Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Save equipment investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

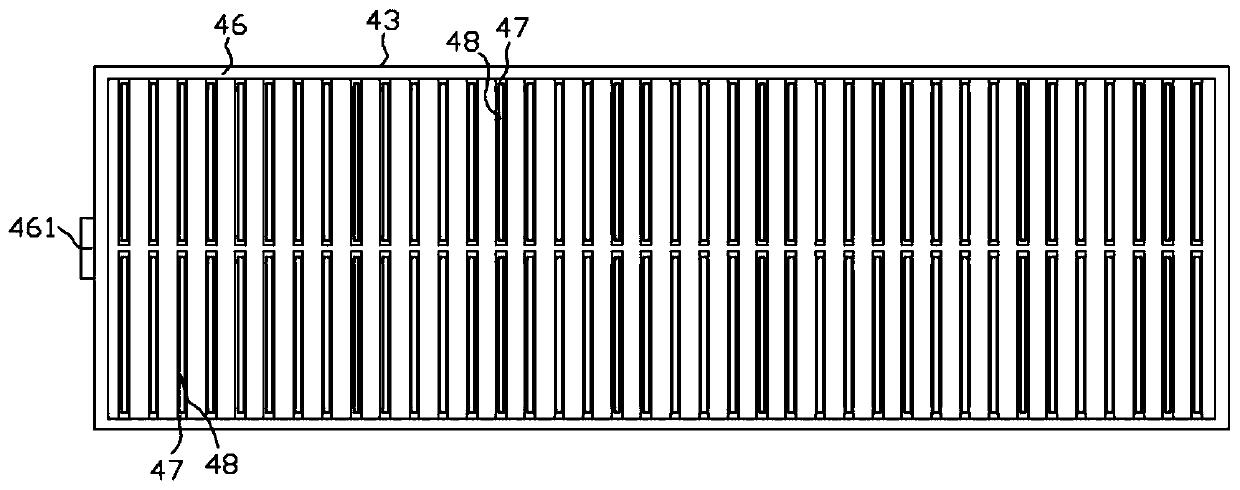

Welding structure and welding method for PCB and FPCB

ActiveCN106304688AIncrease productivityImprove qualityPrinted circuit assemblingMetallurgical bondingElectronic componentTin

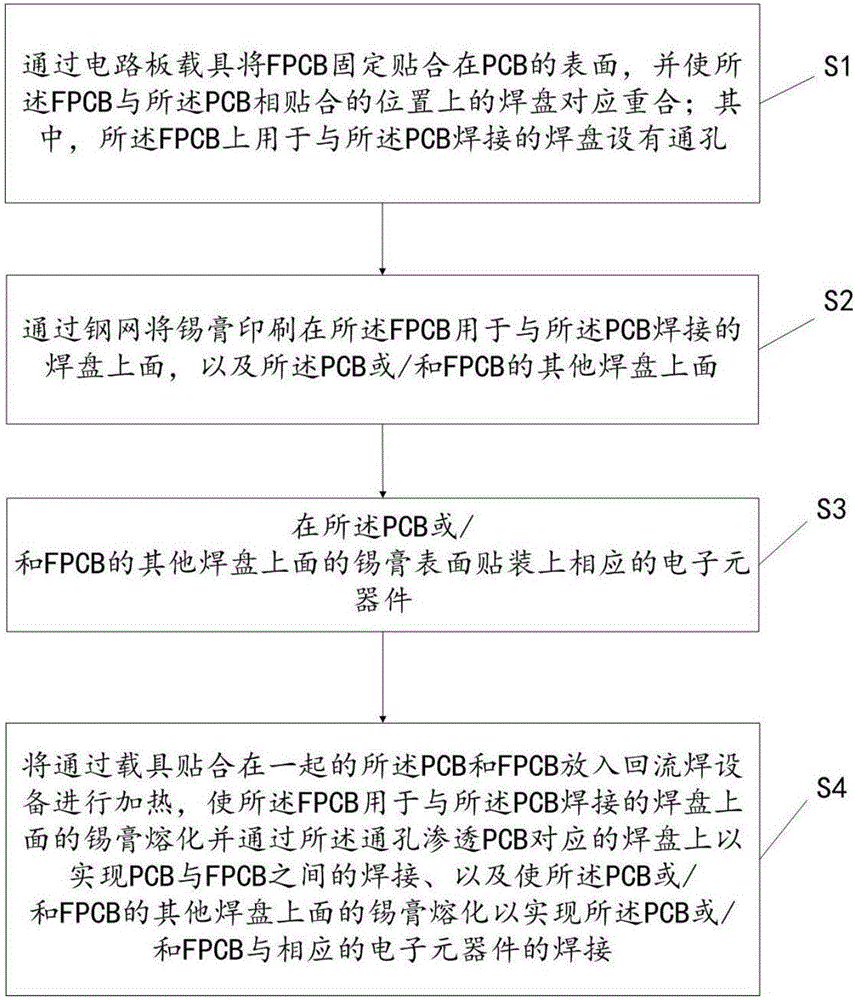

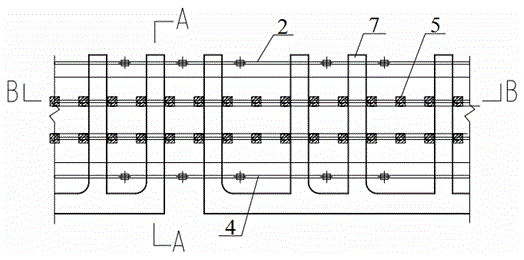

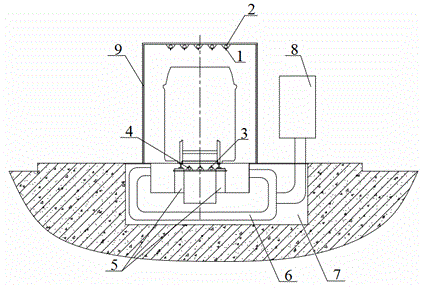

The invention discloses a welding method for a PCB and an FPCB. The welding method comprises the following steps of S1, enabling the FPCB to be fixedly attached to the surface of the PCB through a circuit board carrier, and enabling bonding pads in the attached position to be aligned and attached; S2, printing tin paste on the bonding pads of the attached FPCB and PCB through a steel net; S3, mounting electronic components on the corresponding bonding pads; and S4, putting the PCB and the FPCB which are attached together through the carrier into reflow soldering equipment to be heated to realize the welding of the PCB and the FPCB and the welding of the corresponding electronic components at the same time. The invention discloses a welding structure for the FCB and the FPCB. The welding between the FCB and the FPCB realized by the welding method and the welding structure has the advantages of high production efficiency, capability of reducing cost, and stable welding quality.

Owner:广州明美新能源股份有限公司

Steel ring billet casting technique based on casting and rolling combined forming

ActiveCN104439219AReduce heating timesSave blankingMolten metal pouring equipmentsFurnace typesTemperingCasting mold

The invention discloses a steel ring billet casting technique based on casting and rolling combined forming. The steel ring billet casting technique based on casting and rolling combined forming comprises the steps that firstly, a casting mold is manufactured by means of water glass sand, the casting mold is dried and sprayed with painting, casting raw materials of a steel ring are smelted and are poured into the casting mold, and normalizing, tempering and quenching-tempering heat treatment are conducted on a steel ring billet formed through pouring; secondly, the steel ring billet is cooled to the room temperature, and polishing and machining are conducted on the cooled steel ring billet; finally, the steel ring billet which can be directly used for casting and rolling combined forming is obtained. According to the steel ring billet cast according to the technique, the defects, such as shrinkage cavities, shrinkage porosity and segregation, appearing in the steel ring billet casting process can be reduced, grains are refined to the maximum extent, and the high-quality steel ring billet capable of meeting the requirement for the ring rolling performance is manufactured; due to the fact that the processes of the casting and rolling combined forming technique are simplified, the quality and performance of the ring rolling technique and a ring workpiece are guaranteed.

Owner:盐城市大丰区生产力促进中心

Trolley car purge system

ActiveCN104648338ASolve the problem of only blowing the bottom of the carShorten the timeCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsLand resourcesAutomotive engineering

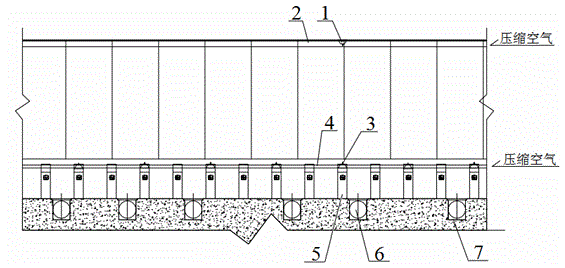

The invention relates to a trolley car purge system. The trolley car purge system comprises a top purge mechanism, a bottom purge mechanism and a dust collecting mechanism, wherein the top purge mechanism comprises a plurality of upper spray heads arranged above trolley car rails and an upper compressed air pipeline connected with each upper spray head; the bottom purge mechanism comprises a plurality of lower spray heads arranged below the trolley car rails and a lower compressed air pipeline connected with each lower spray head; the upper compressed air pipeline and the lower compressed air pipeline are connected with an external compressed air source respectively. According to the trolley car purge system, the top purge mechanism and the bottom purge mechanism are arranged, so that the bottom and the top of the trolley car can be purged simultaneously or respectively, the problem that a vehicle purge device in the prior art only can purge the bottom is solved, land resources and equipment investment are saved, the vehicle purge and maintenance time is shortened, and the working efficiency is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

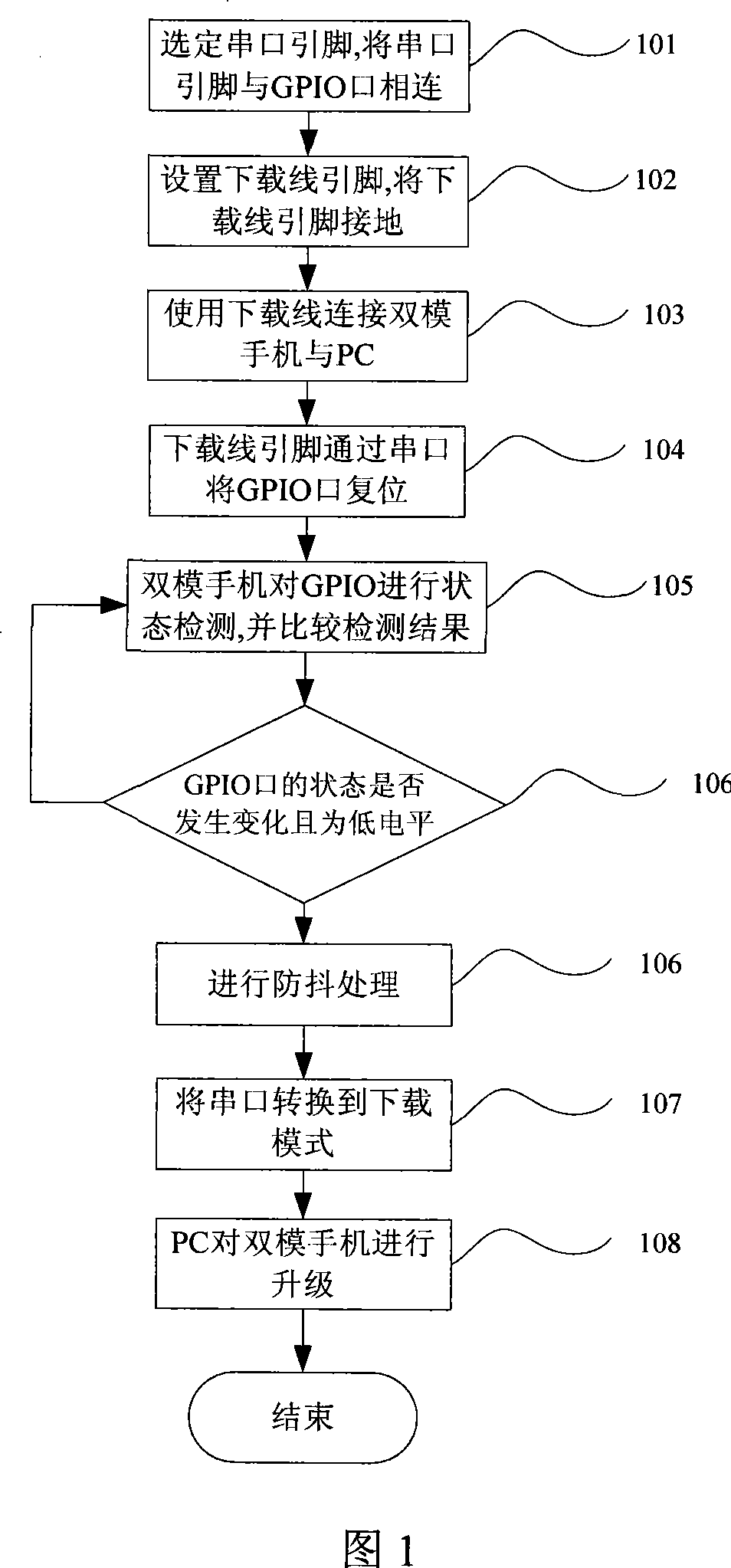

A method for upgrading dual-mode mobile phone via multiplexing serial port

InactiveCN101237650ASimplify the upgrade processSave costsRadio/inductive link selection arrangementsProgram loading/initiatingMobile phoneHandset

The invention discloses a method for upgrading a dual mode handset through a multiplexed serial port. The method comprises the following: Step a, a dual mode handset and a PC are connected by inserting one end of a download cable provided with a pin of the download cable into a serial port of the dual mode handset and connecting the other end to the PC; Step b, after the connection of the dual mode handset and the PC is finished, the pin of the download cable makes a state conversion to a signal input port connected with a serial port pin through the serial port pin corresponding to the position of the pin of the download cable; Step c, when the dual mode handset detects that the state of the signal input port changes, the state of the serial port is switched to a download mode, and the PC finishes the upgrading to the dual mode handset. The method of the invention saves the special equipment adopted when the working mode of the serial port is preset, saves the cost and the equipment investment, simplifies the upgrading process of the dual mode handset and provides the working efficiency.

Owner:ZTE CORP

Clamp nut casting technology based on casting and rolling combined forming

The invention discloses a clamp nut casting technology based on casting and rolling combined forming. According to the casting technology, casting ingredients are mixed by the ratio of carbon steel: scrap iron=89-90%:10-20%, a clamp nut is directly formed through rolling and expanding in the casting process, and the working procedures of blanking, forging and punching in an existing technology are omitted. According to the designed clamp nut casting technology based on casting and rolling combined forming, in the casting process, the defects of shrinkage, porosity, segregation and the like of a casting blank are reduced, and grains are refined as much as possible, so that the high-quality clamp nut capable of meeting the requirement for rolling and expanding forming performance is manufactured; the clamp nut is provided with an obvious yielding platform which does not disappear along with time, the delayed fracture resistance is high, plasticity is high, machining and manufacturing pollution is small, and cost is low.

Owner:佛山市南海区冠辉机电设备实业有限公司

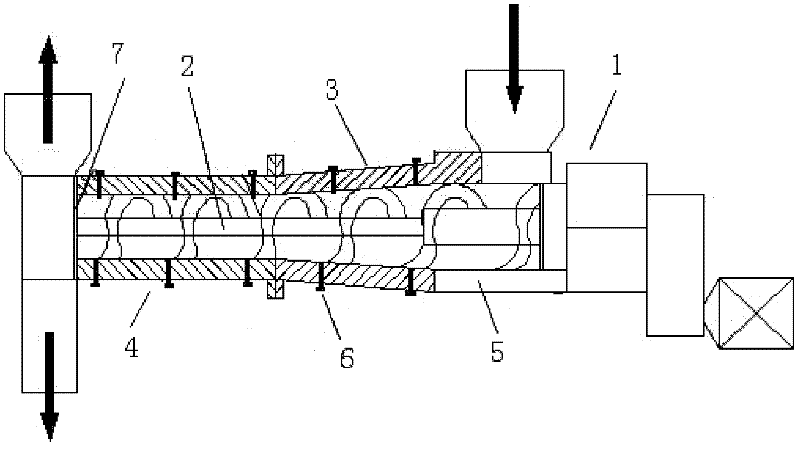

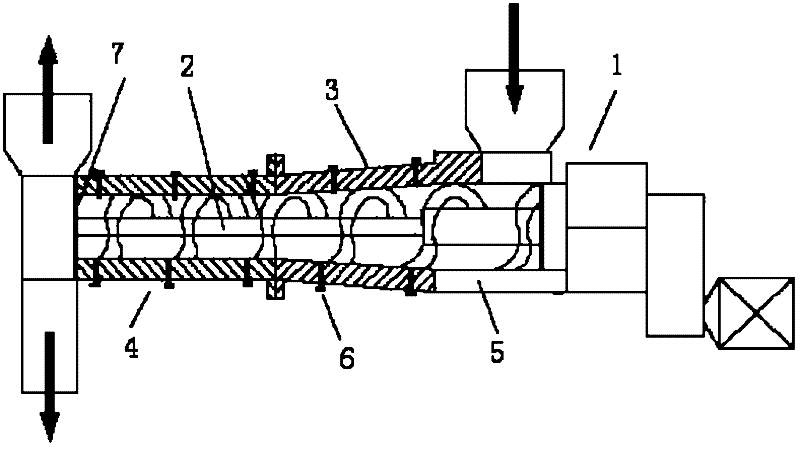

Dehydrating and drying method for producing isoprene rubber through solution polymerization process

A dehydrating and drying method for producing isoprene rubber through a solution polymerization process comprises the steps as follows: isoprene rubber material synthesized through the solution polymerization process is separated from solvent through a condensation procedure and then is dehydrated through a dehydration sieve; thereafter, the material is continuously fed into an extrusion dehydrating and expansion drying integrated machine, passes through an extrusion dehydrating segment and an expansion drying segment sequentially under the push of a screw rod, and then gets out of a mold plate at the tail end of the expansion drying segment, so as to form the isoprene rubber. The rotational speed of the screw rod is controlled within the range of100 to 250 rpm, the temperature of the extrusion dehydrating segment is 80 to 140 DEG C, and the temperature of the expansion drying segment is 150 to 220 DEG C. While the dehydrating and drying effect of the aftertreatment procedure of isoprene rubber granules is guaranteed, the drying process in the aftertreatment procedure is simplified, so as to reduce device investment and the labor intensity of workers and further reduce production cost.

