Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Solve explosion-proof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

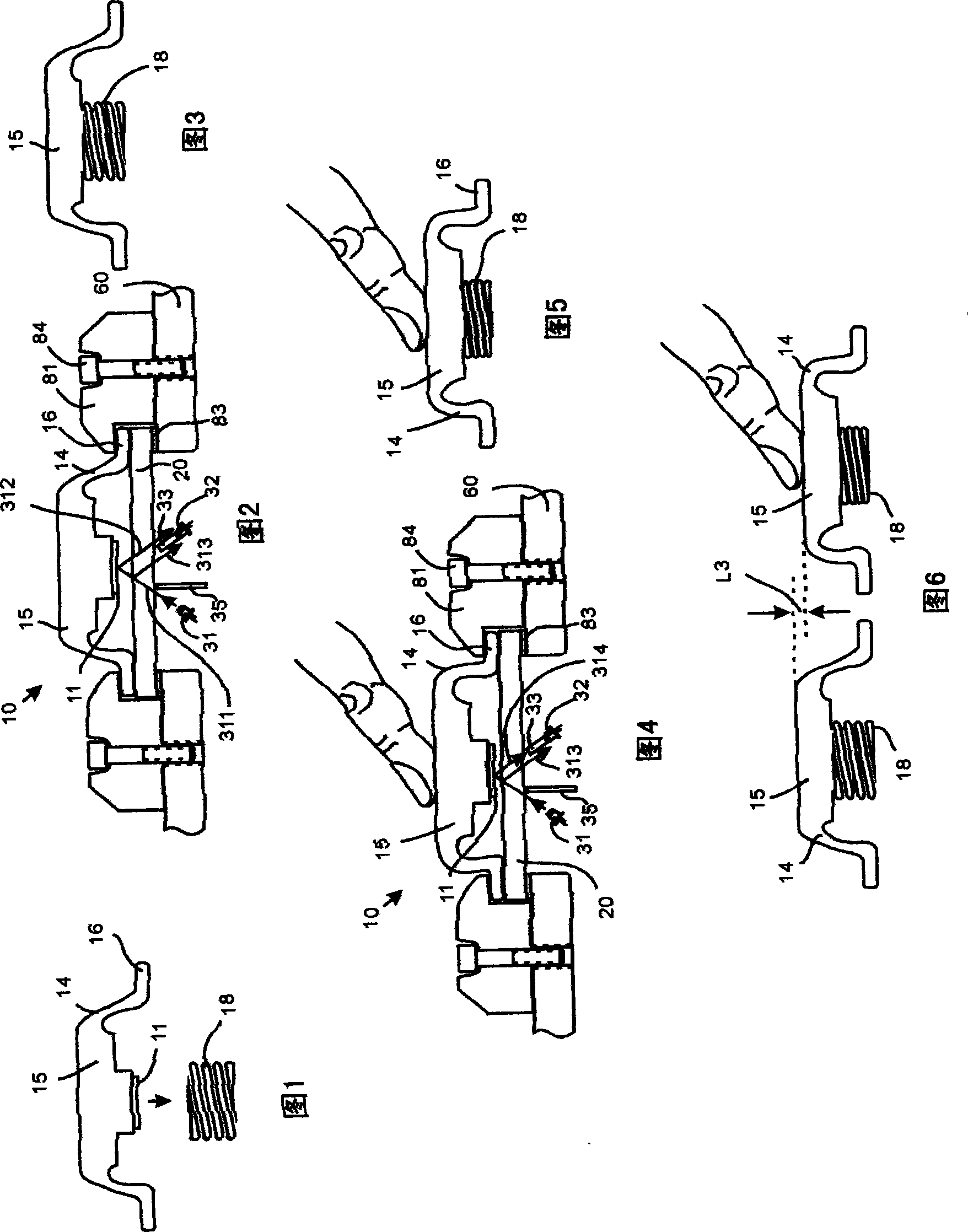

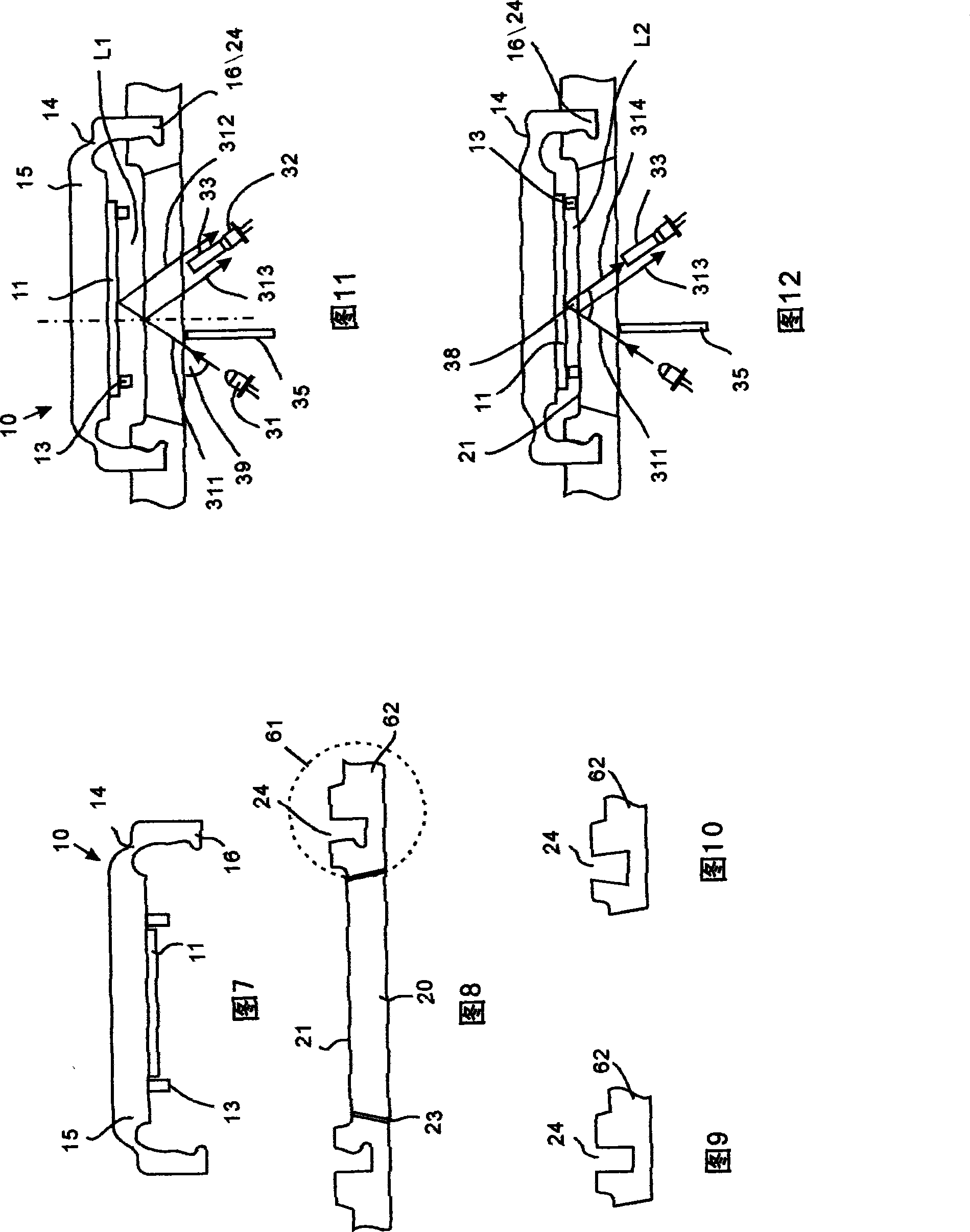

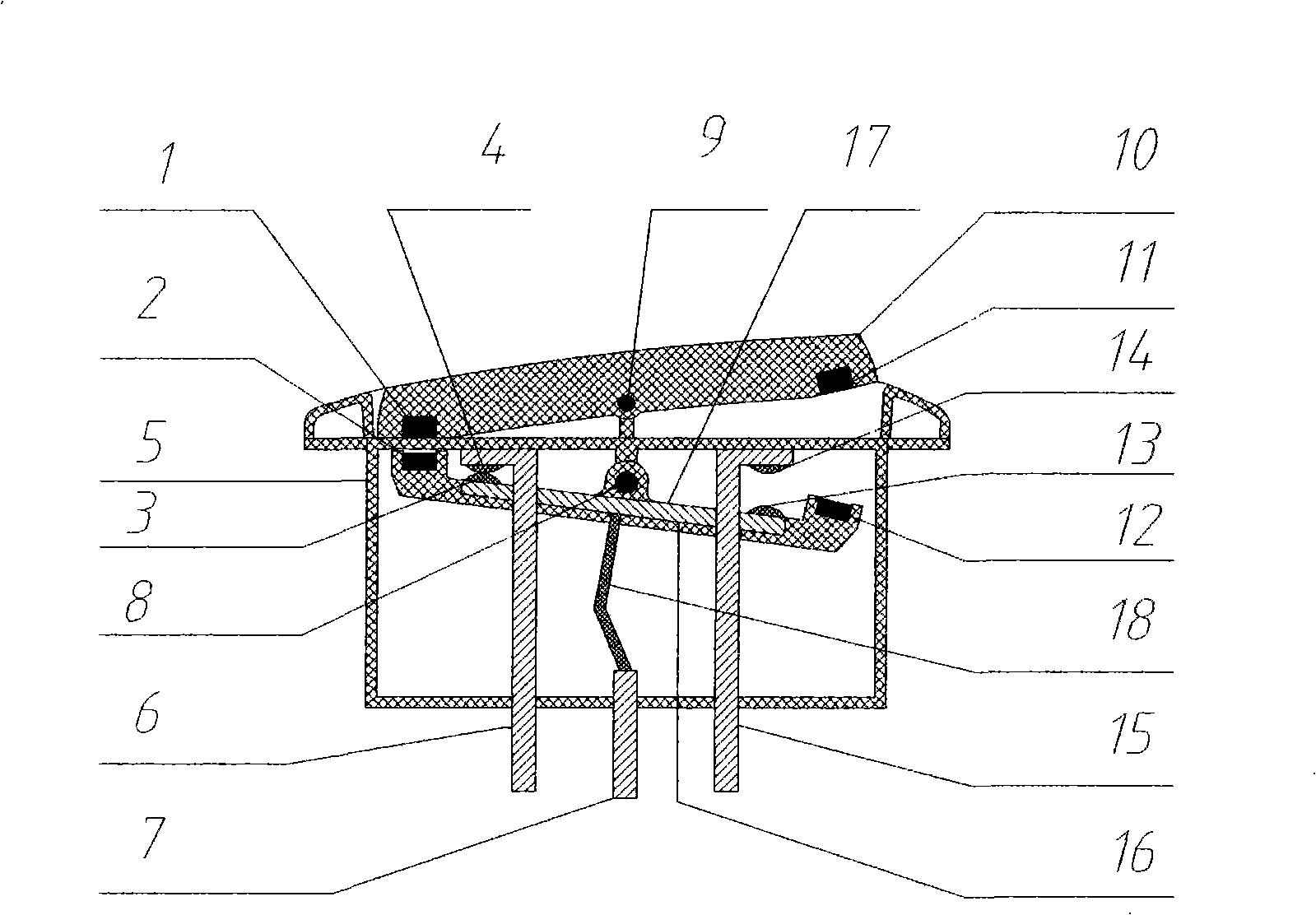

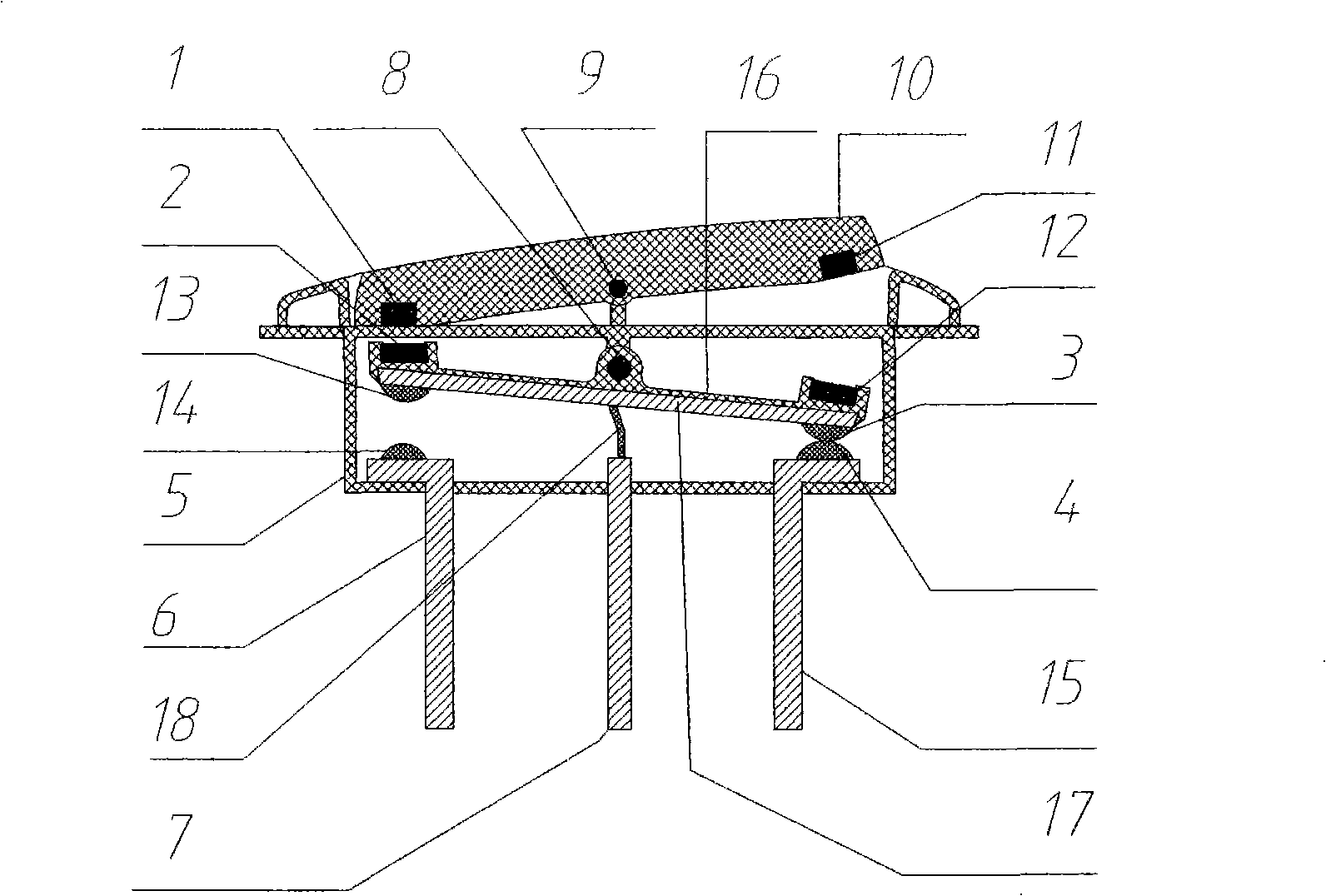

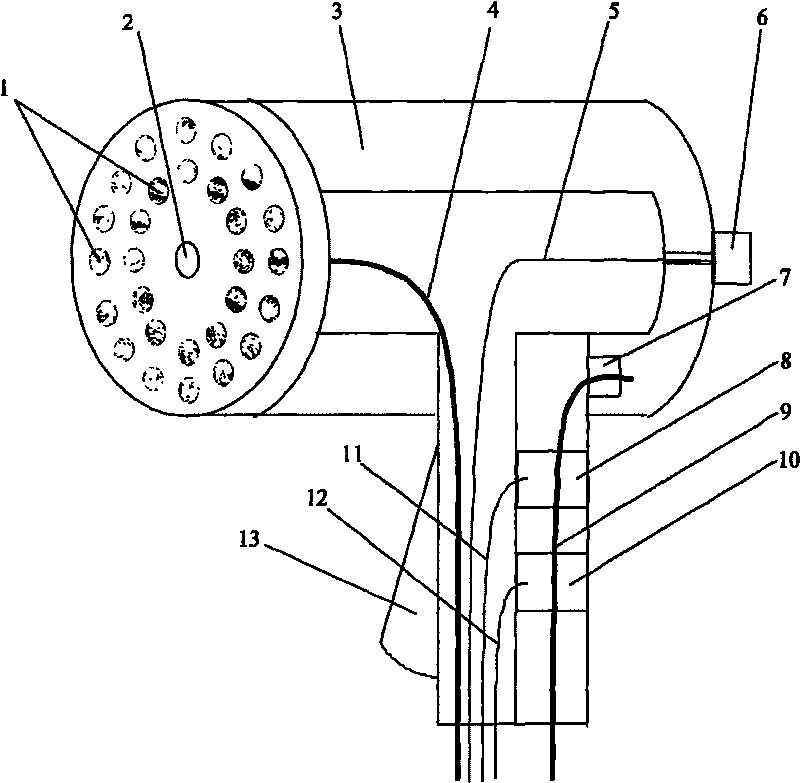

Press keys for coal mine information device

InactiveCN101247120ASolve explosion-proofIn line with the entry habitsElectronic switchingOptoelectronicsInformation device

A coal mine information device press key comprises the following components: an emergent ray axis (311) on the light transmitting device (31) and a receiving ray axis (314) on the light receiving device (32); a lens part (20) which is taken as one part of the explosion-proof casing and is arranged on the upper part of the light transmitting device (31) and the light receiving device (32); and a key cap body (15) which has unique structure and is arranged at the upper side of the lens part (20), and when the key cap body (15) is at the first position, the light transmitting part (11) leads to the transmitting light to the outside of the receiving ray axis (314). The key cap body (15) at the second position when it is pressed the transmitting ray transmits into the light receiving device (32) along the receiving light axis (314) and the light receiving device (32) is accessed into the press key circuit thereby realizing the function of the press key. The structure of the press key of the invention can satisfy the requirement for preventing explosion in the electric device used in the explosive gas atmosphere.

