Method for producing molten steel continuously through microwave and induction heating of carbon-containing pellets

An induction heating and microwave heating device technology, applied in the field of iron and steel metallurgy, can solve the problems of low production efficiency and energy utilization, poor air permeability in the furnace, complex process flow, etc., to ensure full reduction, improve air permeability, and benefit slag iron The effect of melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

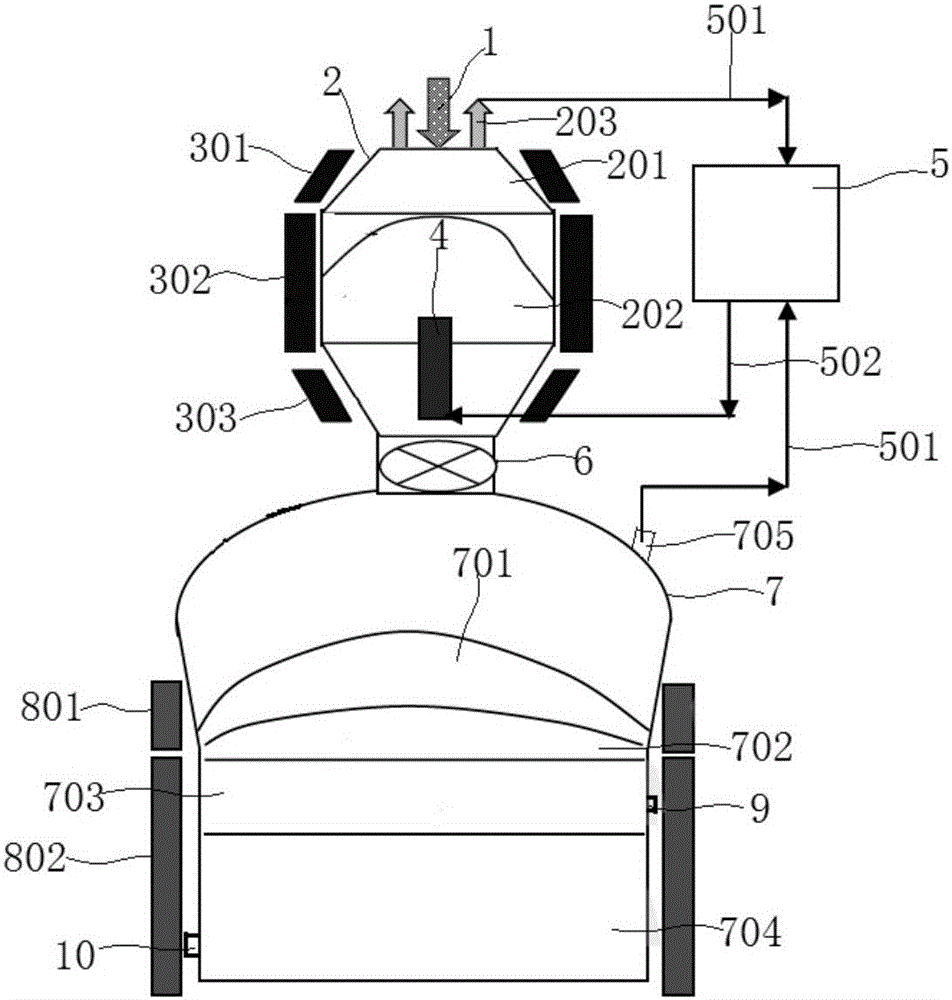

[0046] Such as figure 1 As shown, a device for continuous production of molten steel by microwave and induction heating carbon-containing pellets in this embodiment includes a steelmaking furnace body, and the steelmaking furnace body includes an upper microwave reduction furnace 2 and a lower induction melting furnace 7 , the microwave reduction furnace 2 is used for heating and reducing the carbon-containing pellets, the induction melting furnace 7 is used for the slag iron melting reaction, and the microwave reduction furnace 2 and the induction melting furnace 7 are connected through the discharge valve 6 , the complete isolation of the carbon-containing pellet reduction and slag-iron melting reaction is realized, and the reduction reaction basically does not occur in the induction melting furnace 7, thereby preventing the CO gas generated by the reduction of carbon-containing pellets from affecting the slag, and avoiding the slag containing When the carbon pellets are red...