Owner:广东鲁众华新材料有限公司

Manufacturing method of polycrystalline silicon and manufacturing method of monocrystalline silicon

InactiveCN106283180AFast growthIncrease productivityPolycrystalline material growthFrom chemically reactive gasesHydrogenGas phase

The invention provides a manufacturing method of polycrystalline silicon. The method comprises the following steps of installing a silicon core into a reaction chamber; introducing reaction gas into the reaction chamber, wherein the reaction gas comprises silicon precursors, and the reaction gas further comprises hydrogen gas when the silicon precursors are chlorinated silane; exciting plasma from the reaction chamber or injecting plasma into the reaction chamber from an external plasma source; performing plasma enhancing chemical gas phase polycrystalline silicon deposition on the surface of one or a plurality of silicon chips by the reaction gas, wherein when the plurality of silicon chips are used, the silicon chips are mutually independent in the reaction chamber. The invention also provides a manufacturing method of monocrystalline silicon.

Owner:丁欣

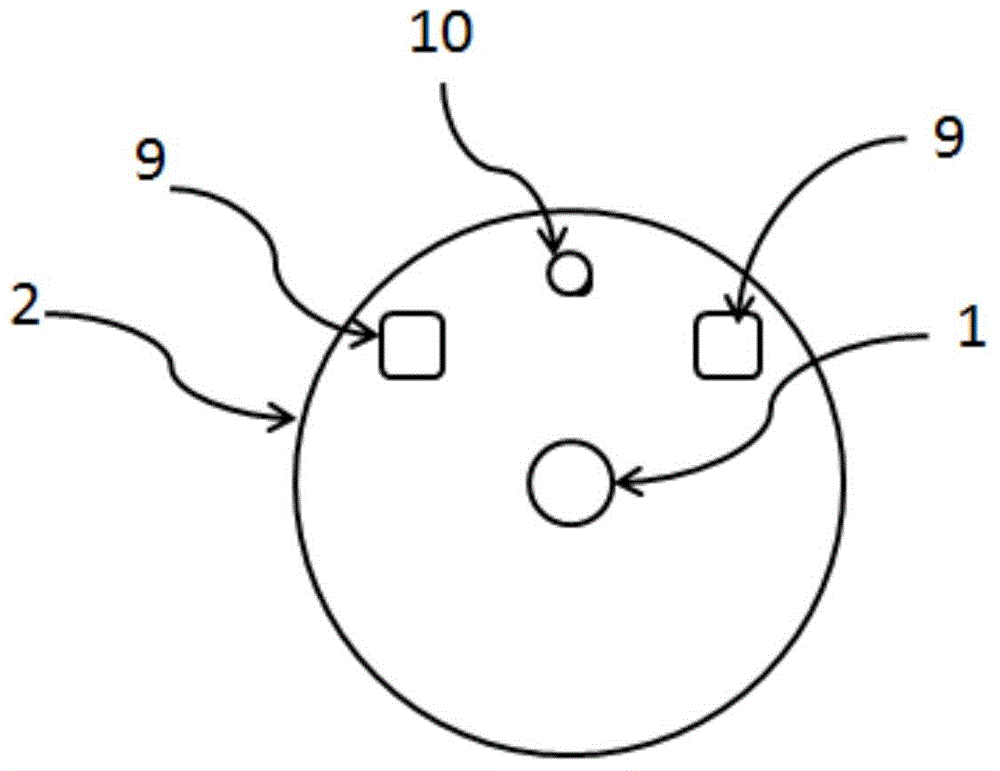

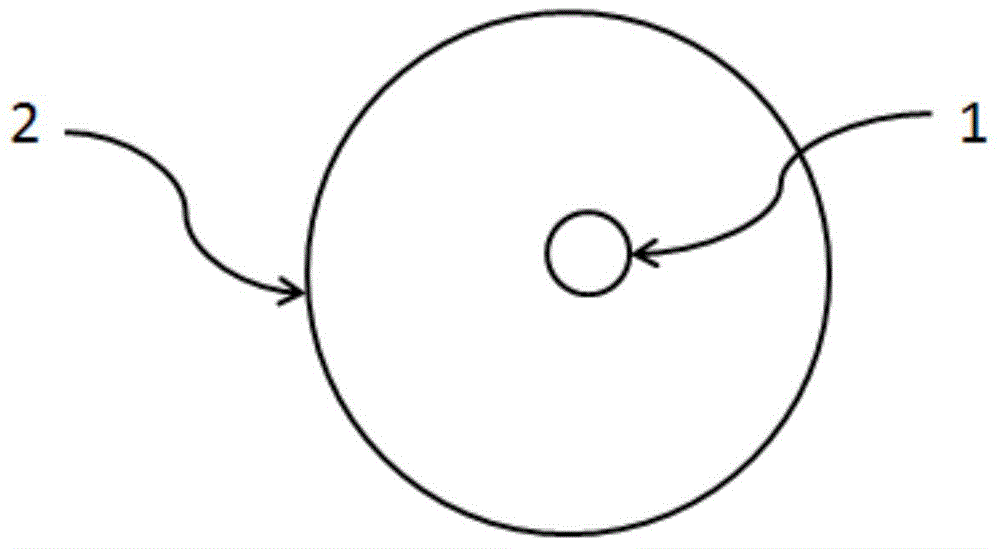

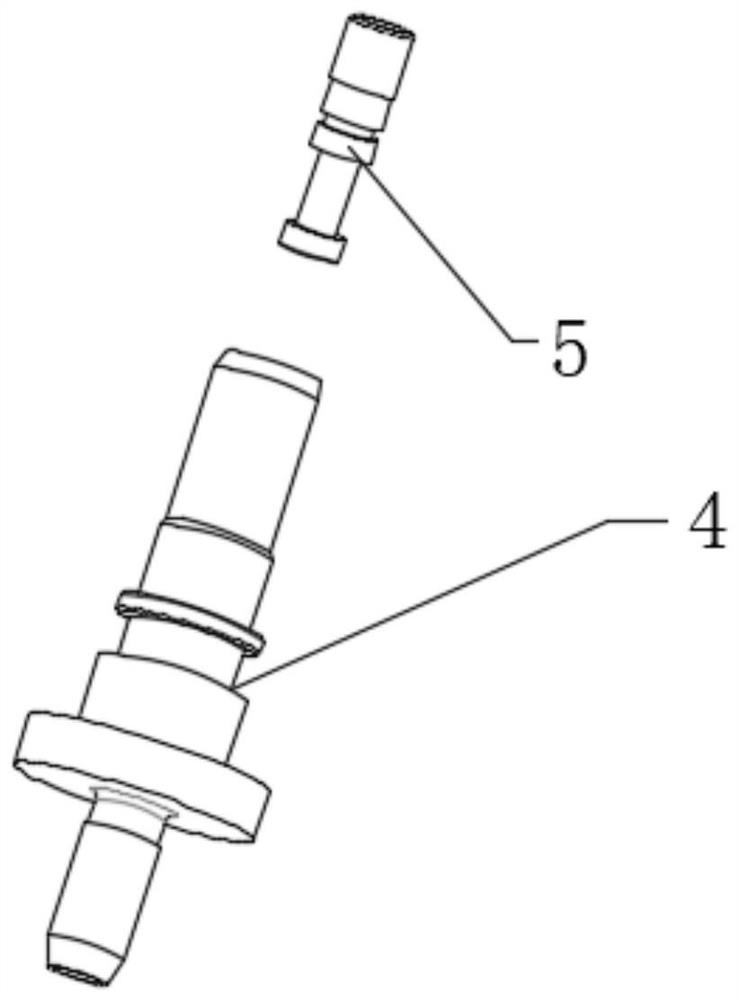

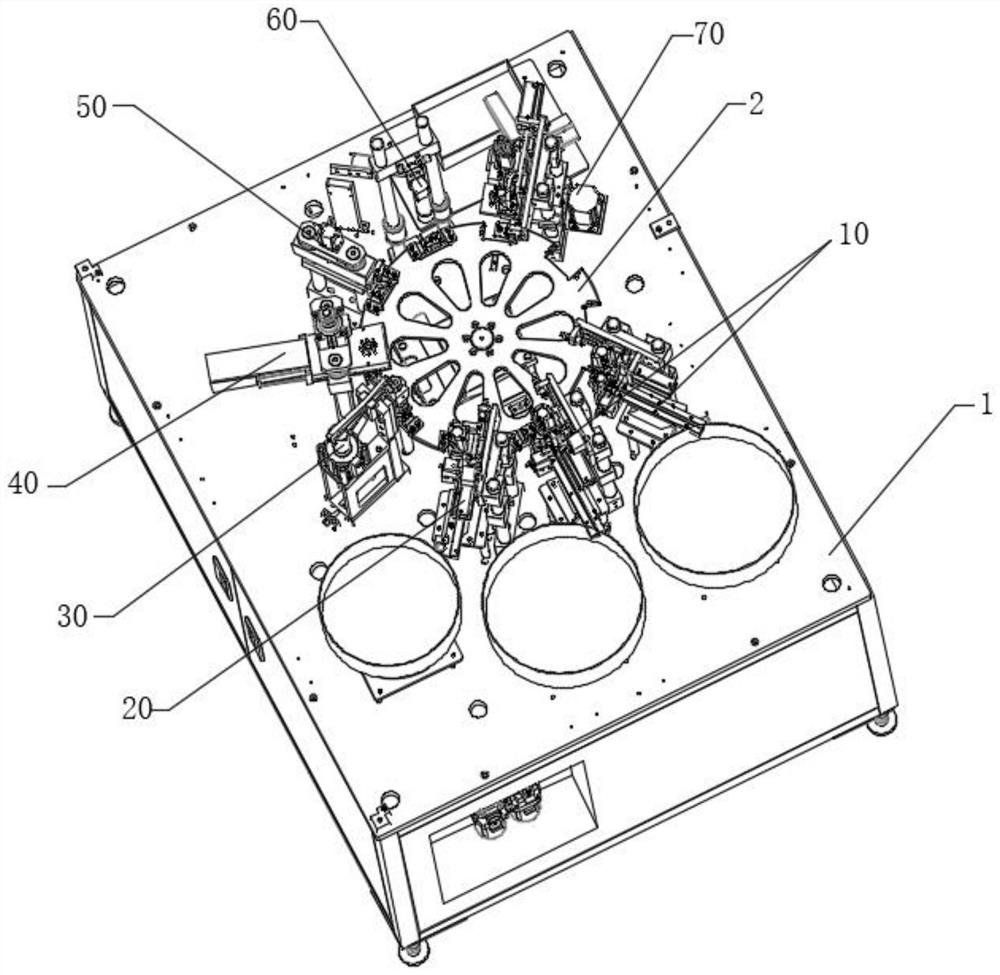

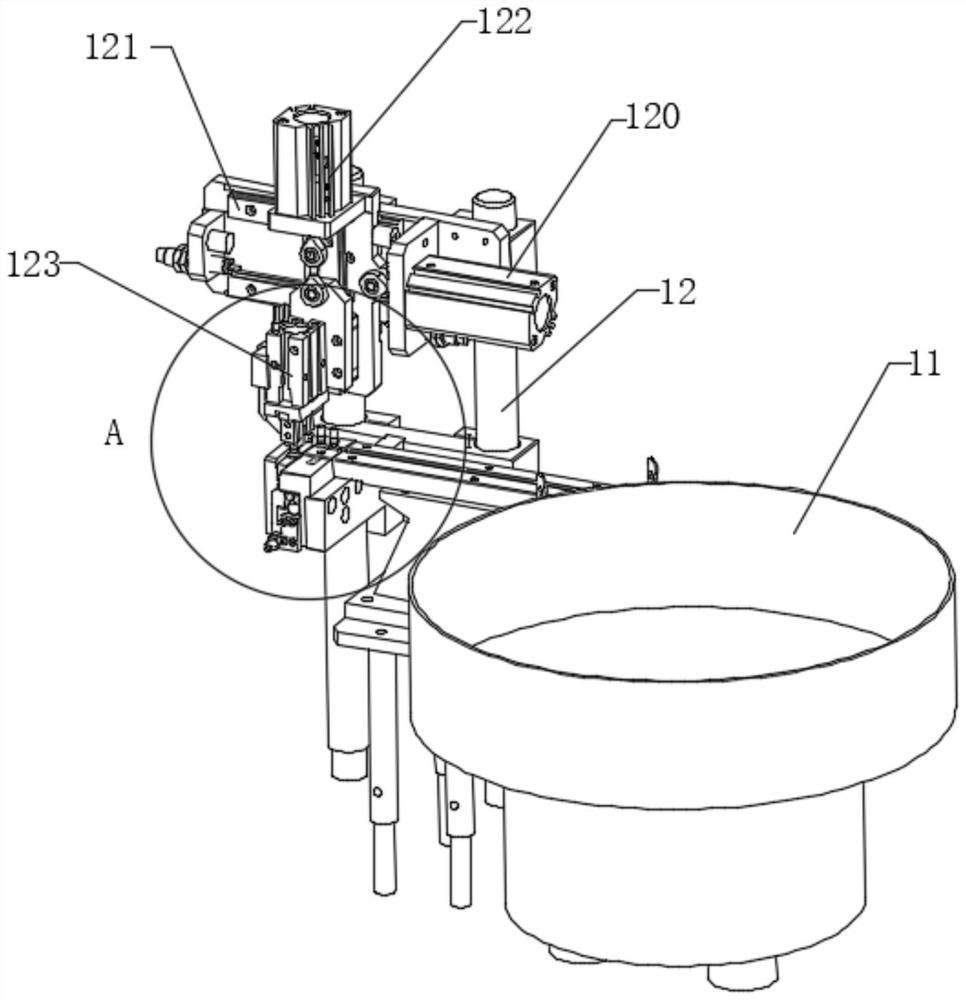

Adaptor connector automatic assembly and detection device and assembly and detection method thereof

ActiveCN111774833ARealize the assemblySave assembly spaceMetal working apparatusAdaptor/connectorStructural engineering

The invention provides an adaptor connector automatic assembly and detection device and an assembly and detection method thereof. The adaptor connector automatic assembly and detection device comprises a metal part feeding mechanism, an insulating part feeding mechanism, an assembly mechanism, a first detection mechanism, a second detection mechanism and a discharge detection mechanism which are arranged around a dividing plate, wherein the assembly mechanism comprises a shell nosing assembly and a dotting assembly. Compared with the prior art, through reasonable arrangement all working positions and mechanisms, the adaptor connector automatic assembly and detection device realizes stable assembly of metal parts and insulating parts through shell nosing and dotting; through detection of the height difference, the inner diameter and the dotting condition, the yield of products is ensured, and the assembly efficiency is improved; through reasonable arrangement of the discharge detectionmechanism, the adaptor connector automatic assembly and detection device can realize discharging of the products and detection of the assembly quality, achieves the functions of equipment and also reduces the occupied space of the equipment.

