Thick oil well bore heating and viscosity reducing hot extraction method and apparatus

An oil well and viscosity reduction technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of inaccurate calculation of oil volume, difficulty in restoring production, non-durability, etc., to save energy and equipment The effect of investment, avoiding high cost and long service life

Inactive Publication Date: 2008-10-22

胜利油田孚瑞特石油装备有限责任公司 +1

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there are more and more mechanical wells in the oil field with high pour point and heavy oil, and the use of conventional development technology has seriously affected the liquid output

In order to solve this problem, various oilfields have adopted different thermal recovery technologies, but the results are not ideal

For example, the application of electric heating pipe rod is to put a single-core cable into the hollow sucker rod to form a heating cable for the electric circuit, and use variable frequency power supply, DC pulse power supply, and three-phase power adjustment power supply to supply power respectively. This technology consumes high power and costs high

The technology of adding hot water into the hollow rod directly injects hot water into the downhole tubing through the hollow sucker rod. Although it is easy to use, it is easy to scale inside the hollow rod. The added water flows out together with the oil, and the oil volume cannot be accurately calculated. And high energy consumption, long process, high input cost

The method of adding chemical agent to reduce viscosity is to add chemical agent to the downhole casing and tubing annulus to reduce viscosity, which greatly increases the production cost of oil production, and the injection of chemical agent by single well dosing pump is limited by the high pressure of the casing, so it cannot Durable, heavy workload, high maintenance cost, not timely dosing will cause well shutdown, difficult to resume production, and pollute the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

