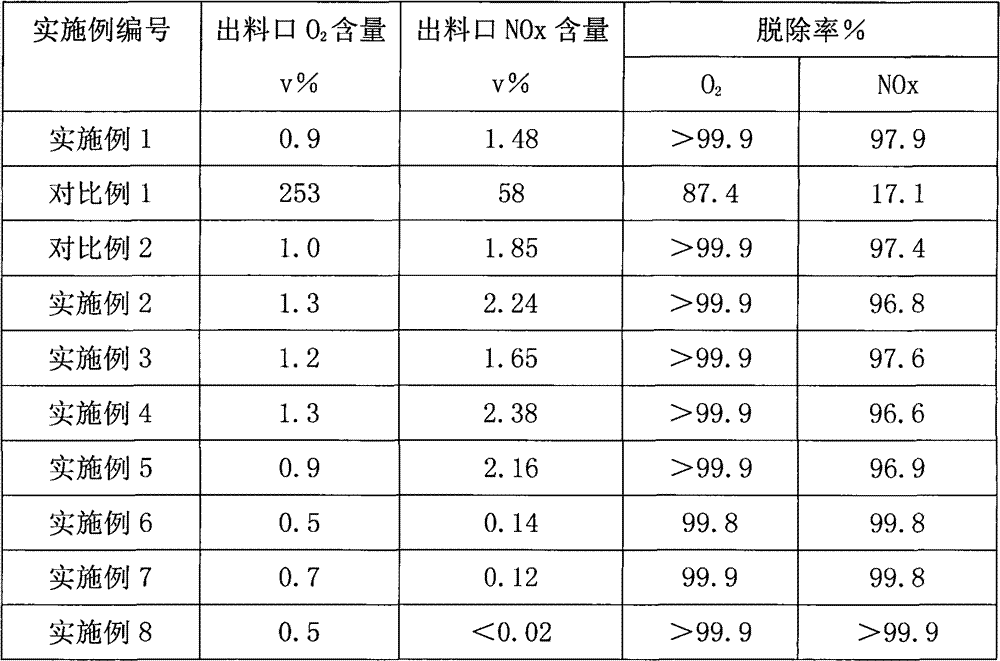

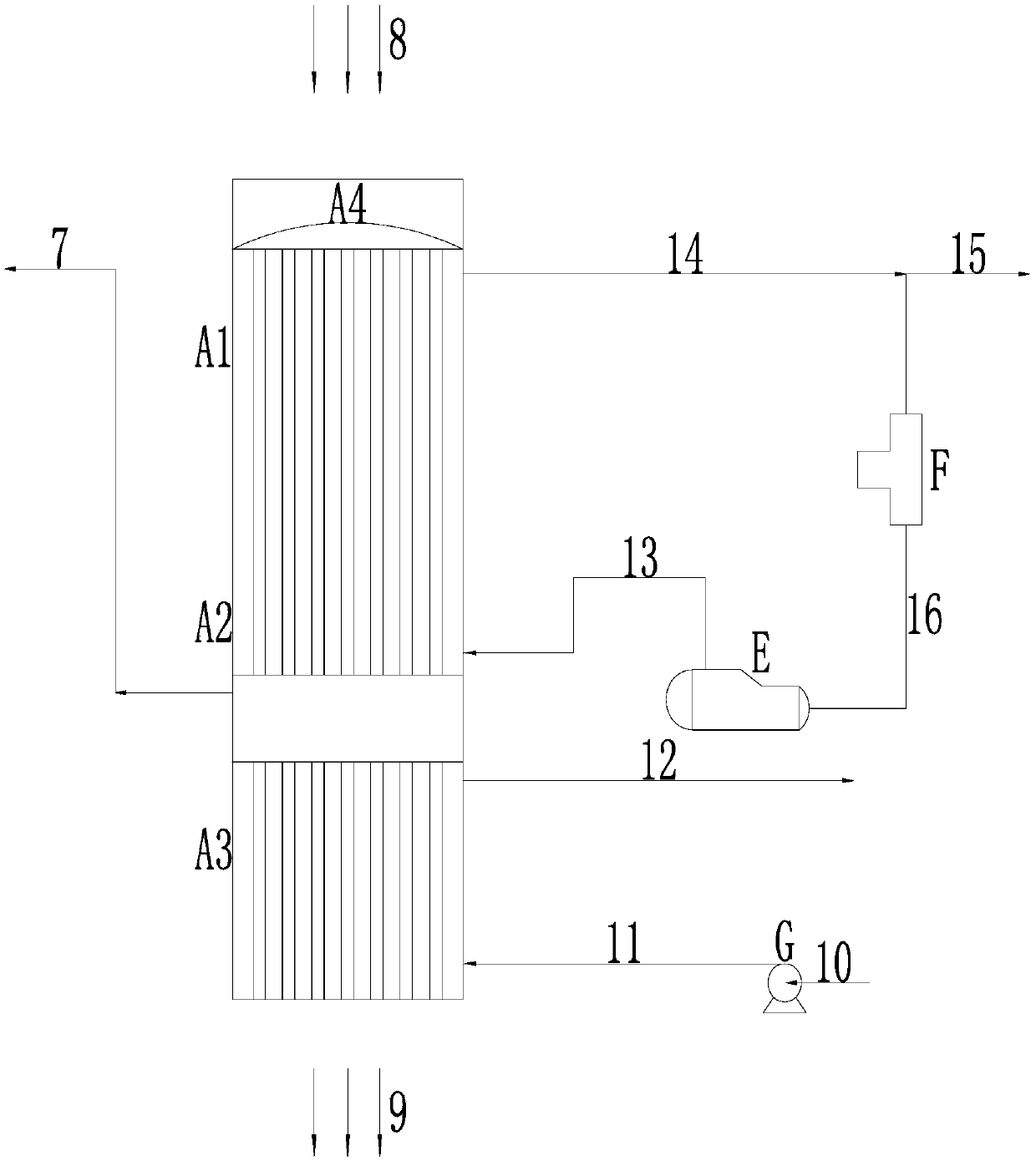

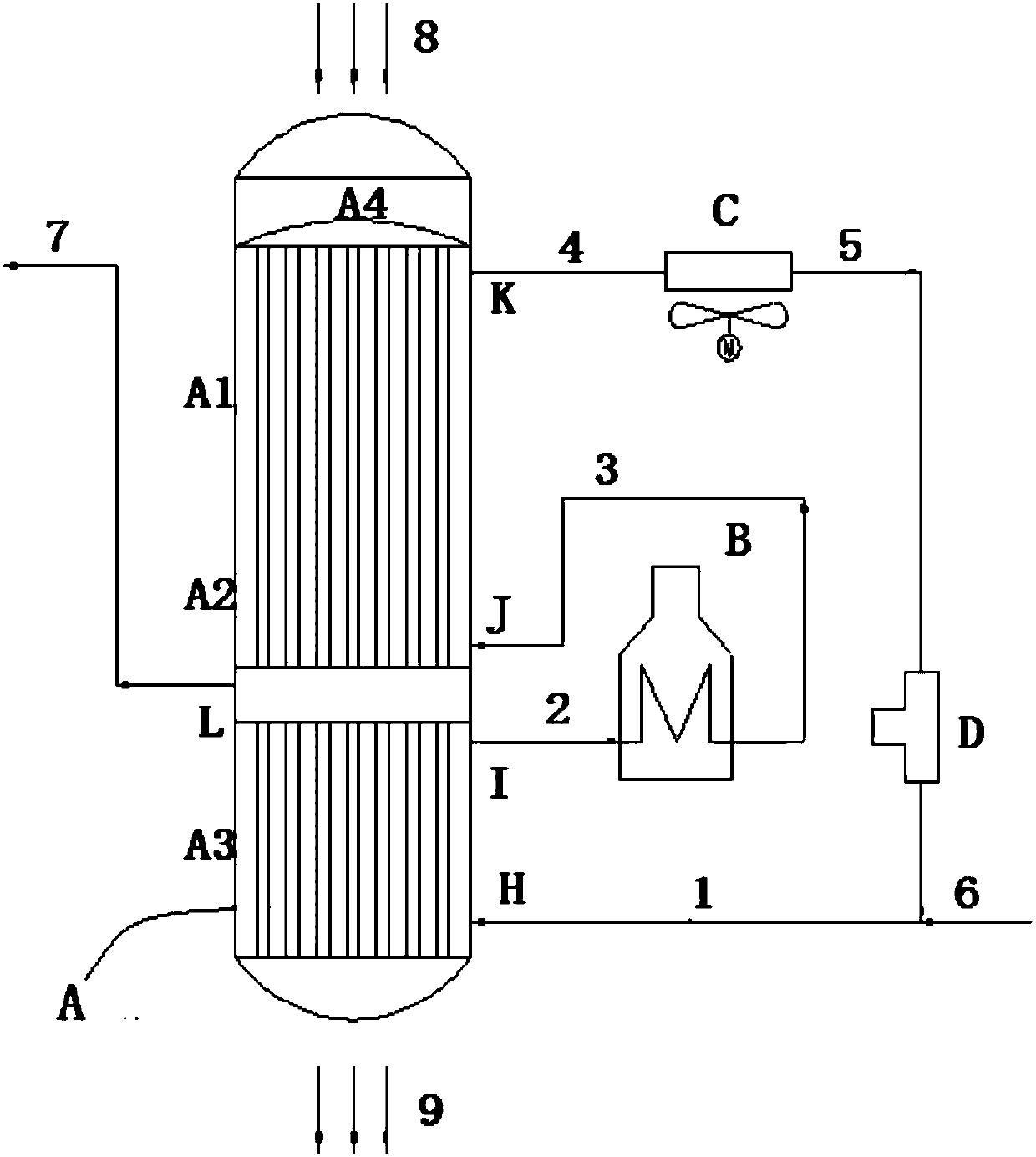

Active coke regeneration system and method

InactiveCN109675406AImprove securityImprove economyGas treatmentDispersed particle separationDesorptionNitrogen