Owner:安费诺凯杰科技(深圳)有限公司

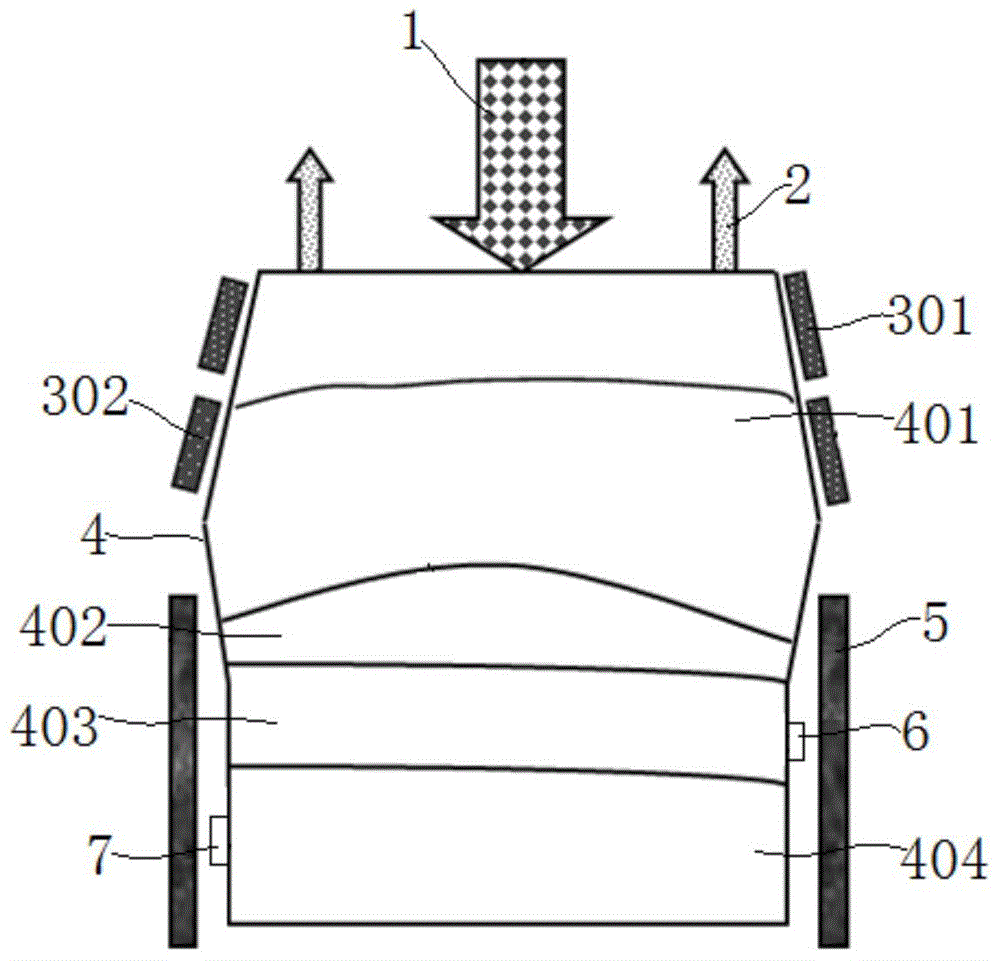

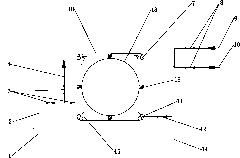

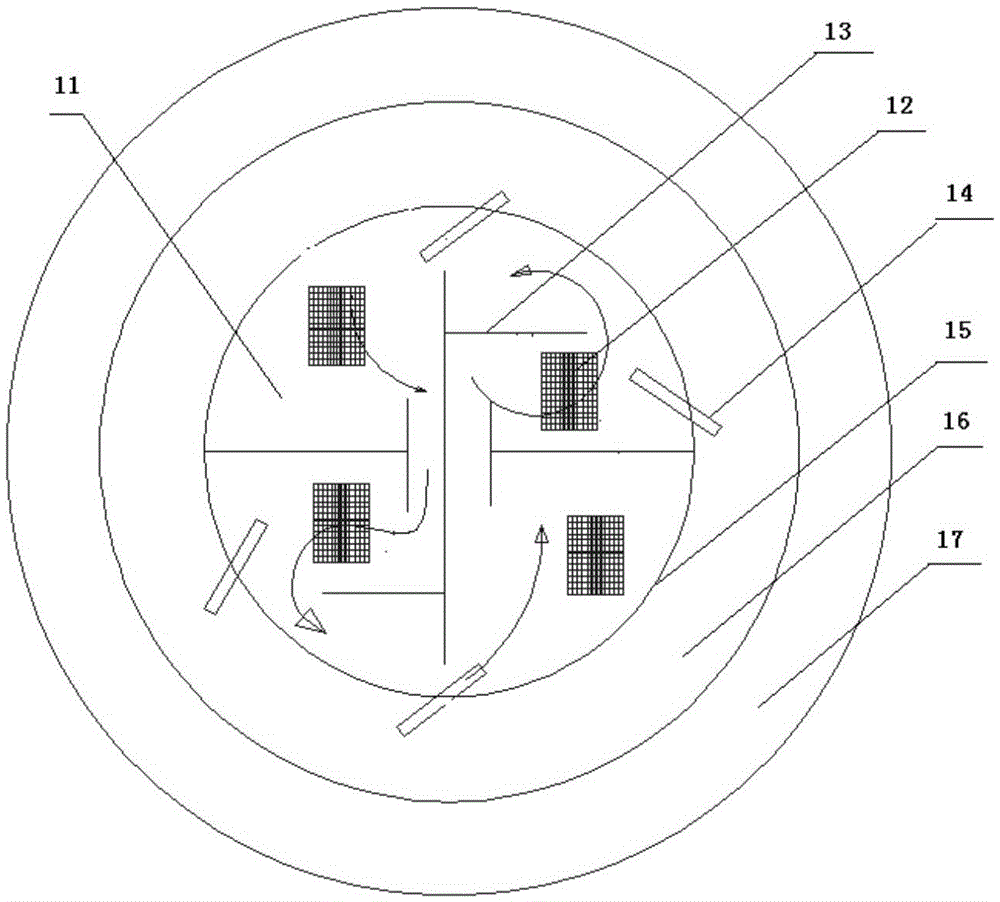

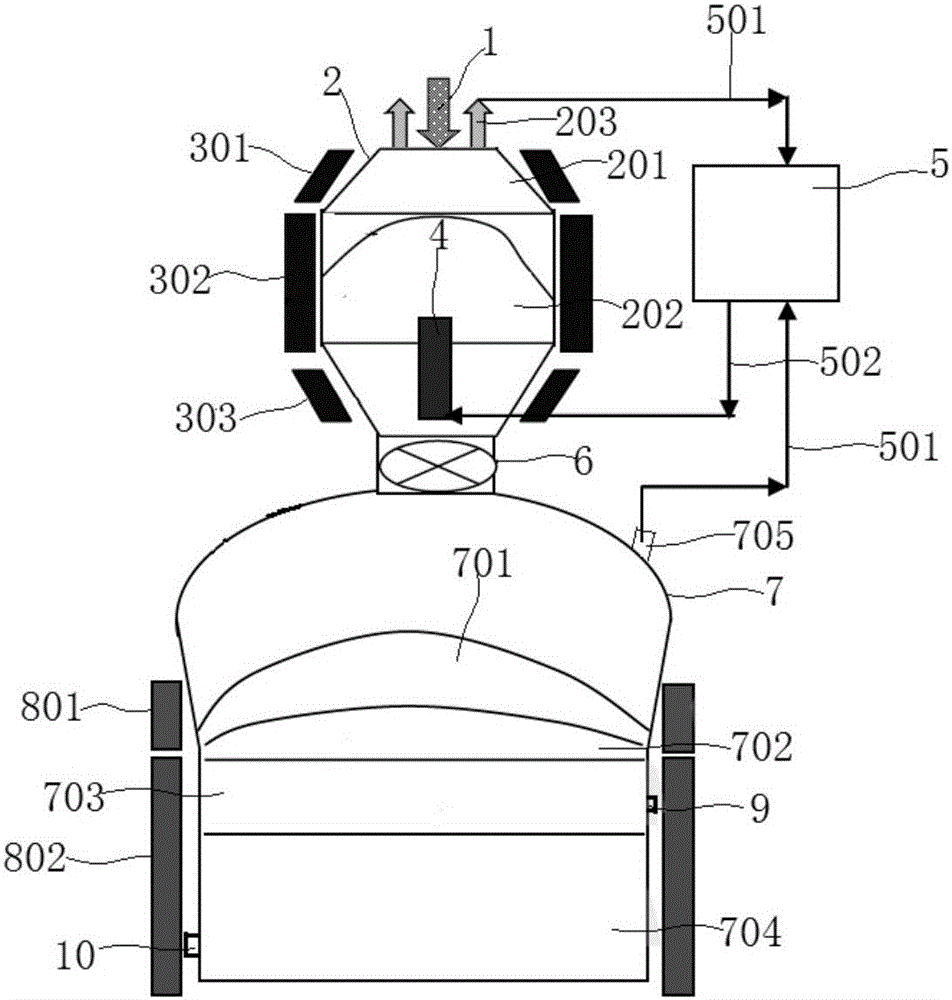

Electromagnetic heating carbon-bearing pellet continuous direct steelmaking device

ActiveCN104988268AStrong electromagnetic stirringImprove liquidityElectric furnaceSteelmakingMicrowave

The invention discloses an electromagnetic heating carbon-bearing pellet continuous direct steelmaking device and belongs to the technical field of ferrous metallurgy. The electromagnetic heating carbon-bearing pellet continuous direct steelmaking device comprises a steelmaking furnace body, a material distributing port and a coal gas outlet are formed in the top of the steelmaking furnace body, a double-circular-truncated-cone structure is composed of a material distributing area, a reduction area and a soft melting area of the steelmaking furnace body, and an iron slag melting separation area is of a cylindrical structure. At least two rows of microwave heating devices are arranged on the parts, in the material distributing area and the reduction area, of the periphery of the furnace body, and electromagnetic induction heating devices are arranged on the parts, in the soft melting area and the iron slag smelting separation area, of the periphery of the furnace body. By means of the electromagnetic heating carbon-bearing pellet continuous direct steelmaking device, an iron smelting and manufacturing device and a steelmaking device can be integrated, qualified high-quality molten steel can be produced directly through carbon-bearing pellets without blowing, the problem that secondary decarburization is needed in traditional furnace slag foaming and molten iron carburization is solved, the production efficiency is high, continuous steelmaking is achieved, and the capital construction cost and equipment investment are greatly saved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

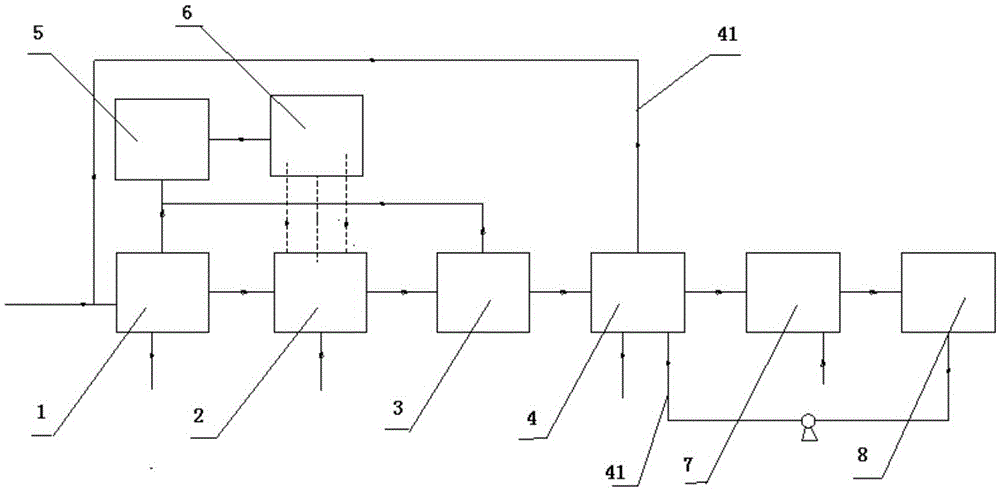

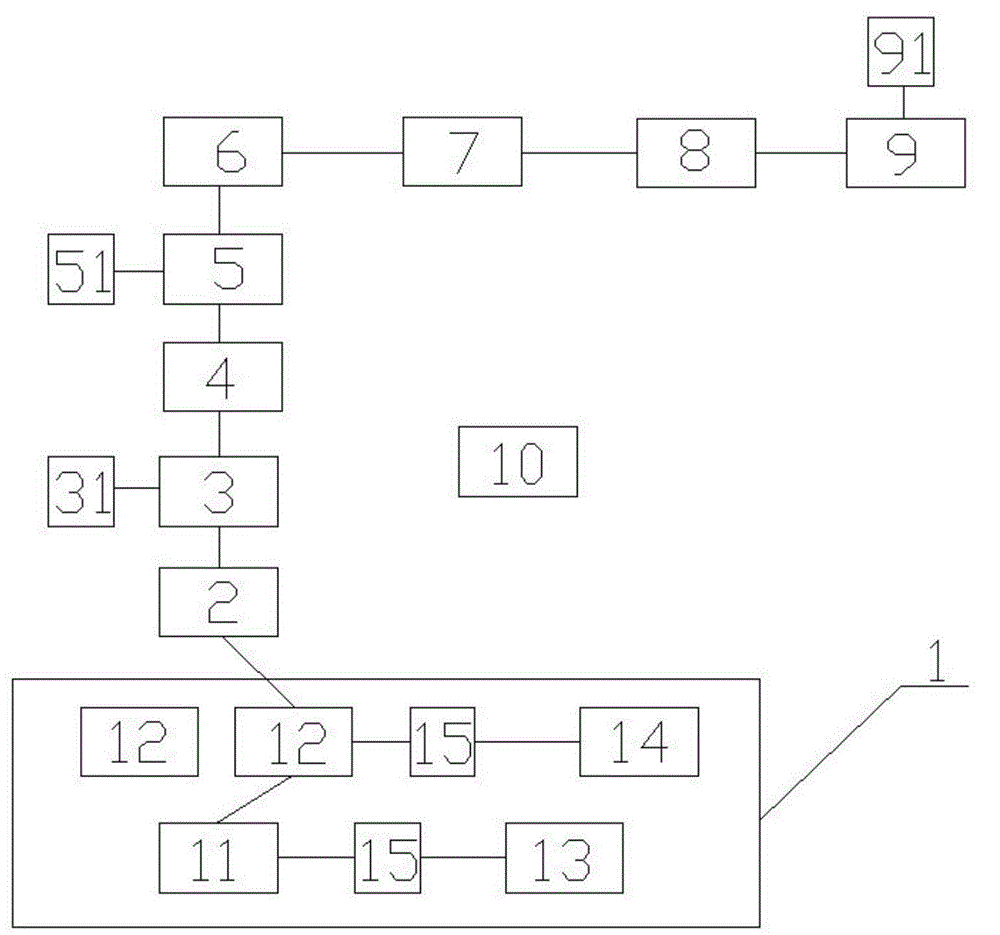

Pre-flushing refined filtration oil filling circuit device

ActiveCN106958558AAvoid abnormal wearAvoid stuck faultsFluid-pressure actuator componentsFiltrationFuel tank

The invention relates to a pre-flushing refined filtration oil filling circuit device. The pre-flushing refined filtration oil filling circuit device is characterized by comprising a first refined filter, a second refined filter, a pre-flushing oil tank, a temperature controller, a main system oil return filter set, a main oil tank circulating filter, a main oil tank, an oil-water-gas separator, a main system circulating pump, a first high-flow flushing pump set, a second high-flow flushing pump set, a circulating pump and a main control cabinet. The main control cabinet is used for conducting logic control over elements including an electric control valve. The pre-flushing oil tank temperature controller is installed on the pre-flushing oil tank to detect and control the temperature of the pre-flushing oil tank. A main oil tank oil return filter is connected to the main oil tank and used for filtering return oil of a main system. The main system circulating pump and the circulating filter are connected to the main oil tank and used for conducting continuous circulating filtering on oil in the main system oil tank. The oil-water-gas separator is connected with the pre-flushing oil tank and the main oil tank through the electric control valve.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

