Gold wet purification process

A wet purification and process technology, applied in the field of gold wet purification process, can solve the problems of large environmental pollution, high loss of hydrochloric acid, high production cost, etc., and achieve the effect of complete reduction, high product purity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

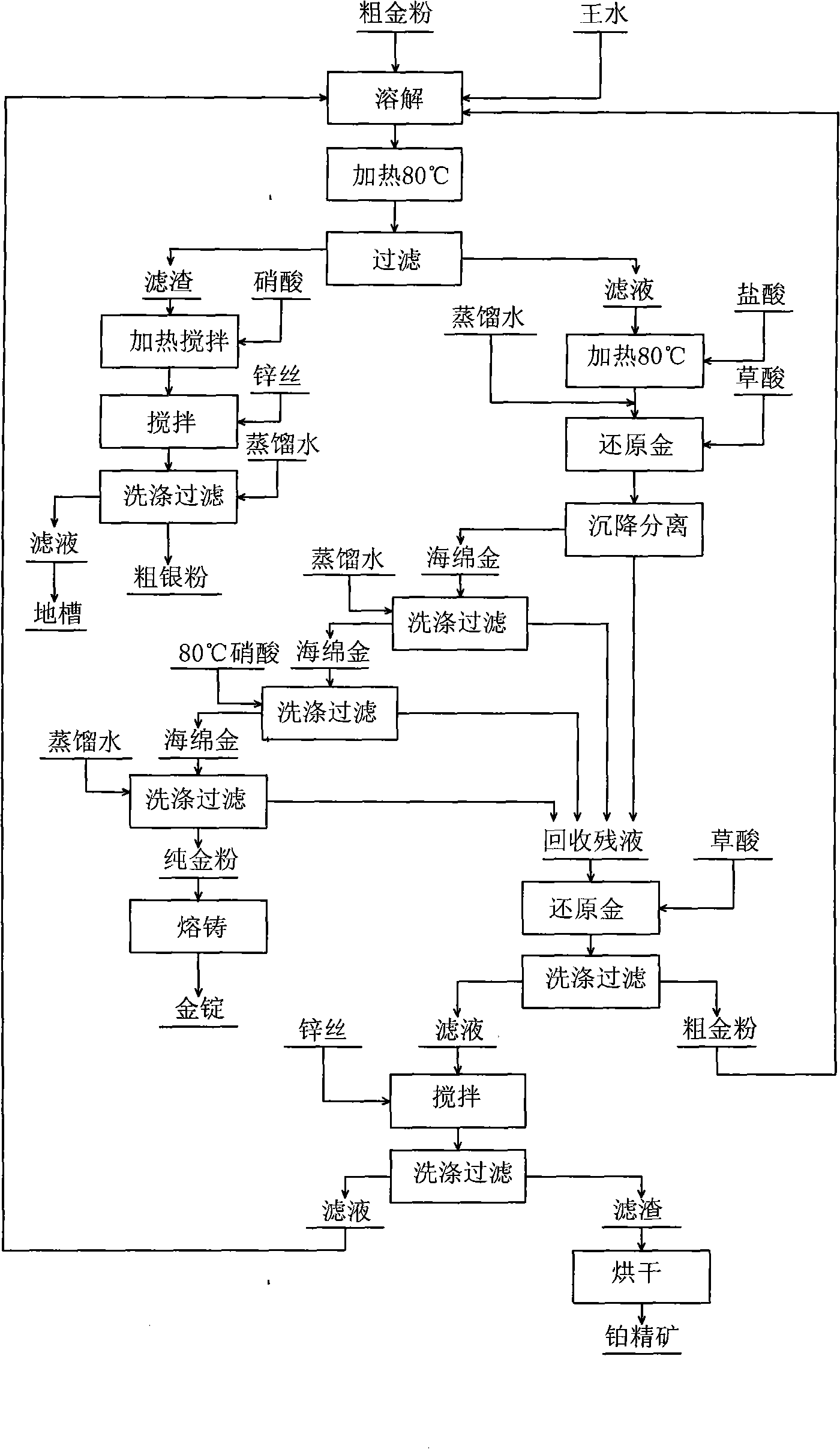

[0025] The following is the reference attached figure 1 An embodiment of the invention is described by way of illustration, but it must be understood that this embodiment is not to be construed as a limitation of the invention.

[0026] The specific implementation process of the purification process of this specific embodiment is:

[0027] a. Put 41.9 grams of coarse gold powder in a 250 ml beaker, add 150 ml of aqua regia to submerge the coarse gold powder to partially dissolve the coarse gold powder, then heat to 80°C while stirring to dissolve the remaining coarse gold powder, cool and stand for 1 hour, and filter , to separate the filter residue;

[0028] b. Heat the filtrate to 80°C, slowly and continuously add hydrochloric acid to catch up with nitric acid, observe the color of the smoke on the liquid level of the filtrate while stirring, and stop adding hydrochloric acid when there is no brown smoke;

[0029] c. Mix and dilute the solution after catching up with nitri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com