Owner:东莞市广易电子科技有限公司

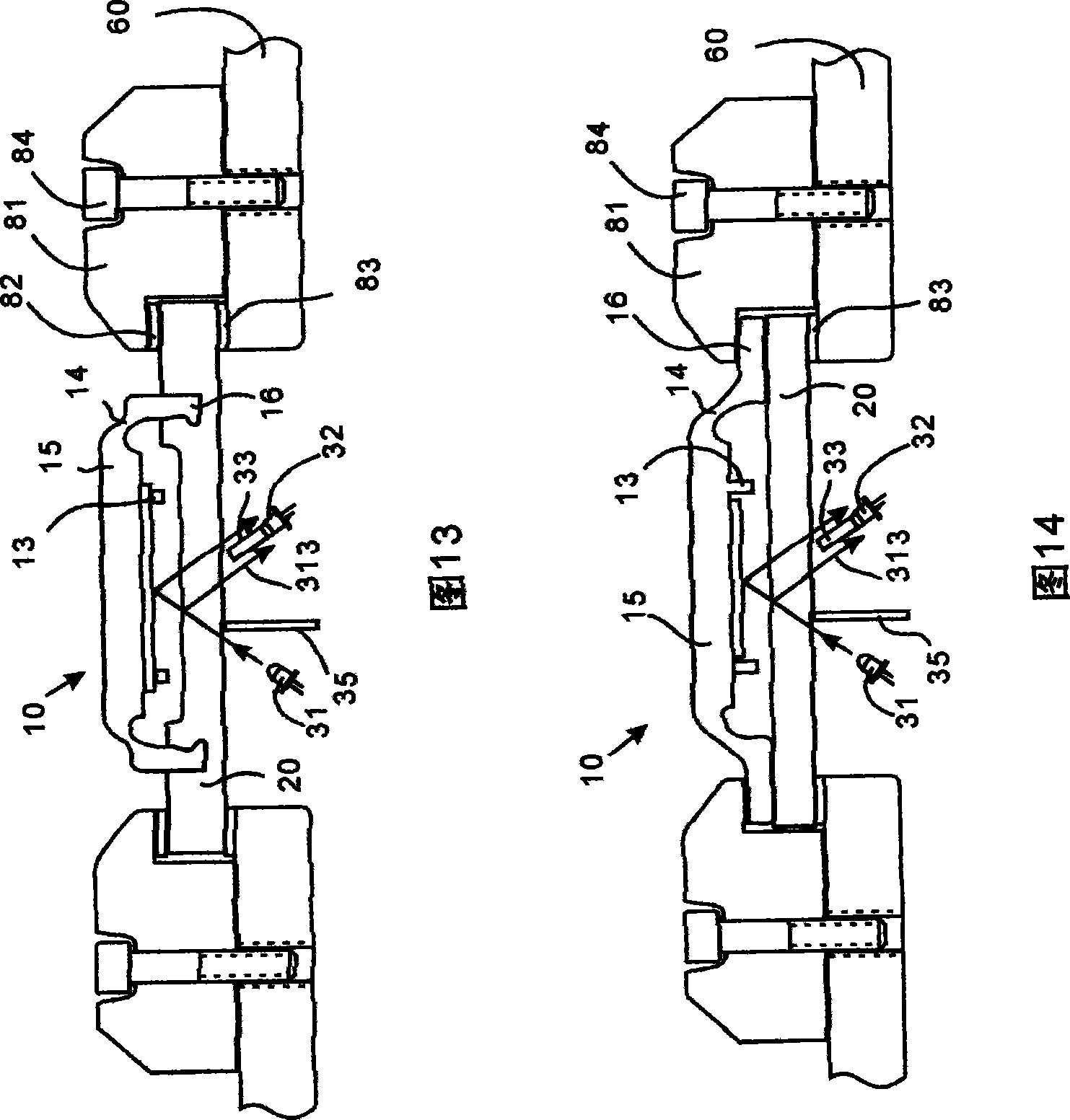

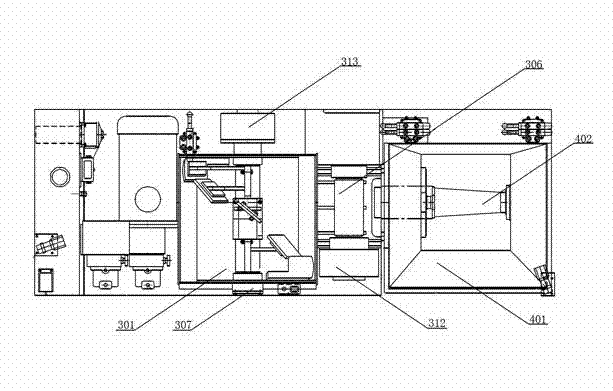

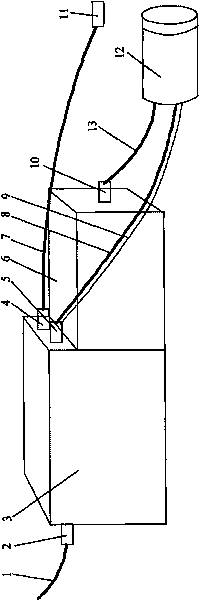

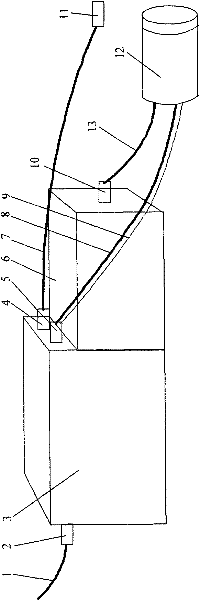

Crawler belt walking wet type concrete sprayer

The invention relates to a crawler belt walking wet type concrete sprayer comprising a frame, a crawler belt walking mechanism, a stirring and overturning mechanism, a spraying mechanism and a hydraulic system. The crawler belt walking mechanism is arranged at the both sides of the frame; a hydraulic pump of the hydraulic system drives a walking motor of the crawler belt walking mechanism through a hydraulic oil path; the walking motor drives a driving wheel to rotate through a speed reducer, so that the machine walks; the hydraulic system and the spraying mechanism are respectively arranged at the both ends of the frame; the stirring and overturning mechanism is arranged on the frame between the hydraulic system and a conveying mechanism; the stirring and overturning mechanism forcibly stirs a concrete material, and overturns a stirring tank, so that the concrete material inside the stirring tank is poured into a material tank of a concrete pump; and the material is conveyed through the concrete pump; and compressed air is added at the position of a spraying opening in a mixing manner, so that the concrete is sprayed. The wet type concrete sprayer provided by the invention integrates the functions of walking, stirring, conveying and spraying into a whole; the rebound ratio is less than 5%; the wet type concrete sprayer has the advantages of no dust, safe, reliable and high-efficiency use and humanization. The wet type concrete sprayer uses full-hydraulic control and has the advantages of stable conveying and simple operation, so that the underground anti-explosion problem can be effectively solved.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

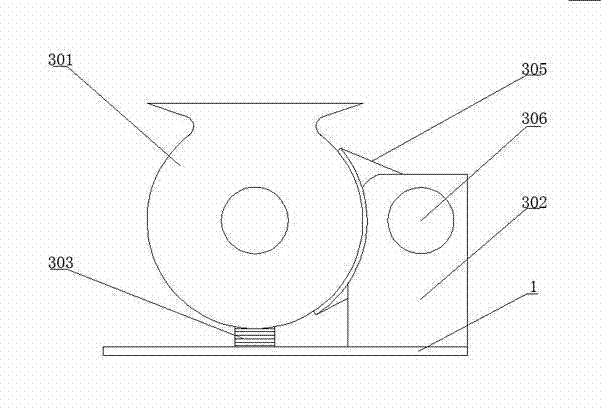

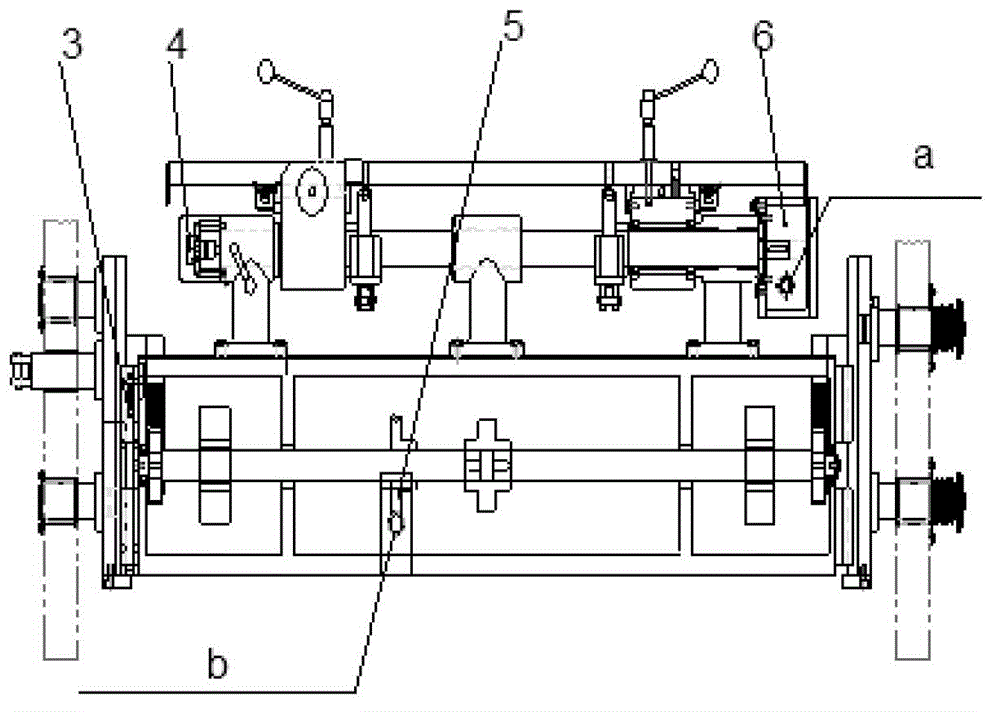

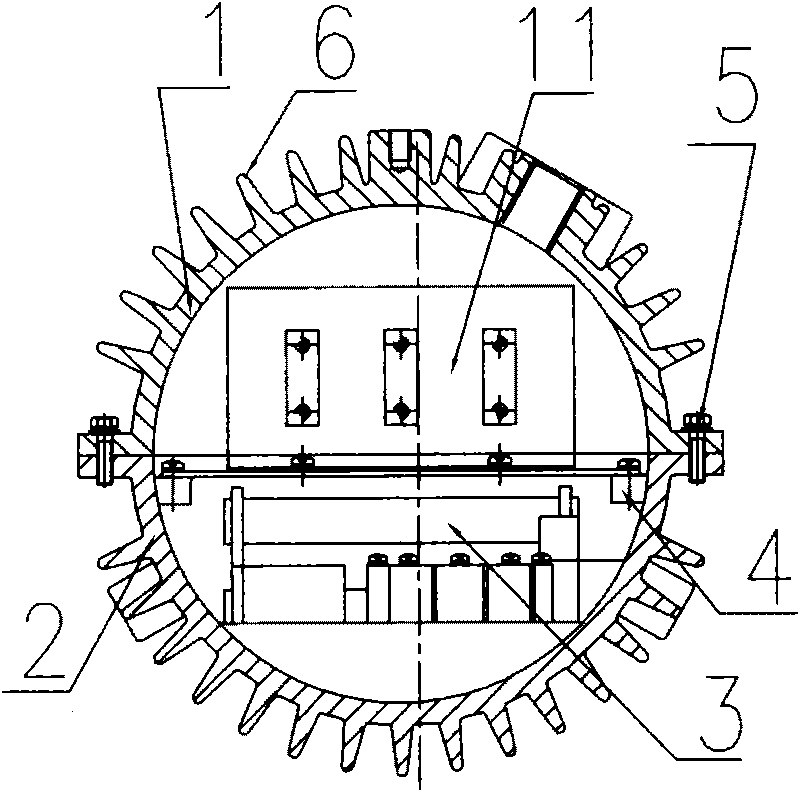

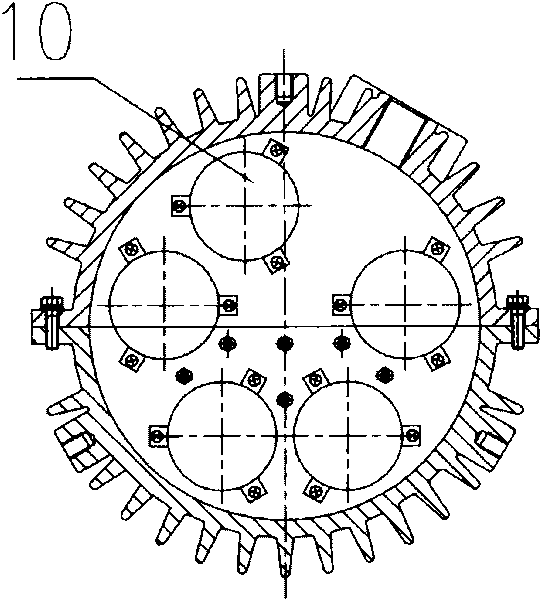

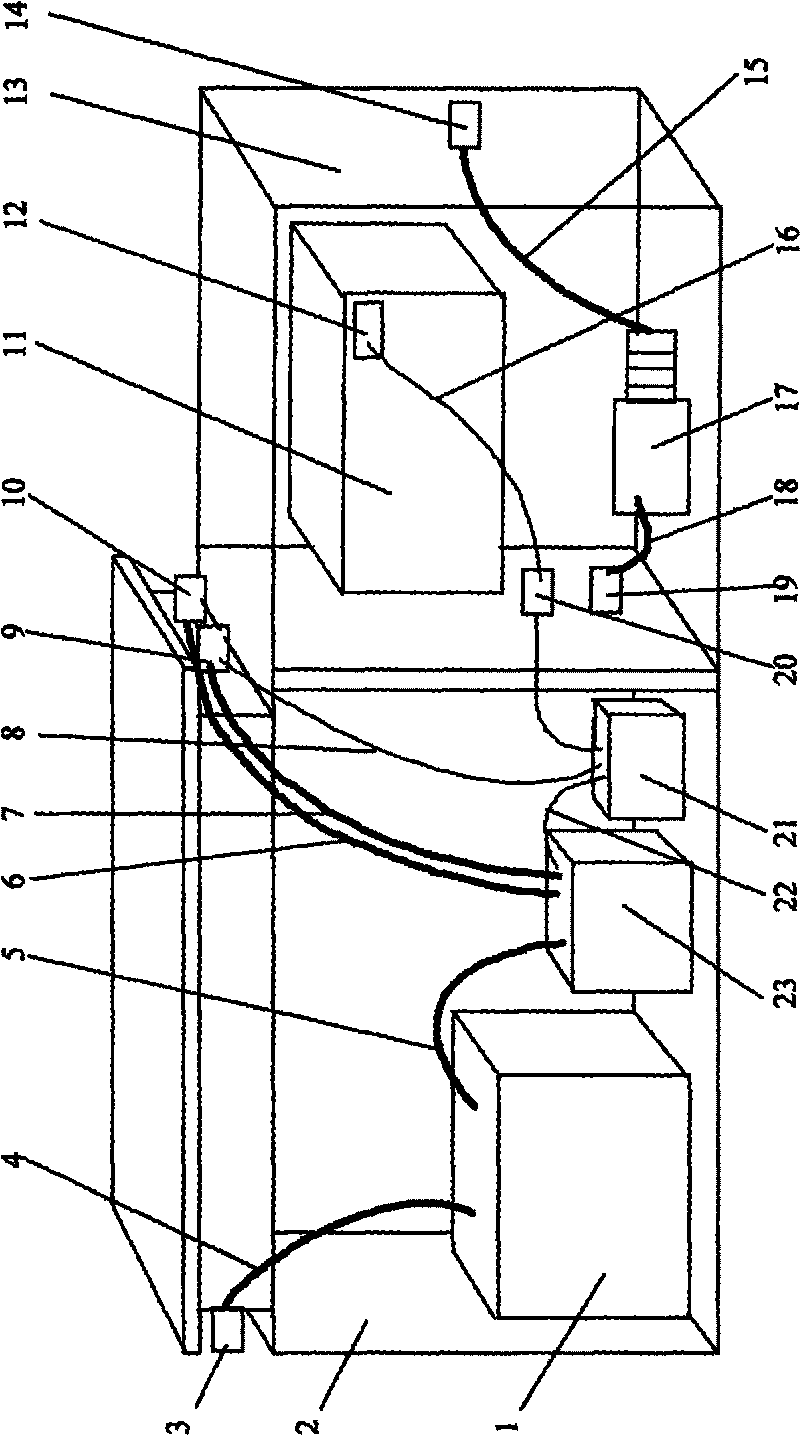

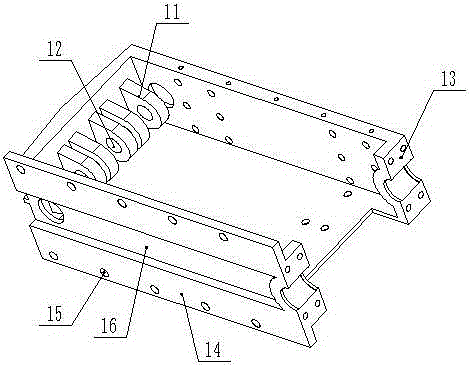

Same-distribution-angle hydraulic cylinder motor

ActiveCN104131945AReduce speedReduce output torque rippleCrankshaftsReciprocating piston enginesHydraulic cylinderHydraulic motor

The invention belongs to the field of mining hydraulic motors, and especially discloses a same-distribution-angle hydraulic cylinder motor. A technical problem to be solved is providing a same-distribution-angle hydraulic cylinder motor with the advantages of simple structure, operation convenience, high safety coefficient, long service life and effective reduction of the coal mine underground accident rate. The motor comprises a case body, three hydraulic cylinders, a crankshaft, a case body front end assembly and a control system, the whole case body is a shell structure, the three hydraulic cylinders are arranged in the case body side by side, the front end of the case body is provided with a case body semicircle seat for installing the crankshaft, the case body front end assembly is fixedly connected with the case body to fix the crankshaft, the piston terminals of the hydraulic cylinders are connected with the crankshaft through piston terminal covers, the hydraulic cylinders move back and forth to drive the crankshaft to rotate, the crankshaft drives the control system to move, and the control system controls the reciprocating motion of the three hydraulic cylinders in order to drive the crankshaft to continuously revolve. The motor adopting the hydraulic cylinders to drive the crankshaft to rotate has the advantages of low rotating speed, large torque, and suitableness for the use requirements of coal mine underground equipment.

Owner:NANTONG JIEFU ELECTRICAL CO LTD

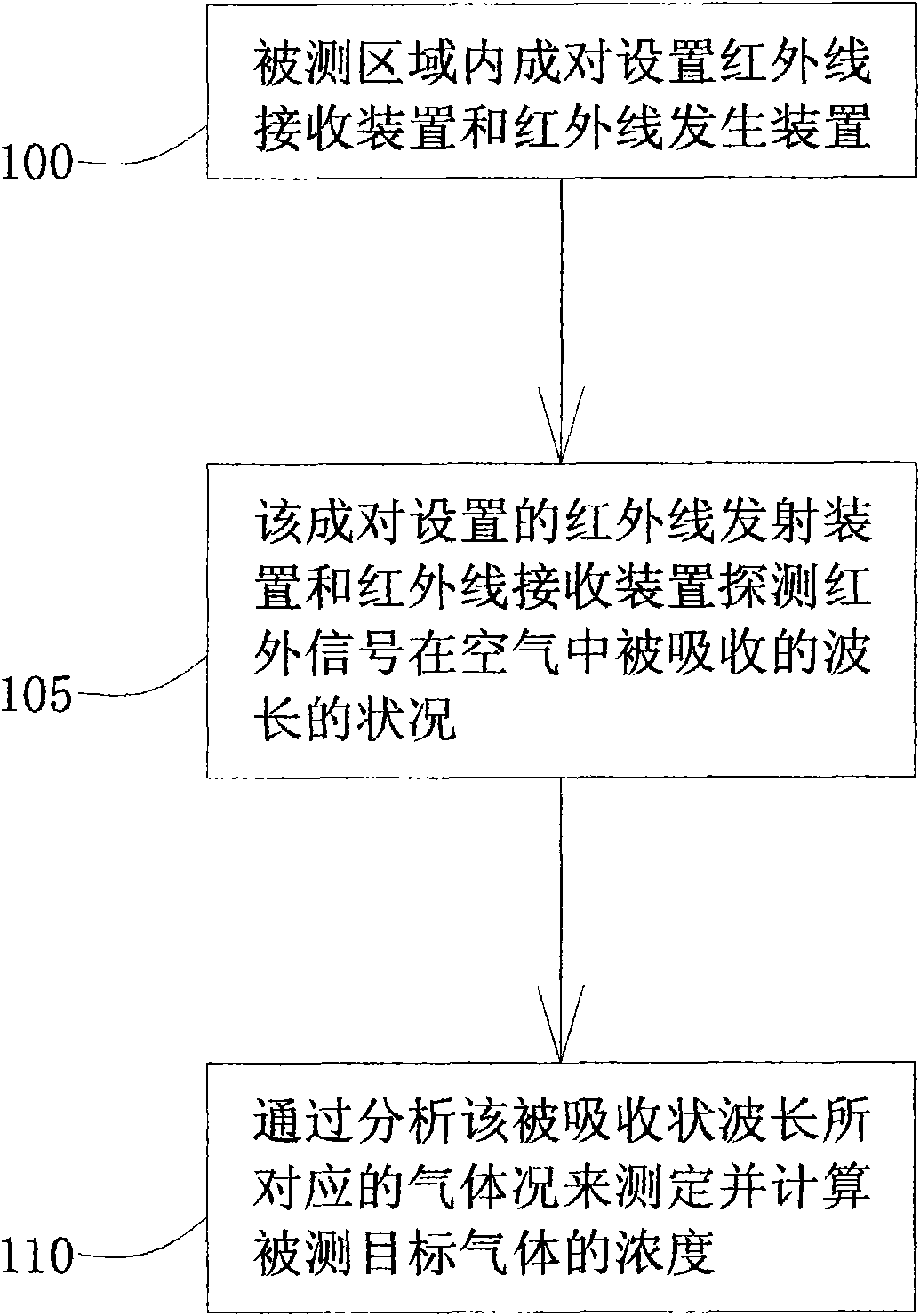

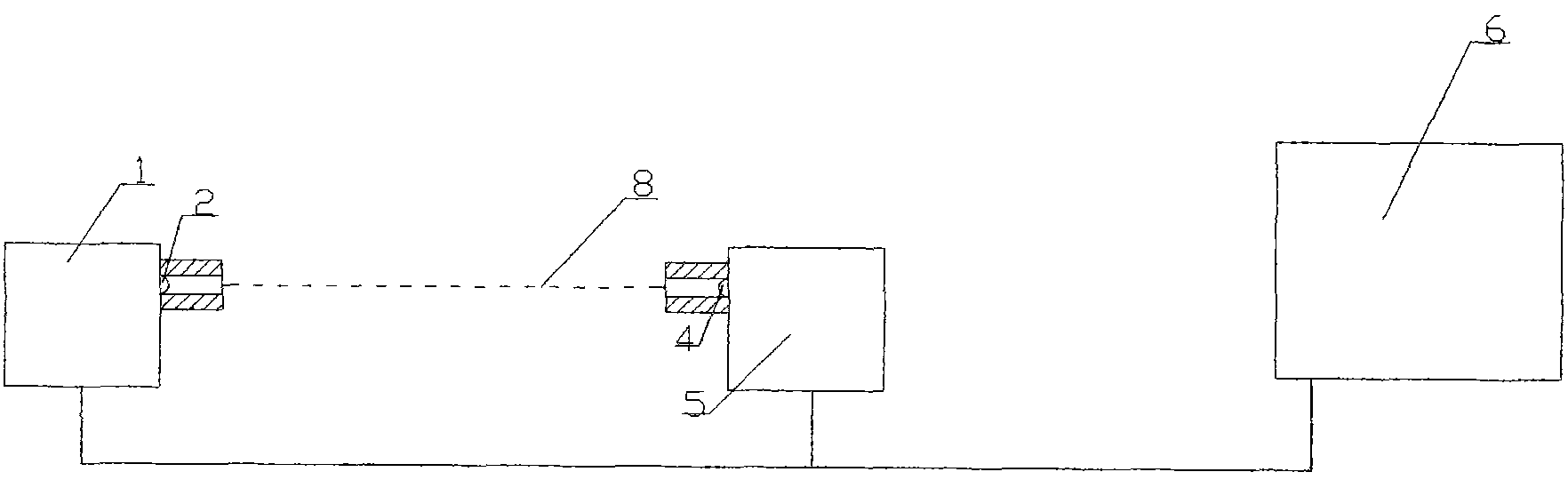

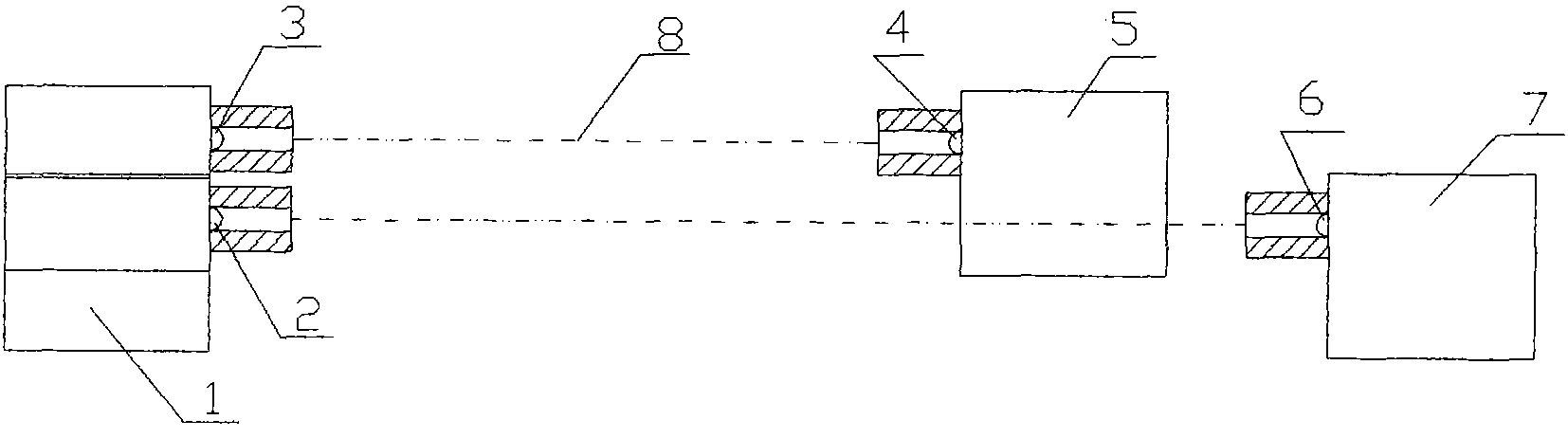

Active gas detection method and alarm device thereof

InactiveCN101776593ASolve explosion-proofFast response timeFire alarmsColor/spectral properties measurementsInfraredEngineering