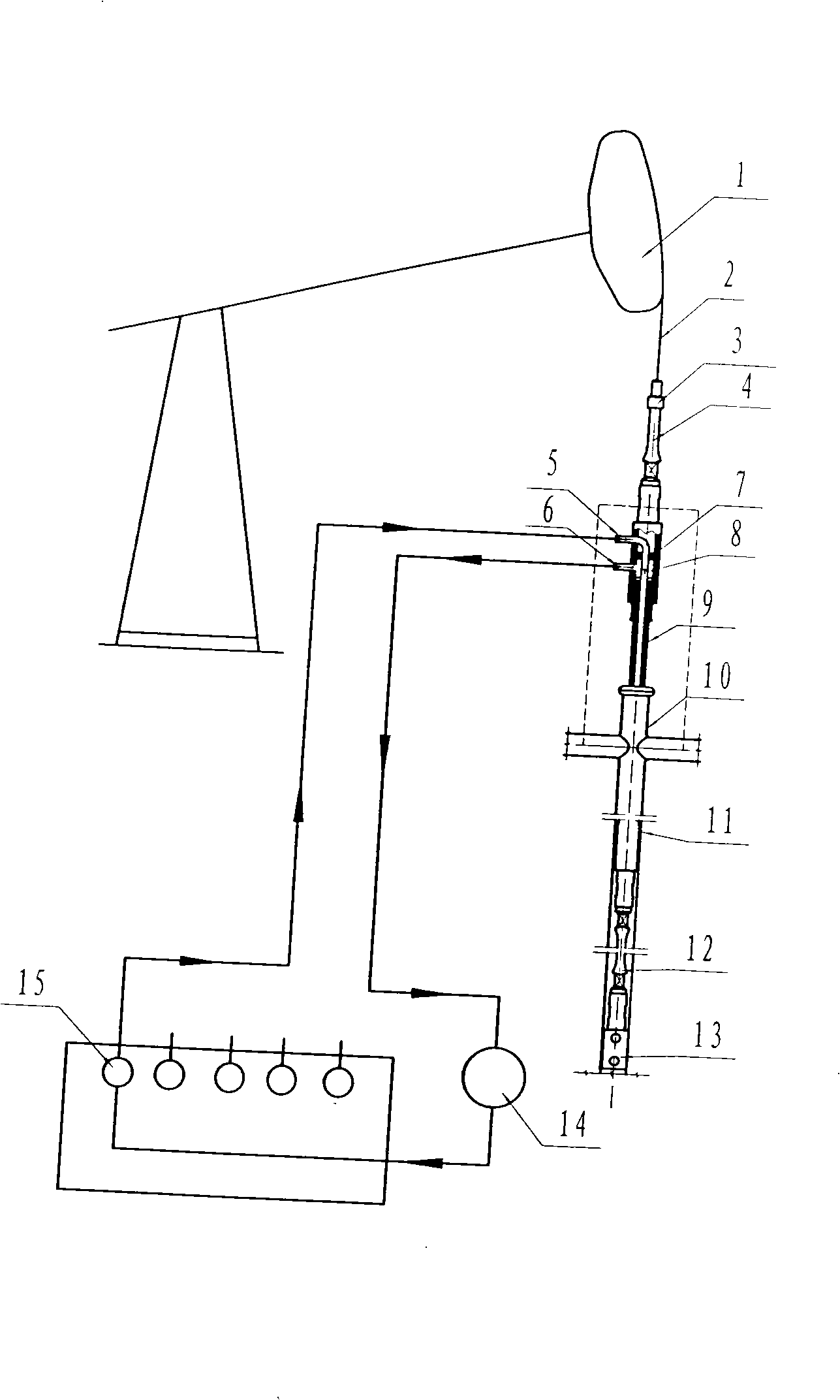

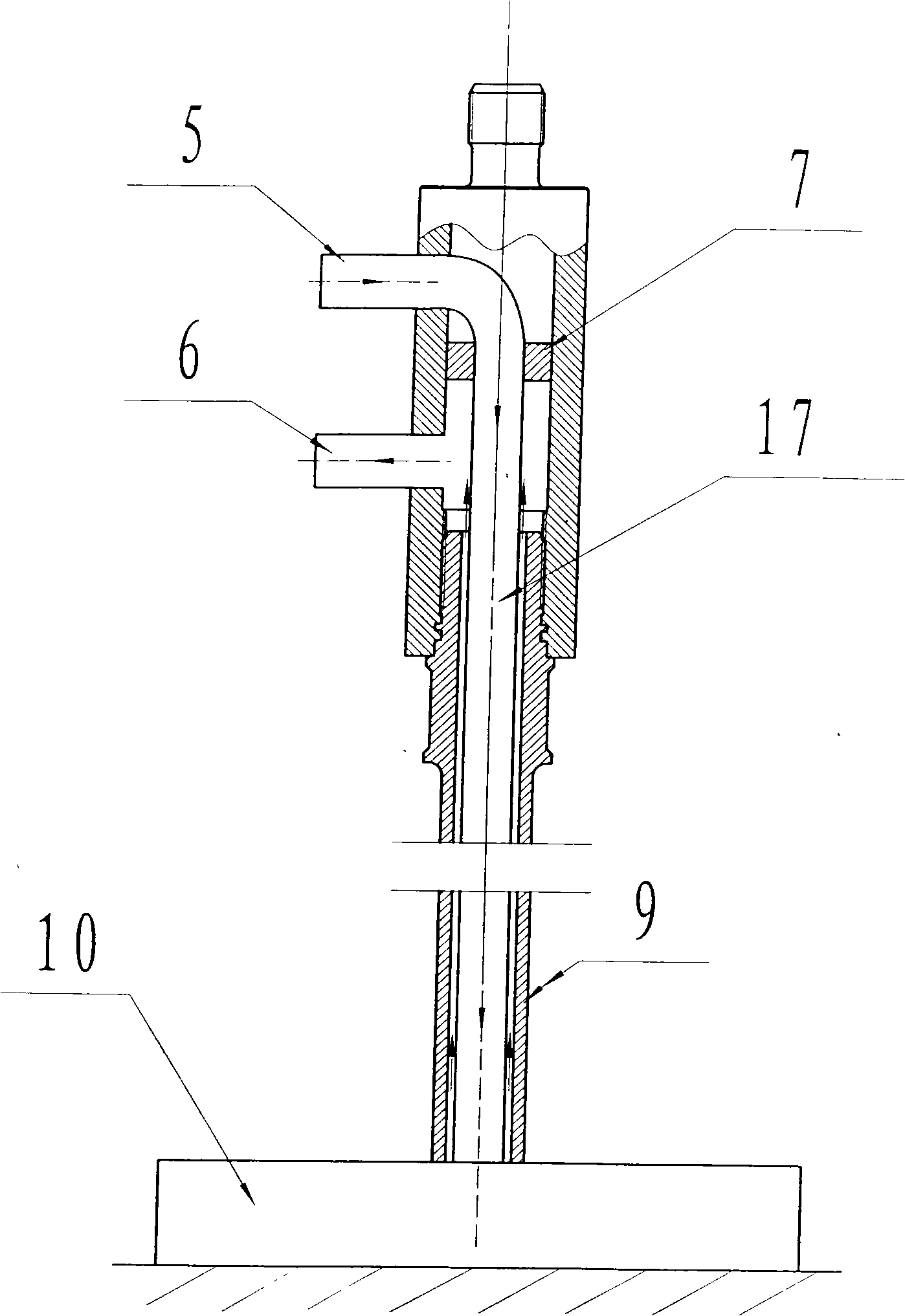

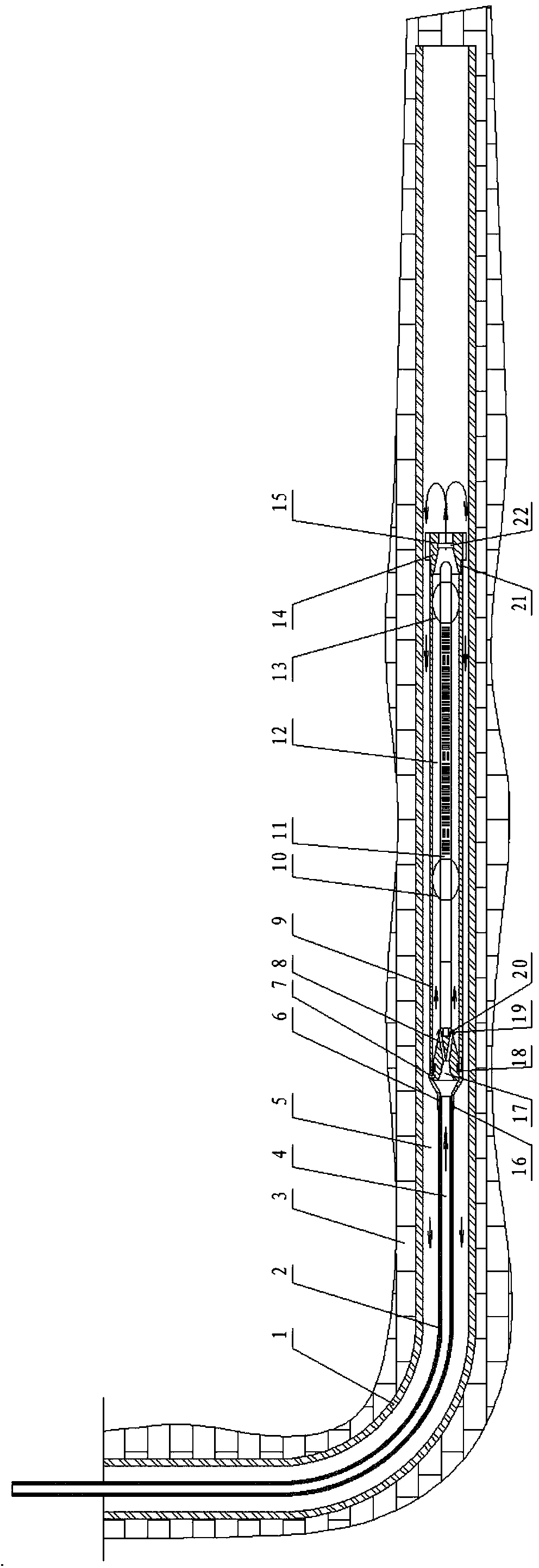

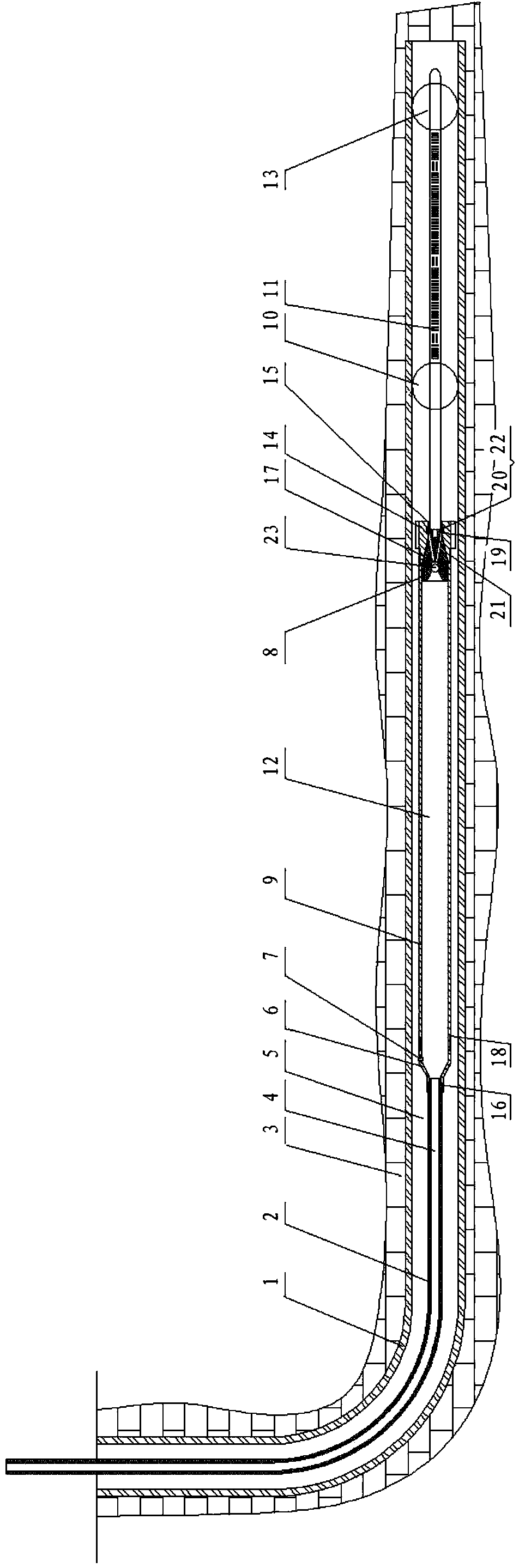

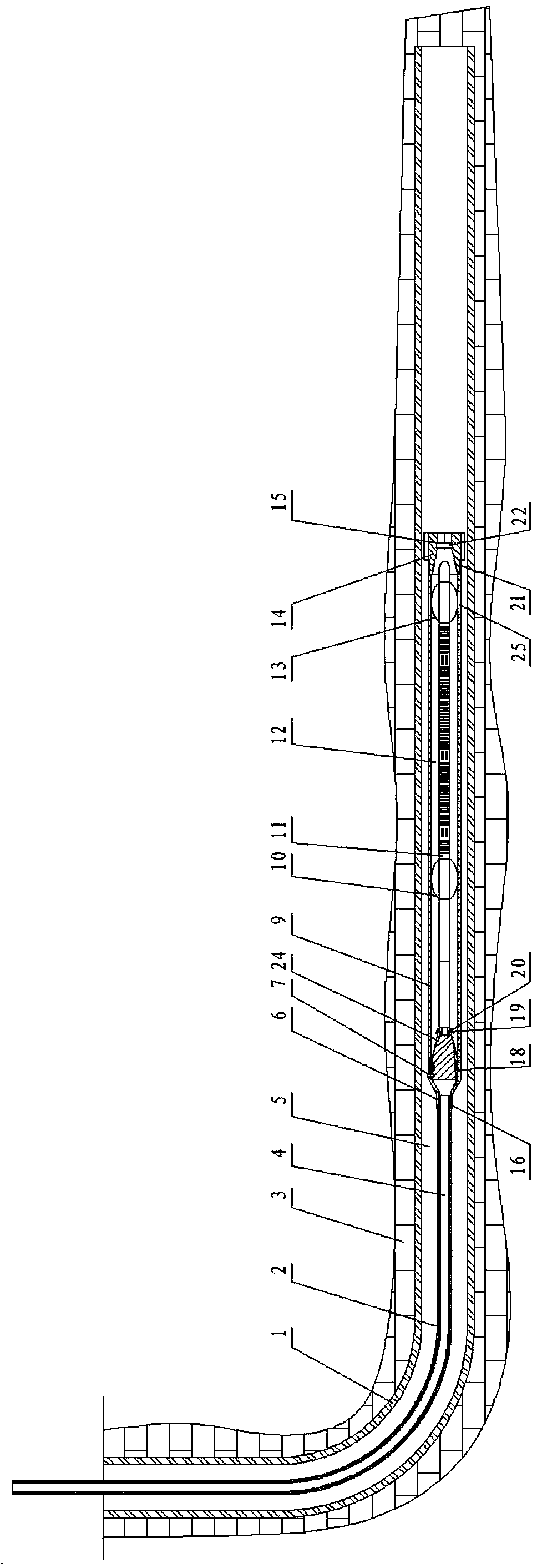

Thick oil well bore heating and viscosity reducing hot extraction method and apparatus

InactiveCN101289933AReduce investmentReduce the disadvantages of inaccurate measurementFluid removalEngineeringEnergy conservation

The invention relates to a viscous oil pitshaft heating and thinning thermal excavation method and a device using the same. The method is as follows: a hollow sucker rod is sleeved with an insulating tube and two thermal cycling tunnels are formed, an external circulation pipe line is connected to a heating furnace and a circulating pump in sequence, and then continuous closed thermal cycling exchanged heating is formed. The device comprises an oil extractor, a polished rod eye, a polished rod clamp, a polished rod connector, the hollow sucker rod, a wellhead device, an oil well pump, the heating furnace, the circulating pump and a circulation pipe line, wherein the hollow polished rod connector is provided with a connecting device, and the insulating tube of the hollow sucker rod and the two thermal cycling tunnels at outer annular space are respectively abutted with the external circulation pipe line through the connecting device. The technology adopts the method that a proper annular clearance is left between the hollow sucker rod and the insulating tube, a closed circulating independent heating system is formed, thereby saving energy, operating conveniently, and being safe, reliable, and long in service life.

Owner:胜利油田孚瑞特石油装备有限责任公司 +1

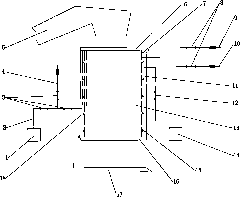

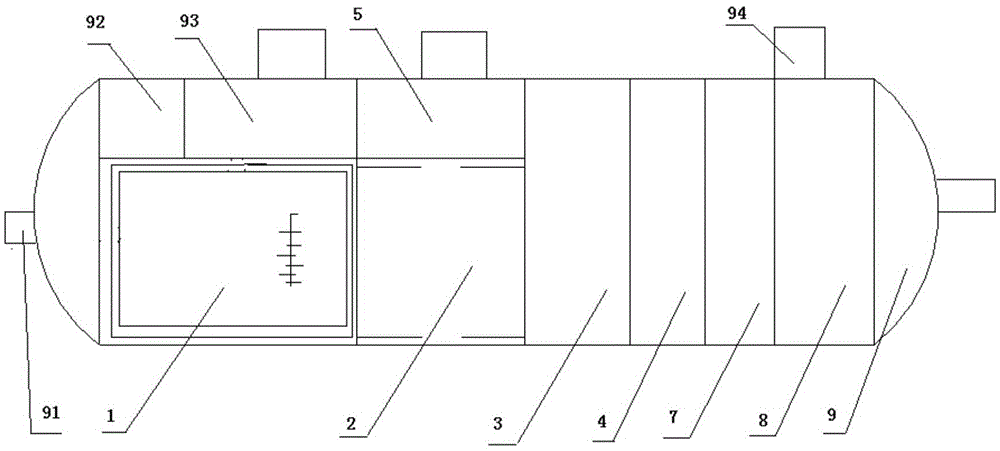

Industrialized vacuum feeding device for tobacco raw material

InactiveCN101822417AImprove uniformityImprove sufficiencyTobacco preparationSpraying apparatusEngineeringRaw material

The invention relates to an industrialized vacuum feeding device for a tobacco raw material, which belongs to the technical field of tobacco raw material production. The vacuum feeding device consists of an external sealed barn (18), a feeding mechanism (5) placed above the external sealed barn (18), a discharging mechanism (17) below the external sealed barn (18), a netlike tobacco raw material barn (13) placed in the external sealed barn (18) and connected with the external sealed barn (18) through a fixed connecting block (19), a vacuum system placed outside the external sealed barn (18), and a steam and compressed air system placed outside the external sealed barn (18). The vacuum feeding device has the advantages of reducing traditional leaf storage process, saving a large amount of time, space and equipment investment, effectively improving production efficiency, along with uniform feeding and liquid loss reduction.