The invention belongs to the field of active coke moving reactor dry flue gas desulfurization, and relates to an active coke regeneration system and method. The active coke regeneration system comprises a regenerator, a heating furnace, a cooler and a compressor, wherein a heating section, a desorption section and a cooling section are successively arranged on the regenerator from top to bottom; afirst nitrogen inlet is formed in the bottom of the cooling section, and a first nitrogen outlet is formed in the top of the cooling section; a second nitrogen inlet is formed in the bottom of the desorption section; and a second nitrogen outlet is formed in the top of the heating section; the heating furnace communicates with the first nitrogen outlet of the cooling section and the second nitrogen inlet of the desorption section; the cooler communicates with the second nitrogen outlet of the heating section; the compressor communicates with the cooler and the first nitrogen inlet of the cooling section; and nitrogen passes through the first nitrogen inlet, the cooling section, the first nitrogen outlet, the heating furnace, the second nitrogen inlet, the desorption section, the heating section, the second nitrogen outlet, the cooler, the compressor, and the first nitrogen inlet successively to form a closed nitrogen circulation system. According to the active coke regeneration systemand method, the technological process is simple, operation is safe and reliable, and safety and the economical efficiency of the active coke regeneration process are improved.

Owner:SINOPEC ENG +1

A kind of waterproof coal powder and preparation method thereof

ActiveCN105062603BReduce hydrophilicityExtend effective storage timeSolid fuelsCoal spontaneous combustionStearic acid

The invention discloses a waterproof coal powder and a preparation method thereof. The waterproof coal powder comprises the following components in parts by weight: 5-30 parts of calcium salt or Ca(OH)2, 1-10 parts of stearic acid or stearic acid Salt and 60-94 parts of coal powder; the preparation method first weighs the component formula of the said parts by weight, puts it into a drum reactor and raises the temperature to 110-140°C, and keeps heating for 20-60 minutes to obtain the waterproof coal powder . The method of the invention can change the coal powder from a hydrophilic substance to a hydrophobic substance, greatly reduce the hydrophilic property of the coal powder, and can prevent the volatilization of the volatile matter in the coal powder, thereby effectively avoiding the coal powder in storage. The problem of spontaneous combustion prolongs the storage time, increases the safety during storage and transportation, and has a good application prospect.