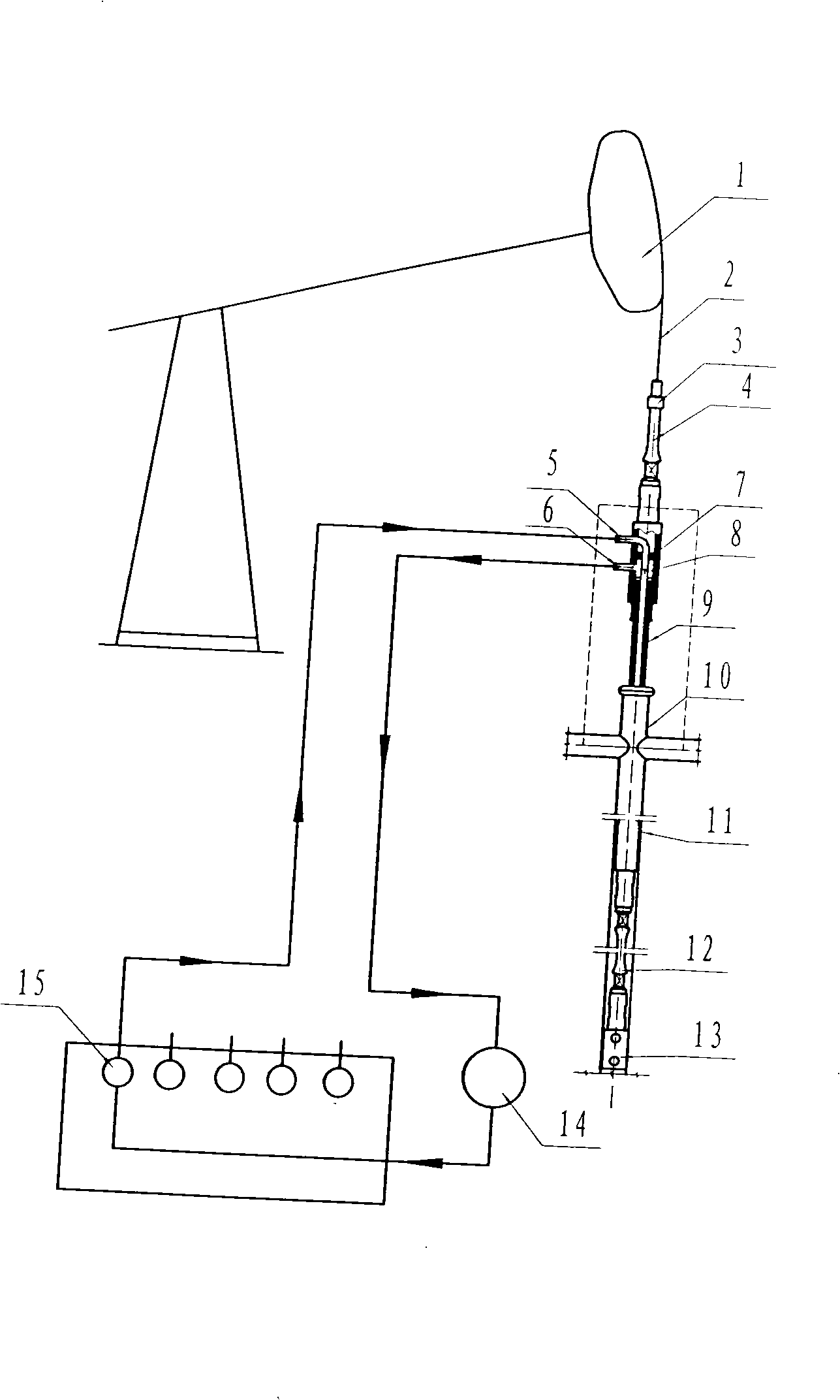

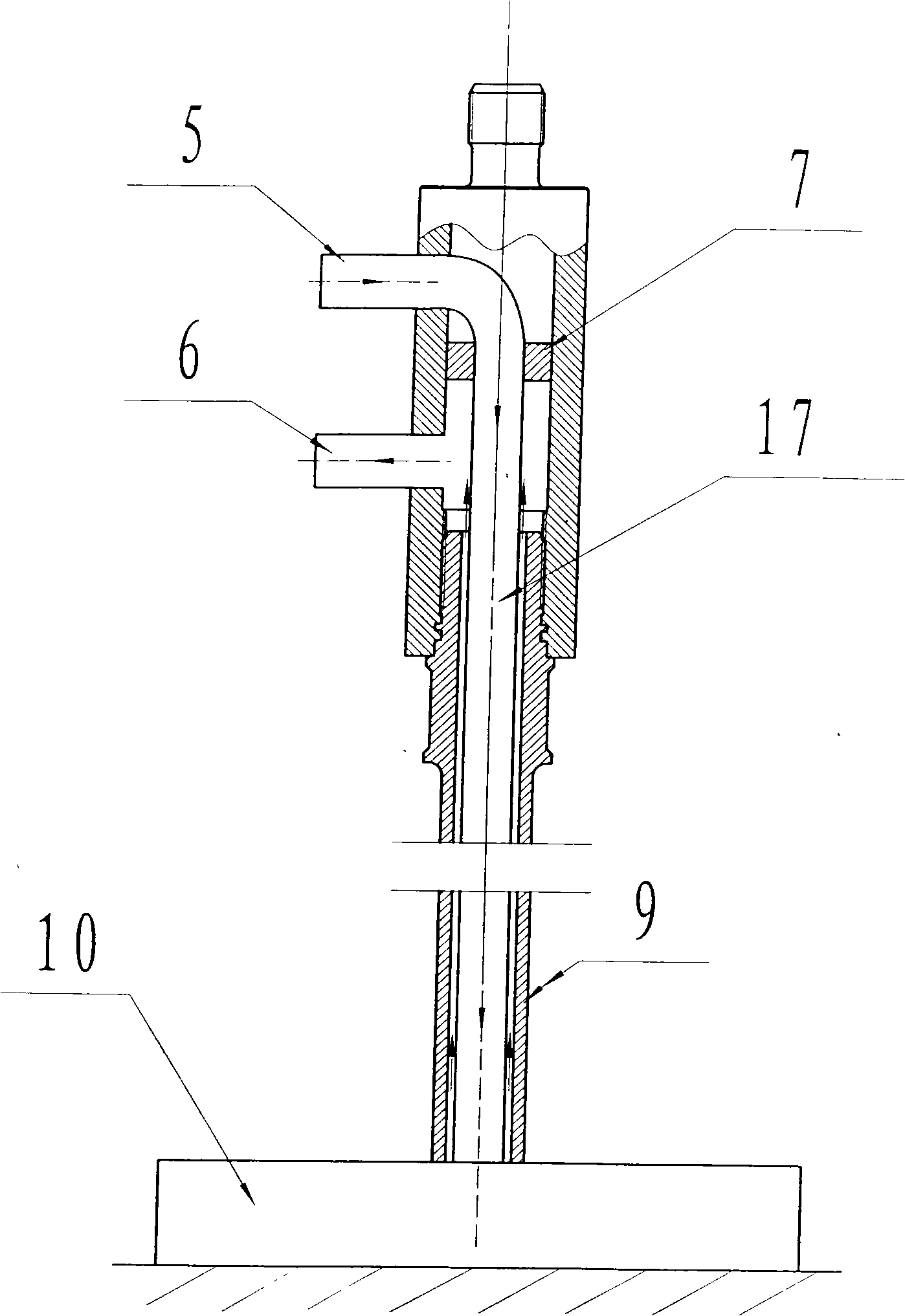

Login to View More Abstract

The invention relates to a viscous oil pitshaft heating and thinning thermal excavation method and a device using the same. The method is as follows: a hollow sucker rod is sleeved with an insulating tube and two thermal cycling tunnels are formed, an external circulation pipe line is connected to a heating furnace and a circulating pump in sequence, and then continuous closed thermal cycling exchanged heating is formed. The device comprises an oil extractor, a polished rod eye, a polished rod clamp, a polished rod connector, the hollow sucker rod, a wellhead device, an oil well pump, the heating furnace, the circulating pump and a circulation pipe line, wherein the hollow polished rod connector is provided with a connecting device, and the insulating tube of the hollow sucker rod and the two thermal cycling tunnels at outer annular space are respectively abutted with the external circulation pipe line through the connecting device. The technology adopts the method that a proper annular clearance is left between the hollow sucker rod and the insulating tube, a closed circulating independent heating system is formed, thereby saving energy, operating conveniently, and being safe, reliable, and long in service life.

Description

Thermal recovery method and device for heavy oil wellbore heating and viscosity reduction technical field The invention relates to a heavy oil wellbore heating and viscosity-reducing thermal recovery method and device in the technical field of oilfield crude oil thermal recovery. Background technique At present, there are more and more mechanical recovery wells for high-condensation and heavy oil in oilfields, and the use of conventional development technology has seriously affected the fluid output. In order to solve this problem, various oilfields have adopted different thermal recovery technologies, but the effects are not satisfactory. For example, the application of electric heating pipe rod is to put a single-core cable into the hollow sucker rod to form a heating cable for the electric circuit, and use variable frequency power supply, DC pulse power supply, and three-phase power adjustment power supply to supply power respectively. This technology consumes high powe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B43/24

Inventor 刘国庆吴德奇周尔洲王江秀李永张力王基伟

Owner 胜利油田孚瑞特石油装备有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com