Electromagnetic heating carbon-bearing pellet continuous direct steelmaking device

A technology of carbon pellets and electromagnetics, applied in the direction of electric furnaces, furnace types, furnaces, etc., can solve problems such as low production efficiency and energy utilization, complex process flow, slag foaming, etc., achieve uniform heating, realize heating conditions, and good The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

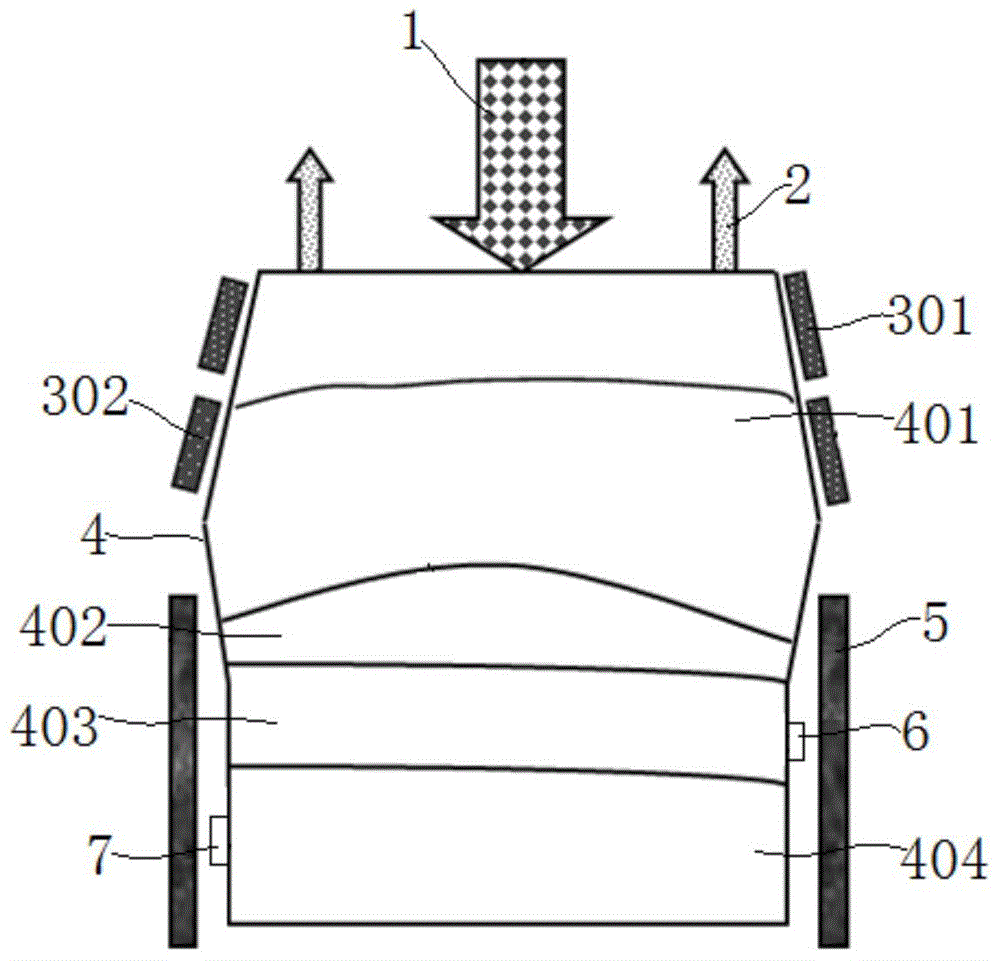

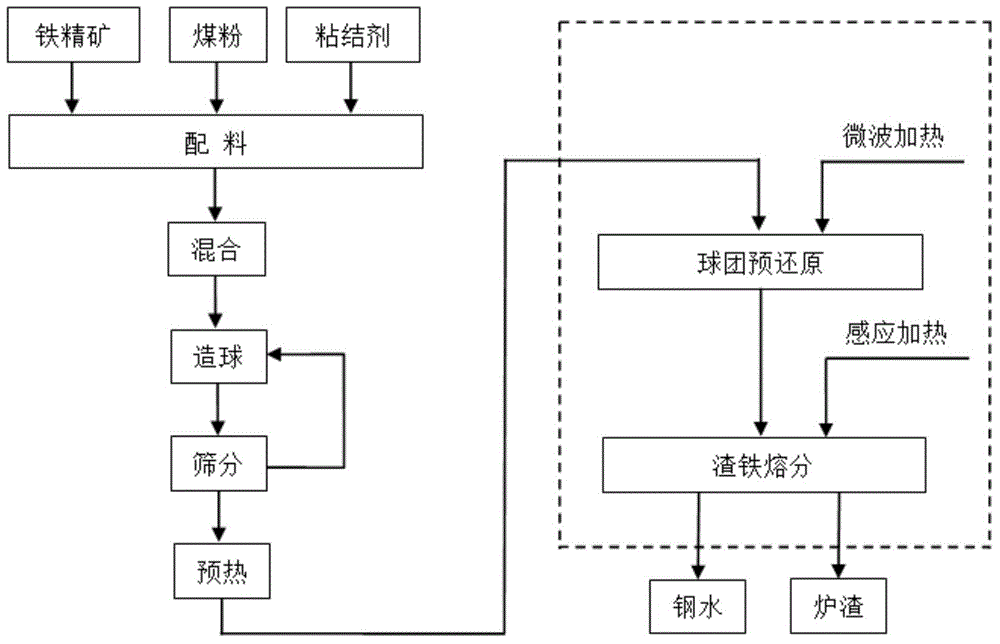

[0029] Such as figure 1As shown, an electromagnetically heated carbon-containing pellet continuous direct steelmaking device of this embodiment includes a steelmaking furnace body 4, and a distribution port 1 and a gas outlet 2 are arranged on the top of the steelmaking furnace body 4, wherein the distribution port 1 is connected with the belt feeder outside the furnace body, and the gas outlet 2 is connected with the gas collection device. The above-mentioned steelmaking furnace body 4 sequentially includes a material distributing area, a reduction area 401, a reflow area 402 and a slag-iron melting area from top to bottom. Among them, the material distributing area, the reduction area 401 and the reflow area 402 form a double circular truncated structure. The reduction area 401 includes two parts, an upper reduction area and a lower reduction area. The upper part of the lower circular platform of the double truncated circular structure, and the reflow zone 402 is located at...

Embodiment 2