Owner:CHONGQING SIJI JINBIAO TECH CO LTD

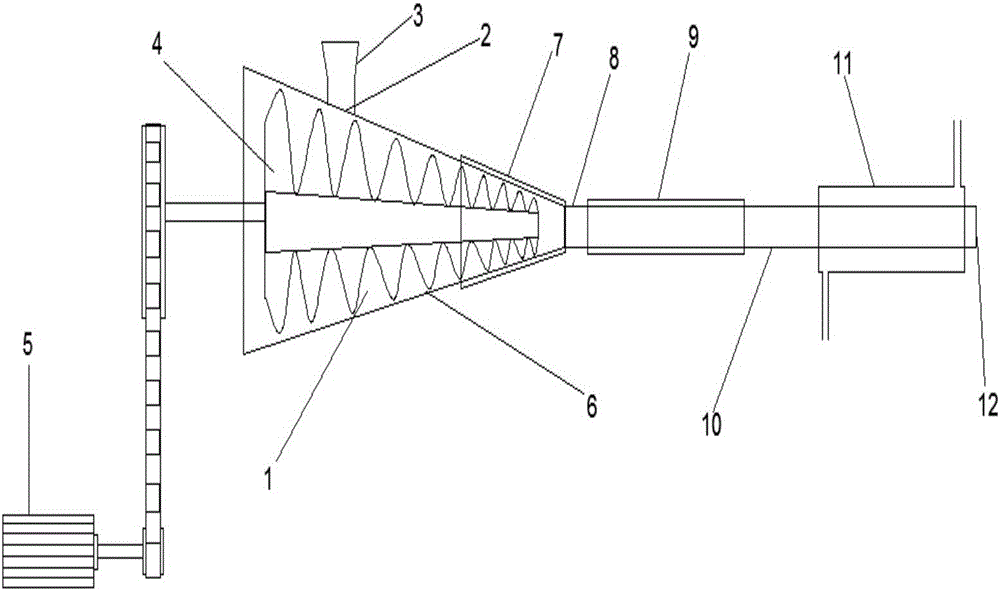

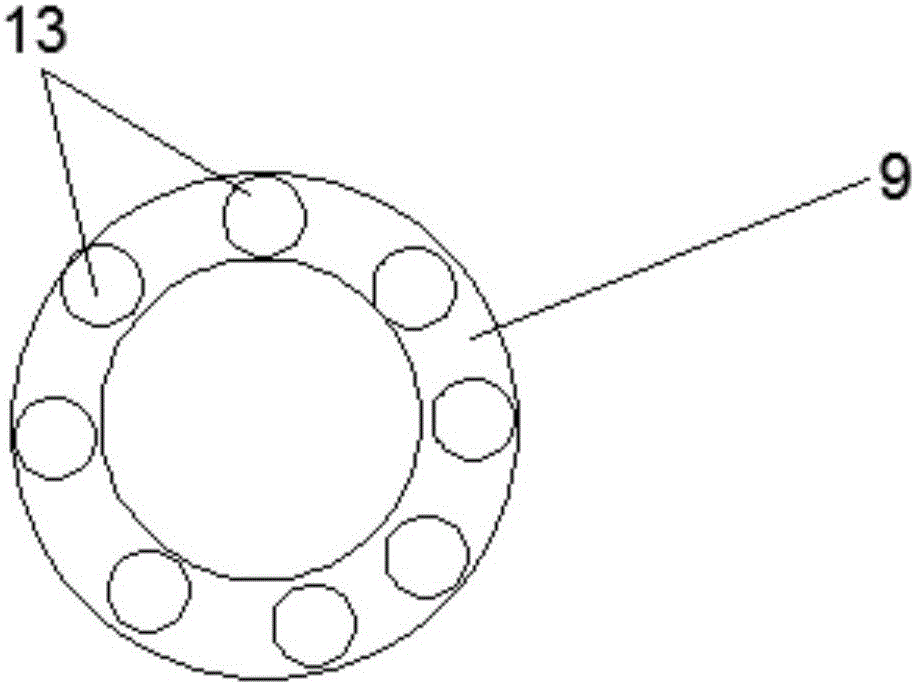

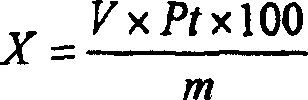

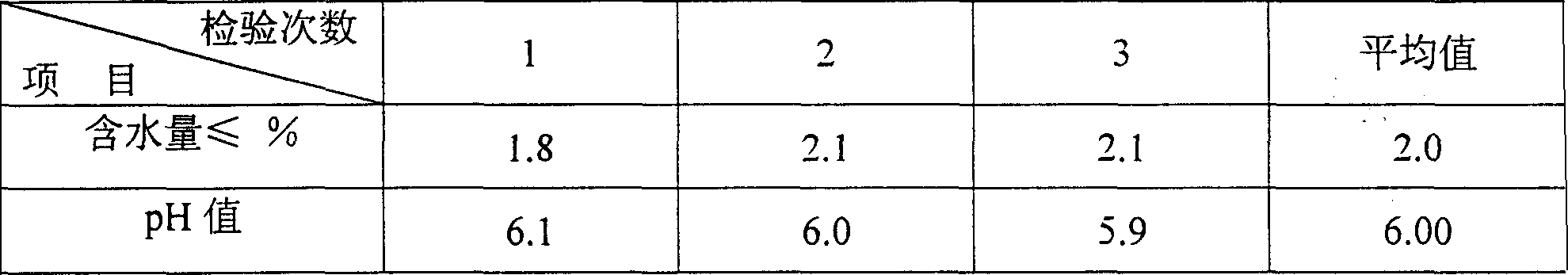

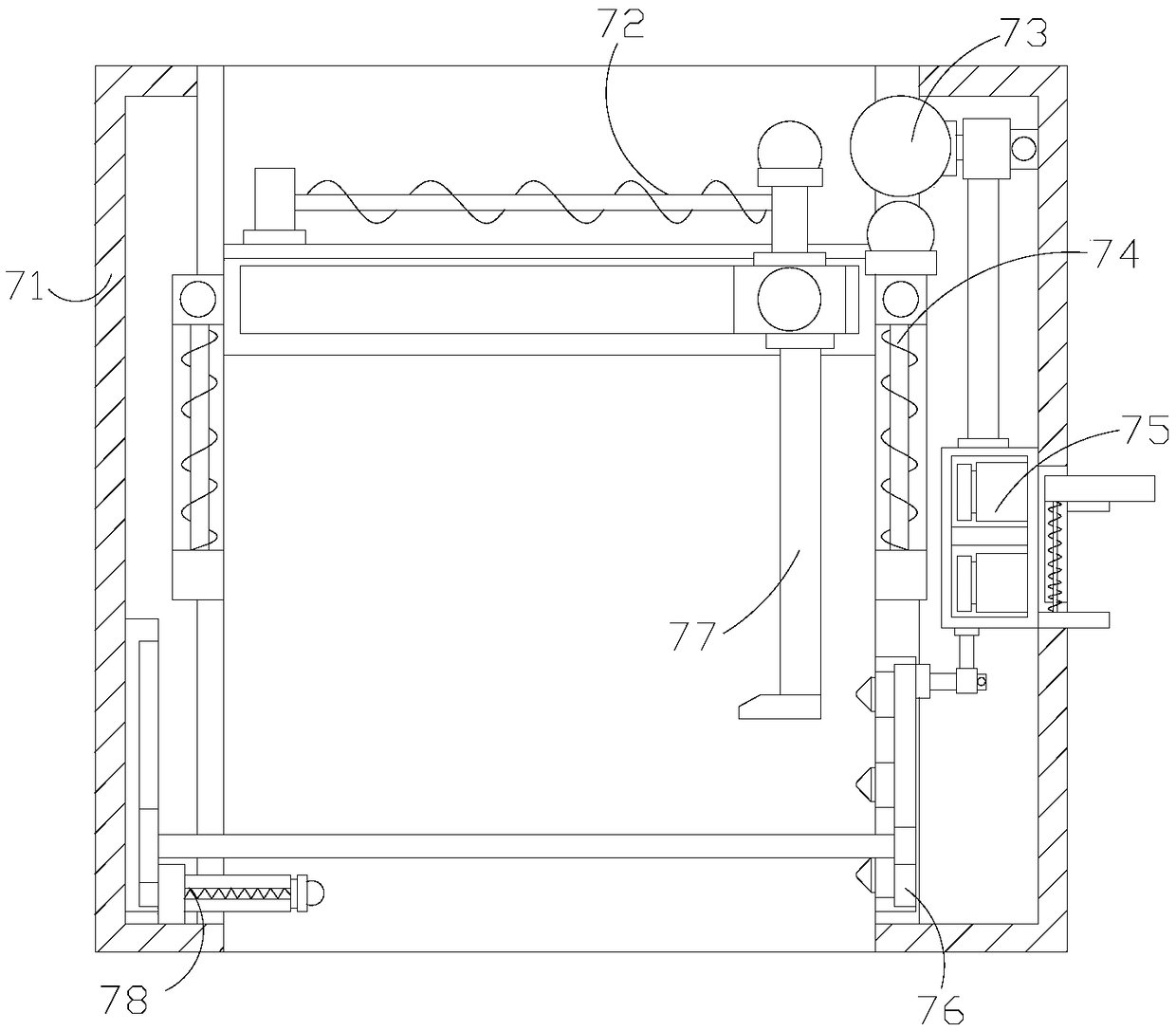

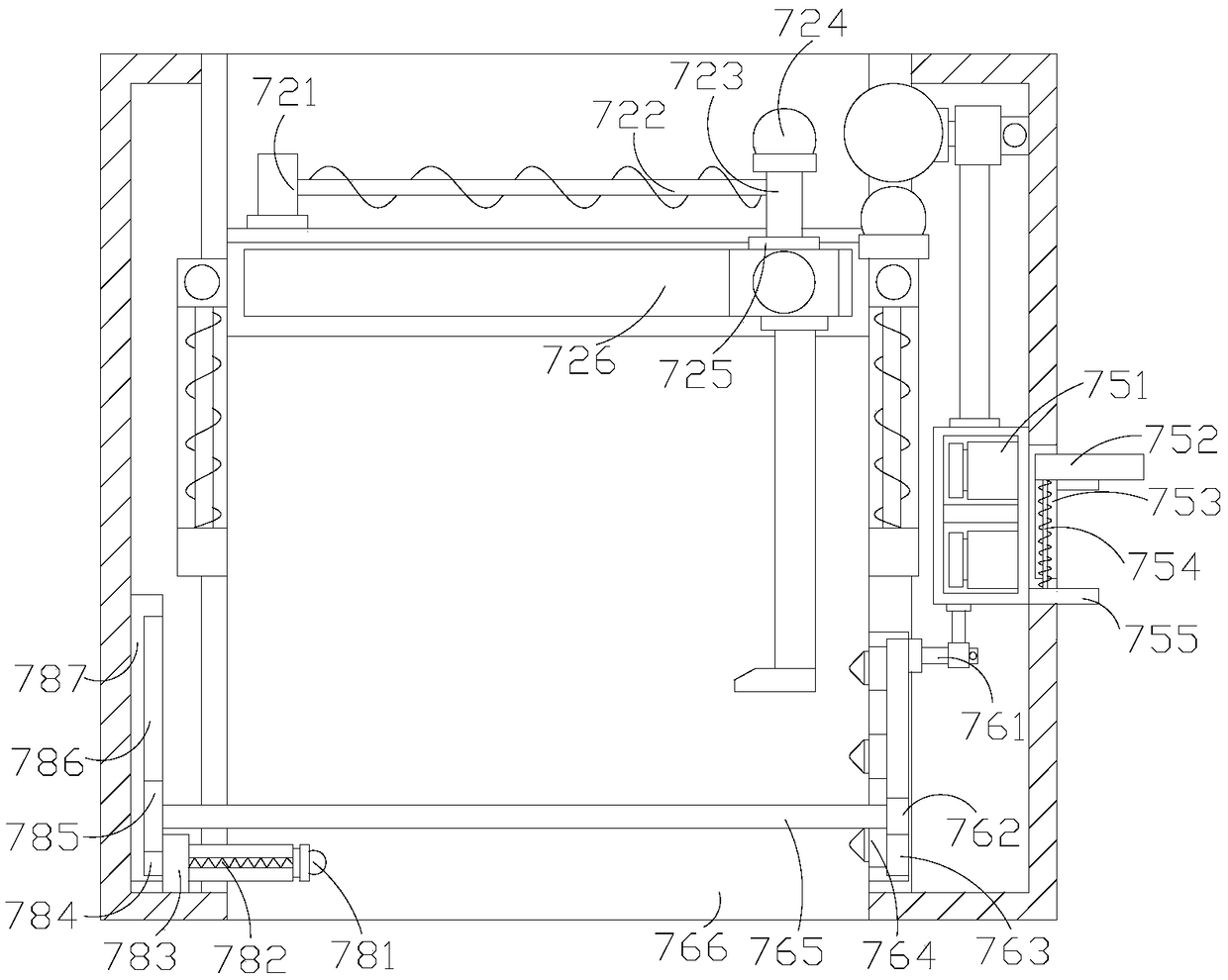

Carbonizing device

InactiveCN105907410AQuality improvementImprove work efficiencyElectrical coke oven heatingPreheating coke ovensSpontaneous combustionPropeller

The invention relates to a carbonizing device which comprises a rod forming machine and a motor. The rod forming machine is provided with a screw propeller, the screw propeller is provided with a belt, the other end of the belt is hinged to the motor, the rod forming machine is provided with a directional conical sleeve, the directional conical sleeve is sleeved by an electric heating sleeve, the rod forming machine is provided with a guiding tube, a carbonizing tube is arranged in the guiding tube, the carbonizing tube is provided with a discharging tube, the discharging tube is provided with a cooling box, a water inlet is formed in the cooling box, a water outlet is formed in the cooling box, and a discharging opening is formed in the discharging tube. The carbonizing device is simple to operate, high in work efficiency and free of emission in a producing process. In addition, manufactured charcoal is high in quality and is prevented from spontaneous combustion in a high temperature without being processed.

