Waterproof pulverized coal and preparation method thereof

A technology of pulverized coal and stearic acid, applied in the field of pulverized coal, can solve the problems of limited storage time, transportation mode and application field of pulverized coal, affecting the use of coal-water slurry, shortening the storage time, etc. Good performance and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

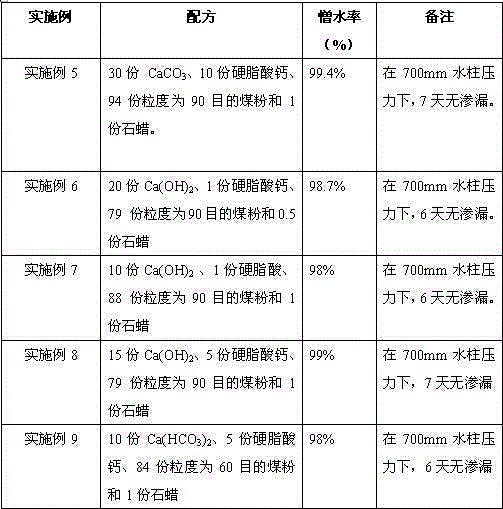

Examples

Embodiment 1

[0016] Embodiment 1 A kind of waterproof pulverized coal and preparation method thereof

[0017] 1. A waterproof coal powder, consisting of the following components by weight: CaCO 3 10 parts, 1 part of stearic acid, and 89 parts of pulverized coal with a particle size of 90 mesh.

[0018] 2. A preparation method of waterproof pulverized coal:

[0019] 1) Weigh the raw materials according to the above formula;

[0020] 2) After mixing and stirring the above-mentioned weighed raw materials evenly, add them to the drum-type heating reaction kettle, and after heating up to 110°C, keep rolling and heating for 20 minutes to obtain the waterproof coal powder; wherein, the heating rate of the heating is 2°C / min.

[0021] According to the method of DB51 / 172-1993, the above-mentioned waterproof pulverized coal prepared in the present embodiment was tested for performance. The results showed that the waterproof pulverized coal produced in the present embodiment had a water-repellent...

Embodiment 2

[0022] Embodiment 2 A kind of waterproof pulverized coal and preparation method thereof

[0023] 1. A waterproof coal powder, consisting of the following components by weight: CaCO 3 10 parts, 1 part of stearic acid, 89 parts of pulverized coal with a particle size of 90 mesh and 0.5 part of paraffin;

[0024] 2. A preparation method of waterproof pulverized coal:

[0025] 1) Weigh the raw materials according to the above formula;

[0026] 2) After mixing and stirring the above-mentioned weighed raw materials evenly, add them to the drum-type heating reaction kettle, and after heating up to 110°C, keep rolling and heating for 20 minutes to obtain the waterproof coal powder; wherein, the heating rate of the heating is 2°C / min.

[0027] According to the method of DB51 / 172-1993, the above-mentioned waterproof pulverized coal prepared in this embodiment was tested for performance, and the results showed that the water-repellent rate of the waterproof pulverized coal prepared ...

Embodiment 3

[0028] Embodiment 3 A kind of waterproof pulverized coal and preparation method thereof

[0029] 1. A waterproof coal powder, consisting of the following components by weight: 5 parts of CaCO 3 , 5 parts of calcium stearate, 60 parts of coal powder with a particle size of 60 mesh and 1 part of paraffin.

[0030] 2. A preparation method of waterproof pulverized coal:

[0031] 1) Weigh the raw materials according to the above formula;

[0032] 2) After mixing and stirring the above-mentioned weighed raw materials evenly, add them to the rolling heating reaction kettle, and after raising the temperature to 130°C, keep rolling and heating for 40 minutes to obtain the waterproof coal powder; wherein, the heating rate of the heating is 1°C / min.

[0033] According to the method of DB51 / 172-1993, the above-mentioned waterproof pulverized coal prepared in this embodiment was tested for performance, and the results showed that the water-repellent rate of the waterproof pulverized c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com