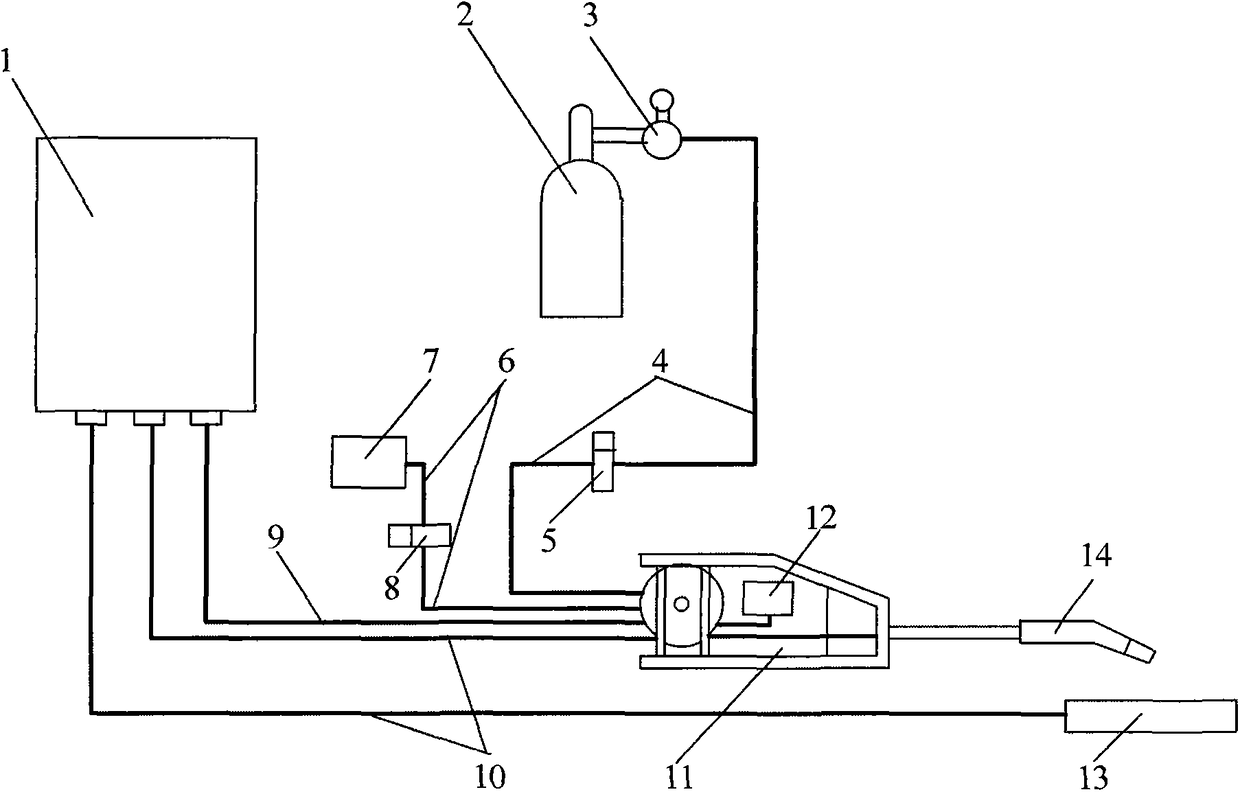

The invention relates to an active gas detection method and an alarm device thereof. An infrared receiving device and an infrared generating device are arranged in an area to be measured and used for detecting the condition that infrared signals are absorbed in the air and measuring the concentration of target gas to be measured corresponding to the wavelength by analyzing the intensity of the absorbed wavelength; the active gas detection alarm device comprises an infrared transmitting device, an infrared receiving device, an alarm device and a central control module; both the infrared receiving device and the infrared generating device are arranged in the area to be measured, correspond to each other and are respectively connected with the central control module; and the alarm device is connected with the central control module. Compared with the traditional point-type detection method, the average concentration represented by the measuring result obtained by the measuring method is more reasonable.

Owner:SHENZHEN JINMING TECH

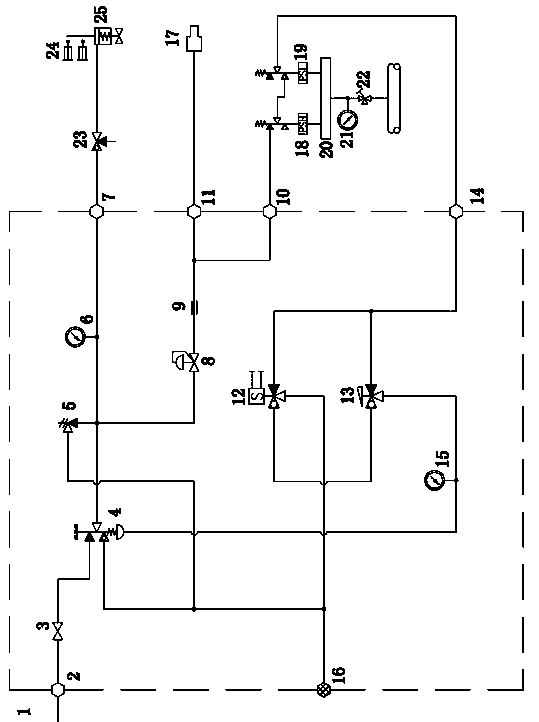

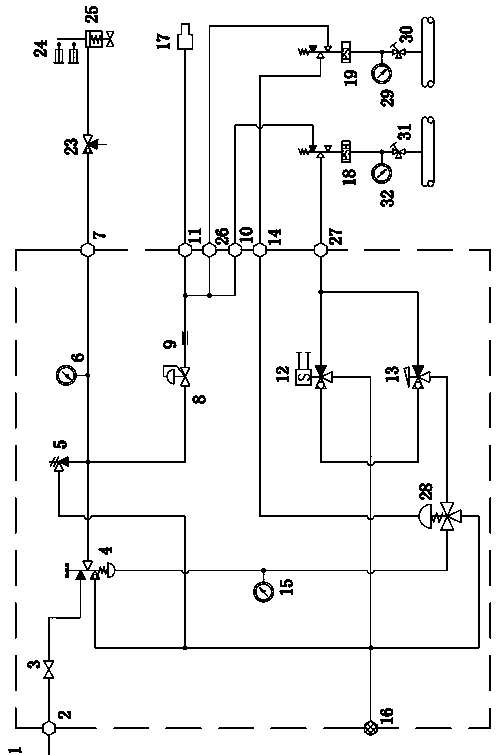

Safety control system for pneumatic well heads

InactiveCN103410471ASolve explosion-proofImprove securityWell/borehole valve arrangementsSealing/packingAutomatic controlSolenoid valve

The invention relates to a safety control device for natural gas well heads, namely a safety control system for pneumatic well heads. The safety control system comprises a control disc, a high-pressure guide valve, a low-pressure guide valve, a fusible plug and a pneumatic block valve. The high-pressure guide valve is communicated with the outlet of an inlet connector of the high-pressure guide valve on the control disc and then is in series connection with the low-pressure guide valve, the outlet of the high-pressure guide valve is connected with the inlet of the low-pressure guide valve, and the outlet of the low-pressure guide valve is connected with the inlet of an outlet connector of the low-pressure guide valve on the control disc. The high-pressure guide valve and the low-pressure guide valve are both installed on an air collecting pipe, and a guide pressure testing check valve I on the air collecting pipe is connected onto a super-decompression detection point on a site plant or a pipeline. The fusible plug is installed on a well head area, the pneumatic check valve is installed at the rear end of a flat valve of a well head gas production tree, and a solenoid valve and a valve position feedback device are both connected with an automatic control system with a remote terminal unit (RTU) or a programmable logic controller (PLC) control sheet. The safety control device for natural gas well heads improves safety and environmental protection property of the natural gas production well heads, achieves remote automation control and reduces using cost.

Owner:重庆达腾科技发展有限公司

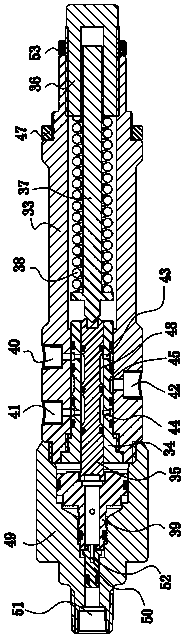

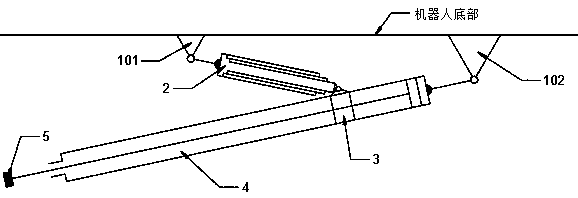

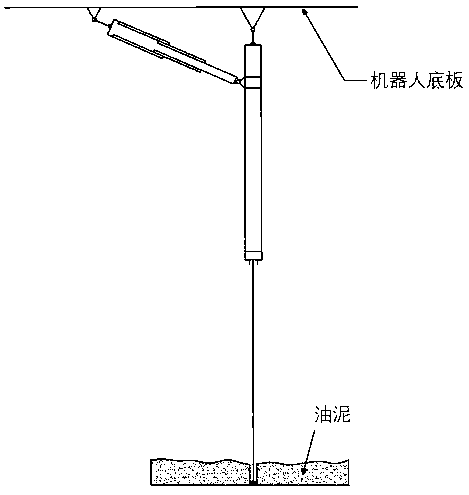

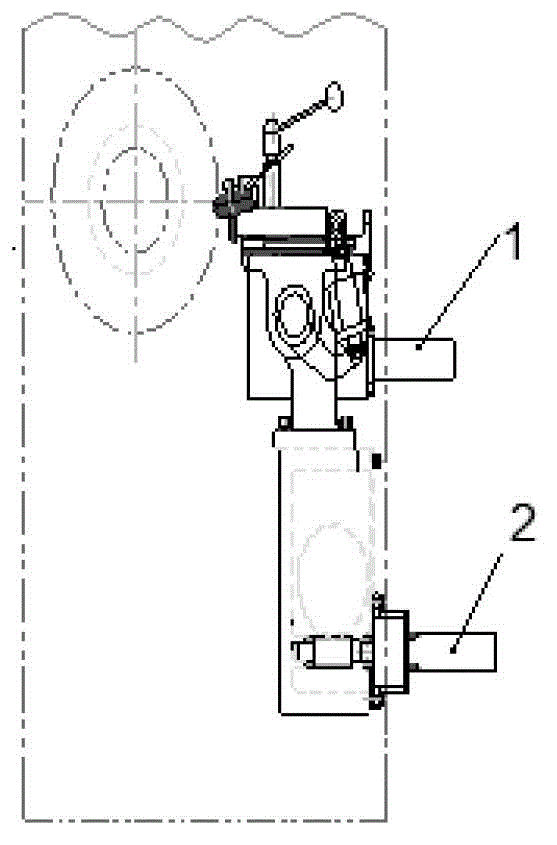

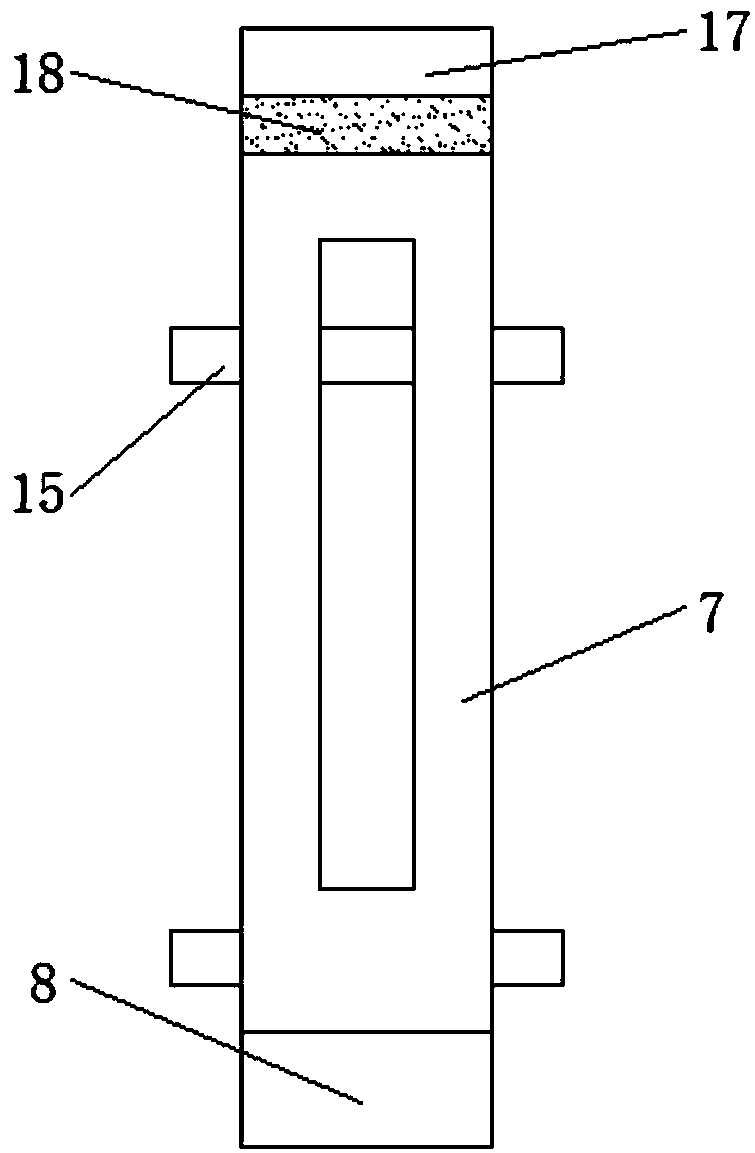

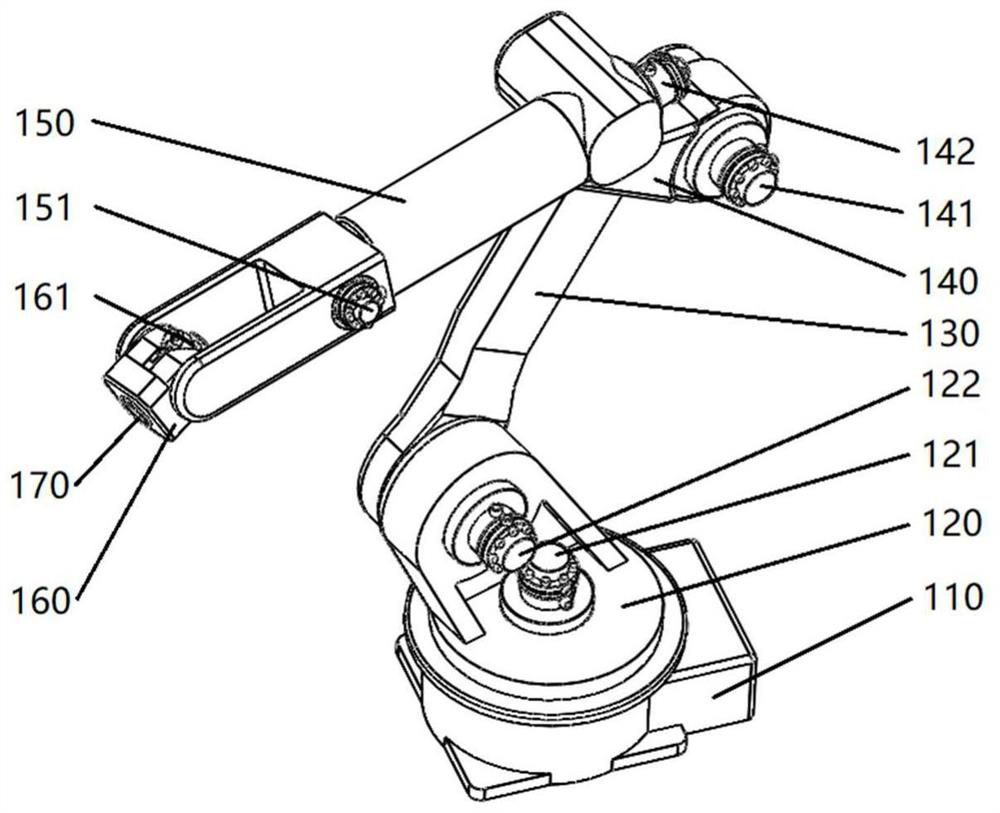

Detection mechanism of robot for detecting corrosion of in-service large crude oil storage tank

InactiveCN107807171ASolve explosion-proofAvoid damageAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansHydraulic cylinderSingle stage

The invention discloses a detection mechanism of a robot for detecting the corrosion of an in-service large crude oil storage tank. The detection mechanism comprises a hinged support, a support rod, adetection rod, a connection piece, and an ultrasonic thickness measuring probe. The hinged support positions the support rod and the detection rod, and the support rod and the detection rod can rotate oppositely relative to each other. The support rod is a secondary hydraulic cylinder, the first stage is a common piston cylinder, and the second stage piston rod and a spring can realize telescoping. The detection rod is a single stage and double effect hydraulic cylinder. Explosion resistance of oil gas is taken into account, and a spring wire for signal transmission is arranged in the cylinder and connected to threaded plugs on two ends of the cylinder. The tail end of the piston rod and the ultrasonic probe are connected by an elastic element to realize grounding buffer. During the process of detection, the support rod pushes out the detection rod, the detection rod penetrates the oil sludge and contacts with the bottom plate of a crude oil storage tank to measure the thickness, after measuring, the detection rod retracts, and the support rod draws back the detection rod. The provided detection mechanism can avoid barriers in the bottom of a crude oil storage tank such as heatingcoiler, and the like, can accurately measure the thickness of the bottom plate, and improves the online storage tank corrosion detection efficiency.