Owner:ANHUI RUISI ENVIRONMENT FRIENDLY ENERGY CO LTD

Safe procymidone smoke agent

InactiveCN1244274CImprove securityWill not spontaneously combustBiocideAnimal repellantsSpontaneous combustionPotassium nitrate

The safe procymidone smoke agent consists of procymidone, combustion assistant and fuel in the ratio of 12-20 to 22-25 to 35-40. The combustion assistant is one or several selected from ammonium nitrate, potassium nitrate, sodium nitrate, potassium perchlorate and potassium permanganate; and the fuel is one or several selected from corn cob, cow, dung powder, straw and bagasse. It is bagged and thus is safe without spontaneous combustion; and it has simple production process and equipment and less environmental pollution.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI

Moisture-proof safe smoke agent composition and its prepn

The smoke agent consists of main agent 12-45 weight portions, combustion promoter 22-35 weight portions and fuel 30-40 weight portions. The combustion promoter is one or several selected from ammonium nitrate, potassium nitrate, sodium nitrate, potassium perchlorate and potassium permanganate; and the fuel is one or several selected from corn cob, cow manure powder, straw and bagasse. The smoke agent is prepared through sieving, crushing, stoving, mixing and bagging. It is safety without self combustion, low in cost and favorable to environment protection, and its package isolates moisture effectively.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI

Utilization method and system for tail gas of calcium carbide furnace

The invention provides a utilization system for the tail gas of a calcium carbide furnace. By the system, without purification treatment, the tail gas of the calcium carbide furnace is directly conveyed into a burner and then burnt, investment to the purification treatment of the tail gas of the calcium carbide furnace is eliminated, and hidden danger in the purification treatment of the tail gas of the calcium carbide furnace, which contains high-concentration carbon oxide (CO), is eliminated. The utilization system for the tail gas of the calcium carbide furnace comprises a heat exchanger, a pressurizing conveying fan and a lime rotary kiln, wherein the heat exchanger cools the tail gas of the calcium carbide furnace; the lime rotary kiln is provided with the burner; and a calcium carbide furnace tail gas discharge pipe, the heat exchanger, the pressurizing conveying fan and the burner are sequentially connected in series. The invention also provides a utilization method for the tail gas of the calcium carbide furnace. The method comprises the following steps of: reducing the temperature of the tail gas of the calcium carbide furnace to 200 to 400 DEG C; pressurizing the tail gas of the calcium carbide furnace to be over 3,000 Pa by using the pressurizing conveying fan; conveying the tail gas of the calcium carbide furnace into the burner of the lime rotary kiln; and burning the tail gas of the calcium carbide furnace.

