Explosion-proof aluminum ash harmless disposal method

A disposal method and technology of harmless treatment, applied in the field of aluminum ash treatment, can solve problems such as hidden safety hazards, high cost, harsh conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

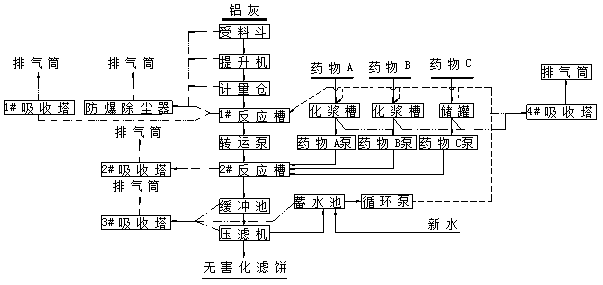

[0028] Specific embodiment one, please refer to figure 1 An explosion-proof aluminum ash harmless disposal method is characterized in that it comprises the steps of:

[0029] Aluminum ash powder mixed pulping:

[0030] Aluminum ash enters the 1# reaction tank through the receiving machine, elevator and metering bin, and the water in the reservoir is injected into the 1# reaction tank through the circulation pump. The elemental aluminum in the aluminum ash undergoes a hydrolysis reaction when it meets water, releasing flammable and explosive gas hydrogen and ammonia. The reaction formula is as follows:

[0031] 2Al+6H2O→2Al(OH)3+3H2↑

[0032] AlN+3H2O→Al(OH)3+NH3↑

[0033] Add drug A once to remove fluoride:

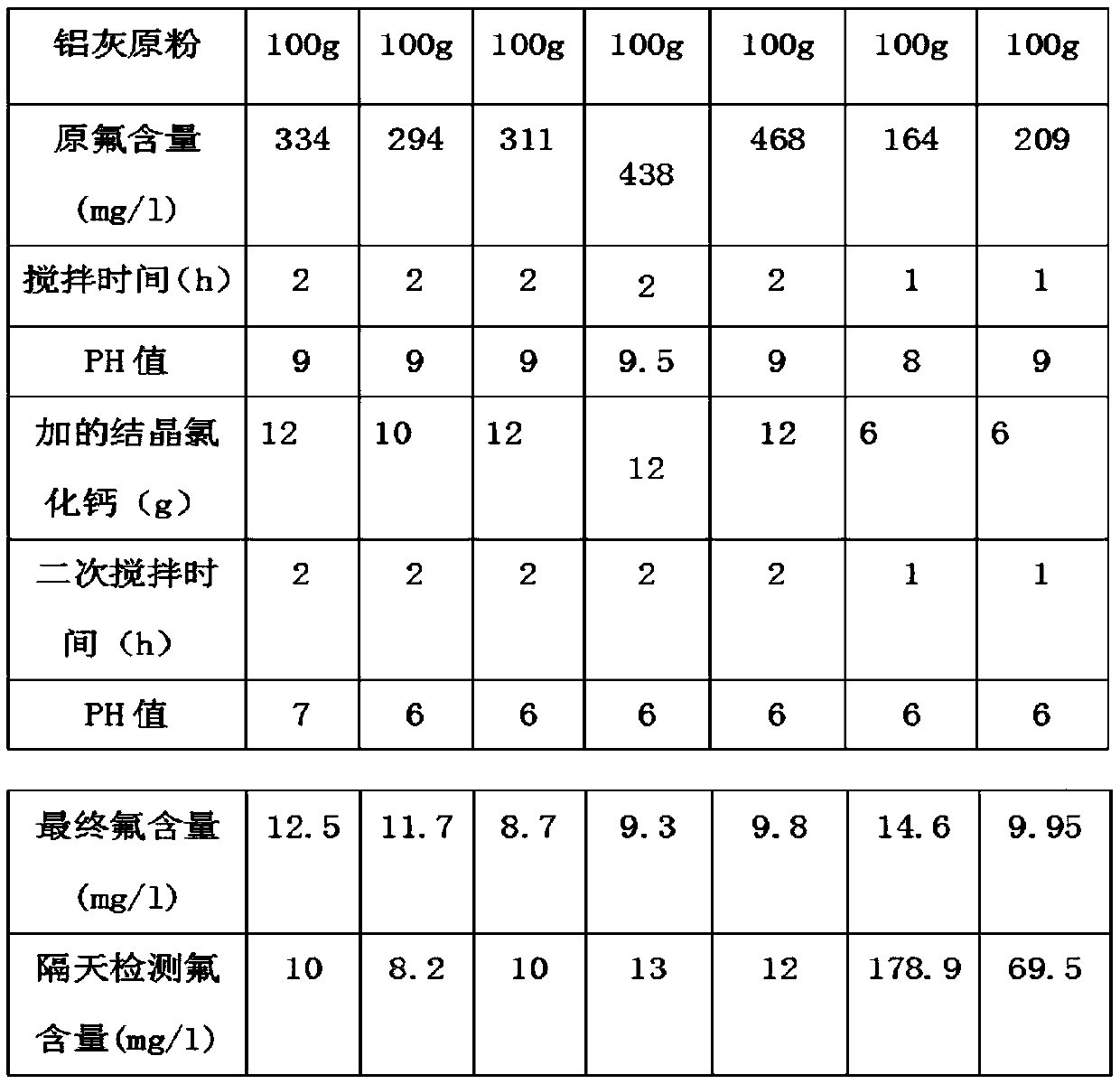

[0034] Wherein the side of the 1# reaction tank is added drug A in the slurry tank, the 1# reaction tank transports the slurry to the 2# reaction tank through the transfer pump, and the slurry tank transports the solution to the 2# reaction tank through the drug A pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com