Embodiment 2

[0067] A kind of microwave and induction heating carbon-containing pellet continuous production molten steel device of this embodiment is basically the same as embodiment 1, and its difference lies in the following aspects: the number of microwave reduction furnace 2 is 3 in the present embodiment, thereby can significantly Improve production efficiency and production capacity, overcome the disadvantage that when only one microwave reduction furnace 2 is installed, the production progress is greatly affected by the fluctuation of the working state of the microwave reduction furnace 2, and when the input amount of carbon-containing pellets is the same, by setting multiple The microwave reduction furnace 2 can further ensure sufficient reduction inside the carbon-containing pellets, which is beneficial to improving the reduction rate and reduction efficiency of the carbon-containing pellets.

[0068] There are 3 rows of microwave heating devices in this embodiment, and an upper r...

Embodiment 3

[0083] A kind of microwave and induction heating carbon-containing pellet continuous production molten steel device of this embodiment is basically the same as embodiment 2, and its difference lies in the following aspects: the number of microwave reduction furnace 2 is 2 in the present embodiment; There are a plurality of air guide pipes 4, all of which are evenly distributed along the axial direction parallel to the microwave reduction furnace 2, so as to further ensure uniform heating of the inside of the carbon-containing pellets and ensure sufficient and complete reduction.

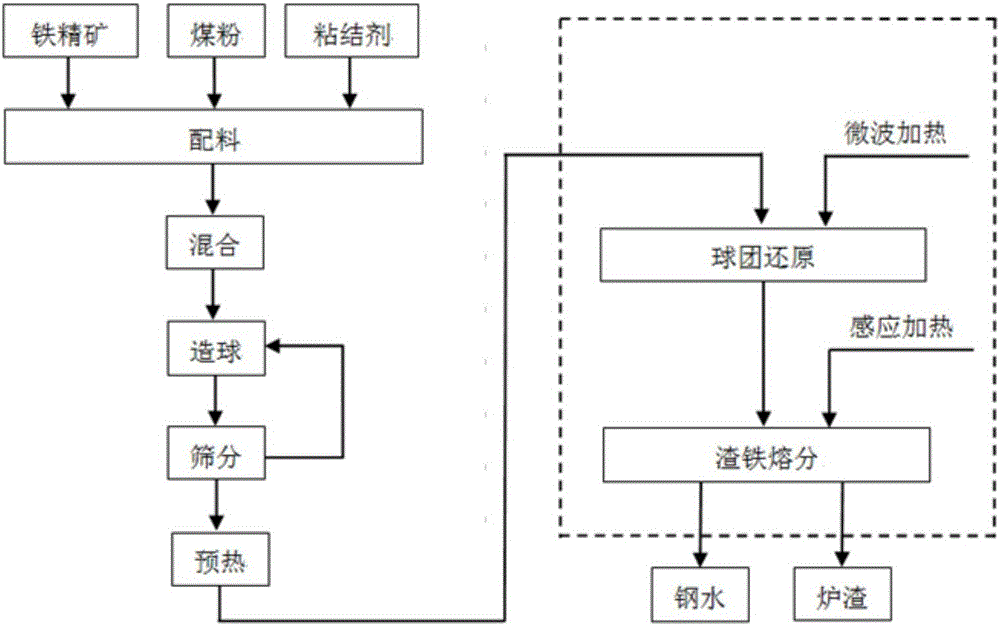

[0084] The method for continuous production of molten steel by microwave and induction heating of carbon-containing pellets in this embodiment comprises the following steps:

[0085] Step 1. Loading and preheating of carbon-containing pellets:

[0086] The carbon-containing pellets are transported to the distribution device 1 through the belt feeder outside the furnace body, and the carbon-containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com