Owner:YUNNAN RES INST OF TOBACCO SCI

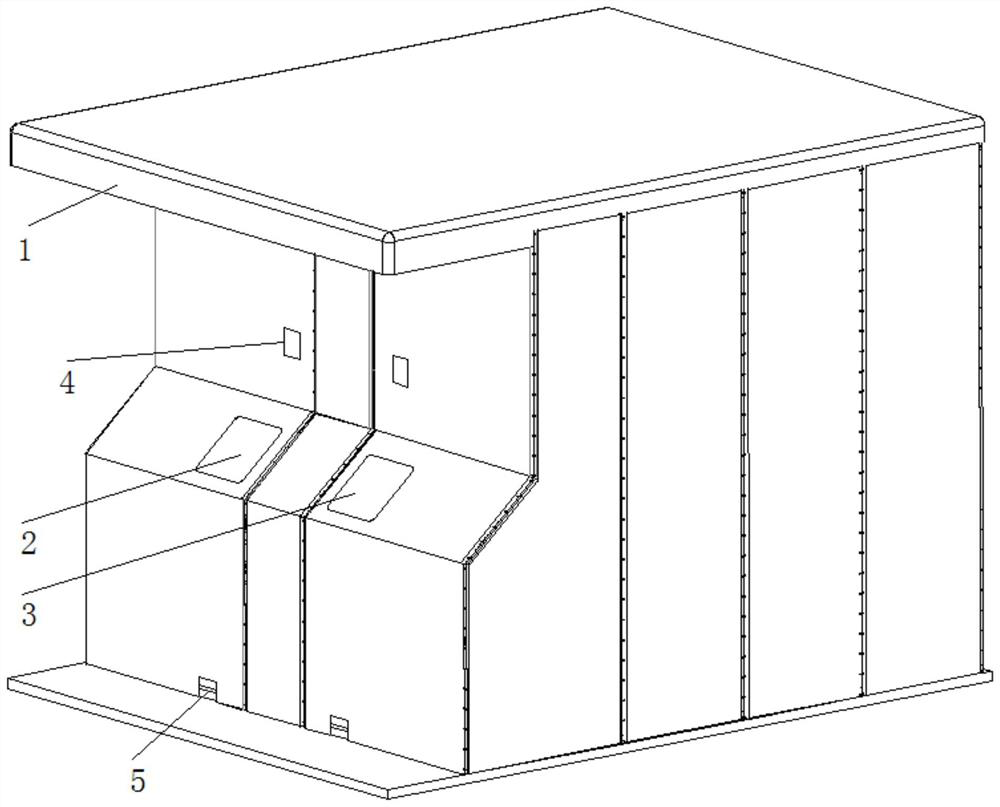

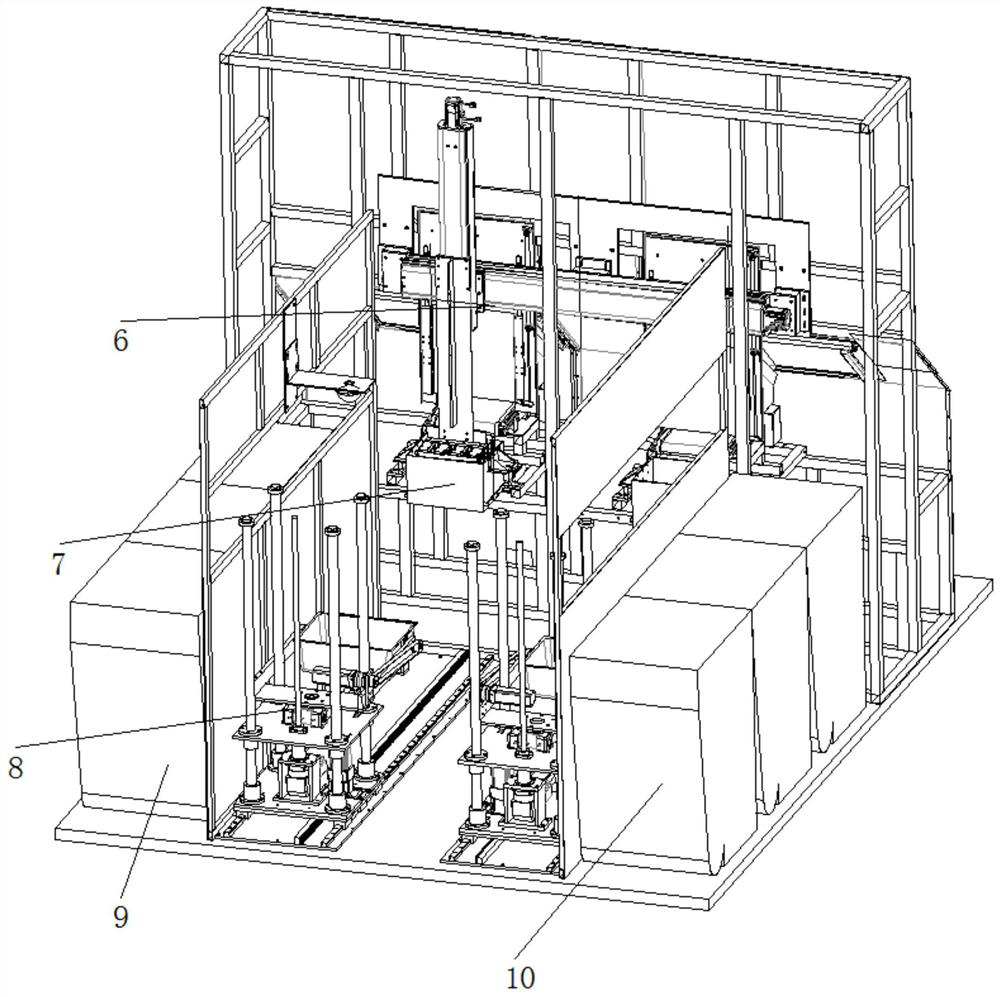

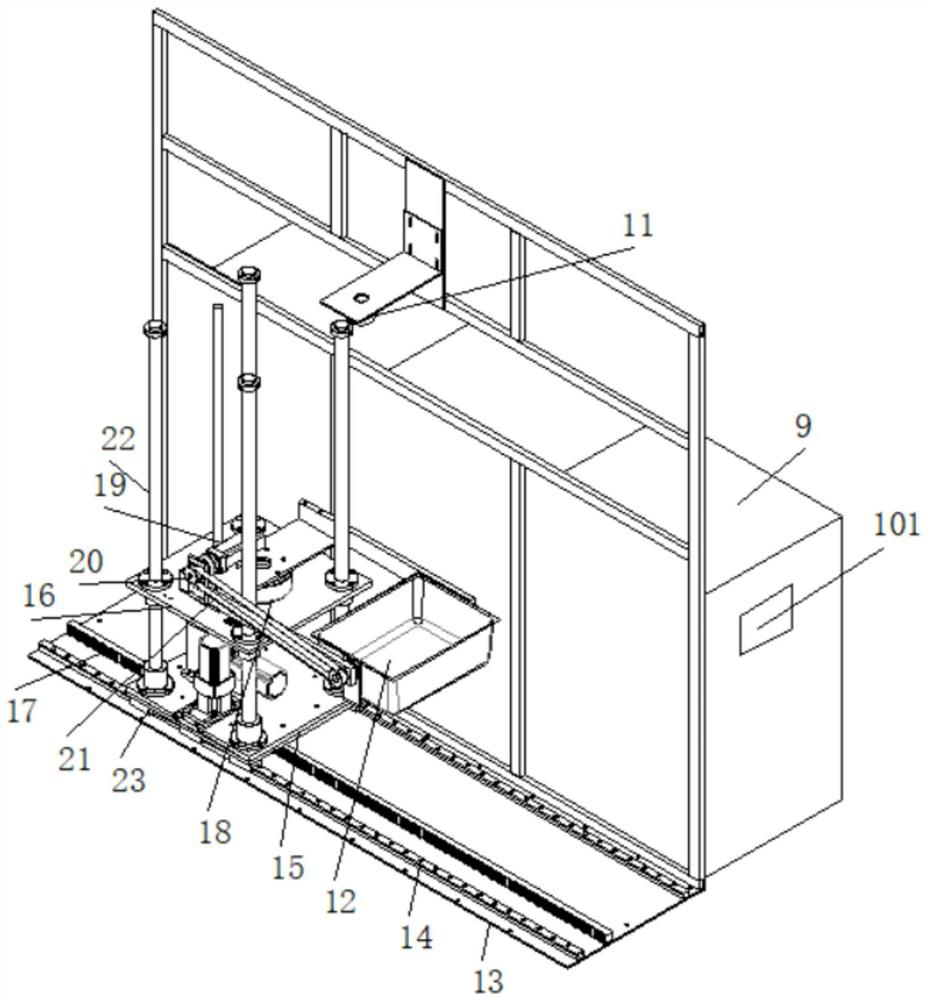

Full-automatic garbage classification and recovery equipment

PendingCN111940340AMaximizeAchieving Zero Landfill GoalWaste collection and transferRefuse receptaclesProcess engineeringIndustrial engineering

The invention belongs to the technical field of garbage classification and recovery, and particularly relates to full-automatic garbage classification and recovery equipment. The full-automatic garbage classification and recovery equipment comprises an equipment body, an automatic bag breaking and taking mechanism, a clamp mechanism, an automatic photographing recognition mechanism and an automatic classification and conveying mechanism. Infrared induction devices are arranged above the top of a perishable garbage inlet and the top of an other garbage inlet, skirting induction devices are arranged below the bottom of the perishable garbage inlet and the bottom of the other garbage inlet, bag taking moving mechanisms are arranged at the inner side end of the perishable garbage inlet and theinner side end of other garbage inlet, and a bag breaking hopper is arranged below a clamp. A receiving hopper is arranged below the bag breaking hopper, a camera is installed above an automatic conveying mechanism, and other garbage cans and perishable garbage cans are distributed on the two sides of the automatic conveying mechanism, so that the functions of automatic bag breaking and taking, automatic photographing recognition and automatic classification throwing of garbage are achieved, and therefore the garbage classification efficiency and classification quality are improved; and the garbage resource utilization is realized.

Owner:嘉兴市智鹏科技有限公司

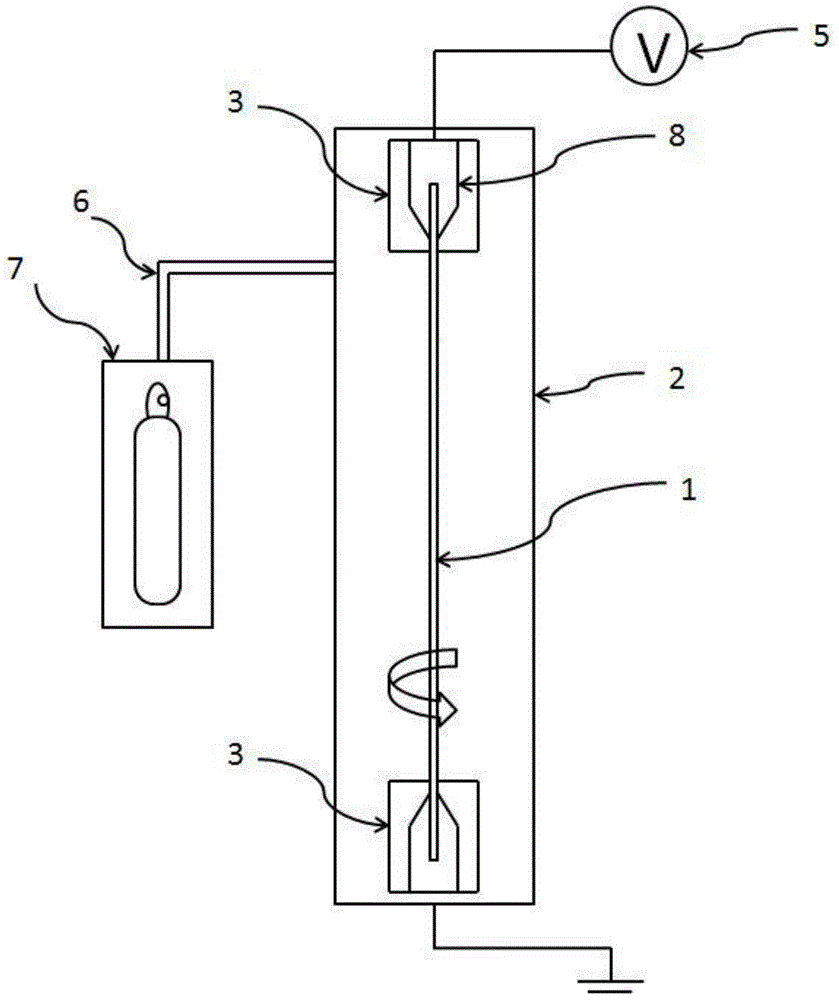

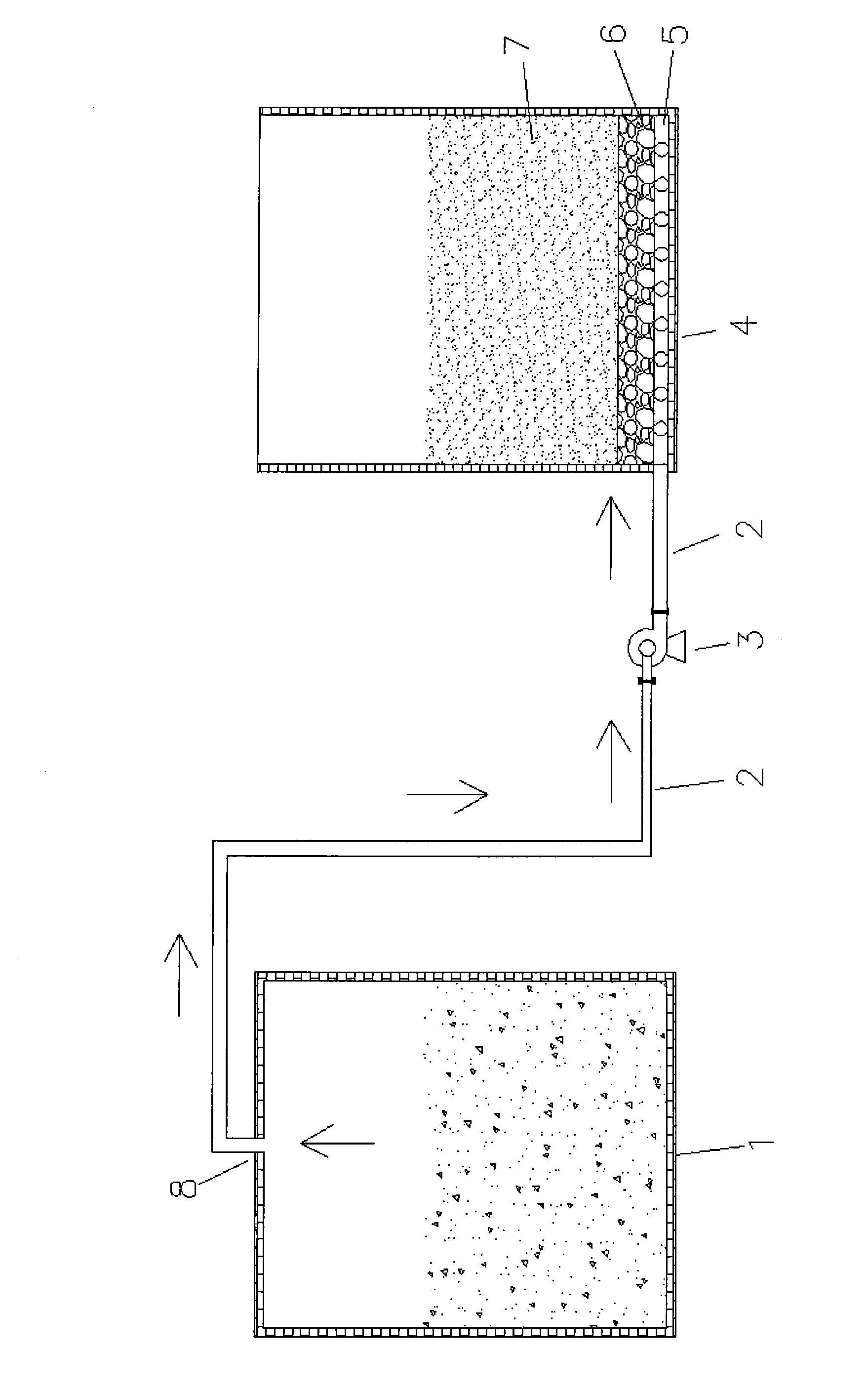

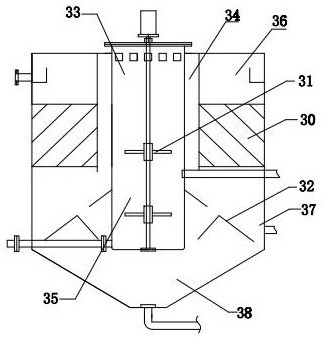

Recovery system suitable for livestock manure compost volatilized ammonia nitrogen and process thereof

ActiveCN104276860AImprove adsorption capacityPromote absorptionClimate change adaptationExcrement fertilisersLivestock manureFeces

The invention discloses a recovery system suitable for livestock manure compost volatilized ammonia nitrogen and a process thereof. The system is composed of a compost fermentation bin, gas conveying pipelines, a centrifugal fan and an ammonia absorption bin. Specifically, the ammonia absorption bin includes a gas distribution system, a cushion material and an absorbing material. In a livestock manure composting process, the centrifugal fan is employed to pump all the ammonia in the compost fermentation bin out and send the ammonia into the ammonia absorption bin, after even distribution by the gas distribution system, the ammonia upward enters the cushion material layer and the absorbing material layer in order, the ammonia is adsorbed by the absorbing material in the contact process of the ammonia and the absorbing material and is digested and utilized as microbial nutrients on the material, thus realizing recovery of nitrogen in the ammonia. The system utilizes the centrifugal fan to convey the ammonia to the absorbing material bottom reasonably, and employs the gas distribution system to distribute the gas evenly and then recover the ammonia, thus greatly improving the recovery efficiency. At the same time, the system has a simple structure, makes full use of agricultural resources, and has the advantages of low cost, high efficiency, and no secondary pollution, etc.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

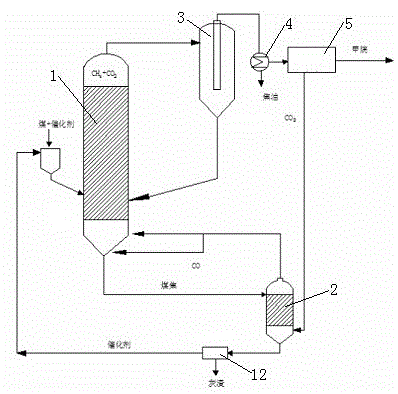

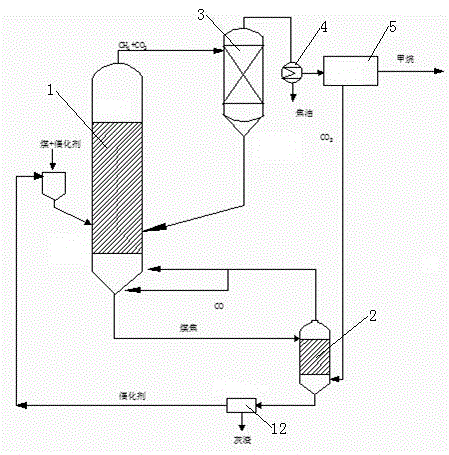

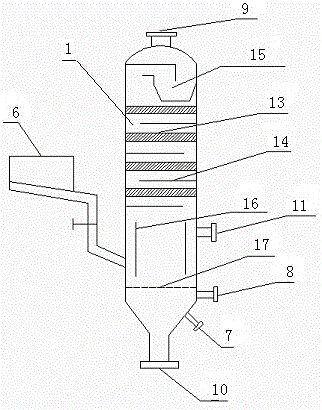

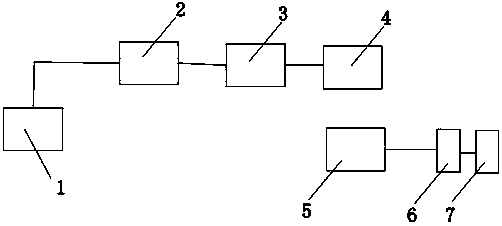

Device and method for catalyzing lignite to prepare methane directly

InactiveCN104651005ASave spaceSave equipment investmentGaseous fuelsBulk chemical productionChemistryCarbon dioxide

The invention discloses a method and a device for catalyzing lignite to prepare methane directly. The method comprises the following steps: forming pulverized coal by raw material lignite, carrying out coal cracking, coal gasification, coal methanation and synthesis gas methanation reactions in a reaction furnace, to generate methane-enriched gas and coke, and processing the methane-enriched gas by a gas-solid separator and a gas separating device to obtain high-content natural gas; and reacting the coke generated in the reaction furnace with the waste gas carbon dioxide separated out by the gas purifying and separating device to generate carbon monoxide gas, inducing the generated carbon monoxide gas into the reaction furnace to participate the reaction, so as to realize the recycling of the carbon. The coal-made natural gas products can be obtained flexibly as required by the process, the process has the characteristics of high carbon conversation rate, clean products and the like; by utilizing the low-quality lignite with higher water content, the production cost is reduced further. The process for producing substitute natural gas by integration of gasification and methanation is a method with high economic benefit and high competitiveness.

