Travel type hydraulic cylinder motor

A technology of hydraulic cylinders and motors, which is applied in variable displacement engines, reciprocating piston engines, machines/engines, etc. It can solve the problems of high safety factor for underground workers, potential safety hazards in high-temperature hot gas, and restrictions on the development of underground equipment. Achieve the effect of improving production safety factor, saving installation space and solving explosion-proof problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

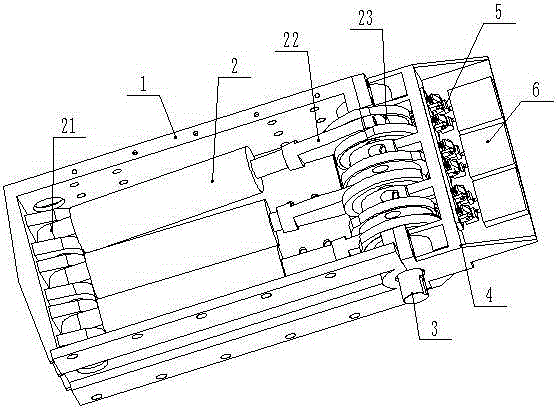

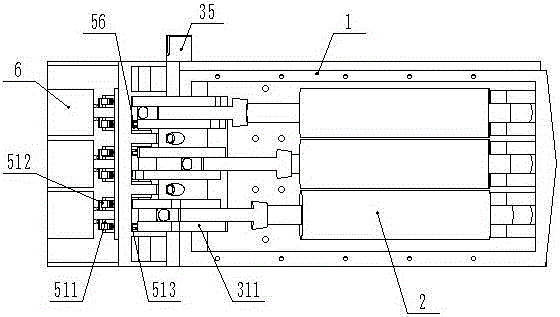

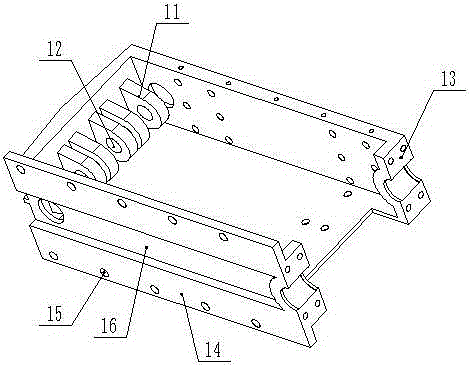

[0038] Such as figure 1 — image 3 As shown, the walking hydraulic cylinder motor includes a box body 1, three hydraulic cylinders 2, a crankshaft 3, a box body front end assembly 4, and a control system 5. The box body 1 is a shell structure as a whole, and the inside of the box body 1 Three earrings 11 for installing hydraulic cylinders 2 are arranged side by side at the rear end. The earrings 11 are provided with hydraulic cylinder mounting holes 12, and one side of the box body is provided with a mounting seat plate 14 which is provided with useful In the two rows of mounting screw holes 15 of the fixed box 1, a through slot 16 is provided in the middle of the mounting seat plate 14. The front end of the box 1 is provided with a box semicircular seat 13 for mounting the crankshaft 3, on the box semicircular seat 13 There is a threaded hole connected with the front end assembly 4 of the box body; the front end assembly 4 of the box body is fixedly connected with the box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com