Method and device for producing ultra-low sulfur diesel fuel by liquid phase hydrogenation

A technology of ultra-low-sulfur diesel and liquid-phase hydrogenation, which is applied in the field of hydrocarbon hydrogenation and liquid-phase hydrogenation to produce ultra-low-sulfur diesel. It can solve the problems that the production of ultra-low-sulfur vehicle diesel cannot be met, and improve product quality. , save land occupation and equipment investment, and improve the effect of quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples. The protection scope of the present invention is not limited to the examples. Any changes made by those skilled in the art within the scope of the claims also belong to the protection scope of the present invention.

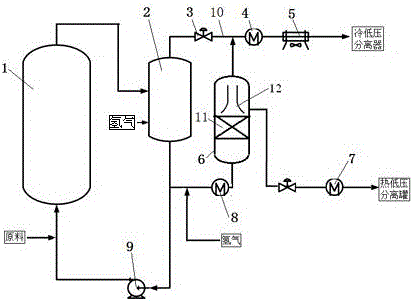

[0015] The device for producing ultra-low sulfur diesel oil by liquid phase hydrogenation of the present invention, such as figure 1 As shown, it includes hydrogenation reactor 1, stripping separator 2, gas pipeline 10, No. 1 heat exchanger 4, air cooler 5, circulation pump 9, No. 2 heat exchanger 7, trickle bed reactor 6, No. 3 heat exchanger 8, cold low-pressure separator and hot low-pressure separation tank. The trickle bed reactor is provided with a catalyst bed 11 and a hot high-pressure separator 12, and the hot high-pressure separator is located on the upper part of the catalyst bed. The raw material pipeline is connected to the raw material inlet at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com