Owner:SOUTHWEST PETROLEUM UNIV

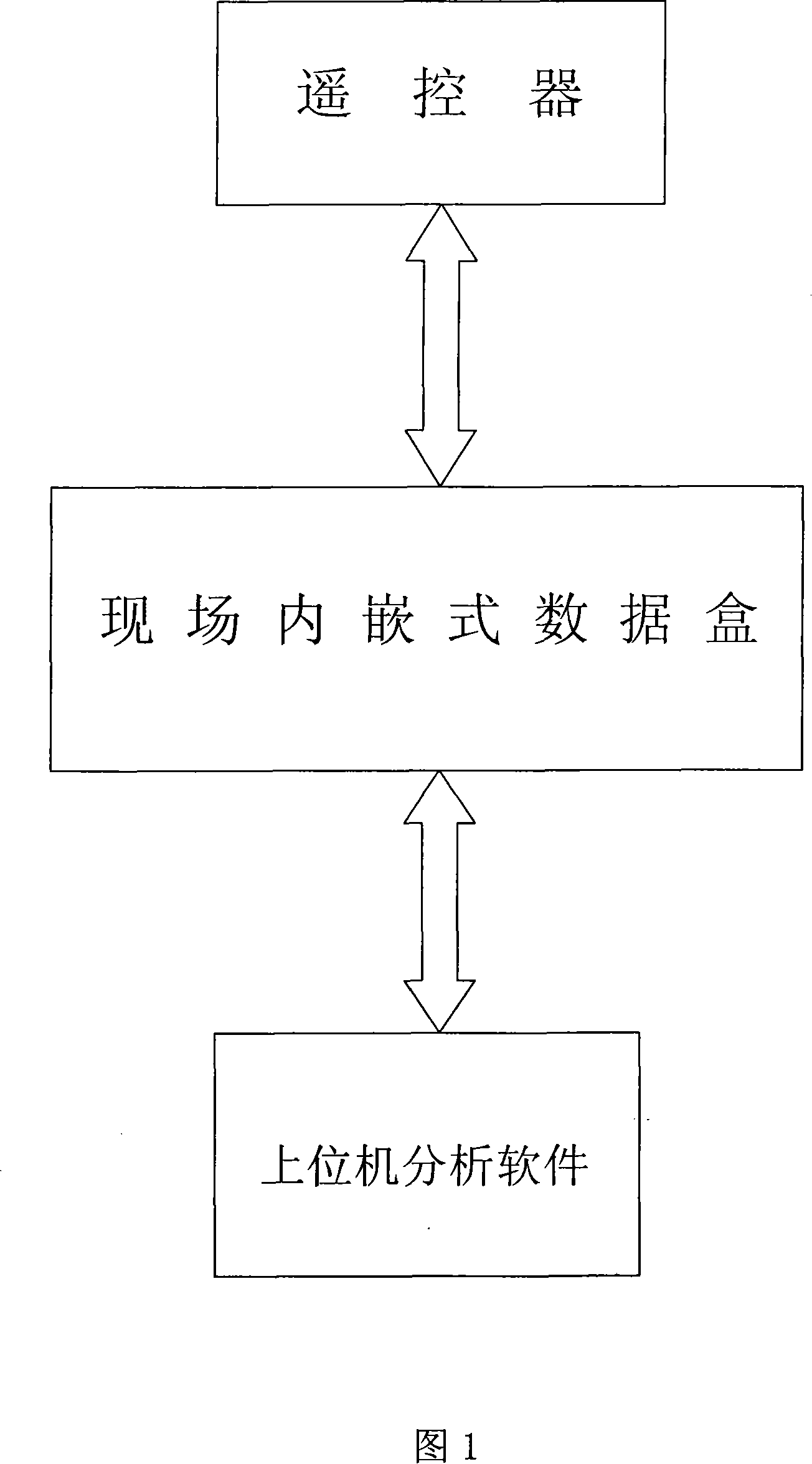

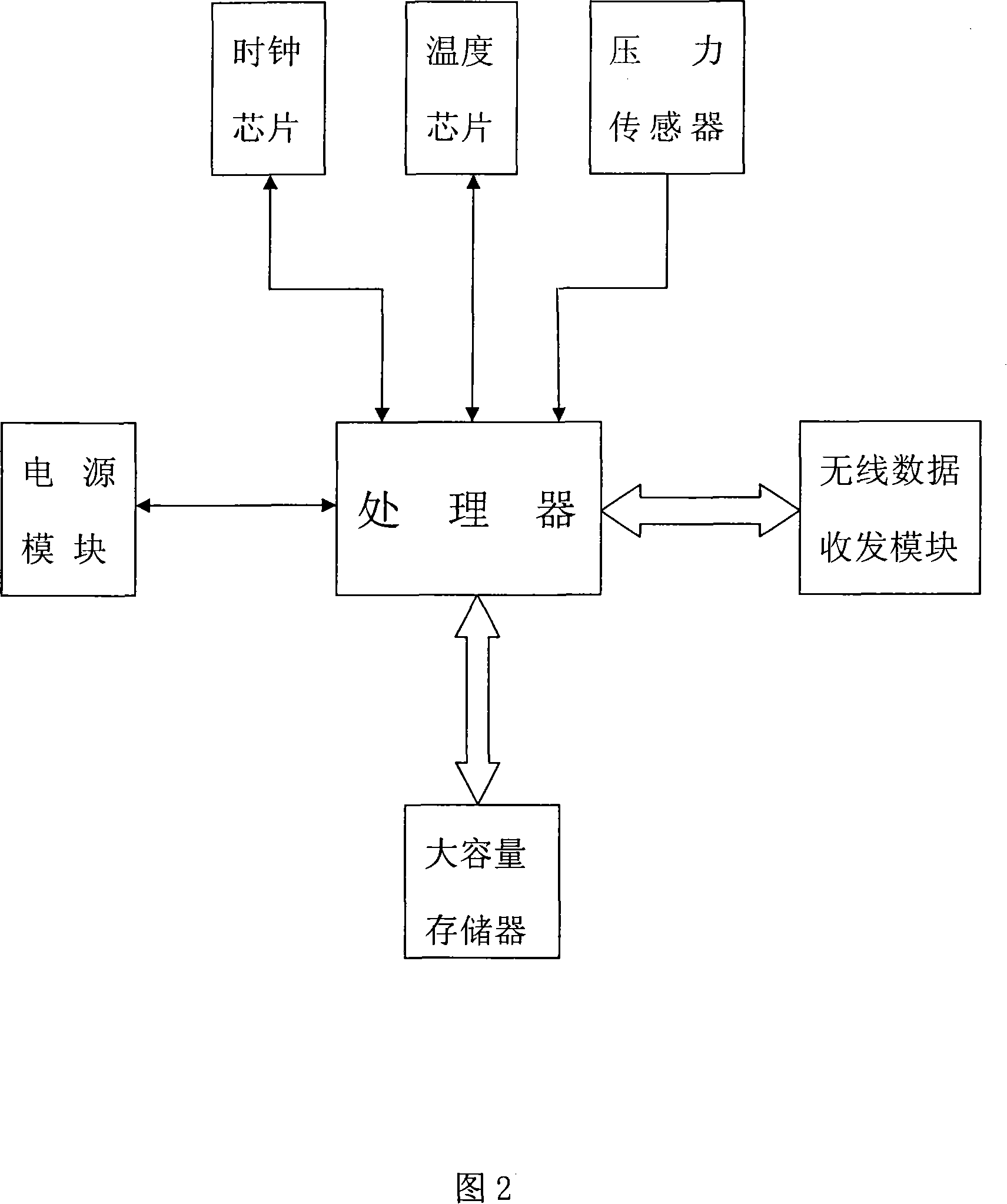

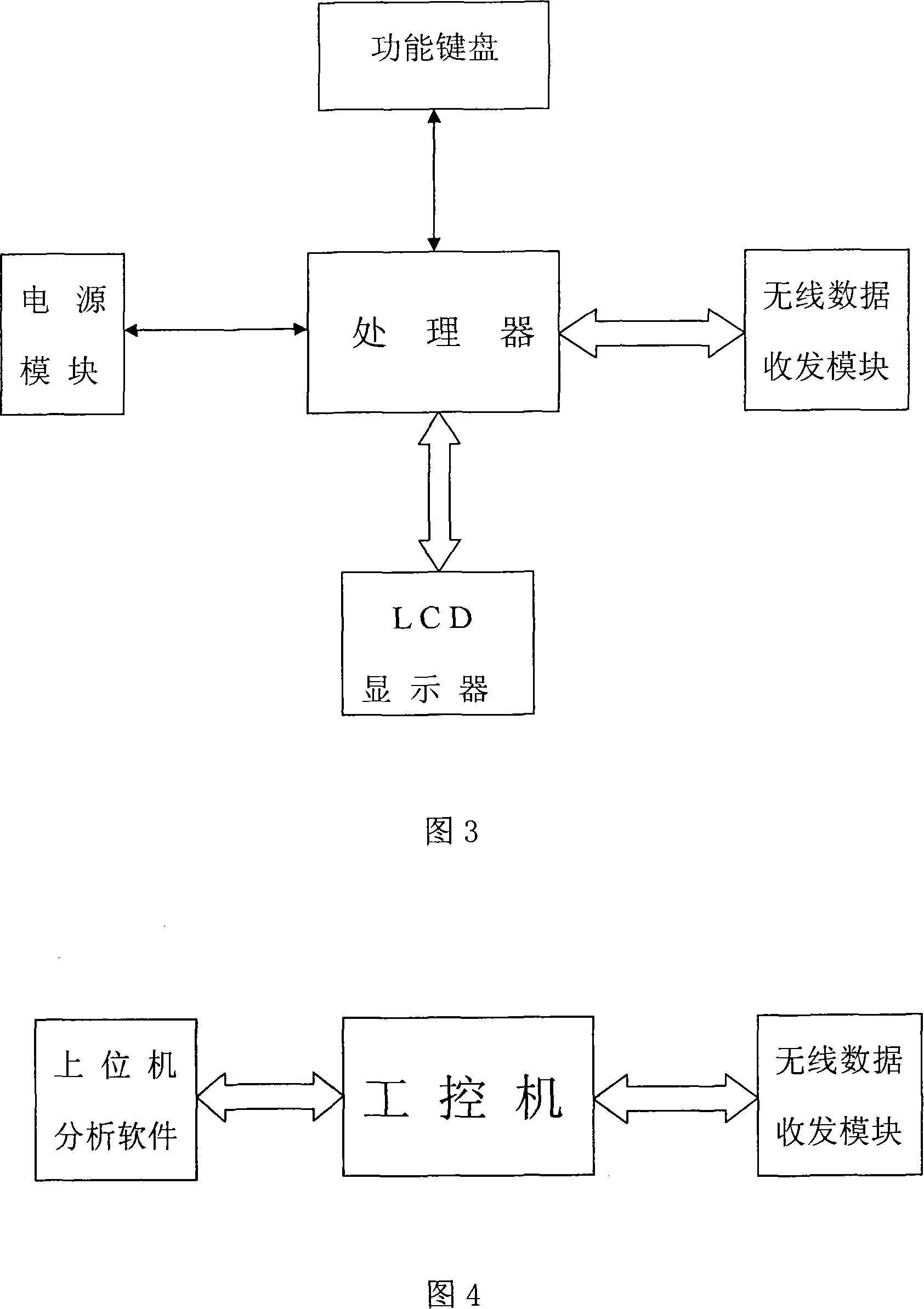

Blowout preventer detecting recording apparatus

InactiveCN101118656ASolve usabilitySolve explosion-proofRegistering/indicating working of machinesRemote controlField data

The present invention relates to a blowout preventer checking record device, which consists of a field data box, a remote control, and an upper computer. The field data box is embedded in the blowout preventer, and is respectively connected with the remote control and the upper computer through wireless communication. The field data box is embedded in the blowout preventer to check the work state of the blowout preventer automatically; the remote control is a hand-hold device communicating with the field data box by wireless when the operator learns the work state of the blowout preventer; the analyzing software of the upper computer and the wireless communication of the field data box read in the history data of the field data box, and analyze the safety state and the service life of the blowout preventer according to the preset requirement. The present invention has strong capacity of resisting disturbance, and can suit the severe condition of industrial locales.

Owner:SHANGHAI GASOLINEEUM & CHEM EQUIP +1

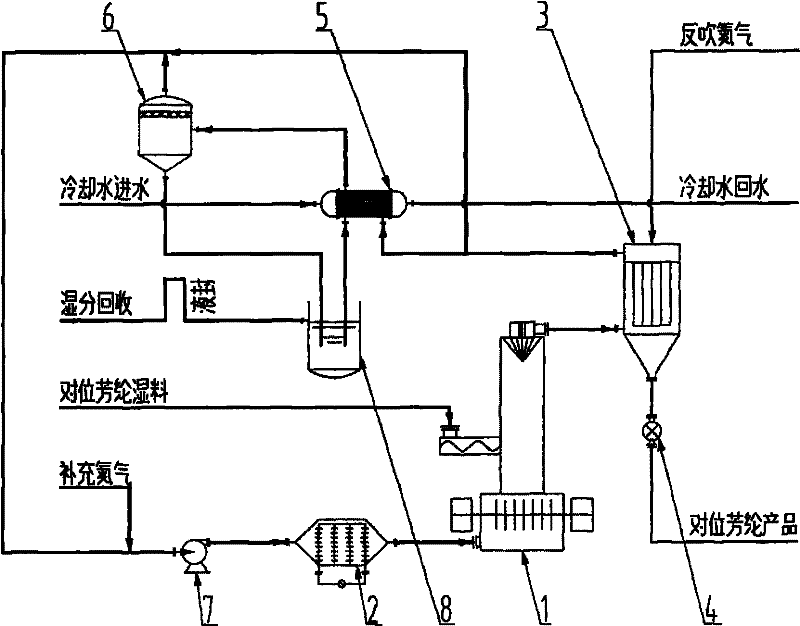

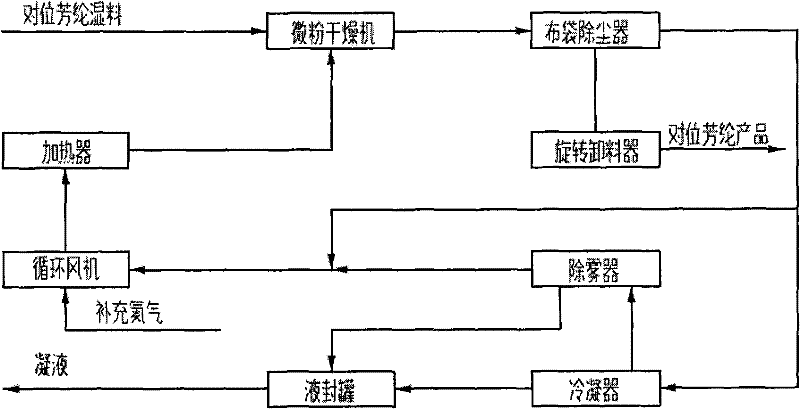

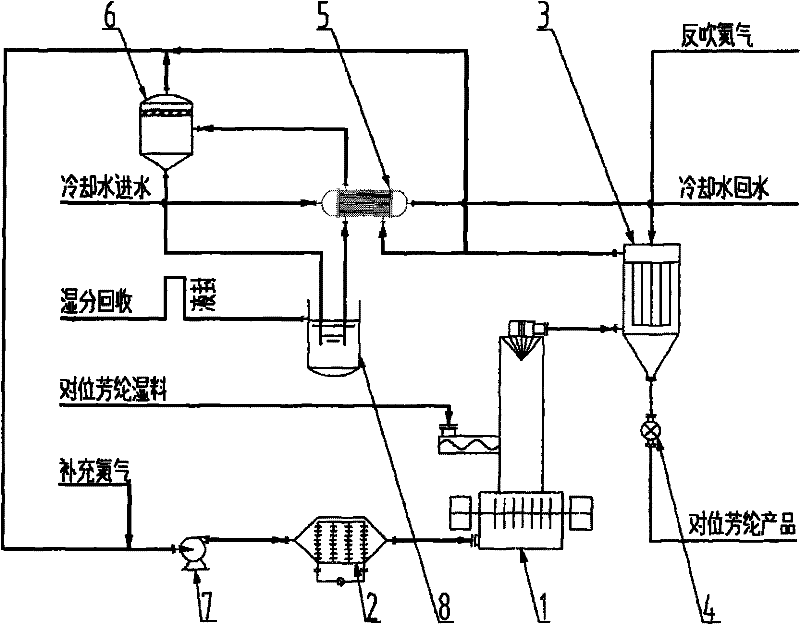

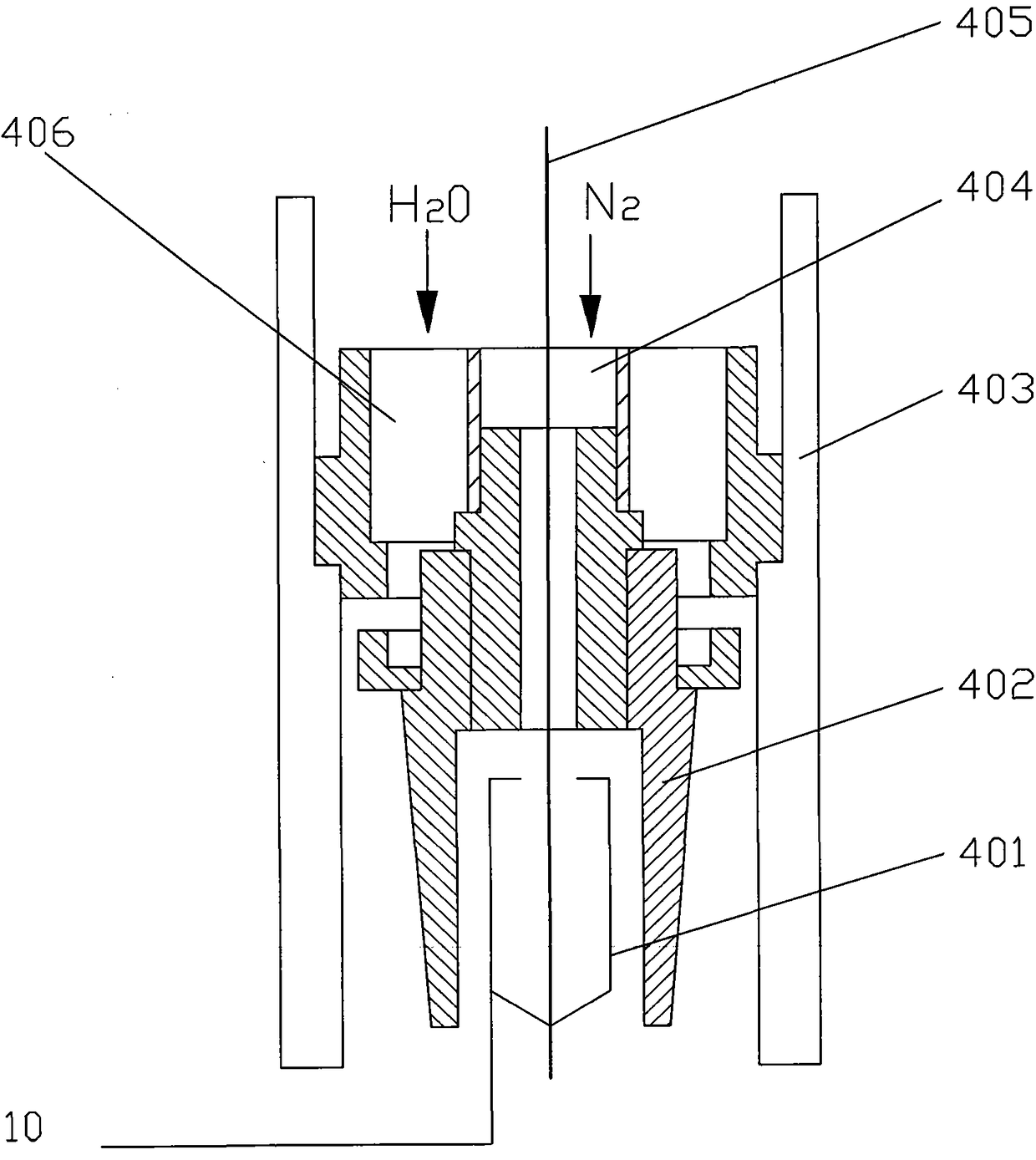

Technique for drying para-aramid micropowder by recycling inert gas

ActiveCN102190796AAvoid uneven particle sizeSolve explosion-proofMonocomponent polyamides artificial filamentBaghouseAramid

The invention relates to a technique for drying para-aramid micropowder by recycling inert gas, which is characterized by comprising steps as follows: wet para-aramid is added into a micropowder drier; after the wet para-aramid is dispersed and crushed, the dispersed para-aramid powder is carried by inert gas into a classificator on the top of the micropowder drier; the para-aramid powder, which passes through the classificator, enters a bag-type dust remover along with the inert gas, and is filtered, and discharged via a rotary discharger; the para-aramid powder, which does not pass through the classificator, returns into the micropowder drier so as to be dispersed and crushed again; part of the inert gas, which is filtered by the bag-type dust remover, enters a condenser and a demister to be dehumidified and demisted, and is mixed with the other part of the inert gas, which is not dehumidified and demisted, for cyclic use; and the moisture generated by the condenser and demister flows into a liquid seal tank respectively via the bottom of the condenser and the bottom of the demister, so as to be recycled. The invention integrates drying, dispersion, crushing and classification, and successfully solves the problem of nonuniform particle size of the dried aramid polymer on the premise of preventing explosion.

