Plug-in explosion-proof hydraulic valve set

A hydraulic valve block, plug-in technology, applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problems of low flow, high integration, large leakage, etc., to save installation space, reliable Enhanced performance and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

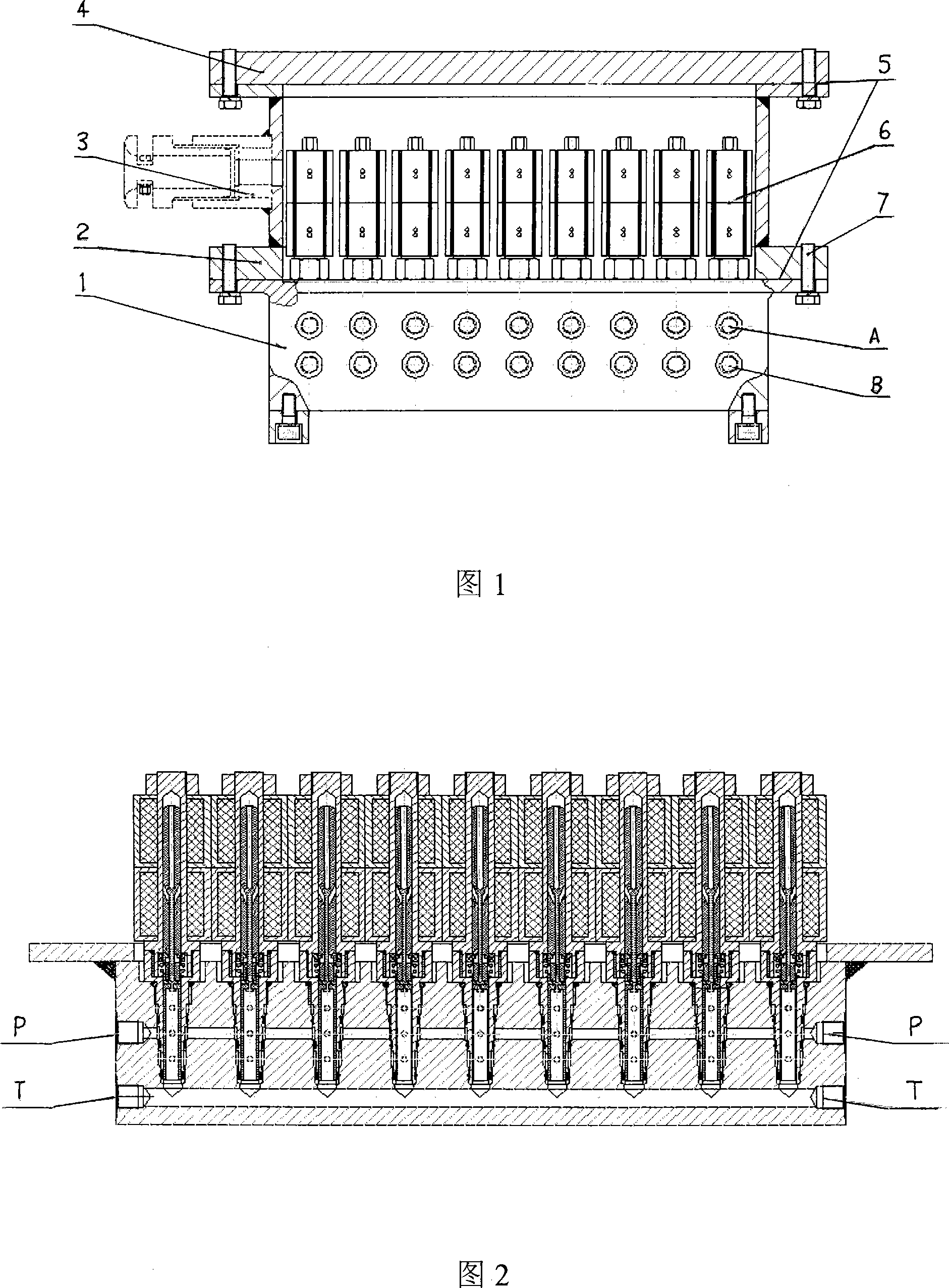

[0008] The plug-in explosion-proof hydraulic valve group of the present invention includes a valve body and a threaded plug-in electromagnetic reversing valve, as shown in Figure 1: it is characterized in that there is a housing 2 on the valve body 1, and the electromagnetic valve 6 is installed in the housing 2, The rectangular upper cover 4 made of steel plate is used to fasten the upper cover 4, the casing 2 and the valve body 1 into a hexahedron by bolts 7, so as to realize the overall explosion-proof performance of the hydraulic solenoid valve group. The cable passes through the explosion-proof lead nozzle 3 shown in Fig. 1 and penetrates into the inside of the housing 2 to be connected with the electromagnetic valve cable.

[0009] There are a number of mounting holes for solenoid valves on the upper surface of the valve body 1, (the specific number depends on the number of circuits controlled by the hydraulic system). It is connected with the hydraulic oil holes A and B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com