Owner:NANJING SUYE CALCIUM IND TECH

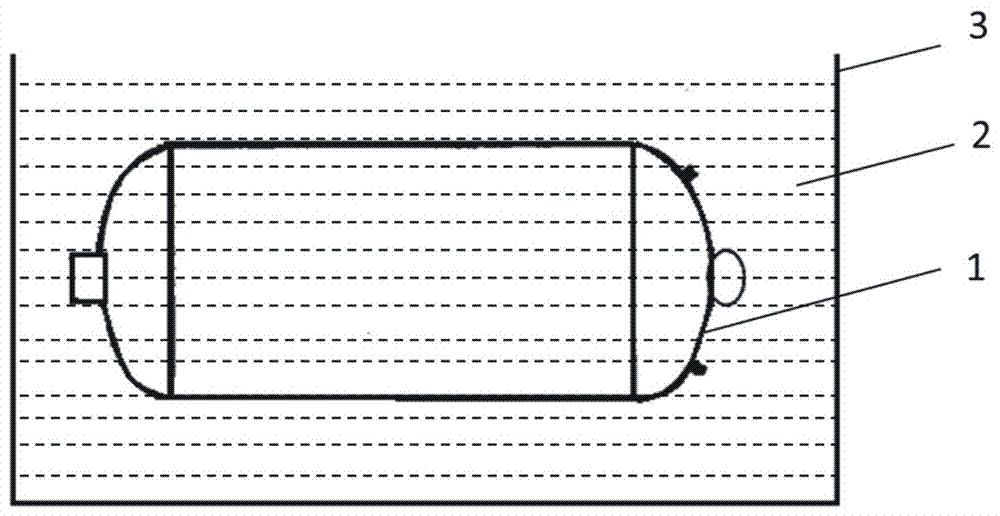

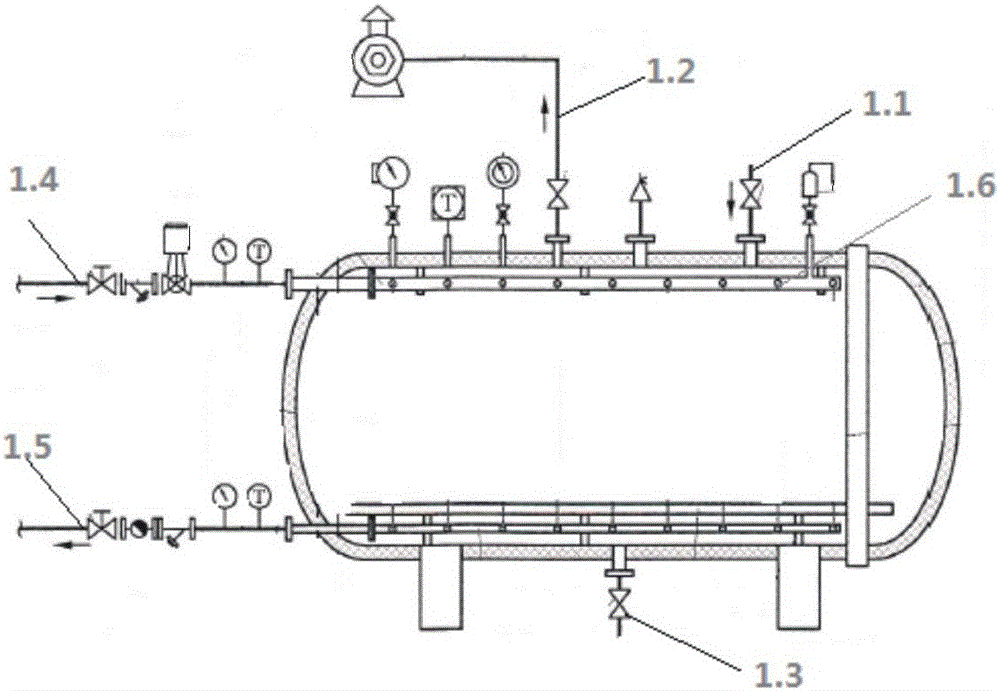

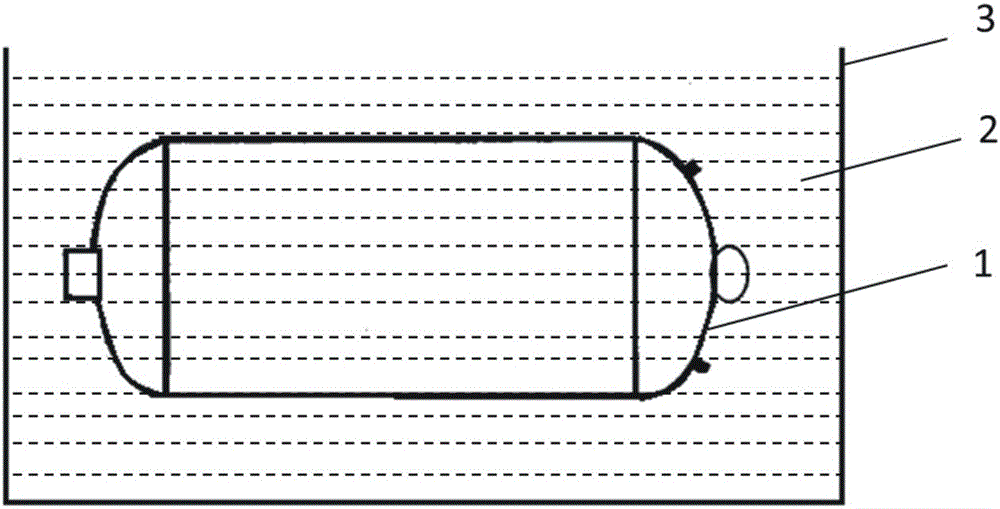

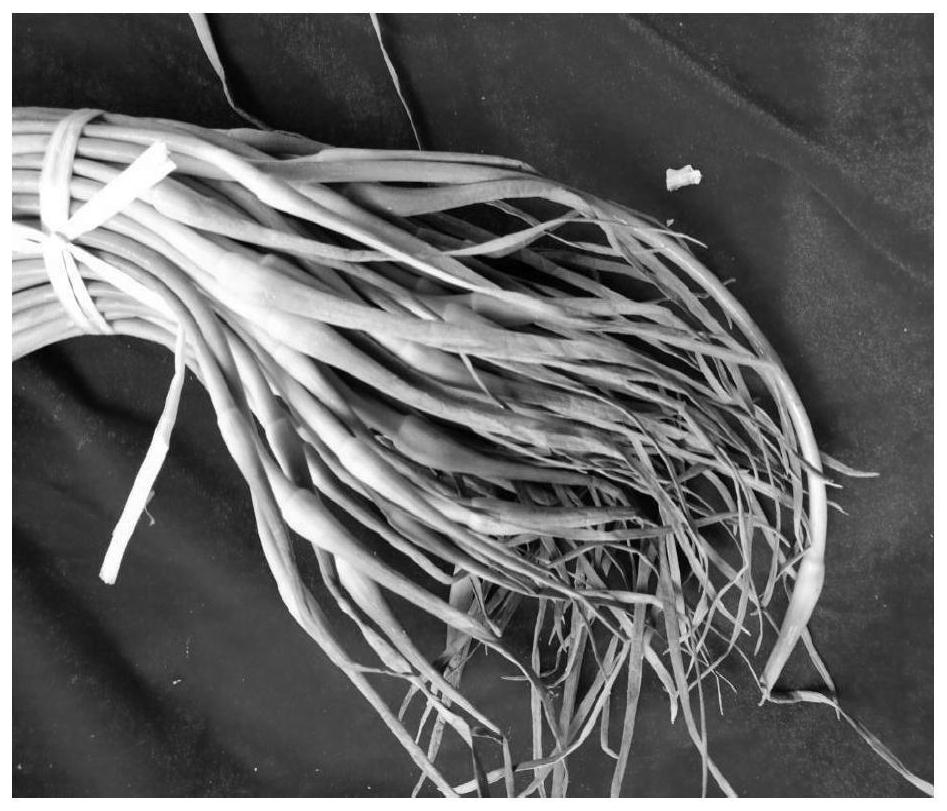

A kind of bamboo beam dry heat treatment method

ActiveCN105538455BImprove uniformityAcid Gas ReductionWood treatment detailsReed/straw treatmentSpontaneous combustionEngineering

The invention discloses a bamboo bundle dry heat treatment method. A pressure tank filled with a bamboo bundle is placed into hot oil, the impermeability of the heat treatment process is guaranteed, and spontaneous combustion cannot happen even when the heat treatment temperature reaches 220 DEG C. A hot oil pool is adopted, it can be guaranteed that in the heat treatment process, the temperature is constantly kept consistent, and the uniformity of heat treatment of the bamboo bundle is improved. The water content of the bamboo bundle not treated is controlled below 10%, acid gas generated through hydrolysis of the bamboo in the heat treatment process can be effectively reduced, corrosivity to equipment is reduced, and the service life of the equipment can be prolonged.

Owner:NANJING FORESTRY UNIV

A method for passivating and cooling anthracite and its integrated device

ActiveCN105885903BHigh thermal efficiencyLong term storageCoke quenchingSolid fuelsHydration reactionAnthracite

The invention discloses a method for passivating and cooling anthracite and an integrated device thereof. The method includes the steps that 1, the anthracite subjected to pyrolysis at the temperature of 550-600 DEG C is cooled to reach 220-250 DEG C, and pretreated anthracite is obtained; 2, the pretreated anthracite reacts with inert gas to conduct oxygen activation on the anthracite so as to obtain middle-temperature passivated anthracite of 150-220 DEG C; 3, cooling water is adopted to simultaneously conduct cooling and hydration reaction on the middle-temperature passivated anthracite in the step 2 to obtain low-temperature passivated anthracite of 40-60 DEG C. The device comprises a feeding bin, a feeding conveyor, a passivating and cooling rotary device and a discharging conveyor which are connected in sequence. Passivation, destructive distillation and pyrolysis of anthracite can be effectively performed and high-grade heat energy can be recovered by adopting the method and the device.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