Owner:TAIYUAN UNIV OF TECH

Method for recovering struvite from municipal sludge

ActiveCN112608005AHigh phosphorus contentHigh extraction recoverySludge treatment by de-watering/drying/thickeningTreatment involving filtrationFluid phaseSludge

The invention provides a method for recovering struvite from municipal sludge, which comprises the following steps: carrying out ultrasonic treatment on the municipal sludge to break cells while breaking the sludge, thereby promoting the release of intracellular moisture and PO4<3-> into the liquid phase; secondly, most of solid TP in the sludge can be promoted to be transferred into a liquid phase in a PO4<3-> form, the phosphorus content in the liquid phase after solid-liquid separation of the sludge can be increased, and the follow-up improvement of the struvite extraction recovery rate is facilitated; thirdly, the municipal sludge is subjected to ultrasonic treatment, no extra reagent needs to be added, the treatment cost is low, the process is simple, expensive equipment investment is not needed, capital construction and equipment investment are saved, and application and popularization are facilitated.

Owner:湖南鑫远环境科技股份有限公司

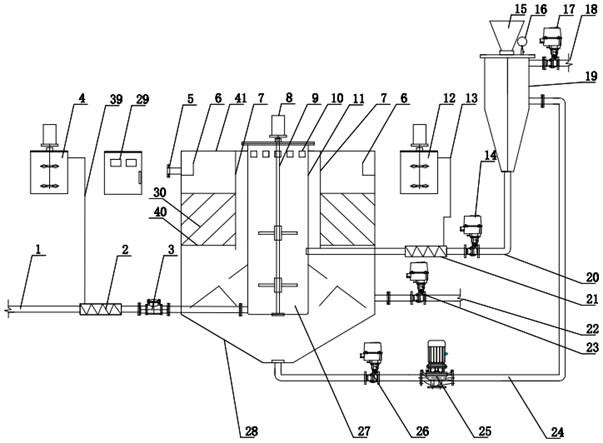

Efficient micro-sand circulating sedimentation device and method thereof

PendingCN114772693AShort stayIncrease in sizeWater/sewage treatment by flocculation/precipitationCheck valveSedimentation

The invention discloses an efficient micro-sand circulating precipitation device and relates to the technical field of sewage treatment. Which comprises a flocculation reaction system, a curing reaction zone, an efficient precipitator, a flocculant dosing device and a micro sand circulating system, the flocculation reaction system is arranged in the efficient precipitator and comprises an inner barrel, a stirring shaft is rotatably arranged in the inner barrel, a mixed reaction zone is arranged at the upper end in the flocculation reaction system, and the flocculant dosing device is arranged in the mixed reaction zone. The outer side of the inner barrel body is connected with a sewage pipe, the upper end of the sewage pipe is provided with a static mixer and a check valve, on the basis of the traditional flocculation and sedimentation tank theory, micro sand is added to accelerate flocculation agglomeration and sedimentation, the retention time of the sedimentation tank is shortened, rapid solid-liquid separation is achieved, the device is integrally designed, the occupied area and energy consumption are saved, and the device is suitable for large-scale popularization and application. The device consists of a flocculation reaction system, a curing reaction area, an efficient precipitator, a flocculating agent dosing device, a macromolecular coagulant aid dosing device, a rotational flow mud-sand separation device, a micro sand circulation supplementing device and a PLC (Programmable Logic Controller) electrical control system.

Owner:QINHUANGDAO PENYAO ENVIRONMENTAL PROTECTION ENG

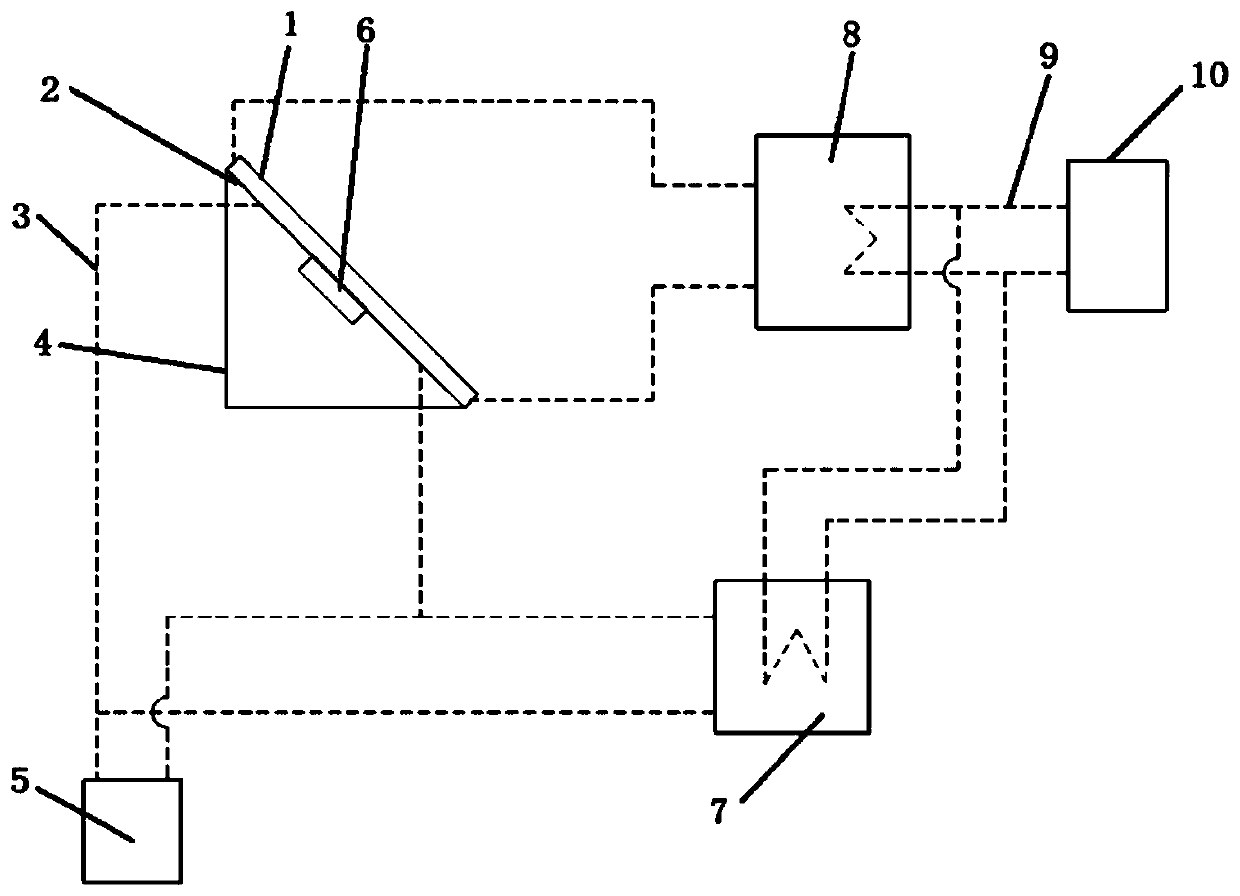

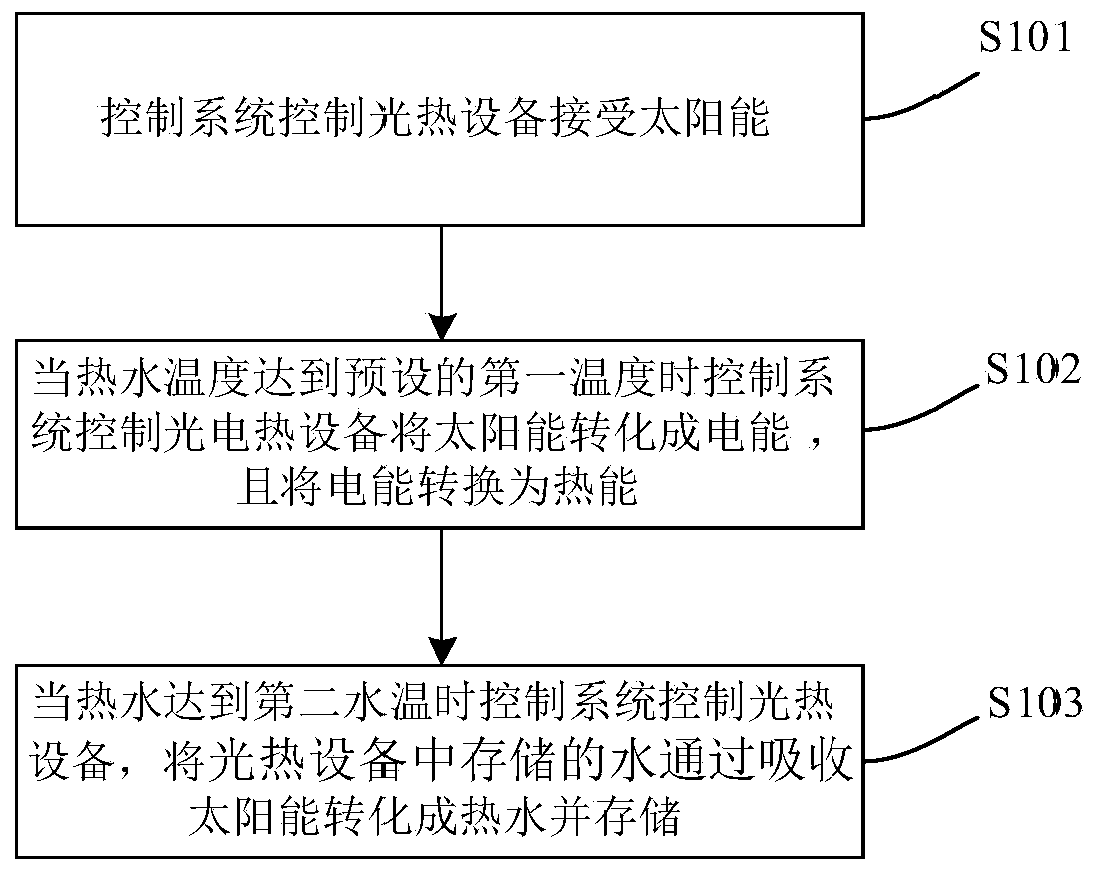

Integrated energy system based on molten salt device

PendingCN110401410ASolve the practical problems of power supply and heatingObvious economic advantagesPhotovoltaicsEnergy storageThermal energyIntegrated energy system

The invention provides an integrated energy system based on a molten salt device. The system includes a photoelectric thermal device used for converting solar energy into electrical energy and converting the electrical energy into thermal energy, a photothermal device used for converting the water stored in the photothermal device into the hot water by absorbing the solar energy, and a control system used for controlling the photoelectric thermal device and the photothermal device to alternately receive the solar energy based on a preset first water temperature and a second preset water temperature, wherein the first water temperature is higher than the second water temperature, not only the cost of cable laying is saved, but also line loss is reduced, decentralized photovoltaic power generation networking difficulty is reduced, the new energy can be locally consumed, the user's heat demand is met, and adaptive adjustment is achieved. The system is advantaged in that the system has huge economic advantages compared with laying of the circuit, can greatly reduce the volume of the equipment, save the floor space and equipment investment, can greatly improve energy conversion efficiency and meet the electricity and heat demand of the user.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

System and method for treating cadmium-bearing solution

InactiveCN105950887AImprove replacement efficiencyIncrease flow rateProcess efficiency improvementFeed devicesProcess engineeringReplacement procedure

The invention discloses a system and method for treating a cadmium-bearing solution. The system for treating the cadmium-bearing solution comprises a cadmium-bearing solution storage device, a first delivery pipeline, a feeding pump, a second delivery pipeline, a pipeline reactor and a zinc powder supply device, wherein the first delivery pipeline is connected with the cadmium-bearing solution storage device; the feeding pump is connected with the first delivery pipeline; the second delivery pipeline is connected with the feeding pump; the pipeline reactor is connected with the second delivery pipeline; and the zinc powder supply device is connected with at least one of the first delivery pipeline, the second delivery pipeline and the pipeline reactor. By the adoption of the system, the technological parameters in the replacement procedure can be optimized to a great extent, the continuity of original operation is guaranteed, and electric energy consumption and equipment investment caused by extra stirring are omitted.

Owner:CHINA ENFI ENGINEERING CORPORATION

Wastewater treatment technology and device using dominant bacteria

InactiveCN105523693AEasy to handleShort hydraulic retention timeSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesSmall footprintReaction zone

The invention discloses a wastewater treatment device using dominant bacteria. The device comprises an efficient fluidized-state aerobic digestion tank, a contact oxidation tank, a settling tank and a biological adsorption tank which are sequentially connected, wherein the efficient fluidized-state aerobic digestion tank comprises an aerobic digestion reaction zone, filler and multiple baffles for turbulence are arranged in the aerobic digestion reaction zone, and multiple aeration heads for driving domestic wastewater of the aerobic digestion reaction zone to produce rotational flows are also arranged in the aerobic digestion reaction zone. The wastewater treatment device using the dominant bacteria efficiently treats domestic wastewater containing suspended solids under the aerobic condition, works stably and occupies a small area, and a wastewater treatment technology using the dominant bacteria treats the domestic wastewater containing the suspended solids by using the wastewater treatment device using the dominant bacteria.

Owner:GUANGZHOU CITY SHUOKANG MEDICAL TECH CO LTD

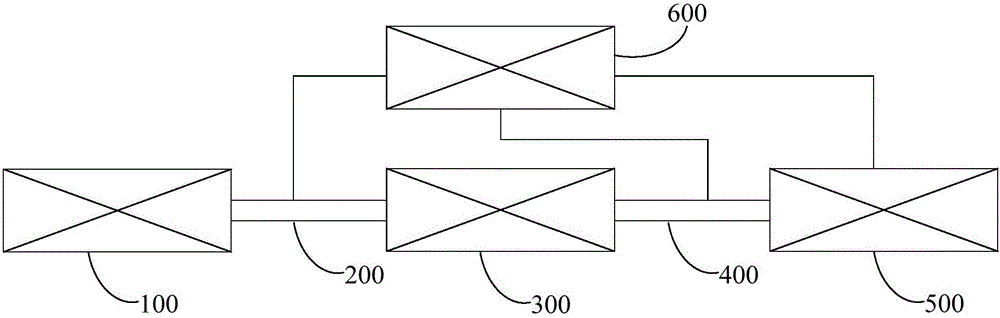

Automatic wall board production device and method

PendingCN108582457AReduces or even eliminates problems with core tube slots that do not fit precisely into the mold cavityImprove work efficiencyCeramic shaping plantsCeramic shaping mandrelsMechanical engineeringEquipment requirement

The invention discloses an automatic wall board production device and method. The automatic wall board production device comprises a feeding unit, a metering unit, a mixing unit, a conveying unit, a die unit, a core pipe unit and a core pipe inserting and pulling unit. The feeding unit is connected with the metering unit. The metering unit is further connected with the mixing unit. The mixing unitis connected with a discharging unit. The die unit is located below the discharging unit. Eight or more rows of core pipes of the core pipe unit are arranged, and the longitudinal section of each core pipe is in a trapezoid shape. The two ends of the die unit are provided with core pipe passing holes. The two ends of the core pipe inserting and pulling unit are provided with core pipe supportingunits. When the core pipes are pulled out, the process is conducted in a row dividing pulling-out manner. By means of the automatic wall board production device and method, eight or more wall boards can be produced at the same time, and the production time of each wall board is shortened by 20% or above; in addition, the requirement for equipment pull force is lowered by 50% or above, the production efficiency is greatly improved; and meanwhile, the equipment requirement is lowered, and the production cost and equipment investment are saved.