Owner:CHINA PETROLEUM & CHEM CORP +2

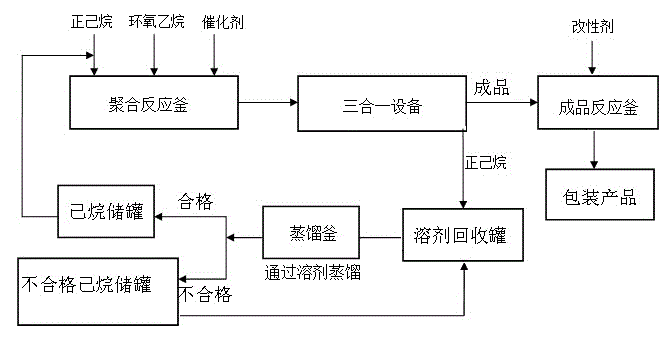

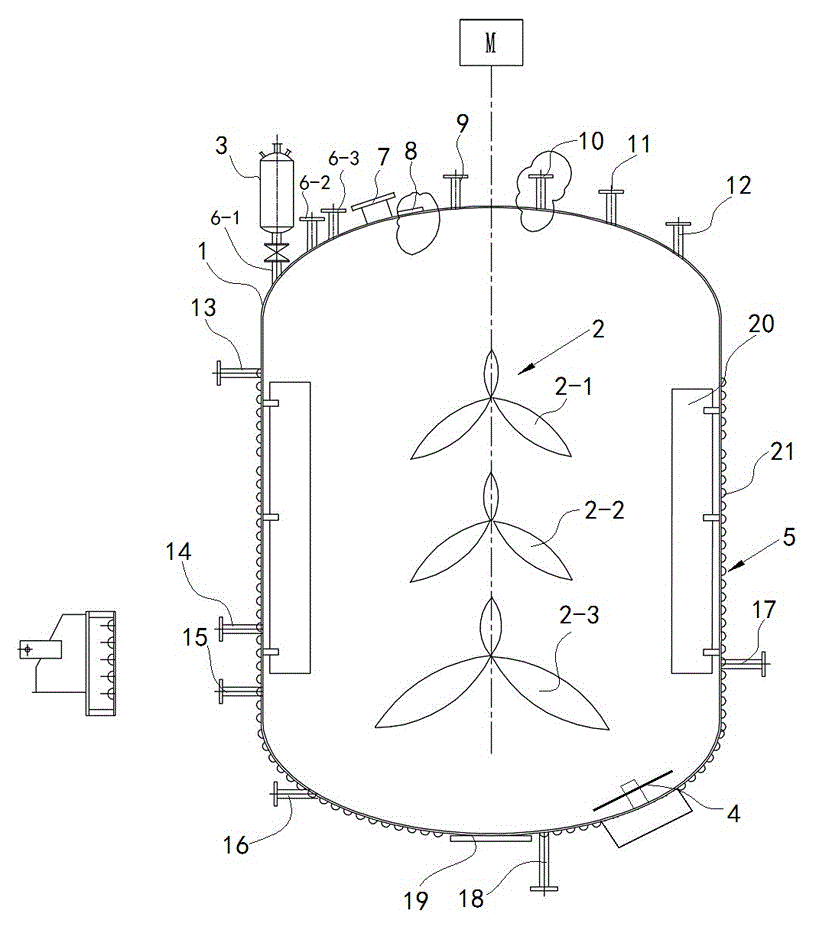

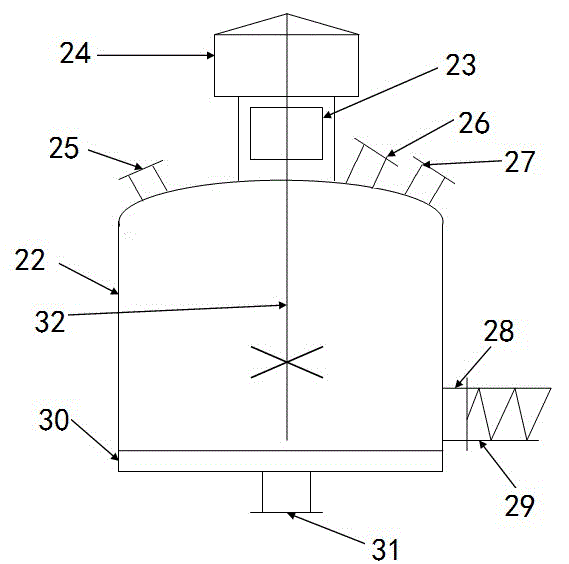

Production equipment for polyoxyethylene products and preparation method thereof

The invention relates to production equipment for polyoxyethylene products and a preparation method thereof. The equipment comprises a polymerization reaction kettle, integrated equipment, a finished product mixing kettle, a solvent recycling tank, a distillation kettle, a hexane storage tank and an unqualified hexane storage tank. The production process of the polyoxyethylene products comprises the steps that ring opening polymerization is performed on ethylene oxidein C6 or C7 solvent through the action of a catalyst, exothermic reaction is performed at a certain temperature and under certain pressure, and the requirements of product specifications are achieved through the growth of polymeric chains; after the reaction is finished, the products are processed through the integrated equipment with the functions of filtering, drying and washing, and then packaging is performed. According to the production equipment for the polyoxyethylene products and the preparation method thereof, the partial implosion phenomenon caused by the reaction is avoided, the volume of the reaction kettle is successfully enlarged to 6000 litres, the production scale of a PEO device is enlarged, and the stability of the product quality is improved; the method solves the problems of solvent dehydrating and solvent recycling and reusing.

Owner:吉化集团吉林市星云化工有限公司

Explosion-proof rocker switch

InactiveCN101345158AThe force is small and uniformExtend your lifeMagnetic/electric field switchesShielding gasMagnetic polarity

The invention provides an anti-explosive rocker switch, consisting of a control rocker, a controlled rocker in a switch core assembly and three terminals. Two ends of the control rocker are provided with control permanent magnets; two ends of the controlled rockers are also provided with controlled permanents and movable contacts respectively; the rocker range of the control rocker is more than the rocker range of the controlled rocker; the magnetic polarity of two permanent magnets at the same side of the control rocker and the controlled rocker are sucking the isomerism correspondingly to the working surface; two rockers are sucked at one pressed end of the control rocker and are separated at the other end thereof; furthermore, one group out of two groups of contacts are turned on and the other group is turned off; the three terminals are respectively connected with corresponding contacts in the switch core assembly and are connected with the external circuits outside the switch core assembly. The switch core assembly is pumped to a vacuum state and where arc distinguish gases or other protection gases are injected and the switch core assembly is sealed, thus protecting the contacts and having the advantages of anti-explosion.

Owner:张大庆

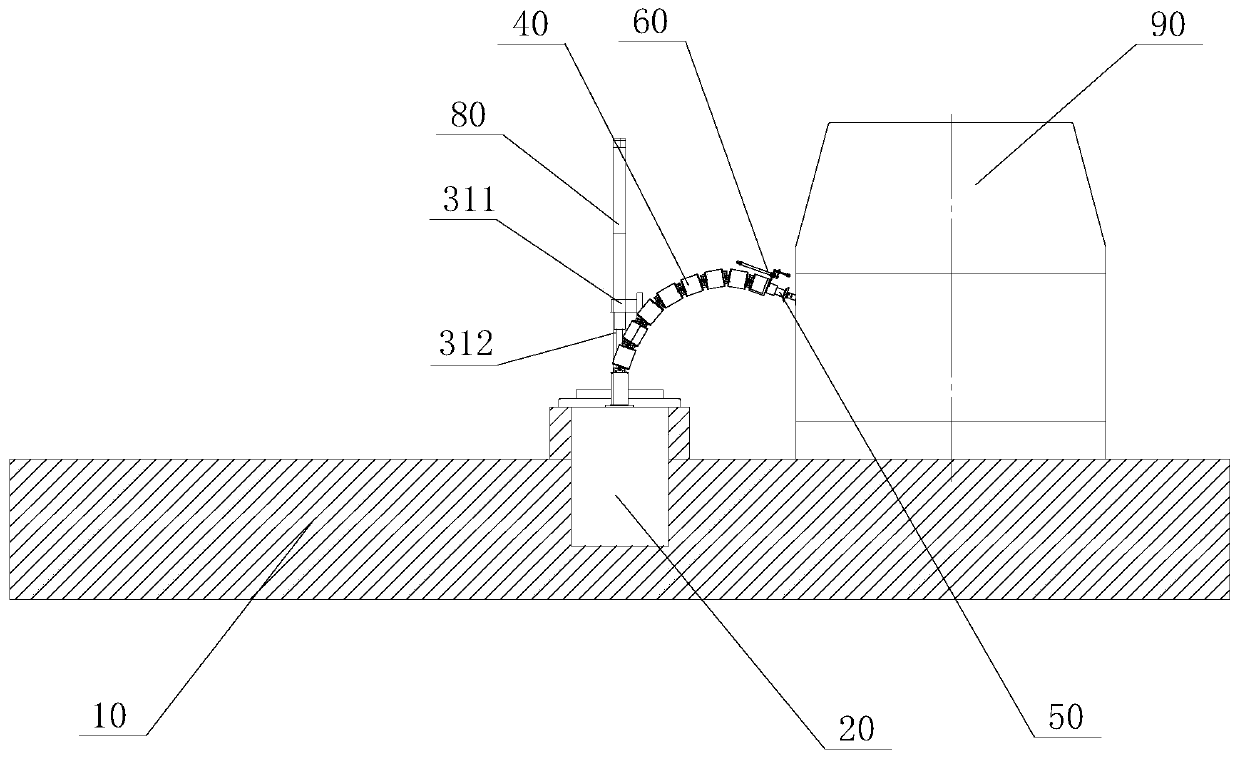

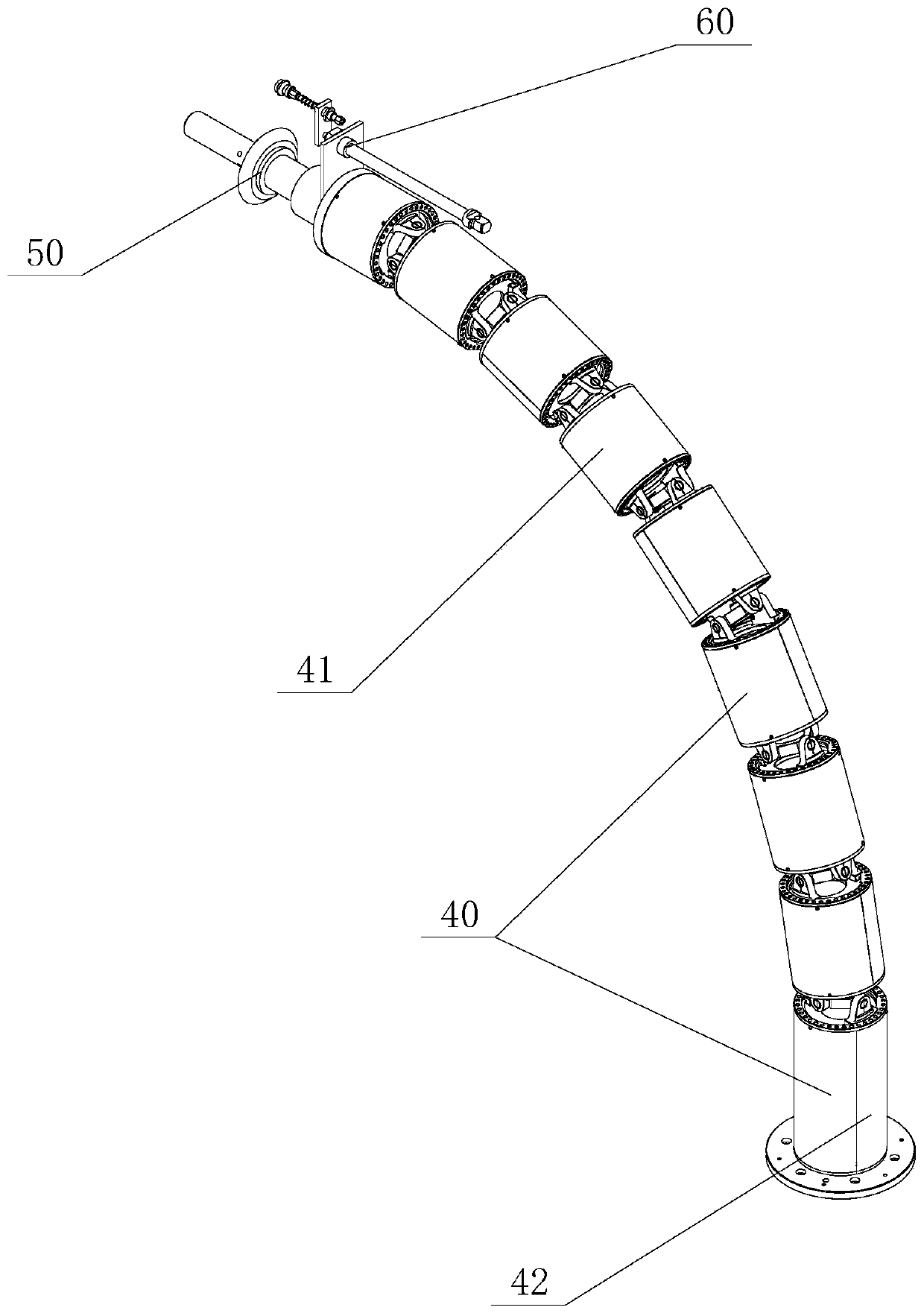

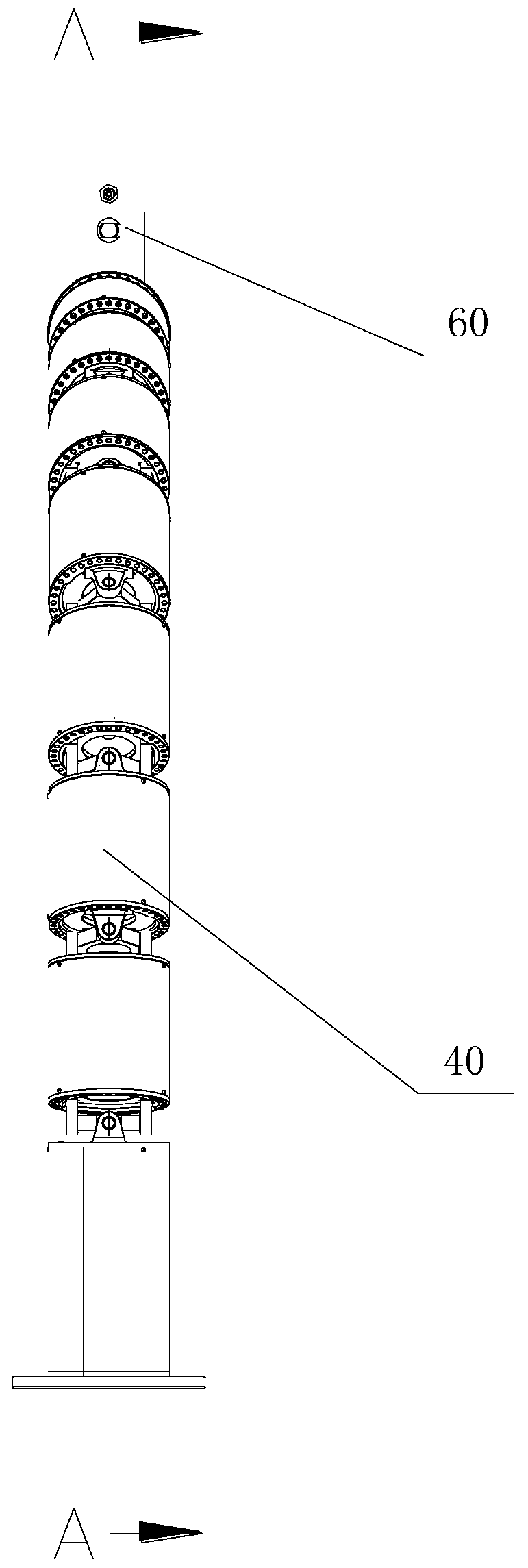

Snake arm refueling robot device and system

PendingCN110329979ASolve explosion-proofSolve the protection problemLiquid transferring devicesSimulationRobot

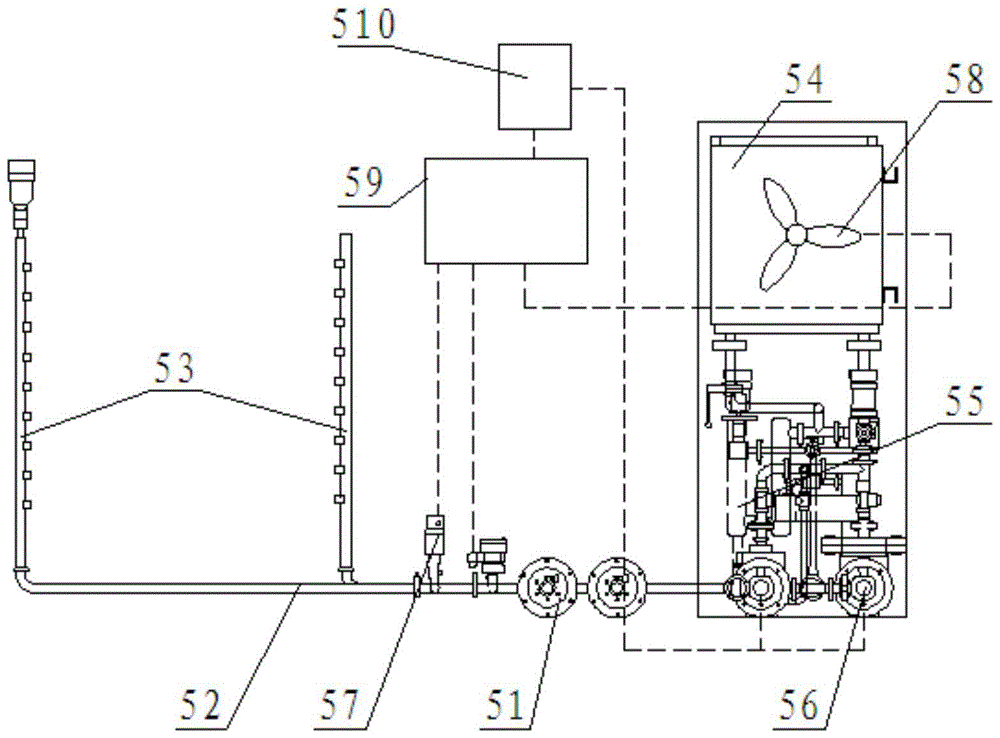

The invention discloses a snake arm refueling robot device and system. The snake arm refueling robot device includes a refueling island, a control driver, a refueling vision device, a snake robot arm,an integrated oil gun and a refueling cover opening and closing device, wherein the refueling island comprises a first embedded cavity; the control driver is installed in the first embedded cavity; the refueling vision device and the snake robot arm are separately arranged at the upper portion of the refueling island; the integrated oil gun and the refueling cover opening and closing device are separately installed at the tail end of the snake robot arm; and the refueling vision device, the snake robot arm, the integrated oil gun and the refueling cover opening and closing device are separately electrically connected with the control driver. The device can achieve automatic refueling and improve the refueling speed, and can meet the requirements of explosion-proof and IP protection level,so that the customer experience is improved well.

Owner:广州市双枪智能科技有限公司

Pichia pastoris fermenting method for improving precursor expression of insulin and analogue thereof

ActiveCN107022591AIncrease profitHigh expressionMicroorganism based processesInsulinsGrowth phasePichia pastoris

The invention relates to the field of biological pharmacy, in particular to a pichia pastoris fermenting method for improving precursor expression of insulin and analogue thereof. The fermenting culture comprises the following stages of an initial growth phase, a glycerin supplementing phase and a methanol inducing phase. The method has the advantages that by controlling a formula of an initial culture medium, and the nitrogen source type and carbon source supplementing type, and continuously or semi-continuously supplementing a small amount of microorganisms or plant-source organic nitrogen sources in the middle and later period of fermenting, the fermenting cycle is extended; while the quality of the target product is guaranteed, the output is increased by not less than 30%.