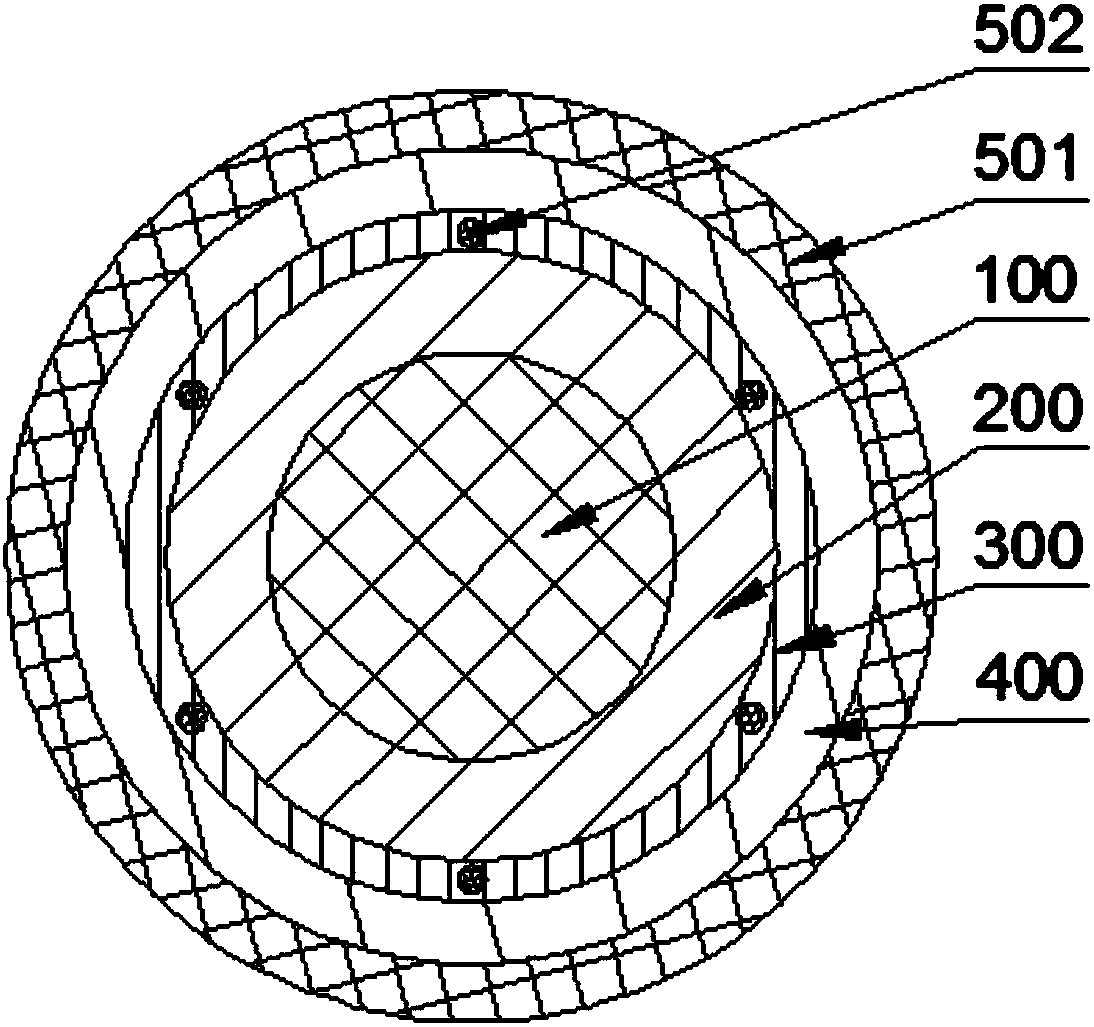

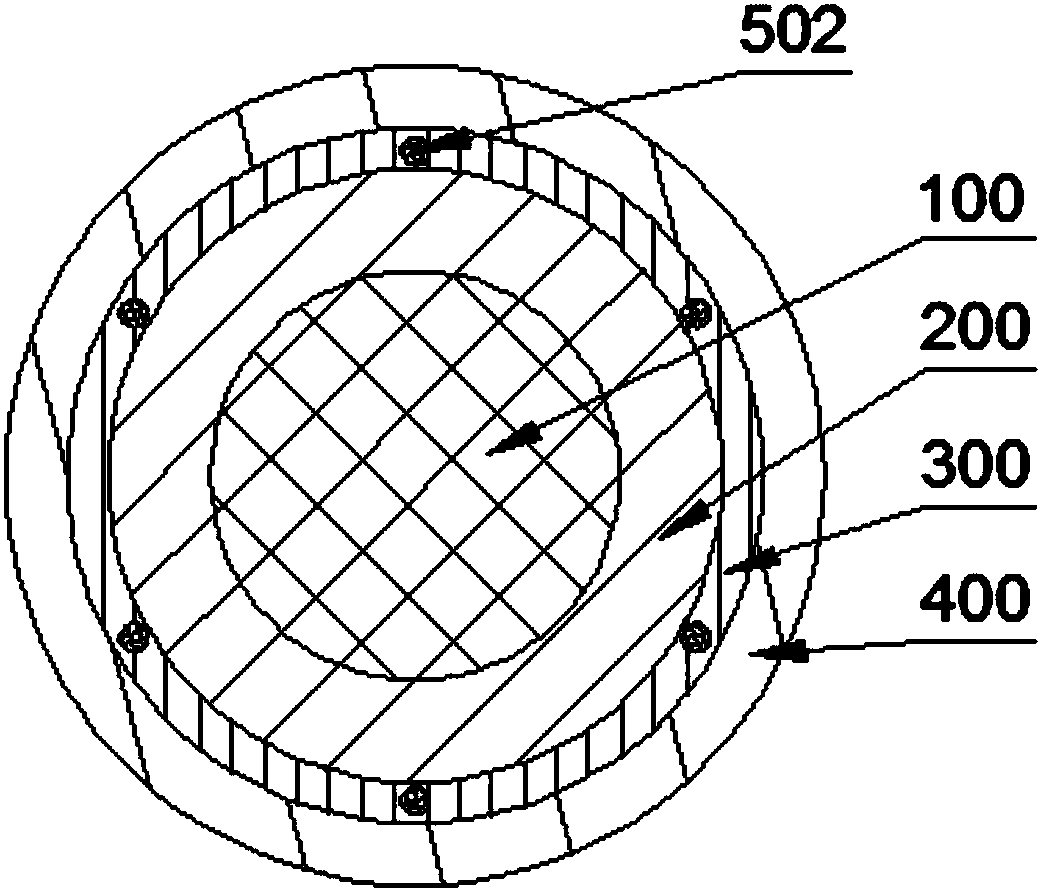

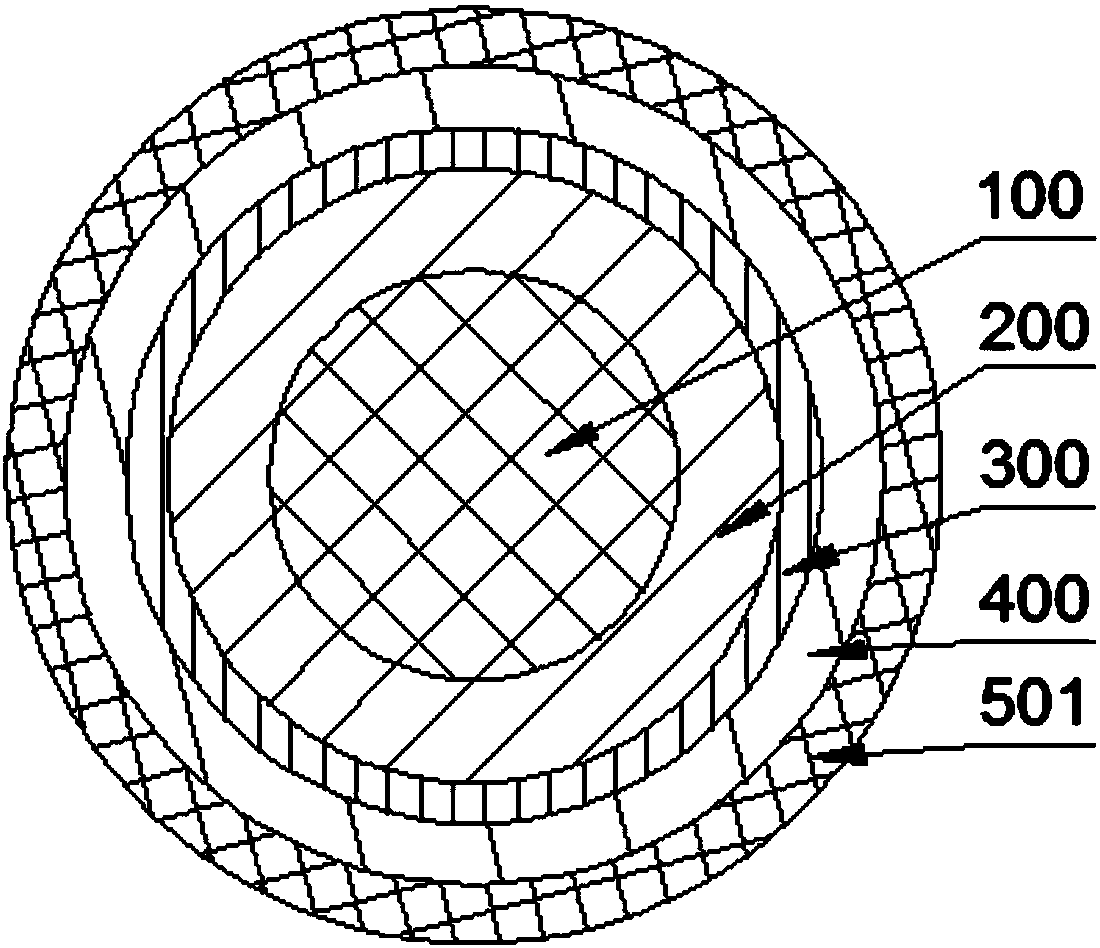

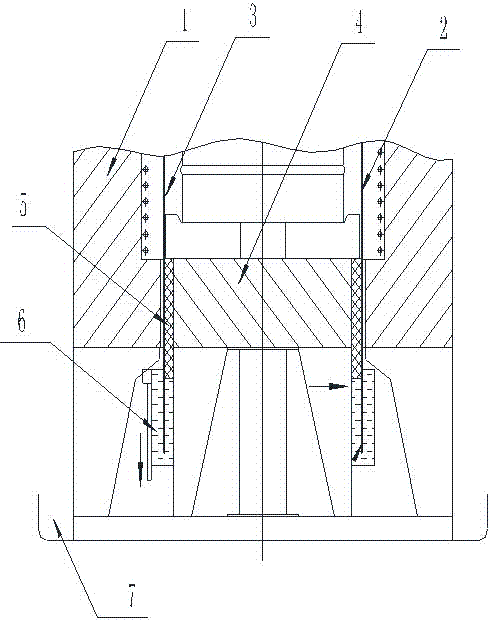

Flowing water-cooled sealing structure of bottomless muffle tank for well type carburizing furnace

ActiveCN105039898BImprove reliabilityBarrier lossSolid state diffusion coatingSpontaneous combustionWater flow

The invention relates to a flow water-cooling sealing structure of a well type carburizing furnace bottomless muffle tank. The flow water-cooling sealing structure of the well type carburizing furnace bottomless muffle tank comprises a carburizing furnace body. The inverted bottomless muffle tank is arranged in the carburizing furnace body. An annular structure sealing layer is arranged between the muffle tank and a furnace platform, namely an inner cavity of the part, penetrating through the furnace platform, of the muffle tank. The gap between the muffle tank and the furnace platform is sealed by the structure sealing layer. A water cooling sealing groove is formed below the structure sealing layer, and cooling water is input into the water cooling sealing groove to cool the tail end of the muffle tank or cool the tail end of the muffle tank and the lower end of the structure sealing layer. The water-cooling sealing structure has the high safety, will not cause spontaneous combustion, avoids or even completely eradicates the spontaneous combustion phenomenon caused by traditional oil liquid sealing, and greatly improves safety. The gap is sealed by the structure sealing layer, the excellent sealing effect is achieved, the phenomenon that losing of the temperature and furnace pressure of the muffle tank or water flowing are caused through the gap is effectively prevented, the reliability is greatly improved, and inferior-quality products or waste products are prevented from being formed in the furnace body.

Owner:CHONGQING AODIAN IND FURNACE

Catalyst for hydrogenation liquefaction of biomass, preparation method and method for hydrogenation of biomass

ActiveCN110180558BImprove hydrogenation performanceLow costPhysical/chemical process catalystsLiquid hydrocarbon mixture productionPtru catalystEnvironmental engineering