Owner:CHENGDU SHANGZHU BUILDING MATERIALS

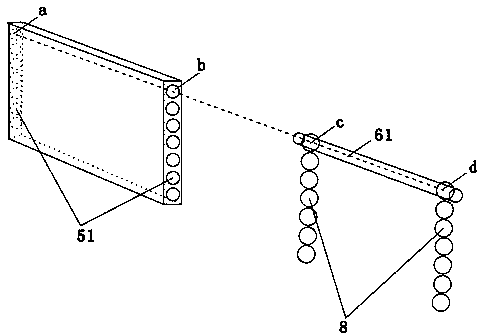

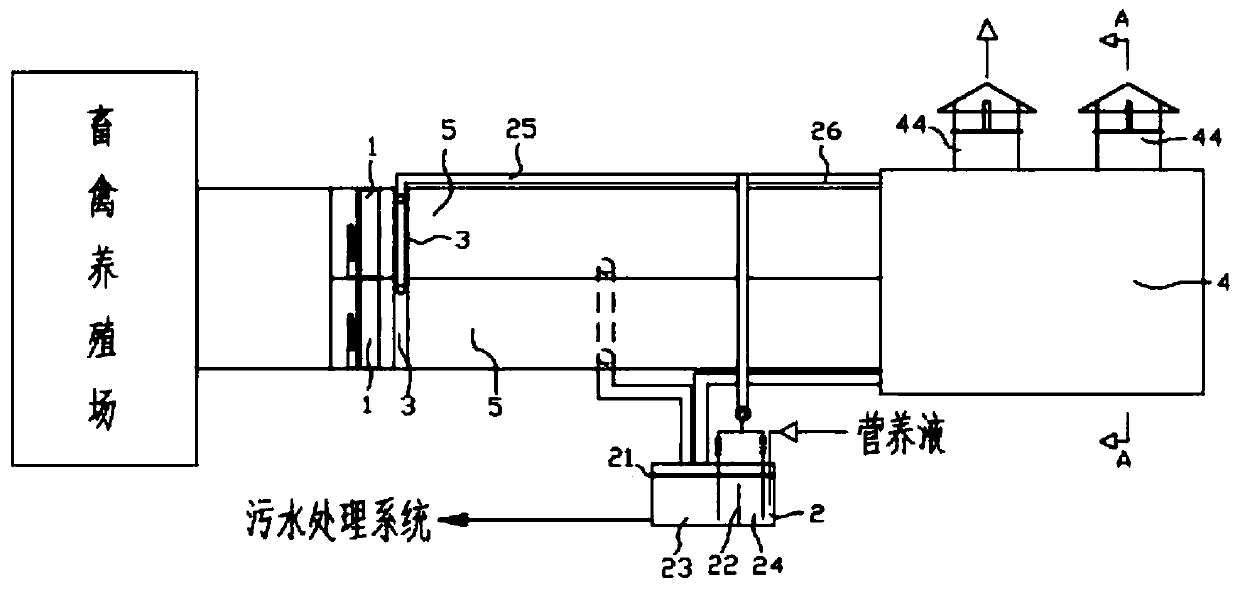

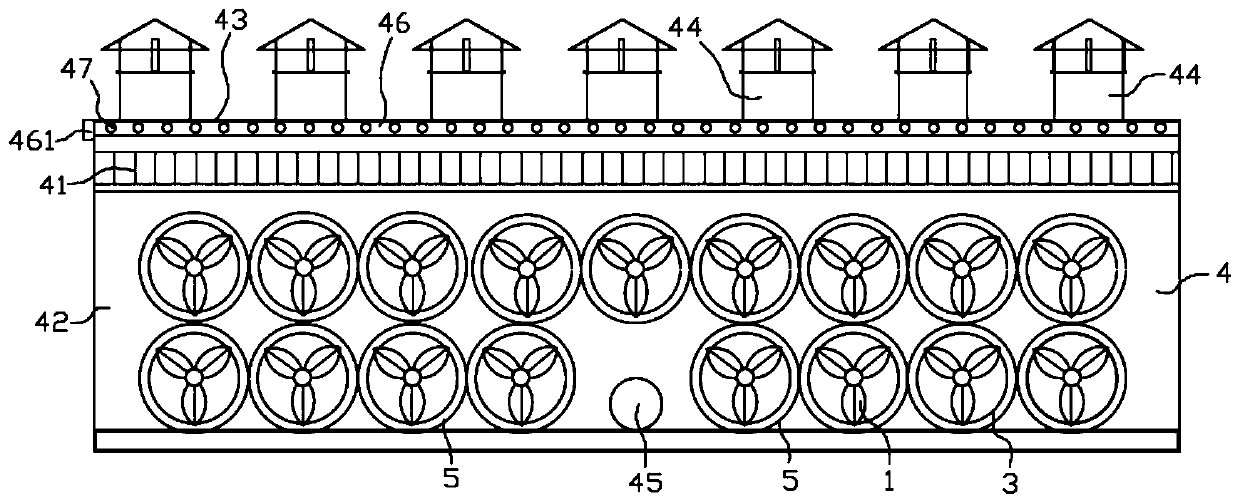

Livestock and poultry breeding waste gas treatment device and deodorizing process thereof

ActiveCN110038422AHigh porositySmall pressure lossGas treatmentUsing liquid separation agentSewageControllability

The invention discloses a livestock and poultry breeding waste gas treatment device and a deodorizing process thereof. The device mainly includes low-pressure exhaust fans, a sewage collection pit, annular water spraying devices and a biological deodorization device. The low-pressure exhaust fans are multiple and are mounted in exhaust pipes near an air outlet of a livestock and poultry farm. Theannular water spraying devices are mounted in the exhaust pipes at air outlets of the low-pressure exhaust fans. An A part of the sewage collection pit is connected to the annular water spraying devices through water pump pipelines, and a B part is connected to a spraying system of the biological deodorization device through a lifting pump pipeline. The air outlets of the low-pressure exhaust fanscommunicate with the biological deodorization device through the exhaust pipes. The middle parts of the exhaust pipes communicate with the A part of the sewage collection pit through pipelines. The bottom of the biological deodorization device communicates with the A part of the sewage collection pit through a pipeline. The device of the invention has the advantages of low energy consumption, strong controllability, good deodorization effect and simple and efficient process during operation.

Owner:恩宜瑞(江苏)环境发展有限公司

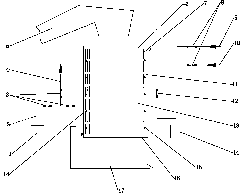

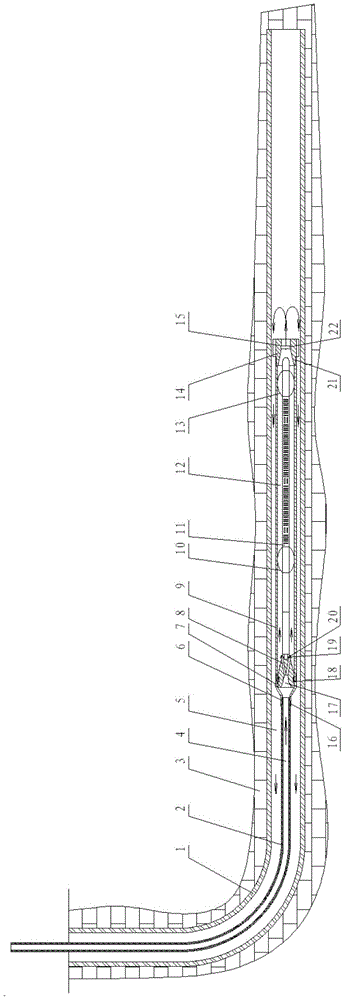

Device and method for integrating well dredging and well flushing, and well logging of cement bond well cementing quality

ActiveCN104343436AReduce the number of tripsReduce in quantityConstructionsFlushingWell loggingLocking mechanism

The invention discloses a device and a method for integrating well dredging and well flushing, and well logging of cement bond well cementing quality. The device comprises a continuous oil pipe, an ordinary oil pipe or a drill rod which extend into a petroleum well to be connected from top to bottom, wherein the continuous oil pipe, the ordinary oil pipe or the drill rod is connected with a protecting pipe through a rotating connector, and an instrument bunch which is centralized through a pair of centralizers is arranged in a pipe cavity of the protecting pipe; the end part of the protecting pipe is connected with a gauge cutter; a piston which is connected with the rotating connector through a shear pin is arranged in the pipe cavity of the protecting pipe, and the piston is connected with the instrument bunch; a locking mechanism is arranged between the piston and a piston rod, and an unlocking mechanism is arranged on the gauge cutter. A technology comprises two stages of the well dredging and the well flushing, and the well logging of cement bond well cementing quality. The integrated technology technique reduces the number of times that equipment enters the well, reduces the amount of well logging equipment, shortens the well logging time, reduces the equipment investment, and has good market application prospects.

Owner:西安威盛电子科技股份有限公司

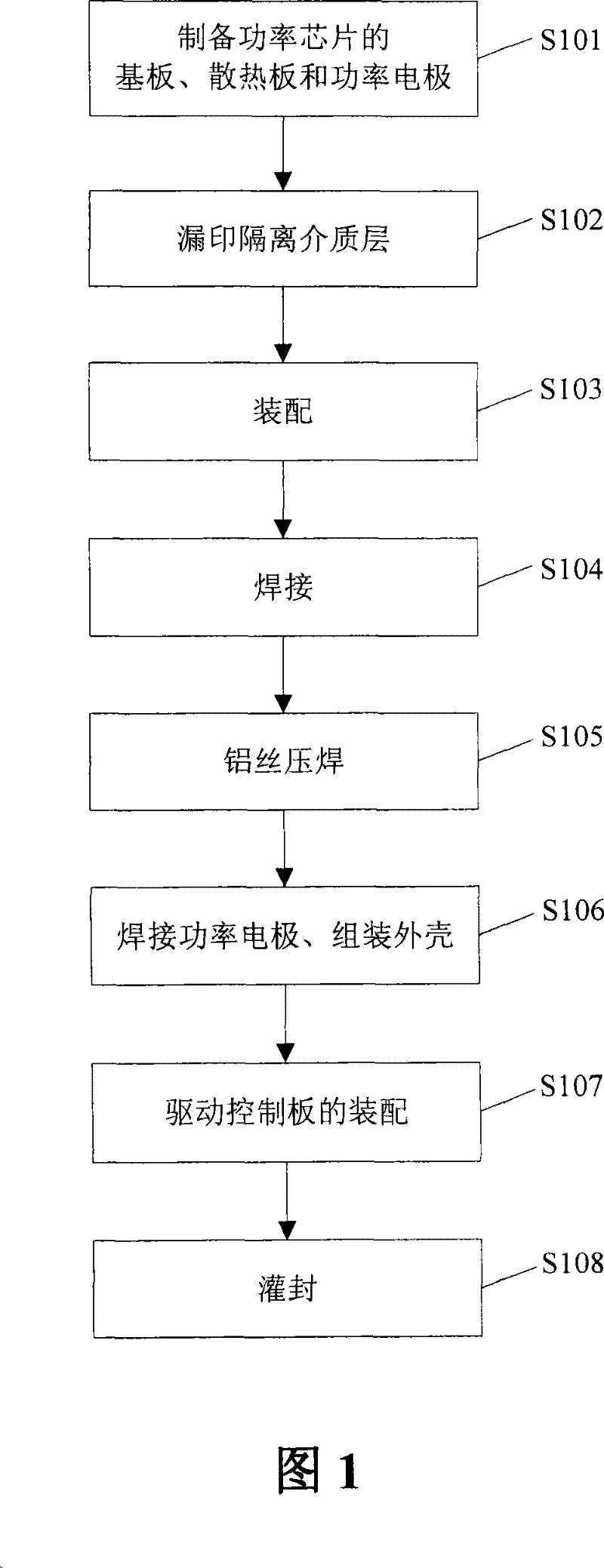

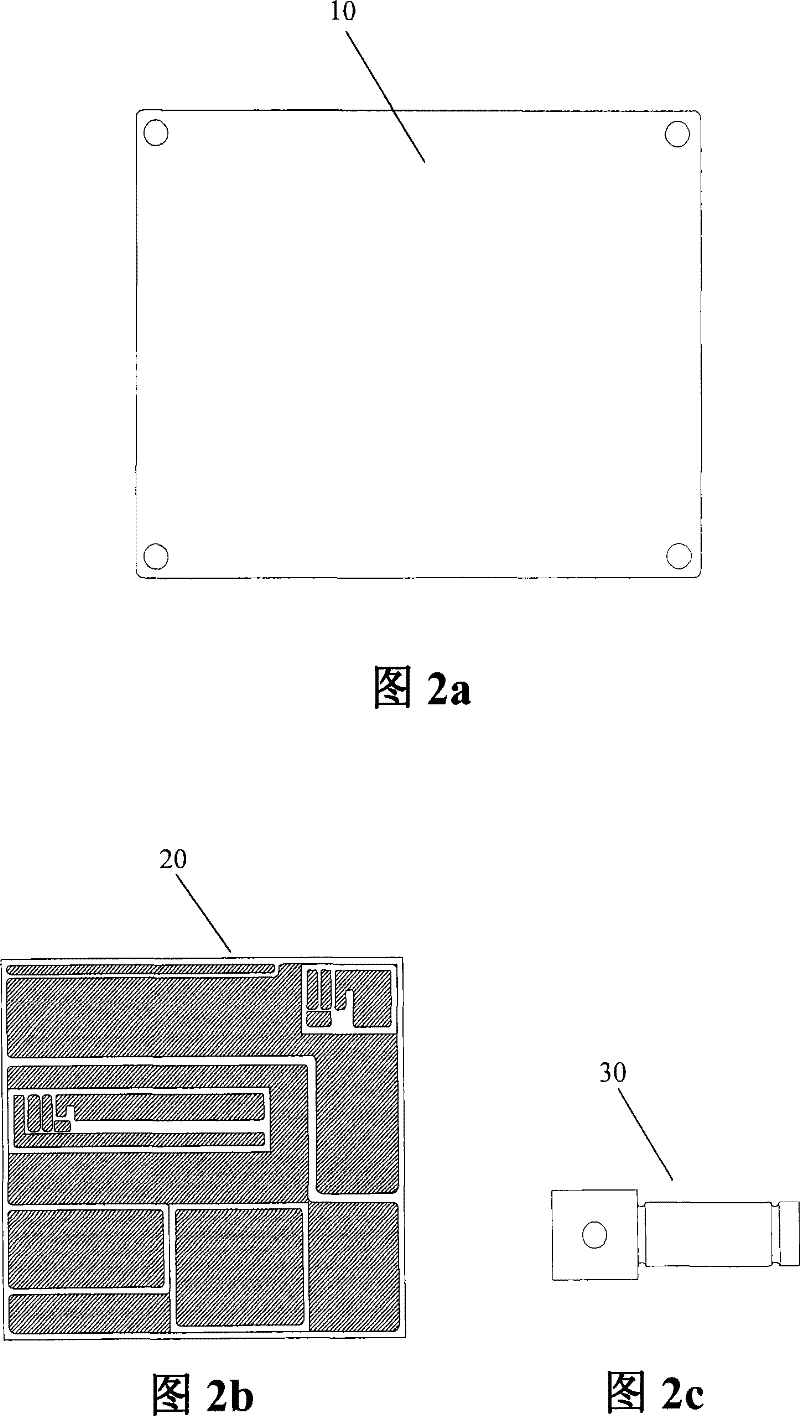

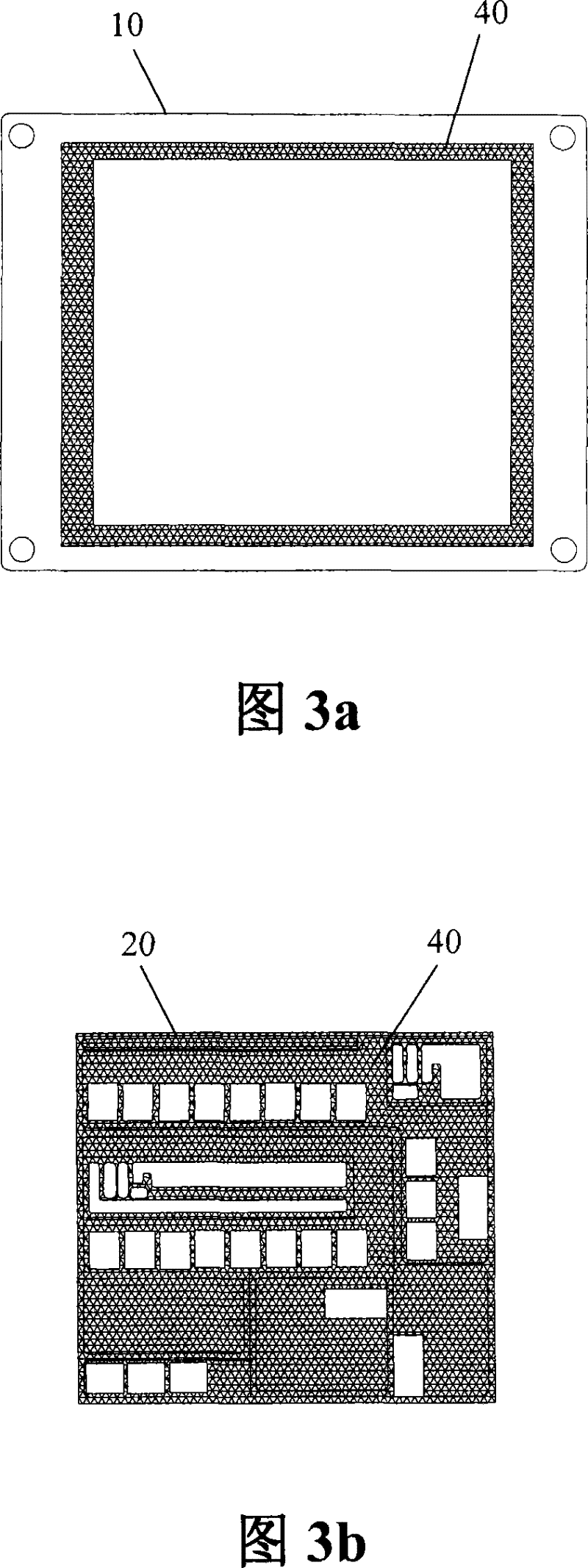

Three-layer stereo power encapsulation method and structure

InactiveCN101494175BImprove bindingEasy to weldSemiconductor/solid-state device detailsSolid-state devicesFirst FillEngineering

The invention discloses a three-layer three-dimensional power encapsulating method and a structure thereof, wherein the method comprises the following steps: step 1. a heating panel, a power electrode and a base plate are prepared and an insulating layer is respectively printed on the base plate and the heating panel to form a hollow picture and ensure the positions of a power chip and the power electrode on the base plate and the position of the base plate on the heating panel fill in the hollow picture; step 2. soldering terminals are arranged on the position of the hollow picture, and the heating panel, the soldering terminal, the base plate, the soldering terminal and the power chip are arranged in a down-top sequence and then welded; step 3. the power chip and the base plate are carried out press welding, an enclosure is arranged on the heating panel, the power electrode is welded on the base plate and a driving control panel is arranged on the power plate; and step 4. a first filled composite is filled between the base plate and the driving control panel and a second filled composite is filled between the driving control panel and the power electrode after the molding of thefirst filled composite. The method realizes that the power base plate, the driving control panel and the power electrode are integrated in one encapsulation.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

