Preparation method of highly heatproof lubricating grease

A lubricating grease, high heat-resistant technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of fire, easy to catch fire, etc., achieve long service life, low cost, reduce consumption and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

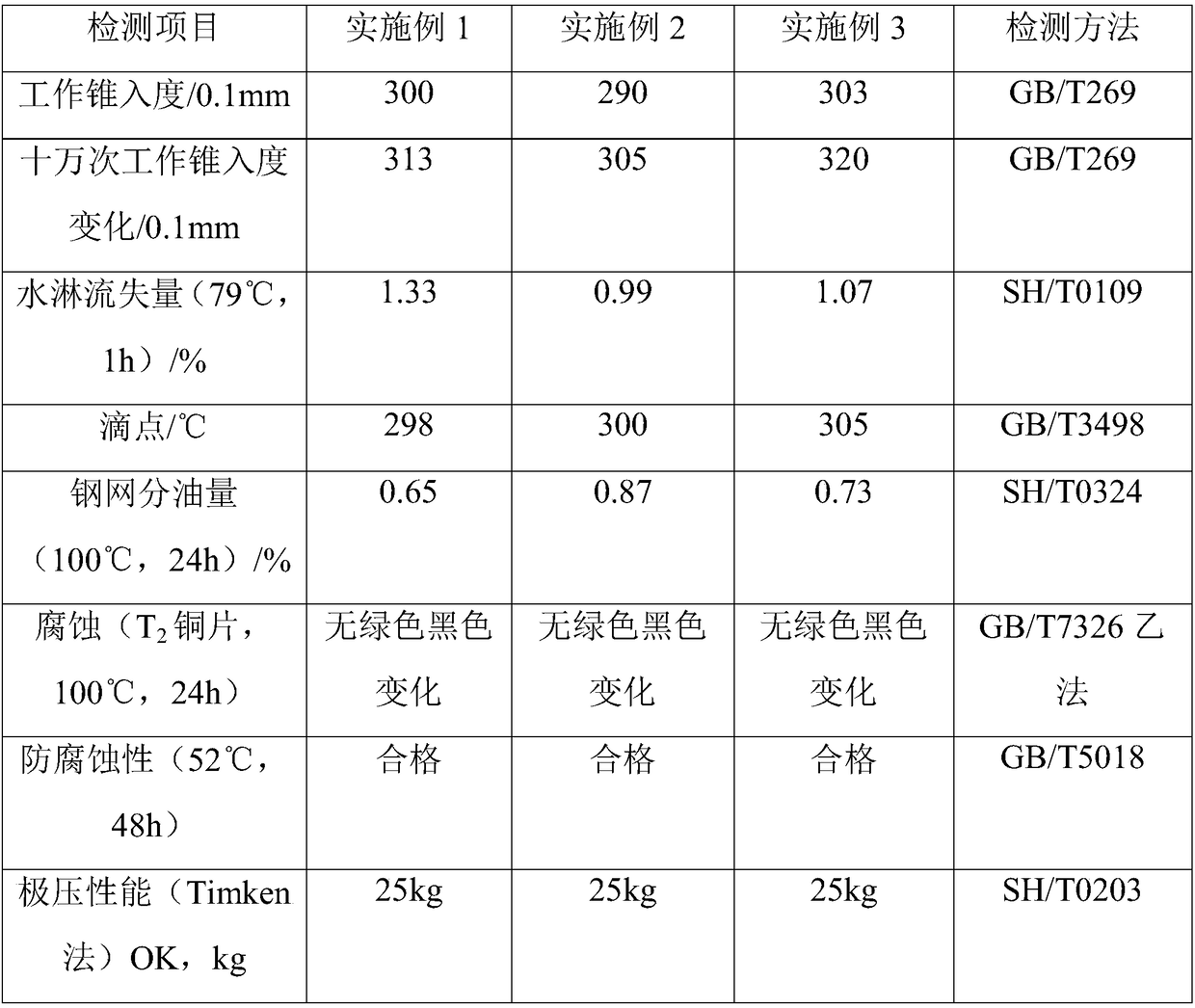

Examples

Embodiment 1

[0046] A preparation method of high heat-resistant lubricating grease, comprising the following steps:

[0047] (1) preparation of mixed organic acids;

[0048] The preparation method of organic acid is:

[0049] (11) Mix the base oil with the binary organic acid and put it into the reaction kettle for heating, stir it at a speed of 20r / min during heating until the temperature of the mixture rises to 120°C, and control the temperature at 120°C Keep stirring for 10min;

[0050] The weight ratio of base oil to binary organic acid is 10:7;

[0051] (12) After heating the mixture to 140°C, add a monobasic organic acid, stir the mixture at a speed of 30r / min for 3min, then add the monobasic organic acid again and keep stirring at 140°C for 5min;

[0052] The weight ratio of the mixture to the monobasic organic acid added for the first time and the monobasic organic acid added for the second time is 10:1:1, and the parts by weight of the monobasic organic acid added respectively ...

Embodiment 2

[0083] A preparation method of high heat-resistant lubricating grease, comprising the following steps:

[0084] (1) preparation of mixed organic acids;

[0085] The preparation method of organic acid is:

[0086] (11) Mix the base oil with the binary organic acid and put it into the reaction kettle for heating, stir it at a speed of 20r / min until the temperature of the mixture rises to 130°C, and control the temperature at 130°C Keep stirring for 15min;

[0087] The weight ratio of base oil to binary organic acid is 15:9;

[0088] (12) After heating the mixture to 150°C, add monobasic organic acid, stir the mixture at a speed of 30r / min for 5min, then add monobasic organic acid again and keep stirring at 150°C for 8min;

[0089] The weight ratio of the mixture to the monobasic organic acid added for the first time and the monobasic organic acid added for the second time is 10:3:3, and the parts by weight of the monobasic organic acid added respectively twice are the same; ...

Embodiment 3

[0120] A preparation method of high heat-resistant lubricating grease, comprising the following steps:

[0121] (1) preparation of mixed organic acids;

[0122] The preparation method of organic acid is:

[0123] (11) Mix the base oil with the binary organic acid and put it into the reaction kettle for heating, stir it at a speed of 20r / min until the temperature of the mixture rises to 125°C, and control the temperature at 1205°C Keep stirring for 10-15min;

[0124] The weight ratio of base oil to binary organic acid is 13:8;

[0125] (12) After heating the mixture to 145°C, add a monobasic organic acid, stir the mixture at a speed of 30r / min for 4min, then add the monobasic organic acid again and keep stirring at a temperature of 145°C for 7min;

[0126] The weight ratio of the mixture to the monobasic organic acid added for the first time and the monobasic organic acid added for the second time is 10:2:2, and the parts by weight of the monobasic organic acid added respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com