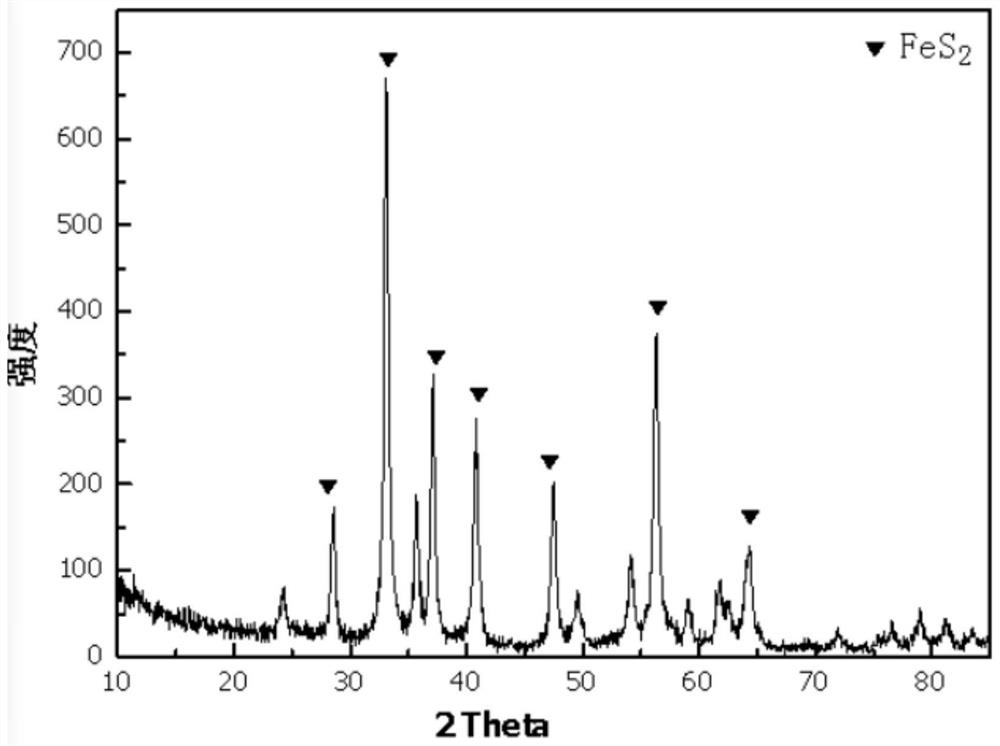

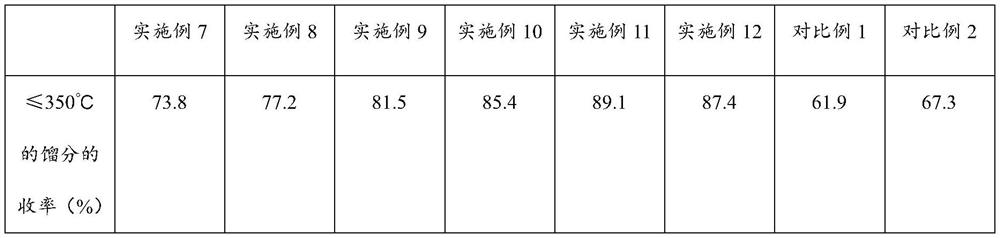

The biomass hydrogenation liquefaction catalyst described in the present invention is an iron-based desulfurizer waste agent, and the active component of the iron-based desulfurizer waste agent is FeS 2 , the FeS 2 The content is 10wt%-70wt% based on the content of iron element. FeS 2 Biomass hydrogenation as an active component, not only has a good hydrogenation effect on biomass, the fraction of ≤350 °C reaches 89%, and FeS 2 The property is stable and will not spontaneously ignite during the grinding process, which improves the safety performance of the catalyst; on the other hand, the hydrogenation catalyst uses waste desulfurization agent as raw material, turning waste into treasure, and avoiding environmental pollution caused by waste desulfurization agent , greatly reducing the cost of biomass hydrogenation.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for preparing silicon carbide crystal by taking single gas as source gas

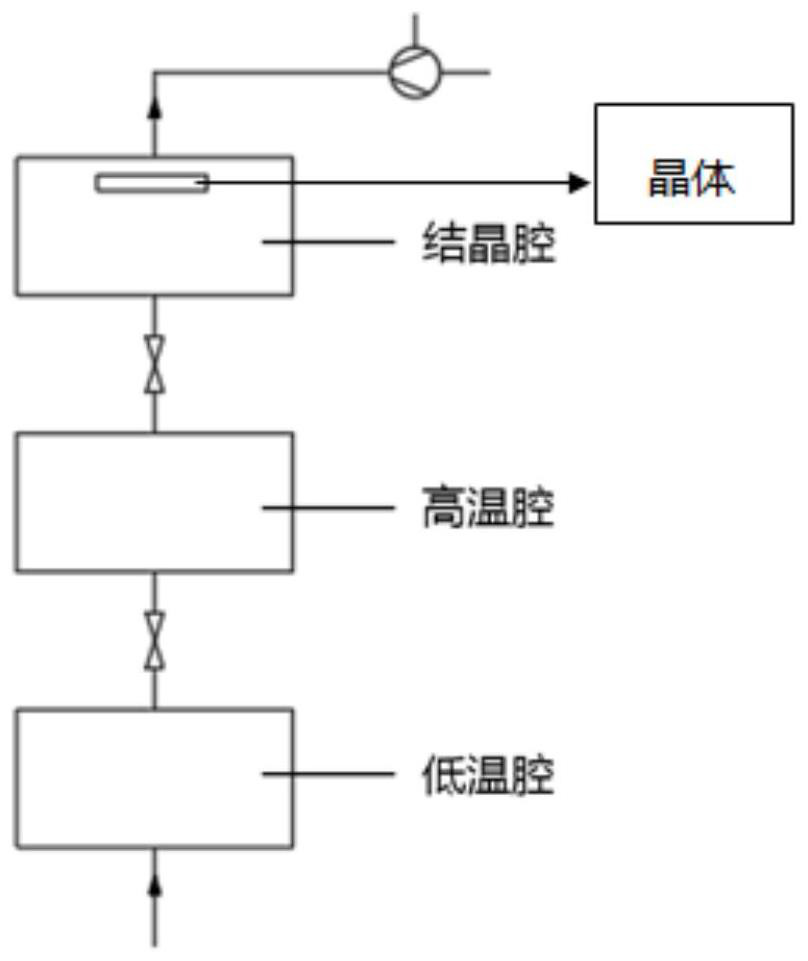

ActiveCN114045558AWill not spontaneously combustReduce use costPolycrystalline material growthFinal product manufactureSilanesPhysical chemistry

The invention discloses a method for preparing silicon carbide crystals by taking single gas as source gas. Equipment adopted by the method comprises a low-temperature cavity, a high-temperature cavity and a crystallization cavity which are sequentially connected through gas pipelines. The method comprises the following steps: (1) preparing silane derivative gas or chlorosilane derivative gas as source gas, introducing the source gas into a low-temperature cavity, and cracking the source gas; (2) introducing a current-carrying gas through an inlet gas pipeline, bringing the cracked product in the low-temperature cavity into a high-temperature cavity, and reacting CxHy or CmHnClo with Si in the high-temperature cavity to obtain a SialphaCbeta; and (3) entraining the SialphaCbeta gas in the high-temperature cavity into the crystallization cavity by the current-carrying gas, depositing and crystallizing SialphaCbeta gas molecules on the surface of the silicon carbide seed crystal, and finally generating the silicon carbide crystal. According to the invention, the silicon carbide crystal is grown only by using single gas, is more stable than silane, and does not spontaneously ignite in the air, so that the use and maintenance cost and risk are greatly reduced.

Owner:江苏超芯星半导体有限公司

Plastic particle drying device

The invention discloses a plastic particle drying device. The plastic particle drying device structurally comprises a discharging turnover cover, a discharging channel, protective bases, supporting rods, an anti-collision layer, a drying operation box, a material conveying connection channel, a material conveying turnover cover, a turnover cover shaft and a rubber strip. The material conveying connection channel comprises a protective shell, a magnetic field auxiliary sliding set, a total pushing magnetic field end, a movable magnetic field auxiliary device, a to-be-triggered total electricitybox, a cooling device, a movable overturning set and temperature sensing and transmitting equipment. The temperature sensing and transmitting equipment is installed at the position, close to the bottom end, in the protective shell. The to-be-triggered total electricity box penetrates through the side of the protective shell. Compared with the prior art, the plastic particle drying device has thebeneficial effects that in the plastic particle drying process, the equipment in the plastic particle drying device is started, the plastic particle drying device is intermittently overturned, plasticparticles of the plastic particle drying device cannot be heated excessively or heated unevenly, when the temperature is too high in the drying process, the too high temperature can be sensed, the inside cooling device is triggered to cool the interior of the plastic particle drying process in time, and the plastic particles cannot spontaneously burn by the too high temperature.

Owner:任新根

A method of heat treatment of wood under high pressure and humidity

ActiveCN105563581BImprove uniformityGood colorPressure impregnationWood impregnation detailsPulp and paper industryHigh pressure

Disclosed is a hot and humid high-pressure wood heat treatment method. Wood is treated through a pressure tank, and the pressure tank is put in hot oil, so that the airtight effect of a heat treatment process is guaranteed, and spontaneous ignition cannot occur even though the heat treatment temperature reaches 220 DEG C; a hot oil pool is adopted so that the effect that the temperature is kept consistent all the time in the heat treatment process can be guaranteed, and accordingly the uniformity of wood heat treatment is improved; the moisture content of the wood before treatment is adjusted to saturated water content and always kept in the state of the saturated water content and the wood is always kept in the environment of saturated steam before drying treatment in the step (5); under the action of water molecules, the heat treatment time can be effectively shortened, and the energy consumption of heat treatment is reduced; nutrient substances in the wood are more thoroughly degraded; and the color and luster of the treated wood are more uniform, the wood can be prevented from being cracked in the heat treatment process, and the quality of the heat-treated wood is effectively improved.