[0041] An electromagnetically heated carbon-containing pellet continuous direct steelmaking device of this embodiment is similar to that of Embodiment 1, the difference being that there are three rows of microwave heating devices around the body of the furnace in the reduction zone 401 of the steelmaking furnace, one of which is located at Around the furnace body corresponding to the material distribution area, the other two rows are located around the furnace body corresponding to the upper reduction area.

[0042] A kind of electromagnetic heating carbon-containing pellet continuous direct steelmaking method of the present embodiment, its steps are:

[0043] Step 1. Preheating of carbon-containing pellets:

[0044] The carbon-containing pellets were preheated at 200° C. for 13 minutes. The carbon-containing pellets in this example were composed of the following components in mass percent: iron fine powder 82%, coal powder 15% and binder 3%, Among them, the mass fraction of ...

Embodiment 3

[0052] The electromagnetically heated carbon-containing pellet continuous direct steelmaking device of this embodiment is the same as that of Embodiment 1.

[0053] A kind of electromagnetic heating carbon-containing pellet continuous direct steelmaking method of the present embodiment, its steps are:

[0054] Step 1. Preheating of carbon-containing pellets:

[0055] The carbon-containing pellets were preheated at 170° C. for 15 minutes. The carbon-containing pellets in this example consisted of the following components in mass percent: 80% iron fine powder, 18.5% coal powder and 1.5% binder, Among them, the mass fraction of TFe in the fine iron powder is 68%, the mass fraction of S is 1.5%, and the mass fraction of P is <0.5%. The fixed carbon content of the coal powder used is 88%, and the binder is selected from bentonite. The specific preparation method of the carbon-containing pellets is as follows: the iron fine powder, coal powder and binder are weighed according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com