A one-stop gas content determination device and determination method in a coal mine

A gas content and measuring device technology, applied in measuring devices, sampling devices, preparation of samples for testing, etc., can solve problems such as affecting work efficiency and reading reliability, affecting reading reliability, and fluctuating water surface, so as to reduce labor costs. Workload, data reliability, and efficiency improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

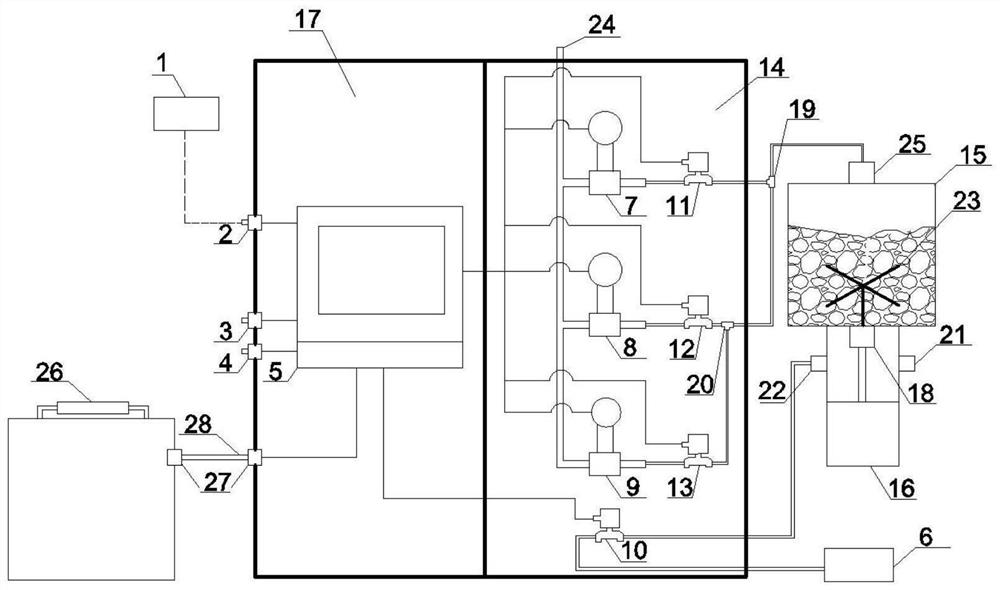

[0042] ① First, connect the battery box 26 to the aviation plug 27 on the intrinsically safe cavity through the mine explosion-proof cable 28 to supply power to the entire device stably and continuously;

[0043] ②Drill on the coal wall of the sample point to be tested in the well, take out the coal sample, weigh 1000g, record the data, and then quickly seal the coal sample to the coal sample tank 15 to measure the gas content in the well, if the gas flow rate is 1500ml / min, the measurement data of the electronic flow sensor I7 is used, and the data is transmitted to the intrinsically safe industrial computer 5;

[0044] ③As the gas desorption flow rate of the coal sample decreases, if the gas flow rate of 1000-2000ml / min is sensed, the intrinsically safe industrial computer 5 controls the solenoid valve II12 and solenoid valve III13 to close through the network cable, and simultaneously opens the solenoid valve I11, using the electronic flow rate. The measurement data of sens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com