Owner:NANJING FORESTRY UNIV

Fuel efficiency improvement method

InactiveCN108048144AImprove combustion efficiencyWill not spontaneously combustLiquid carbonaceous fuelsCombustion chamberAntioxidant

The invention discloses a fuel efficiency improvement method. The method includes the steps of: (1) preparation of a fuel additive: the fuel additive is prepared from the following raw materials by weight: 90-100 parts of lubricating oil, 0.5-2 parts of an antioxidant and 0.5-2 parts of a lanthanide rare earth metal, the lubricating oil is internal combustion engine lubricating oil with mineral oil as the base oil, preferably gasoline engine SF grade engine oil and diesel engine CD grade engine oil; the antioxidant is BHT, diphenylamine antioxidant or 3, 7-diisooctyl phenothiazine; the lanthanide rare earth metal is lanthanum, praseodymium or erbium; and (2) atomization of the fuel additive: subjecting the fuel additive to jet atomization or evaporation atomization, and sending atomizationsteam and air into a combustion chamber together for mixed combustion with fuel. The method achieves a fuel saving rate of at least 20%, at the same time discharges NOx, CO and hydrocarbon substancesin the tail gas, the tail gas emission is far superior to the state V standard, the discharge of pollutants is greatly reduced, and the carbon emissions are significantly reduced.

Owner:周伟明 +2

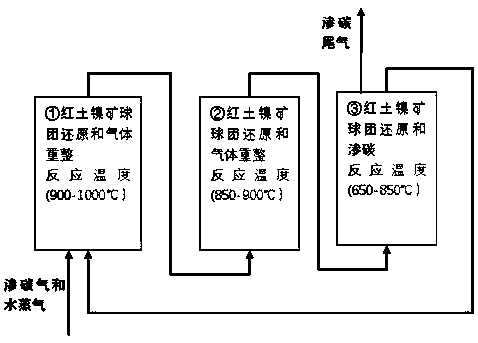

Method for preparing electric furnace smelting nickel-iron alloy raw material by using laterite nickel ore

ActiveCN110735012ALow firing temperatureReduce energy consumptionGas emission reductionSpontaneous combustionCarburizing

The invention discloses a method for preparing an electric furnace smelting nickel-iron alloy raw material by using laterite nickel ore. The method comprises the following steps of (1) uniformly mixing the laterite-nickel ore and an alkaline flux to prepare a pellet; (2) roasting the pellet in an oxidizing atmosphere; and (3) placing the roasted pellet in a reactor, and introducing mixed gas of carburizing gas and water vapor for reaction. Compared with that of an existing method for preparing an electric furnace smelting nickel-iron alloy raw material through a coal-based rotating kiln and gas-based vertical furnace method, the roasting temperature of the method is lower, the relative energy consumption is low, prepared electric furnace raw materials are relatively stable, and oxidation and spontaneous combustion are not prone to occurring.

Owner:SUZHOU INST OF INDAL TECH

A fresh-keeping smoke agent for garlic sprouts

ActiveCN108477293BReasonable formulaEasy to igniteFruit and vegetables preservationFood ingredient for microbe protectionBiotechnologyPharmaceutical drug

The invention discloses a garlic fresh-keeping smoke agent, which is characterized in that the garlic fresh-keeping smoke agent comprises the following raw materials in parts by weight: 5%-20% of fresh-keeping active medicine, 5%-10% of smoke agent, and 10% of cooling agent ‑20%, weighting agent 5%‑10%, combustion agent 15%‑25%, combustion aid 2%‑5% and inert carrier. The invention discloses a garlic fresh-keeping smoke agent, which forms a highly dispersed system of fresh-keeping active drugs, improves the conversion rate of active ingredients in the fresh-keeping smoke agent into smoke, and increases the diffusion range of the drug smoke, thereby further achieving prevention and treatment of garlic sprout ash. In addition, the invention has a high smoke rate and no open flame, which improves the safety performance and environmental protection performance of the garlic fresh-keeping smoke agent.

Owner:山东省农药检定所 +2

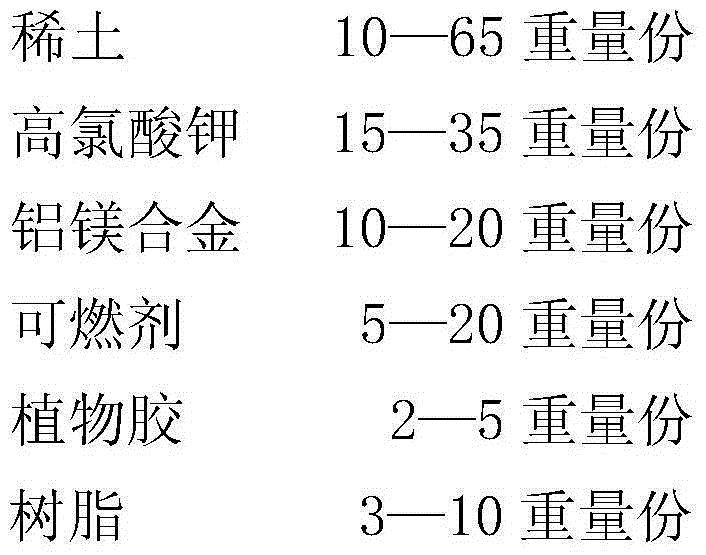

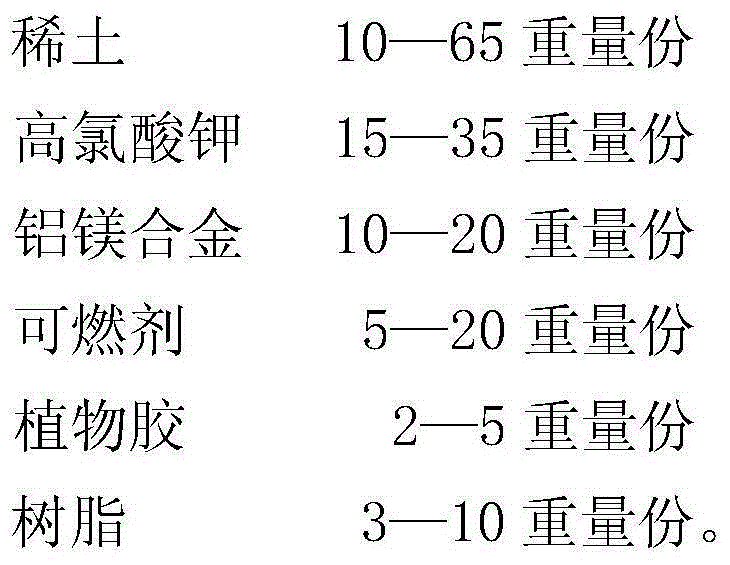

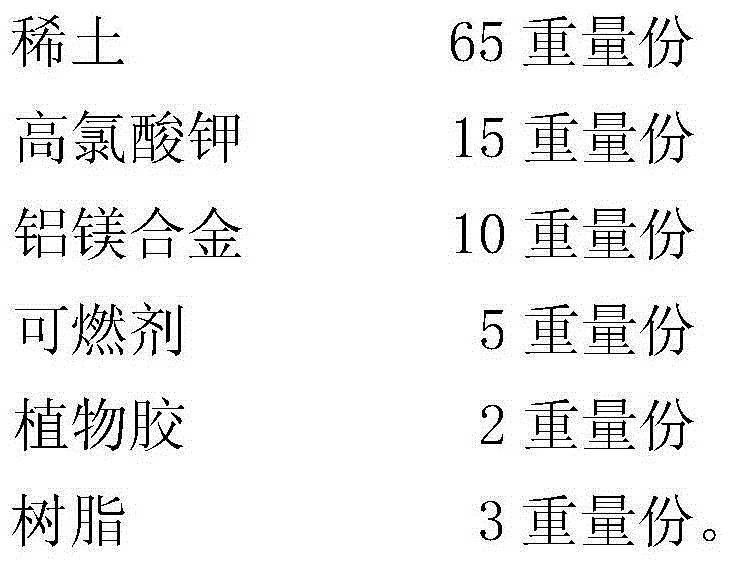

Environmental Fireworks Launcher

The invention discloses an environment-friendly firework propellant which is characterized by being composed of the following components in parts by weight: 10-65 parts of rare earth, 15-35 parts of potassium perchlorate, 10-20 parts of aluminum magnesium alloy, 5-20 parts of combustible agent, 2-5 parts of plant gum and 3-10 parts of resin, wherein the combustible agent is selected from any one or combined by any two from hemp xyloid stem carbon powder and Chinese fir carbon powder at any proportion, and the plant gum is a rice flour adhesive. The environment-friendly firework propellant is free of chlorate, small in horizontal launching force, low in moisture absorption property, low in impact and friction sensitivity, small in dosage of charges for preparing fireworks, slight in smoke, long in shelf life and displaying time, free of residues after displaying, good in physical and chemical stability, simple in processing technology and suitable for various firework propellants.

Owner:喻自达

Composite liquid fuel and its preparing method

InactiveCN1168803CNo pollution in the processNo harmLiquid carbonaceous fuelsLiquid fuelStearic acid

The composite liquid fuel consists of glycol, ethanol, propanol, propyl ether, ethyl acetate, stearic acid, petroleum ether and inorganic combustion improver KNO3 or NaNO3. The fuel of the present invention is used mainly for self-supporting hot pot and in field cooking and may be also used in household. The fuel of the present invention is non-toxic, smell-less, pollution-less, safe, high in heat value and stable in combustion and produces no carbon deposit to blacken kitchen ware.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com