Digital-analog hybrid valve-controlled hydraulic robot system

A hybrid technology of hydraulic robot and simulation, which is applied in the direction of program control manipulator, manipulator, liquid distribution, conveying or transfer device, etc. It can solve the problems of insufficient control precision and achieve slender body, compact structure, high stability and motion precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings, and it is stated here that the present invention is explained with the exemplary embodiment, but not as a limitation of the present invention.

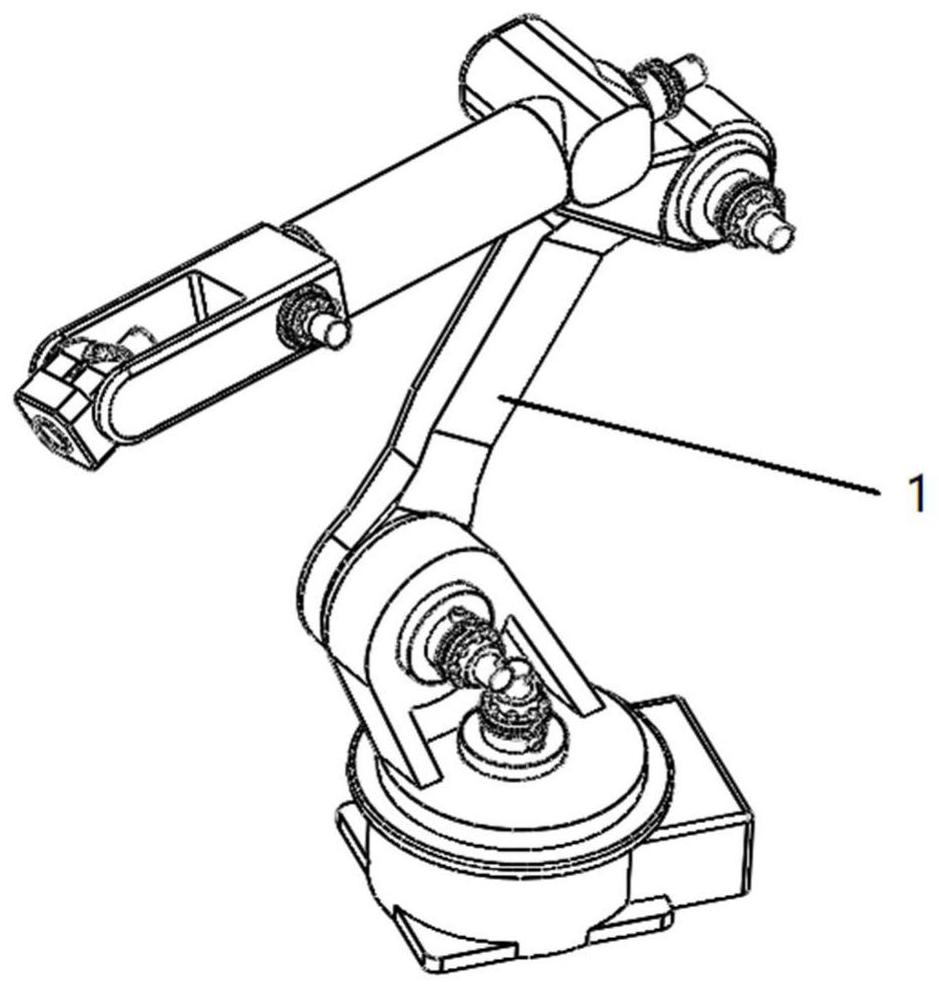

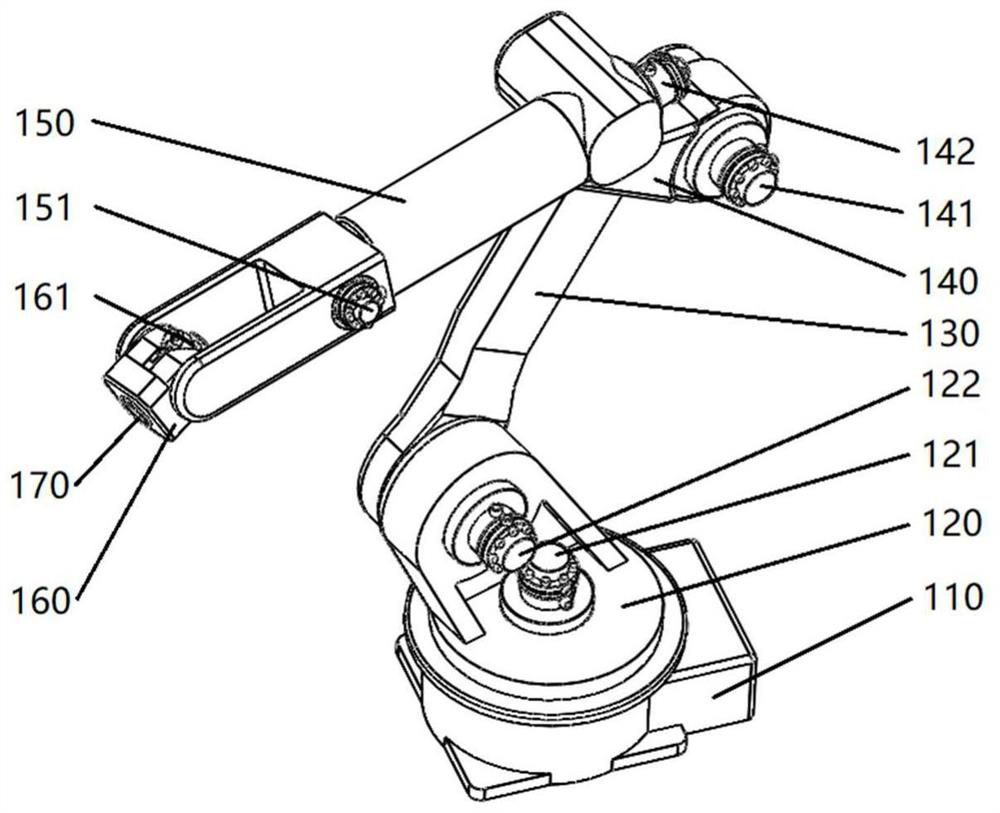

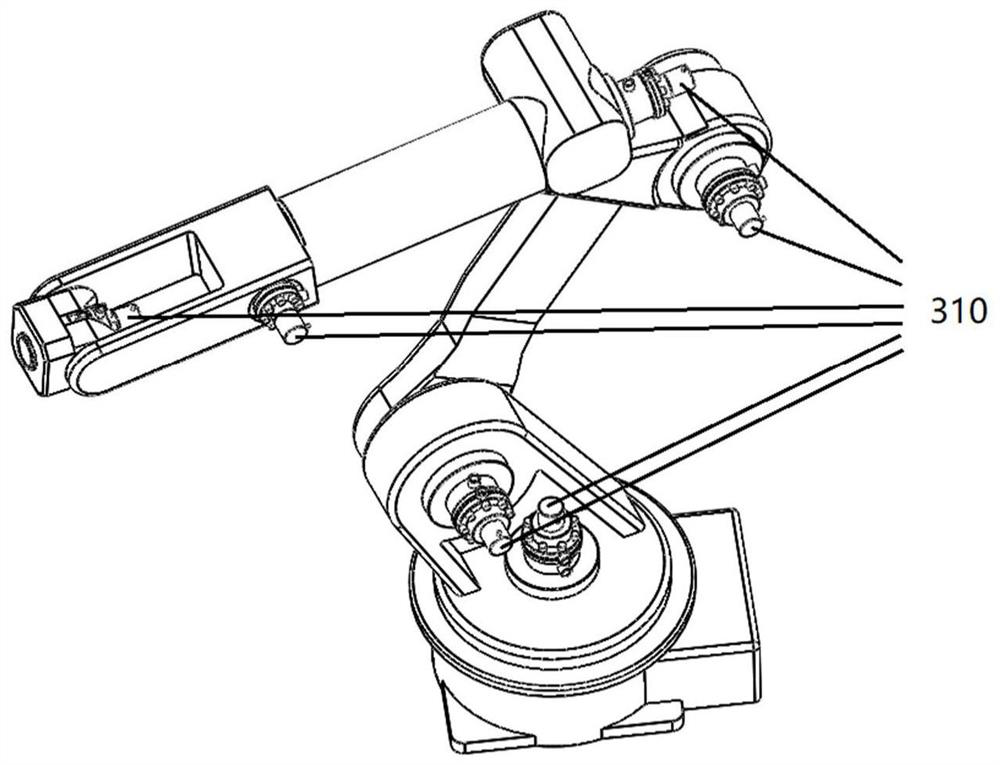

[0041] see figure 1 and figure 2 , a digital-analog hybrid valve-controlled hydraulic robot system proposed by the present invention includes a robot mechanical body 1, a power system, and a sensor detection and control system. Wherein, the mechanical arm body includes a robot base 110, a robot waist part 120 is connected with the robot base 110 through a rotating pair, a robot arm part 130 is connected with the robot waist part 120 through a rotating pair, and a robot middle arm part 140 is connected with the robot through a rotating pair. The big arm part 130 is connected, the robot small arm part 150 is connected with the middle arm part 140 of the robot through a rotating pair, the robot wrist part 160 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com