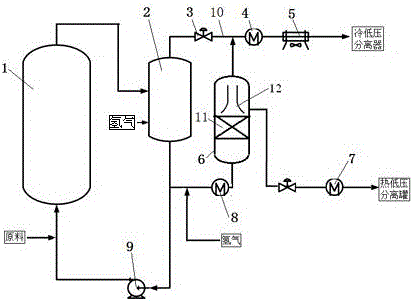

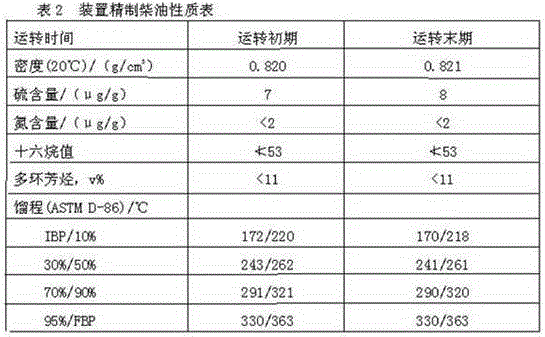

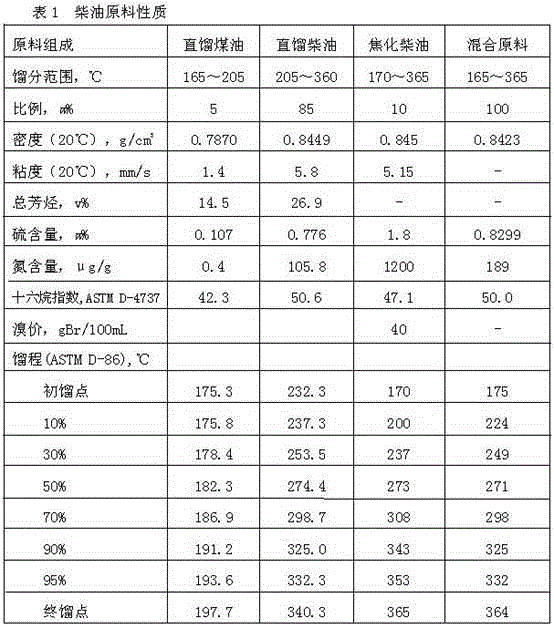

Method and device for producing ultra-low sulfur diesel fuel by liquid phase hydrogenation

ActiveCN105524651BImprove quality levelImprove product qualityTreatment with hydrotreatment processesLiquid productHigh pressure

The present invention relates to a method and an apparatus for producing ultra low sulfur diesel oil through liquid-phase hydrogenation. The apparatus comprises a hydrogenation reactor, a steam stripping separator, a trickle-bed reactor, a gas pipeline, a heat exchanger 1, an air cooler, a circulation pump, a heat exchanger 2, a heat exchanger 3, a cold low-pressure separator and a hot low-pressure separation tank, wherein a catalyst bed layer and a hot high-pressure separator are arranged inside the trickle-bed reactor. According to the present invention, a diesel oil raw material is subjected to a hydrogenation reaction in the hydrogenation reactor, the reaction product is separated in the steam stripping separator to obtain a liquid product, one part of the liquid product returns to the hydrogenation reactor, the other part of the liquid product is mixed with supplemented hydrogen, the obtained mixture is subjected to a second-stage hydrogenation reaction in the trickle-bed reactor, the second-stage hydrogenation reaction product is directly subjected to second-stage hot high-pressure separation to obtain a liquid product, the obtained liquid product is subjected to heat exchange, and the product being subjected to the heat exchange enters the hot low-pressure separation tank; and the second-stage hydrogenation reactor and the second-stage hot high-pressure separator are additionally arranged, the diesel oil raw material is subjected to the first-stage hydrogenation, the obtained raw material is continuously subjected to the deep hydrogenation reaction, and the sulfur content in the diesel oil being subjected to the two-stage hydrogenation is reduced to less than or equal to 10 ppm so as to improve the quality grade of the diesel oil product.

Owner:CHINA PETROLEUM & CHEM CORP

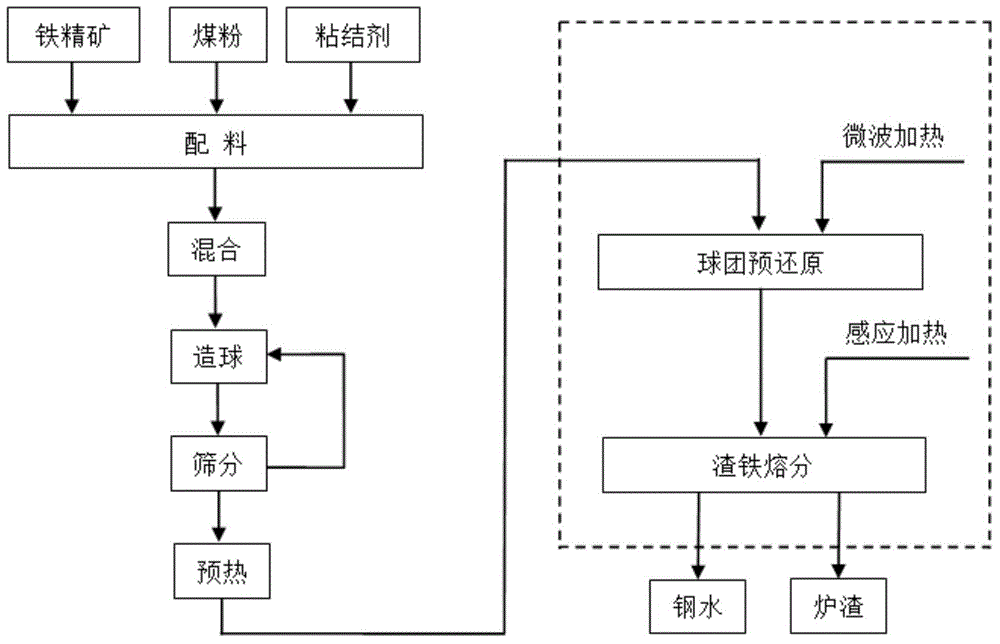

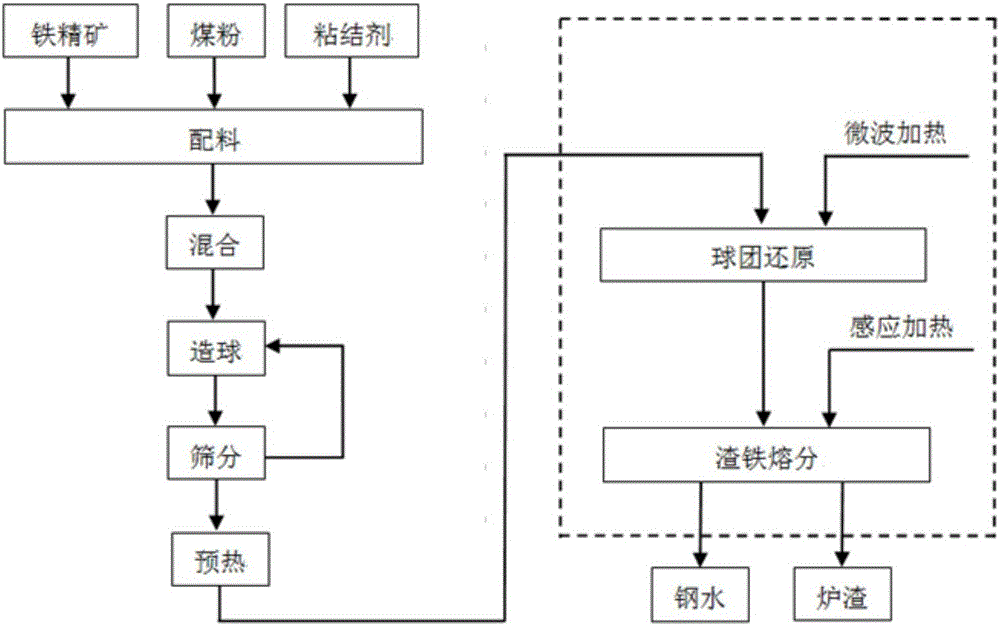

Method for producing molten steel continuously through microwave and induction heating of carbon-containing pellets

ActiveCN105950810AComplete restorationReduce trimmingProcess efficiency improvementSteelmakingMicrowave

The invention discloses a method for producing molten steel continuously through microwave and induction heating of carbon-containing pellets and belongs to the technical field of ferrous metallurgy. The method for producing the molten steel continuously through microwave and induction heating of the carbon-containing pellets comprises the steps of feeding and preheating of the carbon-containing pellets, reduction of the carbon-containing pellets, formation of a steel bath pool, and the melt separation reaction of iron slag. By using the technical scheme, ultrashort-procedure direct steemaking can be achieved; by controlling the C / O molar ratio of the added carbon-containing pellets, control over the C content in the molten steel is achieved, and the problems that in the prior art, bubblization of furnace slag is caused, and the metallization ratio is low after the carbon-containing pellets are reduced are solved; the energy utilization rate is high, the production efficiency is high, and continuous steelmaking is achieved; and in addition, the capital cost and equipment investment are greatly reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Comprehensive recycling process for potassium-containing tailings after extraction of potassium sulfate from salt lake brine

ActiveCN112110461ASolve the problem of introducing flotation mother liquorReduce manufacturing costSievingScreeningEnvironmental engineeringPotassium sulfate

The invention discloses a comprehensive recycling process for potassium-containing tailings after extraction of potassium sulfate from salt lake brine. The comprehensive recycling process comprises the following steps: (1) separating potassium chloride flotation tailings and picromerite flotation tailings through a vibrating screen; (2) mixing the potassium chloride flotation tailings obtained inthe step (1) and the picromerite flotation tailings screen underflow, adding water or brackish water or picromerite conversion mother liquor, then adding a reverse flotation reagent, and carrying outflotation-solid-liquid separation to obtain industrial salt; (3) adding fresh water or brackish water or potassium sulfate high-potassium mother liquor into the sodium chloride flotation tailings obtained in the step (2) to be mixed, and conducting conversion-solid-liquid separation; and (4) mixing potassium chloride with the picromerite concentrate obtained in the step (3) and water or brackish water, conducting converting to generate potassium sulfate and potassium sulfate high-potassium mother liquor, and after solid-liquid separation, washing and drying solid potassium sulfate to obtain apotassium sulfate product. The method does not need an ore grinding process, is low in energy consumption, mainly prepares potassium sulfate and industrial salt, and is good in product purity, high inyield and low in cost.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Full-automatic keel door plate production assembly line

The invention provides a full-automatic keel door plate production assembly line. The full-automatic keel door plate production assembly line comprises a molding machine, a pre-heating unit, a filling unit, a traction unit, a heating device, a material fracturing unit, a semi-finished product sizing platform, a semi-finished product buffering region and a packaging unit which are connected in sequence, and further comprises a rolling machine PLC computer control device for controlling the whole assembly line to work; the molding machine comprises a panel molding unit, a plurality of back plate molding units, a panel discharging unit and a back plate discharging unit; the panel molding unit is connected with the panel discharging unit; any back plate molding unit is independently connected with the panel molding unit; and the back plate molding unit which is independently connected with the panel molding unit is connected with the panel discharging unit. According to the full-automatic keel door plate production assembly line provided by the invention, the automatic production is realized and the occupied space is small; and the labor cost and the equipment investment are saved, so that the production cost is reduced, the yield is increased and the production efficiency is improved.

Owner:无锡华腾门业科技有限公司

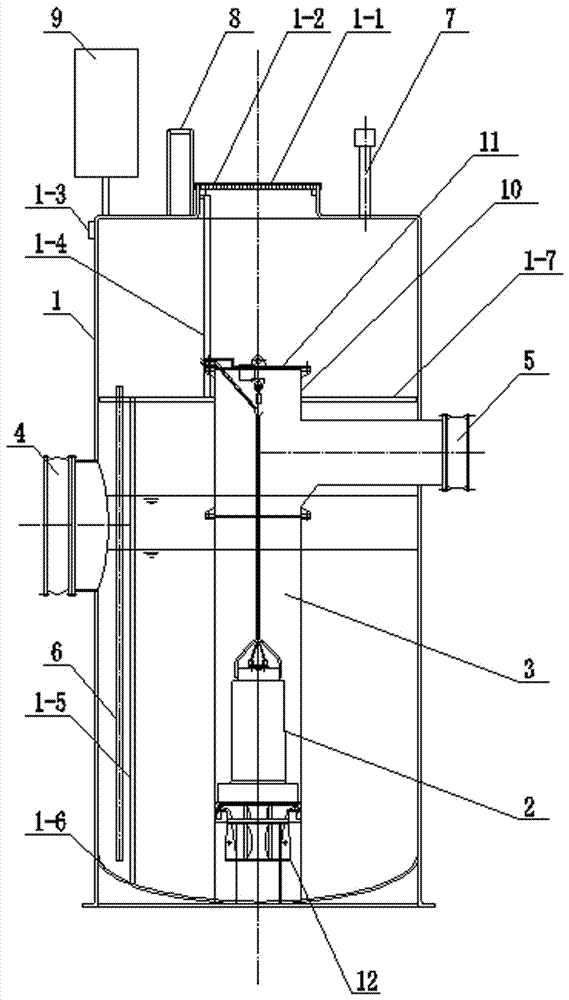

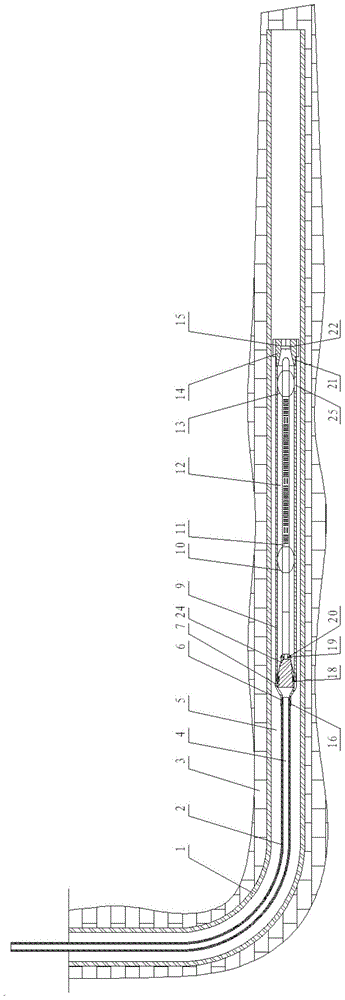

Inner-cylinder axial-flow integrated pre-fabricated pumping station

PendingCN107165257ASave floor spaceSave equipment investmentSewerage structuresControl systemEngineering

The invention relates to an inner-cylinder axial-flow integrated pre-fabricated pumping station. The pumping station comprises a cylinder, a submersible axial-flow type sewage pump, an air discharge pipe and a control system. The cylinder is provided with the air discharge pipe. The submersible axial-flow sewage pump is installed in the middle, or the lower part or the middle-lower part of a shaft. The lower part of the shaft is coaxially installed in the cylinder. The lower part of the shaft communicates with the lower part of the cylinder. The side wall of the middle of the cylinder is provided with a water inlet. The upper part of the shaft is connected with a lower opening of a three-way connector. The side opening of the three-way connector is connected with a water outlet stretching out of the cylinder. The water outlet is higher than the water inlet. An upper opening of the three-way connector is provided with a connector sealing cover. One end of the connector sealing cover is movably hinged and the other end thereof is snapped onto and locked with the upper opening of the three-way connector. The upper opening of the cylinder is provided with a well lid with a safety grille. One end of the well lid is movably hinged and the other end thereof is snapped onto and locked with the upper opening of the cylinder. A maintenance platform is arranged in the cylinder. The height position of the maintenance platform is arranged between a water outlet and the connector sealing cover. An upper ladder is connected between the upper opening of the cylinder and the maintenance platform. The maintenance platform is downwardly connected with a pressure sensor and a lower ladder, both of which stretch into an inner cavity of the cylinder. The submersible axial-flow sewage pump and the pressure sensor are connected with the control system.

Owner:亚太泵阀有限公司

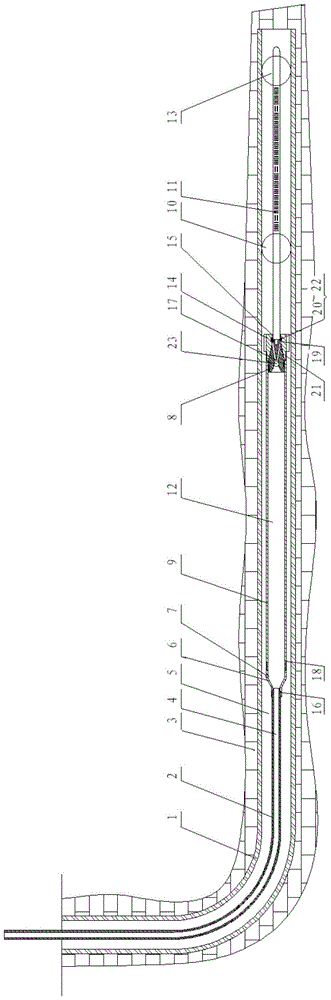

An integrated device and method for well drilling, cement bonding and cementing quality logging

ActiveCN104343436BReduce the number of tripsEasy to operateConstructionsFlushingWell loggingLocking mechanism

The invention discloses a device and a method for integrating well dredging and well flushing, and well logging of cement bond well cementing quality. The device comprises a continuous oil pipe, an ordinary oil pipe or a drill rod which extend into a petroleum well to be connected from top to bottom, wherein the continuous oil pipe, the ordinary oil pipe or the drill rod is connected with a protecting pipe through a rotating connector, and an instrument bunch which is centralized through a pair of centralizers is arranged in a pipe cavity of the protecting pipe; the end part of the protecting pipe is connected with a gauge cutter; a piston which is connected with the rotating connector through a shear pin is arranged in the pipe cavity of the protecting pipe, and the piston is connected with the instrument bunch; a locking mechanism is arranged between the piston and a piston rod, and an unlocking mechanism is arranged on the gauge cutter. A technology comprises two stages of the well dredging and the well flushing, and the well logging of cement bond well cementing quality. The integrated technology technique reduces the number of times that equipment enters the well, reduces the amount of well logging equipment, shortens the well logging time, reduces the equipment investment, and has good market application prospects.

Owner:西安威盛电子科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com