Owner:YICHANG HEC CHANGJIANG PHARMA CO LTD

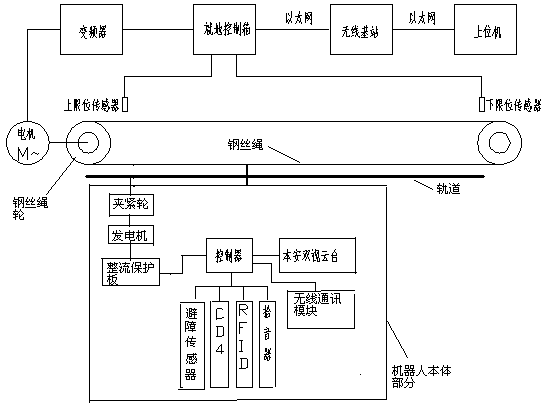

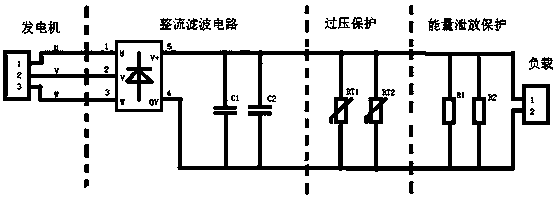

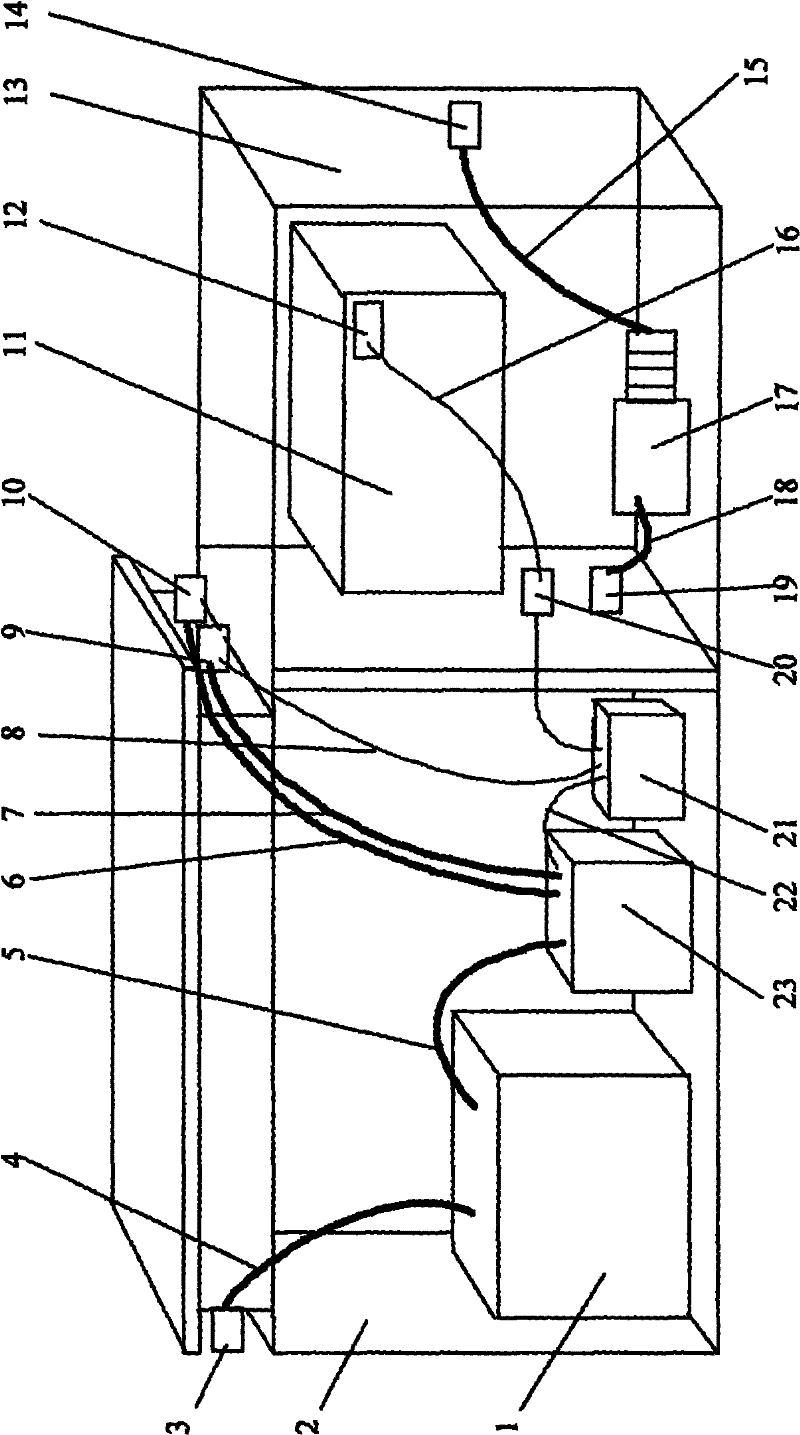

Mining self-power-generation type inspection robot system and control method

PendingCN110989609ASolve explosion-proofSolve the problem of frequent chargingPosition/course control in two dimensionsRobotic systemsIntrinsic safety

The invention discloses a mining self-power-generation type inspection robot system and a control method. The mining self-power-generation type inspection robot system is composed of a drive control part and a robot body, wherein the drive control part comprises an upper computer, a wireless base station, a local control box, a frequency converter, a motor, a steel wire rope, a steel wire rope wheel, a rail, an upper limiting sensor and a lower limiting sensor; and the robot body comprises clamping wheels, a generator, a rectification protection plate, a controller, an intrinsic safety double-vision holder, a wireless communication module, a CD4, a pickup, an obstacle avoidance sensor and an RFID. The robot body is fixedly suspended on the steel wire rope, when the steel wire rope pulls the robot body to move, the robot body generates power by itself and supplies power to circuits and detection instruments in the robot body, the problems that a storage battery is prone to explode and needs to be charged frequently are solved, thus the robot system can work for a long time under a coal mine, and 24-hour unattended continuous operation inspection is achieved.

Owner:CITIC HIC KAICHENG INTELLIGENT EQUIP CO LTD

Scraper one-key reset device

InactiveCN102744963ASimple structureEasy to install and debugPrinting press partsPotentiometerEngineering

The invention discloses a scraper one-key reset device. The device comprises a scraper angle rotating air motor, a scraper lifting air motor, a scraper lifting potentiometer, a scraper angle potentiometer, a worm and gear pair and a reducer, wherein the scraper lifting air motor is connected with a scraper angle adjusting mechanism through the worm and gear pair, the scraper angle adjusting mechanism is connected with the scraper lifting potentiometer, the scraper angle rotating air motor is connected with a scraper angle rotating mechanism through the reducer, and the scraper angle rotating mechanism is connected with the scraper angle potentiometer. The device has the advantages that the device is suitable for various printing machines, by means of an air motor driving, the lifting of a scraper and the adjustment of angles can be achieved, the air motor is utilized to achieve the lifting of the scraper and the adjustment of angles, the anti-explosion problem in a printing unit anti-explosion area is solved consequently, besides, the structure is simple, the device is convenient to install and debug, the performance is stable and reliable, and the usage is convenient.

Owner:SHAANXI BEIREN PRINTING MACHINERY

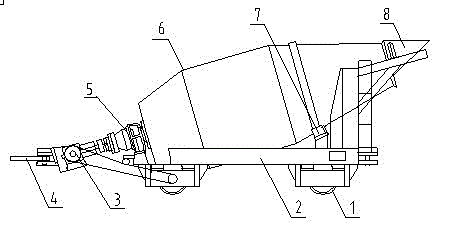

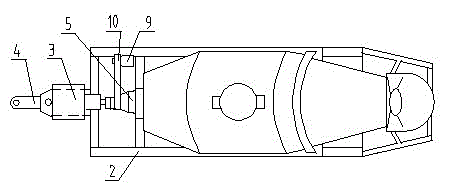

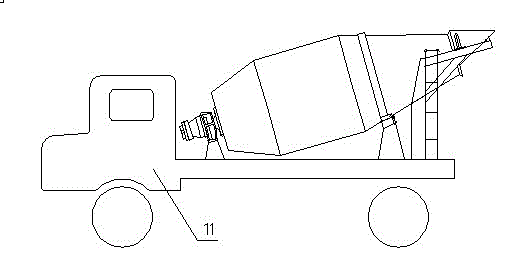

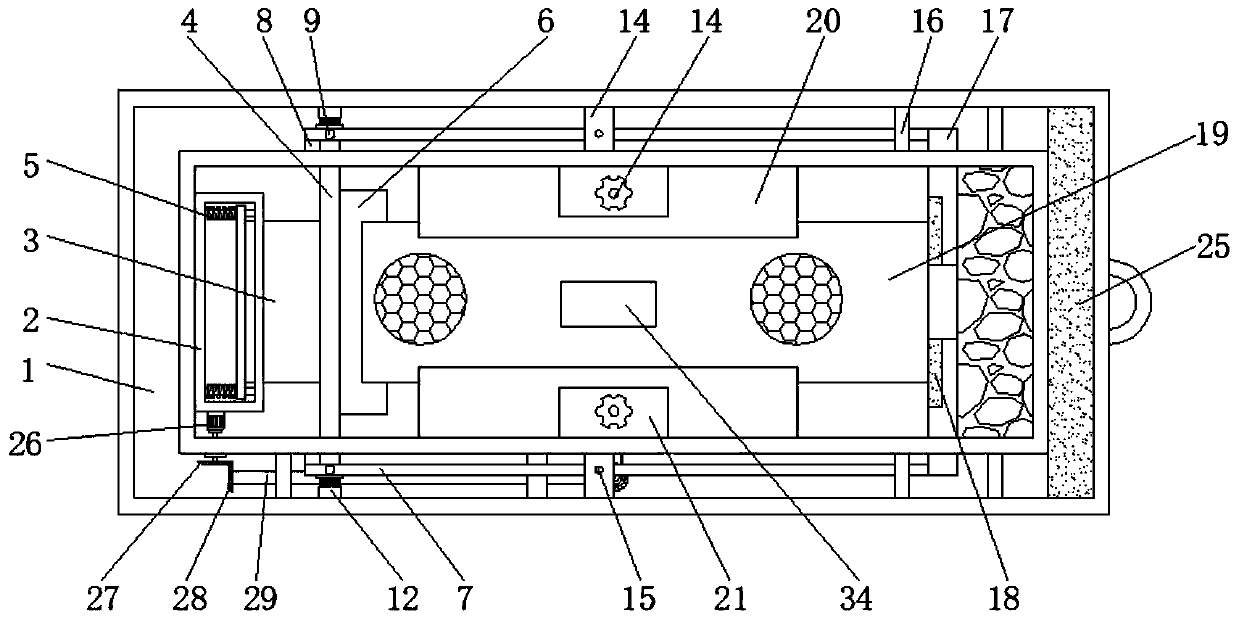

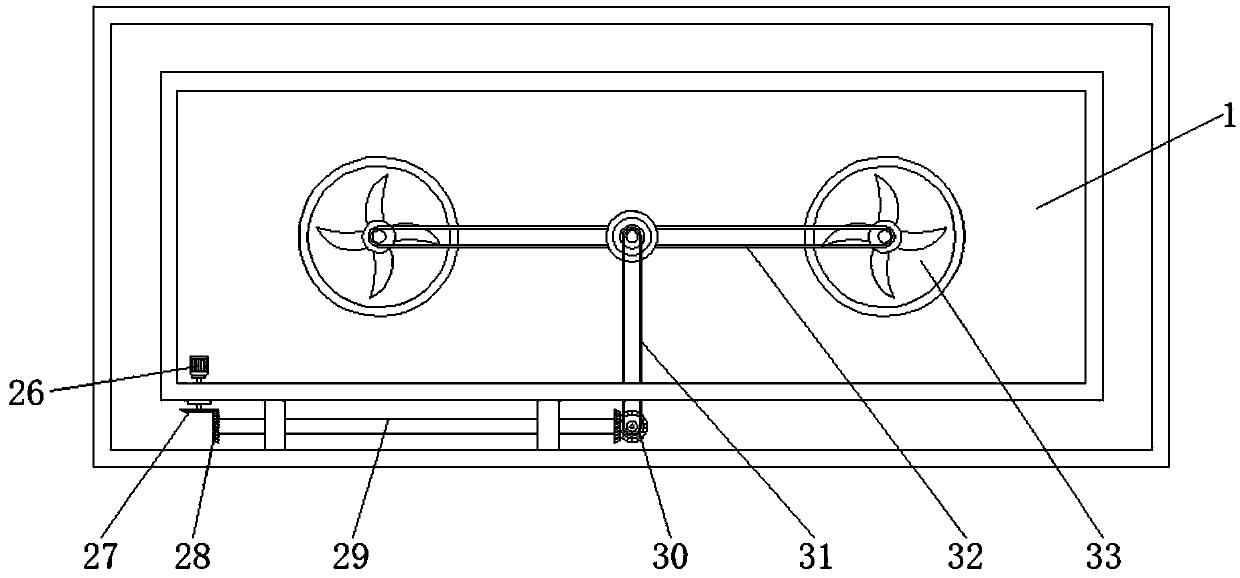

Mining pneumatic stepless speed change concrete agitating conveying vehicle

InactiveCN102745122AImprove energy saving and reduce consumptionGuarantee job securityConcrete transportationVehicle frameDiesel locomotive

The invention discloses a mining pneumatic stepless speed change concrete agitating conveying vehicle. The mining pneumatic stepless speed change concrete agitating conveying vehicle comprises a frame (2), an agitating barrel (6) moveably arranged on the frame and a planetary reducer (5). One end of the agitating barrel (6) is connected with the planetary reducer while the other end of the agitating barrel is provided with a hopper (8). The frame is provided with a pneumatic motor (9) which is connected with the planetary reducer through a belt transmission mechanism (10). The frame is supported on a traveling mechanism (11) or an explosion-proof diesel locomotive (11). The traveling mechanism is driven by an explosion-proof traction locomotive. At first, the mining pneumatic stepless speed change concrete agitating conveying vehicle provided by the invention solves the explosion-proof problem under a shaft; second, the mining pneumatic stepless speed change concrete agitating conveying vehicle provided by the invention realizes stepless speed regulation, realizes rapid discharge by adjusting displacement at the inlet and outlet of a valve body of the pneumatic motor, meets the demand on the quantity of concrete for roadway construction, maintains continuous construction, improves the speed and the efficiency of roadway construction, and shortens the construction period; third, gas source under the shaft is abundant, electricity is replaced by wind power, and the production cost is reduced; and fourth, the mining pneumatic stepless speed change concrete agitating conveying vehicle provided by the invention can meet demands of construction of various mining roadways in the aspect of conveying way, and expands the application of the product.

Owner:JIANGXI SITONG HEAVY IND MACHINERY

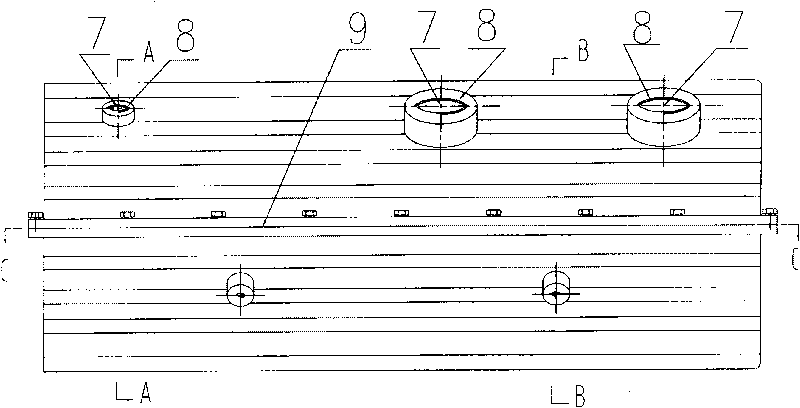

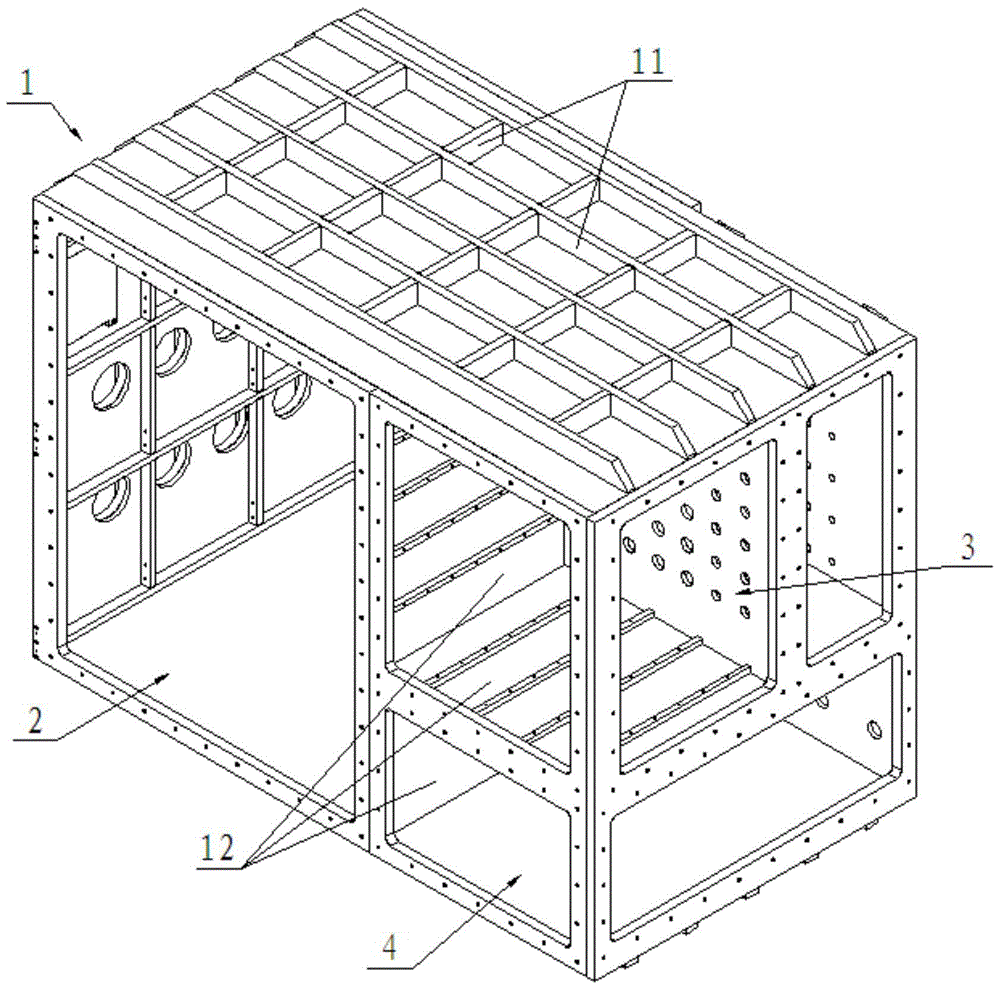

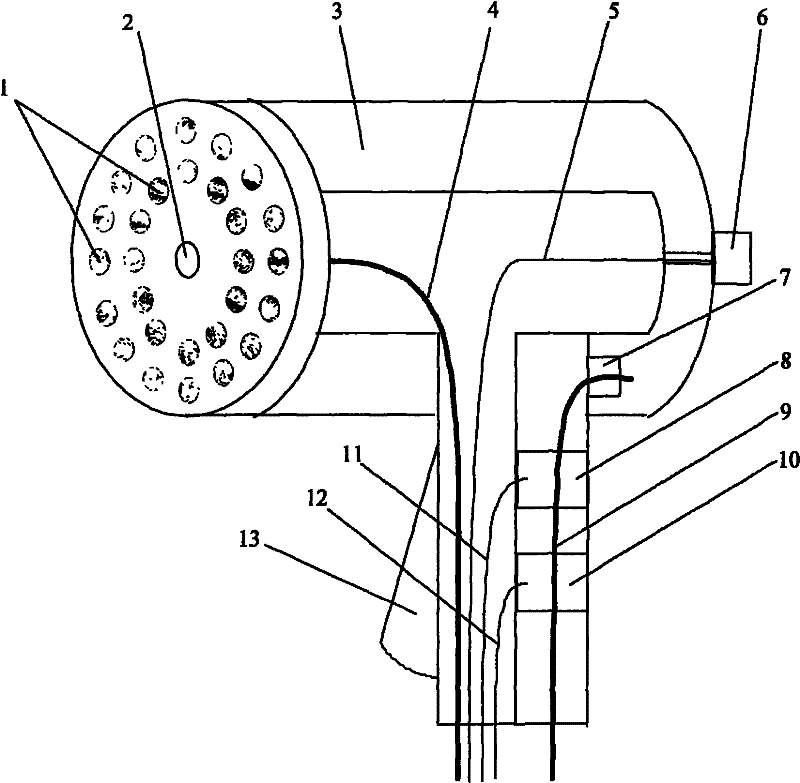

Transducer body for mines

ActiveCN101702570ASolve explosion-proof and heat dissipationReduce volumeCircuit arrangements on support structuresElectrical apparatus casings/cabinets/drawersPower componentInternal cavity

The invention relates to a transducer body for mines, which mainly solves the technical problems that the traditional anti-explosion transducer has poor heating dispatching effect and overlarge size. In the invention, an upper half shell (1) and a lower half shell (2) are fixedly connected in a sealing match into a cylindrical shell with two sealed ends; both cavities of the upper half shell (1) and the lower half shell (2) are in the shape of a half slot with end plates on the two ends; an explosion-suppression joint (9) is arranged between the connecting surfaces of the upper half shell (1) and the lower half shell (2); a connection cable through hole (7) is arranged on the wall of the upper half shell (1) or the lower half shell (2); and a through hole explosion-suppression joint (8) is arranged in the connection cable through hole (7). By adopting a runner design, a power component of a transducer is installed on the inner wall of the transducer body; easy heat-transmission and high-strength material is made into a cylindrical explosion-suppression body and the external diameter of the explosion-suppression body fits that of a muffling inner cylinder of a matched ventilator, which does not influence the ventilation of a runner; and the transducer body has small size and good heat dissipation effect and is mainly applied to all transducers.

