Vacuum-sealed container, vacuum sealing method, and vacuum heat treatment method

A vacuum sealing and container technology, which is applied to the sealing of engines, engine components, mechanical equipment, etc., can solve problems such as long-term and inability to meet sealing requirements, improve vacuum sealing performance, increase effective storage time, and achieve low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

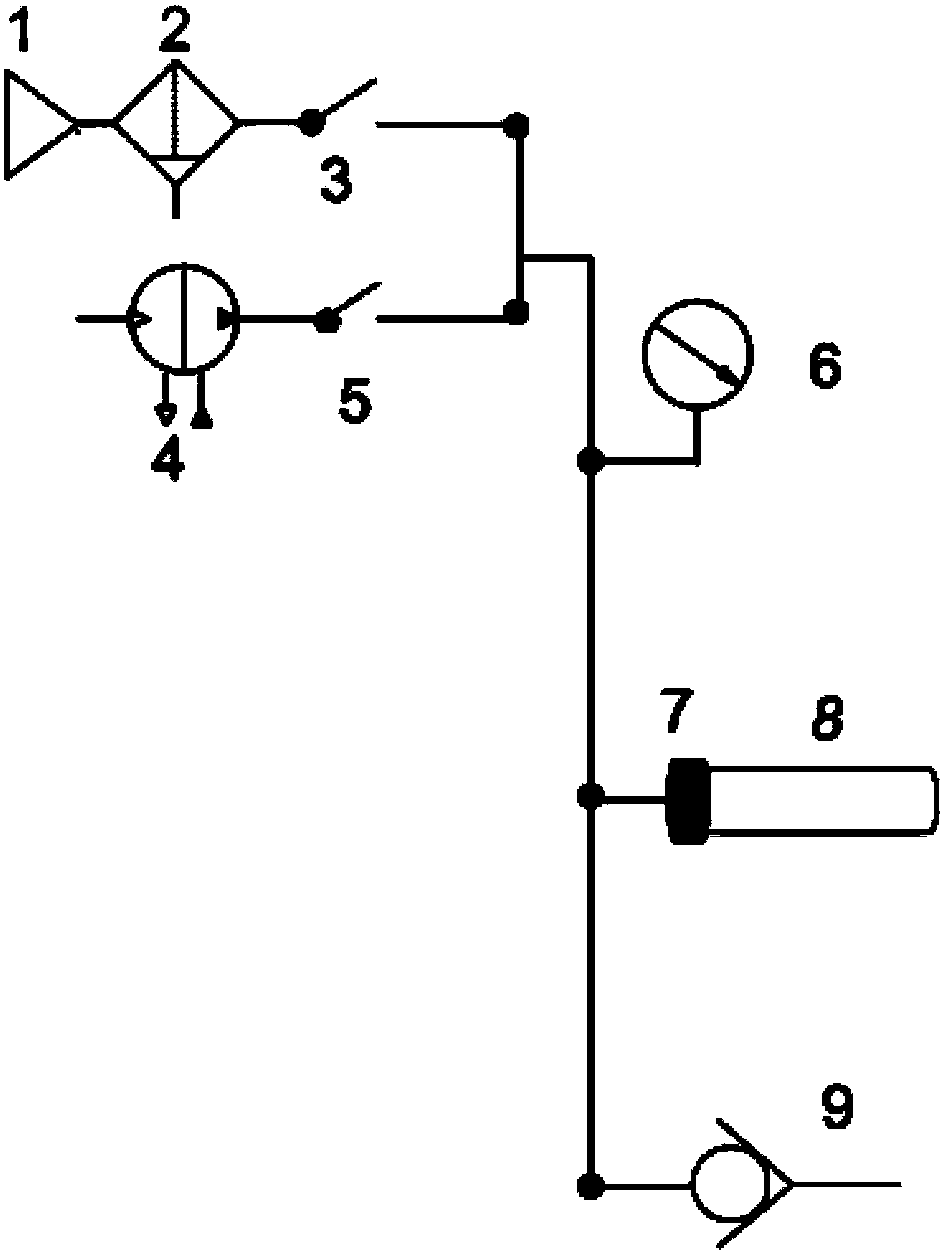

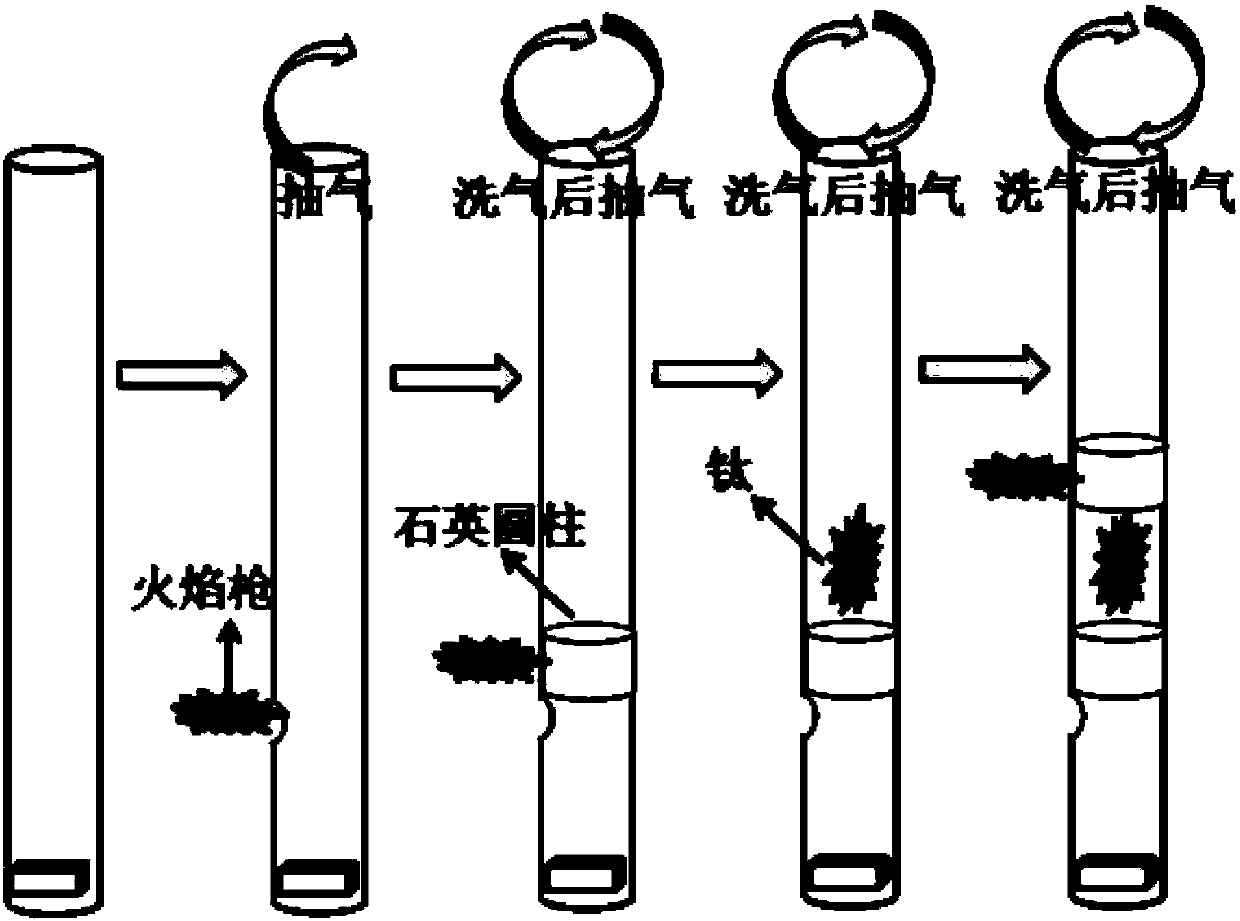

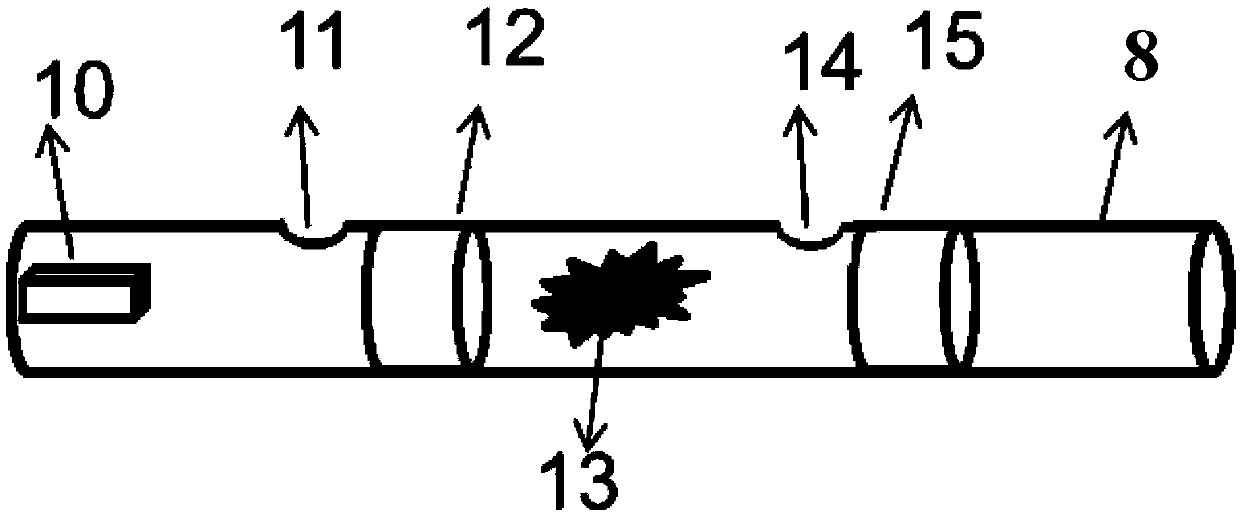

[0023] The present invention aims at the problem that the existing vacuum sealing technology based on quartz tubes cannot meet the sealing requirements of long-term vacuum heat treatment, and improves the vacuum sealing method. The sealing structure of the titanium sponge between the two sealing parts, on the one hand, uses the two sealing parts to improve the vacuum sealing performance, and more importantly, the titanium sponge can absorb the infiltrated air well, so that the entire vacuum-sealed container can last for a long time. There is almost zero leakage during the heat treatment process for a long time, which ensures the effect of the experiment and improves the effective storage time of the sample.

[0024] Specifically, in the vacuum-sealed container proposed by the present invention, the container is a quartz tube with an open upper end, and a sealing structure is provided between the bottom of the quartz tube and the opening end, and the cavity between the sealing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com