Owner:PINGAN ELECTRICAL

A Pichia fermentation method for improving the expression of insulin and its analogue precursors

ActiveCN107022591BIncrease profitHigh expressionMicroorganism based processesInsulinsGrowth phasePichia pastoris

The invention relates to the field of biological pharmacy, in particular to a pichia pastoris fermenting method for improving precursor expression of insulin and analogue thereof. The fermenting culture comprises the following stages of an initial growth phase, a glycerin supplementing phase and a methanol inducing phase. The method has the advantages that by controlling a formula of an initial culture medium, and the nitrogen source type and carbon source supplementing type, and continuously or semi-continuously supplementing a small amount of microorganisms or plant-source organic nitrogen sources in the middle and later period of fermenting, the fermenting cycle is extended; while the quality of the target product is guaranteed, the output is increased by not less than 30%.

Owner:YICHANG HEC CHANGJIANG PHARMA CO LTD

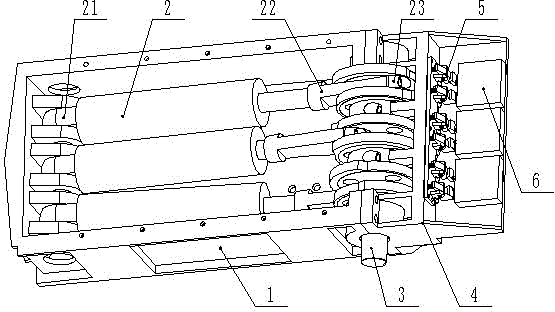

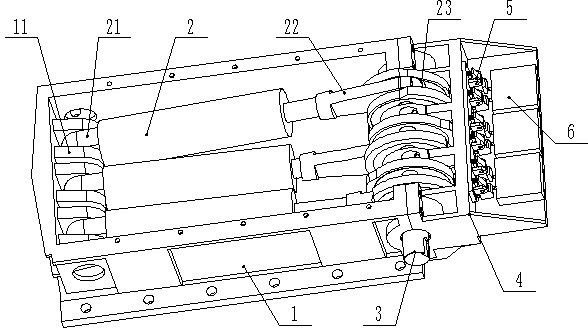

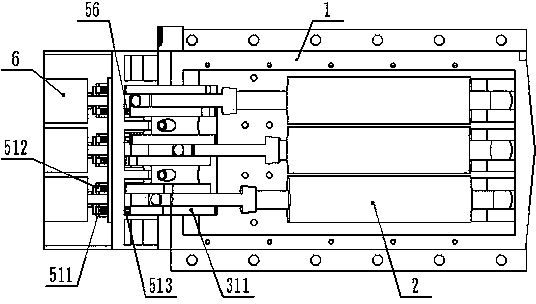

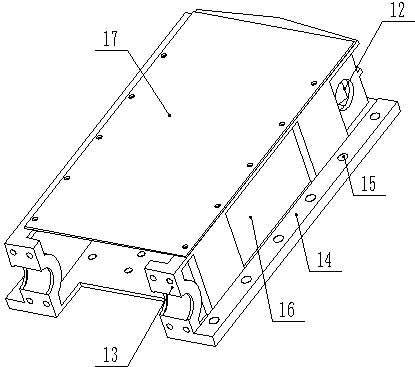

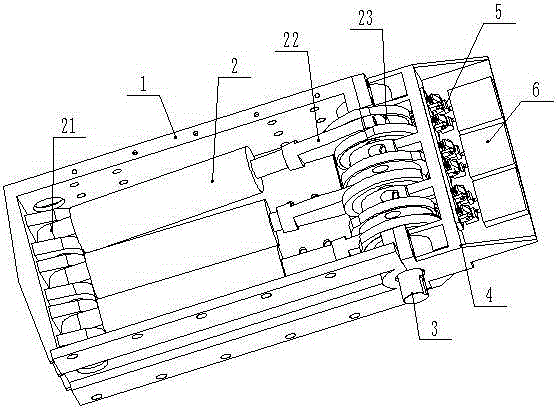

Horizontal hydraulic cylinder type motor

InactiveCN104141587AReduce speedReduce output torque rippleCrankshaftsReciprocating piston enginesHydraulic motorHydraulic cylinder

The invention belongs to the field of mining hydraulic motors, and particularly discloses a horizontal hydraulic cylinder type motor. The horizontal hydraulic cylinder type motor aims to achieve the technical purposes that the structure is simple, operation is convenient, safety coefficients are high, service life is long, and the underground coal mine accident rate can be effectively reduced. The horizontal hydraulic cylinder type motor comprises a box, three hydraulic cylinders, a crankshaft, a box front end assembly and a control system. An installing seat board is arranged at the bottom of the box, the hydraulic cylinders are arranged in the box side by side, the ends of pistons of the hydraulic cylinders are connected with the crankshaft through piston end covers, the output end of the crankshaft and the installing seat board are arranged on the same side, the hydraulic cylinders move in a reciprocating mode to drive the crankshaft to rotate, the crankshaft drives the control system to move, the control system controls reciprocating motion of the three hydraulic cylinders to drive the crankshaft to conduct continuous rotational motion, the hydraulic cylinders drive the crankshaft to rotate, the rotating speed is low, torque is large, and the horizontal hydraulic cylinder type motor meets the requirements for use of underground coal mine equipment.

Owner:长治市永华机械有限公司

Anti-explosive method of electric welder

InactiveCN101733531ASolve explosion-proofEnsure safetyElectrode supporting devicesWelding accessoriesElectrical devicesHigh pressure water

The invention relates to an anti-explosive method of an electric welder, which is suitable for welding large machinery equipment on working surfaces in coal mine underground excavation. The electric welder, a contactor and other electrical equipment are arranged in an explosion-isolation outer casing to isolate explosion, a high-pressure water pump and a water tank are arranged in an outer casing without explosion isolation, and a protection control circuit is arranged in the explosion-isolation outer casing. The protection control circuit comprises the gas locking protection of anti-explosive electric welding handle clippers, flow locking protection, water pressure locking protection and electric welder over-current protection. The ends of the anti-explosive electric welding holder clippers are provided with clamping mechanisms for clamping electrodes, and are also provided with a plurality of spray nozzles. During welding, a high-pressure water curtain is sprayed out of the spray nozzles, and the arc light generated by electric welding is sealed by the water curtain.

Owner:双鸭山金德工贸有限责任公司

New energy battery explosion-proof protection box

InactiveCN109599515AAvoid explosionSolve explosion-proofSecondary cellsCell component detailsNew energyEngineering

The invention relates to the technical field of battery protection and discloses a new energy battery explosion-proof protection box, comprising a mounting box; a damping sleeve is fixedly connected to the side face of an inner cavity of the mounting box, a damping rod is movably connected to the side face of the damping sleeve in a sleeved mode, a damping block is fixedly connected to the side face of the damping rod, one end of the damping rod that penetrates and extends to the inner cavity of the damping sleeve is in transmission connection with the side face of the inner cavity of the damping sleeve through a damping spring, a fixed sleeve is fixedly connected to the side face of the damping block, and a movable rod is movably connected to one end, which penetrates and extends to the inner cavity of the side wall of the mounting box, of the damping block. According to the new energy battery explosion-proof protection box, an early warning device is connected with the mounting box so that it is ensured that when the new energy battery explosion-proof protection box is in use and the new energy battery is in an expanded state, early warning can be carried out in time, thereby avoiding explosion caused by continuous expansion of the new energy battery and solving the battery explosion-proof problem.

Owner:蔡洁葵

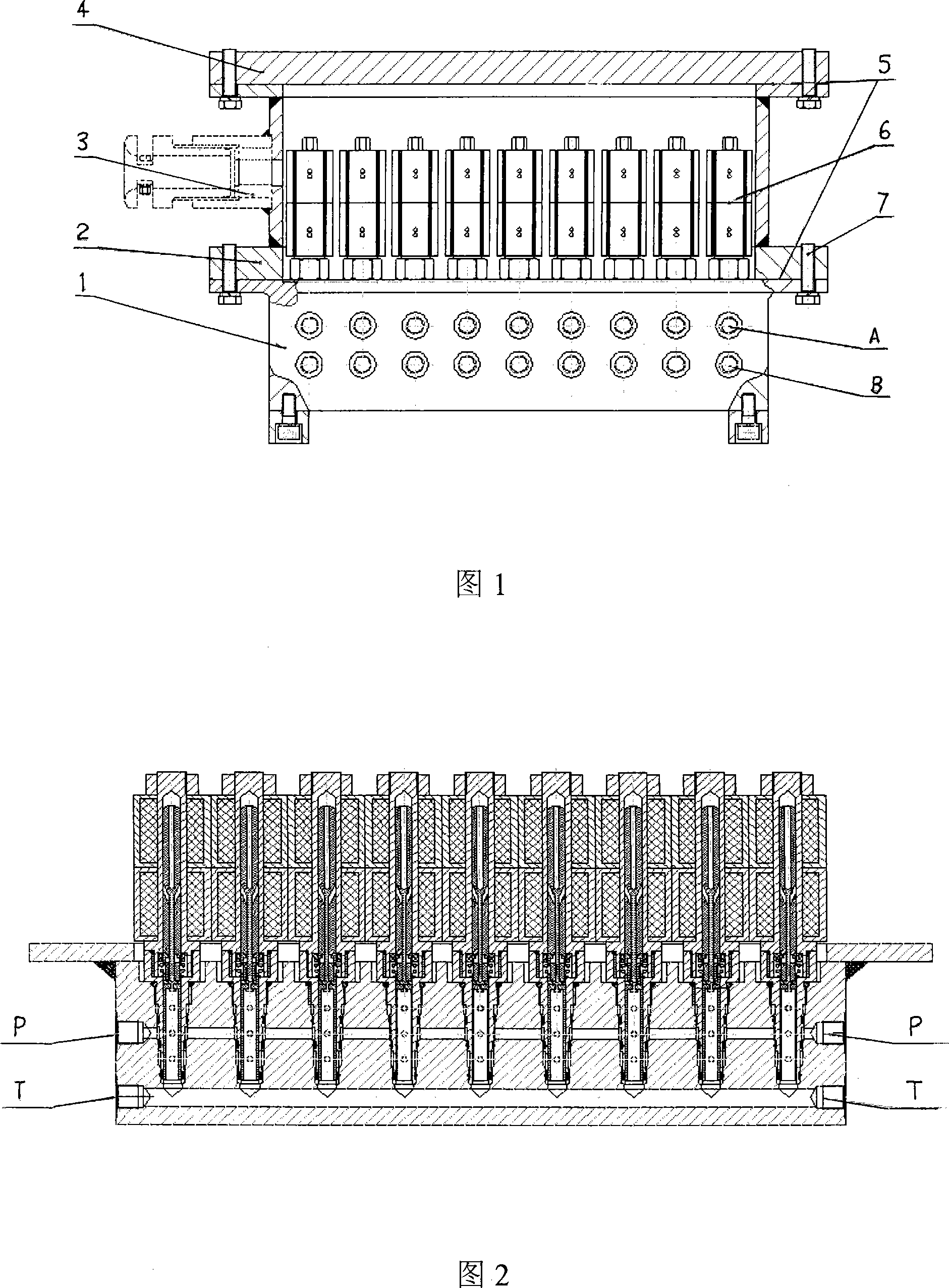

Plug-in explosion-proof hydraulic valve set

InactiveCN101144492AWith flameproof functionReduce volumeServomotor componentsSolenoid valveElectromagnetism

An inserting type explosion-proof hydraulic valve group is disclosed. The invention comprises a valve body and a thread inserting electromagnetism reversing valve, and the invention is characterized in that a casing body is arranged on the valve body, a valve is arranged in the casing body, a cover is added; and an upper cover, the casing body, and the valve body are tightly fixed into a hexahedron through bolts; a plurality of installing holes of a solenoid valve are arranged on the upper surface of the valve body, and an oil inlet opening P and an oil return opening T communicated with the installing holes and hydraulic pressure oil holes A and B communicated with the controlled hydraulic mechanism are arranged in the valve body; the rectangular installing surface of the valve body, the casing body, and the upper cover edge and the leading wire mouth are respectively processed according to the explosion isolation standards. The combination surface of the upper cover and the valve body of the invention is processed according to the flatness and smoothness of the explosion isolation standards, the invention solves the explosion-proof problem, and the advantage of the inserting type solenoid valve is contained, compared with the plate type valve, the flow is greatly enhanced without leakage, the reliability of the hydraulic system is greatly enhanced, the installing space is obviously saved, and the cost is remarkably reduced.

Owner:SHENYANG MINING MACHINERY GROUP

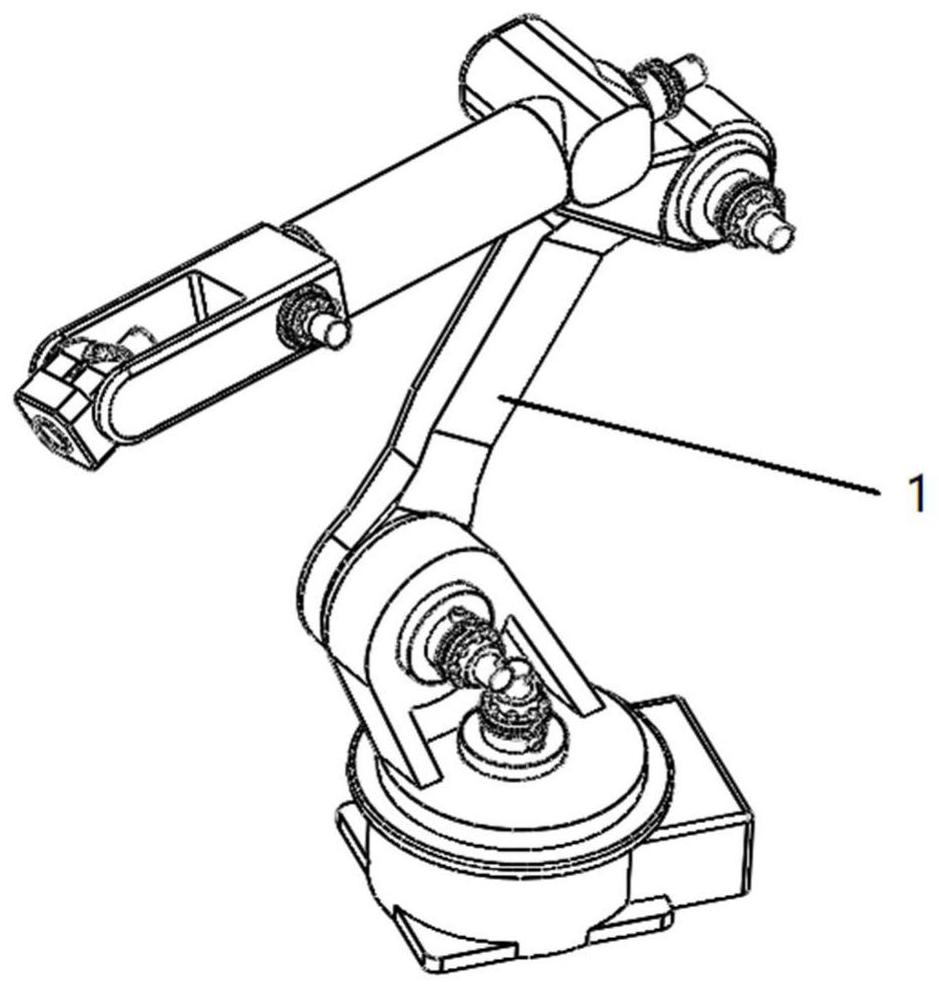

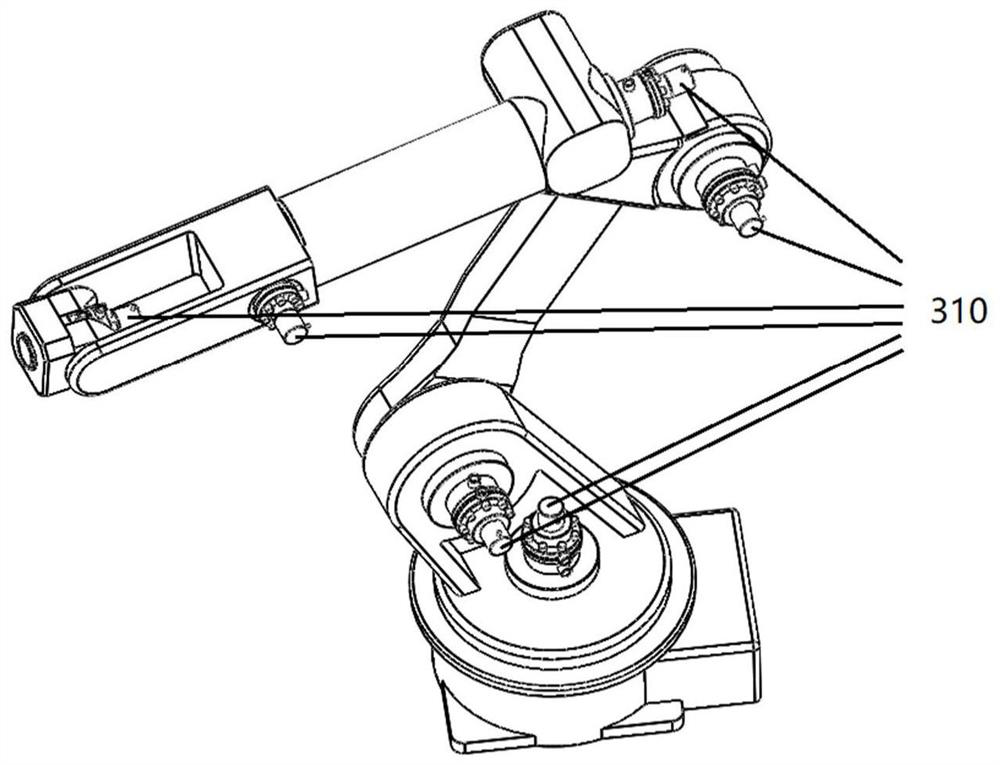

Digital-analog hybrid valve-controlled hydraulic robot system

ActiveCN113021318AMeet explosion-proof design requirementsEnables digital-analog hybrid controlProgramme-controlled manipulatorLiquid transferring devicesHydraulic cylinderControl system

The invention discloses a digital-analog hybrid valve-controlled hydraulic robot system. The digital-analog hybrid valve-controlled hydraulic robot system comprises a robot mechanical body, a power system and a sensor detection and control system; the robot mechanical body comprises a robot base, a robot waist part, a first joint hydraulic cylinder, a second joint hydraulic cylinder, a robot large arm part, a robot middle arm part, a third joint hydraulic cylinder, a fourth joint hydraulic cylinder, a robot small arm part, a fifth joint hydraulic cylinder, a robot wrist part, a sixth joint hydraulic cylinder and a robot tail end flange part; the power system is used for providing a power source for the robot mechanical body; and the sensor detection and control system is used for detecting the rotating angles of the six hydraulic cylinders correspondingly and controlling the six hydraulic cylinders to act correspondingly. According to the digital-analog hybrid valve-controlled hydraulic robot system, a hydraulic swing cylinder is adopted as an execution element for rotation of all joints of a six-degree-of-freedom mechanical arm, hybrid control over the rotating hydraulic cylinders is conducted through an electro-hydraulic servo valve and a high-speed switch valve at the same time, and high-precision control over the robot hydraulic system is achieved.

Owner:XI AN JIAOTONG UNIV

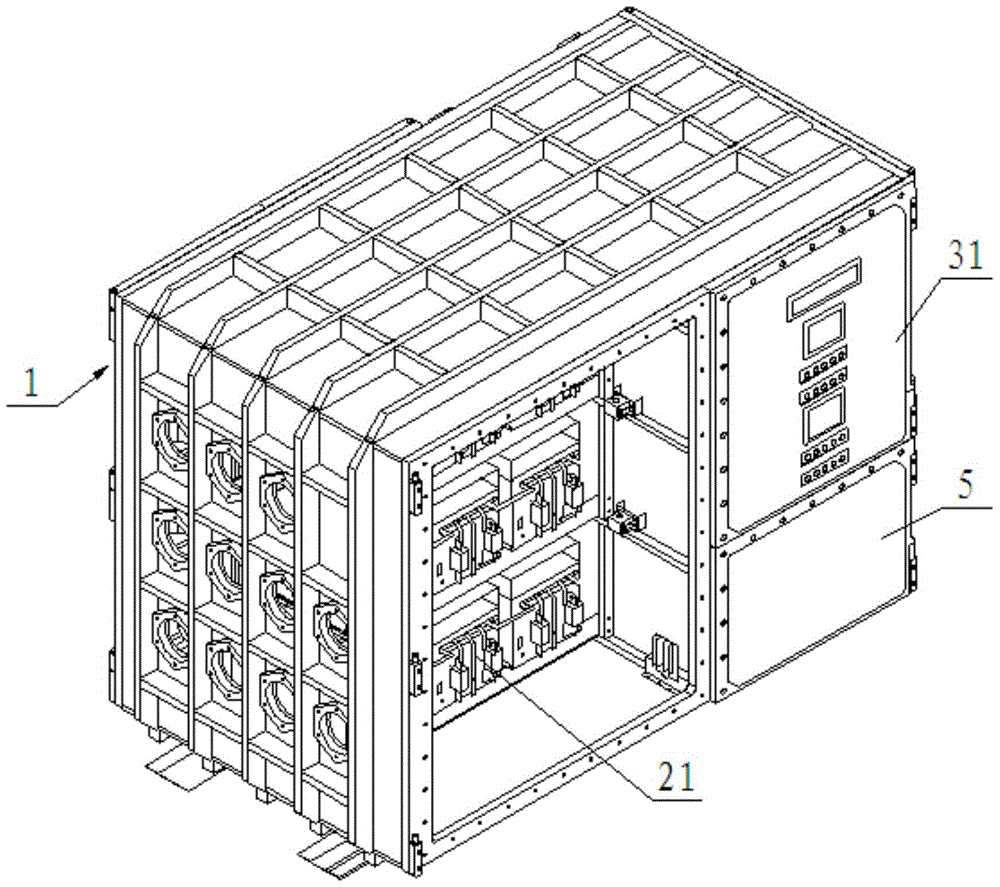

A mine-used voltage-type high-voltage explosion-proof frequency converter

ActiveCN104124856BSolve explosion-proofReduce volumeCooling/ventilation/heating modificationsPower conversion systemsEngineeringHigh pressure

Owner:武汉合智数字能源技术有限公司

Explosion-proof aluminum ash harmless disposal method

InactiveCN111420968AEasy to buyReduce processing costsSolid waste disposalAluminium powderExhaust fumes

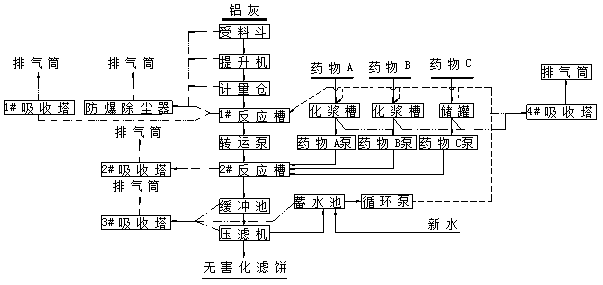

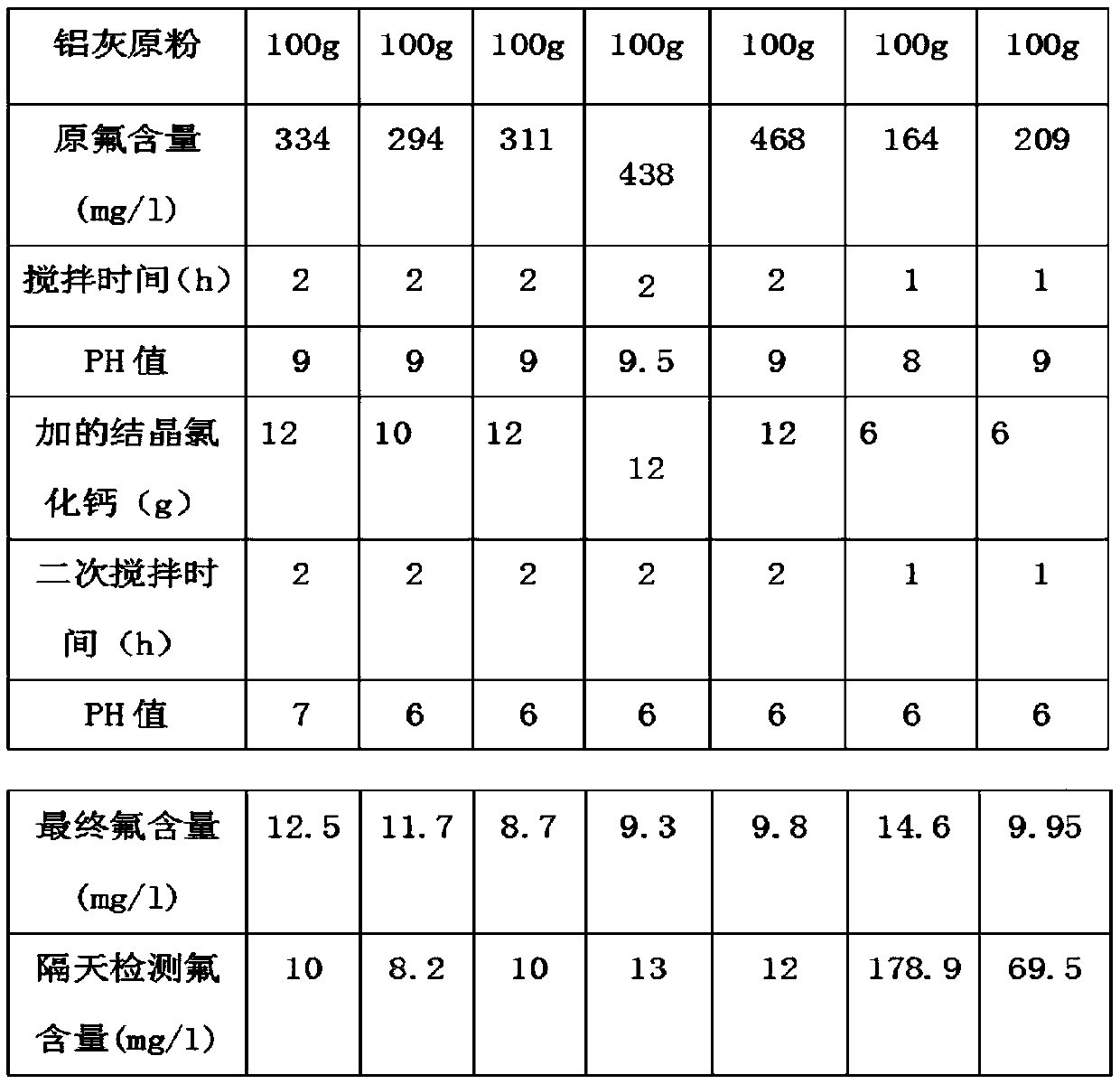

The invention discloses an explosion-proof aluminum ash harmless disposal method. The method comprises the following steps of: carrying out the first reaction to remove fluorine by aluminum ash powder, adding material and water for mixed pulping, discharging after fluoride detection is qualified, and adding drug B for the second reaction to remove ammonia, adding drug C to adjust pH, filter pressing and dewatering, and returning filtrate to a reservoir for recycling. The method not only separates the solid-liquid aluminum powder slurry, but also effectively solves the explosion-proof problemsof ammonia and hydrogen, etc.; in short, the explosion-proof aluminum ash harmless disposal method reacts at a room temperature without heating by a heat source, and the drug is easy to purchase, theprocessing cost is low, the explosive gas hydrogen released in the reaction is specially treated, and the method steps are safe and reliable.

Owner:河南绿泽环保科技有限公司

Composite material for fitness yoga balls and preparation method thereof

The invention provides a composite material for fitness yoga balls and a preparation method thereof. The composite material for the fitness yoga balls is prepared from the following components in parts by weight: 50 parts of pasty PVC resin powder, 15-30 parts of a thermoplastic polyurethane elastomer (TPU), 30-50 parts of a plasticizer, 1-3 parts of a stabilizer, 1-3 parts of a viscosity reducer,2-10 parts of a moderate and high temperature thermal expansion microballoon and 5-10 parts of pigment. According to the composite material for fitness yoga balls and the preparation method thereof,through a TPU and pasty PVC alloying technology, the hardness of a formula product can be reduced, and the elasticity of the yoga balls is improved. The expandable microballoon is added, the dosage ofthe pasty PVC resin powder can be obviously reduced, meanwhile, the dosage of the plasticizer is further obviously reduced, the thickness of a ball body can be kept invariable or increased, the ballbody surface of the prepared fitness yoga balls is fine and smooth, bumps with uniformly distribution are formed in the surface, as the fitness yoga balls have higher buffering performance, when the fitness yoga balls touch sharp objects accidently, the yoga balls are in a slow staleness process, potential safety hazards do not exist, and the problem of explosion proofing is solved.

Owner:CRERAX SCI & TECH CO LTD

An explosion-proof method for an electric welding machine

ActiveCN104439630BSolve the explosion-proof problemSolve explosion-proofWelding protection meansWelding power supplyHigh pressure water

Owner:浙江星火机电厂

Anti-explosive method of electric welder

InactiveCN101733531BSolve explosion-proofEnsure safetyElectrode supporting devicesWelding accessoriesStructural engineeringHigh pressure water

The invention relates to an anti-explosive method of an electric welder, which is suitable for welding large machinery equipment on working surfaces in coal mine underground excavation. The electric welder, a contactor and other electrical equipment are arranged in an explosion-isolation outer casing to isolate explosion, a high-pressure water pump and a water tank are arranged in an outer casingwithout explosion isolation, and a protection control circuit is arranged in the explosion-isolation outer casing. The protection control circuit comprises the gas locking protection of anti-explosive electric welding handle clippers, flow locking protection, water pressure locking protection and electric welder over-current protection. The ends of the anti-explosive electric welding holder clippers are provided with clamping mechanisms for clamping electrodes, and are also provided with a plurality of spray nozzles. During welding, a high-pressure water curtain is sprayed out of the spray nozzles, and the arc light generated by electric welding is sealed by the water curtain.

Owner:双鸭山金德工贸有限责任公司

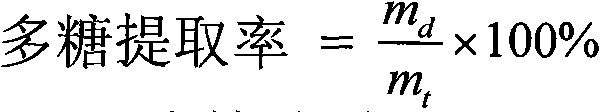

Pretreatment method for extracting plant effective components

InactiveCN101530435BAvoid Attenuating AbsorptionAlter and disrupt organizational structurePlant ingredientsPretreatment methodOrganosolv

The invention relates to a pretreatment method for extracting plant effective components. Before extraction, wet basis plant materials are radiated by vacuum microwaves first, and then mechanical extrusion force and shearing force are repeatedly applied to plant materials after the radiation by vacuum microwaves by a screw extruder. After the pretreatment, the plant effective components of the plant materials are extracted subsequently according to a conventional method so that the extraction of the plant effective components has higher yield. The method also has the advantages of high microwave utilization rate, no damage to target effective components, short processing time and low energy consumption, can avoid an explosion accident of an organic solvent because the organic solvent is not used in the pretreatment of plants, and is suitable to be applied to industrial production.

Owner:JIANGNAN UNIV

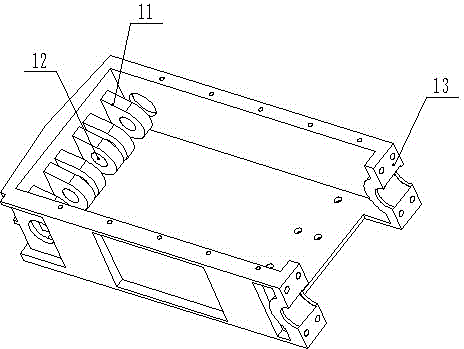

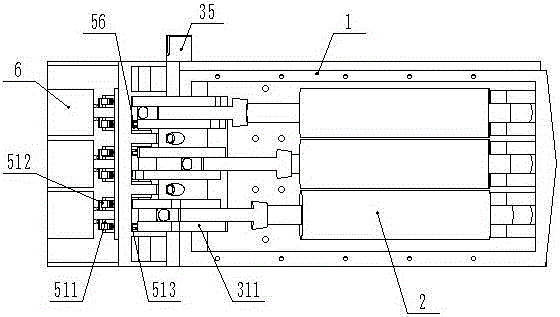

Travel type hydraulic cylinder motor

ActiveCN104088750BReduce speedReduce output torque rippleReciprocating piston enginesHydraulic motorHydraulic cylinder

The invention belongs to the field of mining hydraulic motors, particularly discloses a walking type hydraulic cylinder motor. The hydraulic cylinder motor with equal distributed angles is simple in structure, convenient to operate, high in safety coefficient, long in service life, is capable of effectively reducing the accident rate under a coal mine. The hydraulic cylinder motor comprises a box body, three hydraulic cylinders, a crank shaft, a box body front end component and a control system, wherein an installing plate fixed together with a tractor is arranged at one side of the box body; the hydraulic cylinders are arranged in the box body side by side; the hydraulic cylinders do reciprocating motion to drive the crankshaft to do rotating motion and the crankshaft drives the control system to move; the control system is used for controlling the three hydraulic cylinders to do reciprocating motion so as to drive the crankshaft to do continuous rotating motion; the hydraulic cylinders drives the crankshaft to rotate and can be used as left and right input devices of the tractor and a crane so as to drive the tractor and the crane to move simultaneously.

Owner:JIANGSU DUKE NEW ENERGY AUTOMOBILE

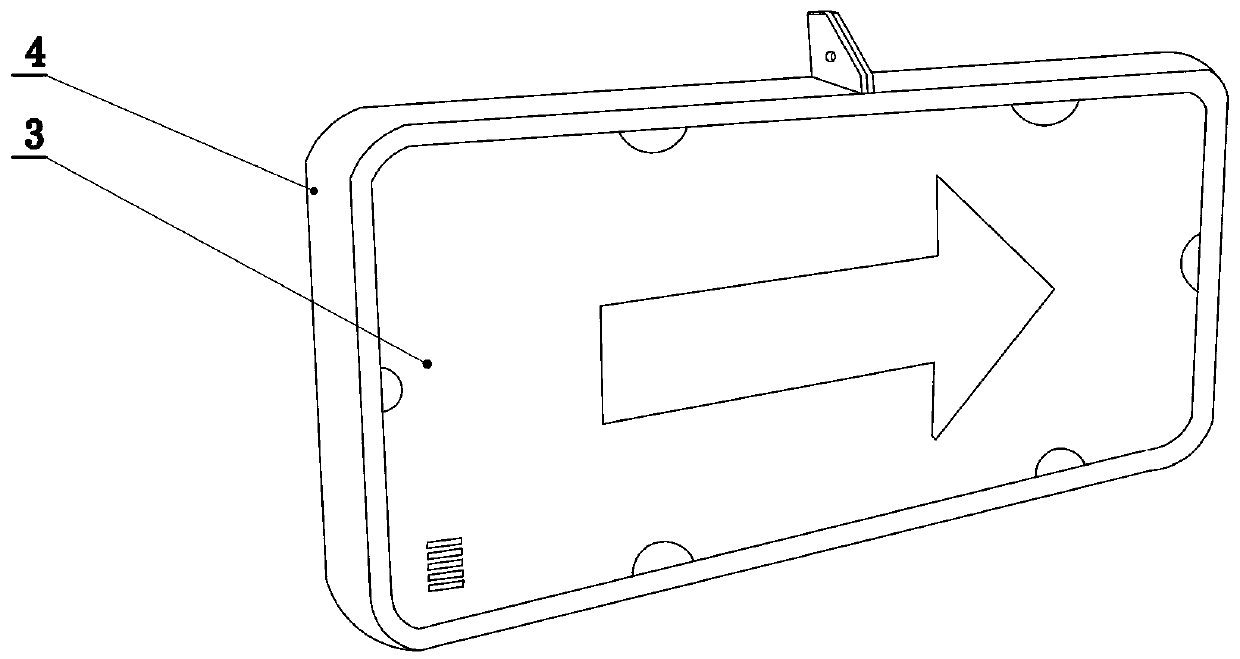

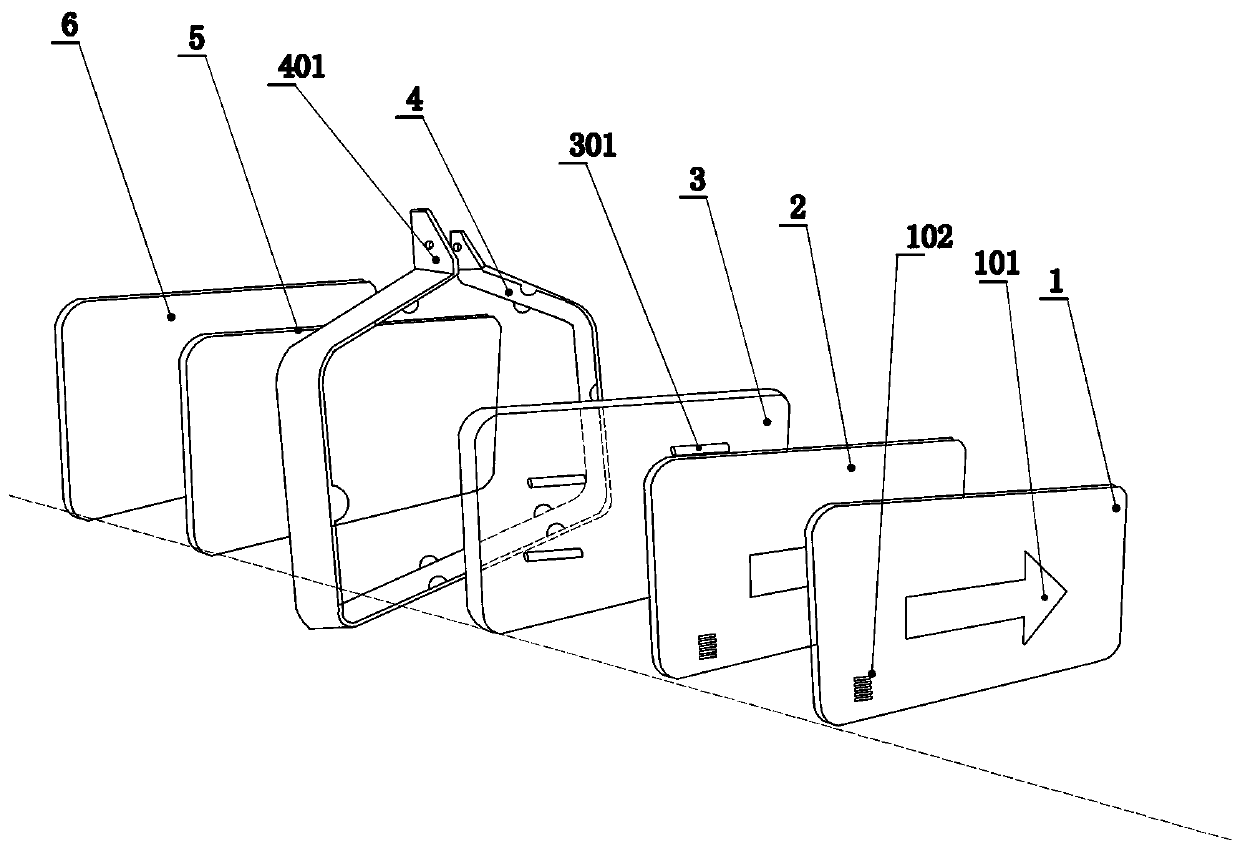

Underground passive beta emergency access indicating lamp

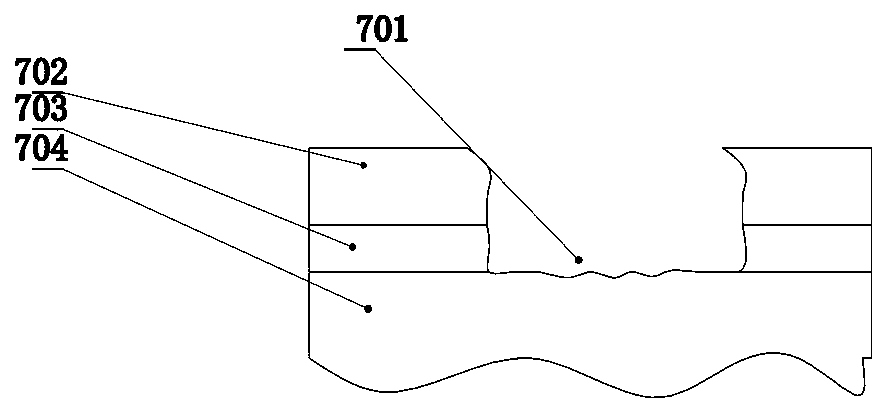

InactiveCN109671370ASolve explosion-proofWith safety seal designIlluminated signsEpoxyReflective layer

The invention discloses an underground passive beta emergency access indicating lamp, and relates to a passive indicating lamp which is designed to be fully sealed, safe, explosionproof and suitable for underground coal mine and non-coal mine emergency accesses. According to the technical scheme, the underground passive beta emergency access indicating lamp comprises a shell with an indicating pattern, and a luminophor, the luminophor is mounted in the shell, the passive luminophor is adopted by the indicating lamp, and comprises a tritium tube and a high-transparency epoxy resin body, and thetritium tube is poured and sealed in the high-transparency epoxy resin body. The surface of the high-transparency epoxy resin body is sequentially coated with a reflection layer and a protection layer, the indicating pattern is arranged on the front face of the high-transparency epoxy resin body, and the surface of the indicating pattern is not covered with a coating. The high-transparency epoxyresin body is provided with a frame for protecting the passive luminophor.

Owner:中检集团公信安全科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com