Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reduce thermal aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high-performance mould-press type mixed silicone rubber

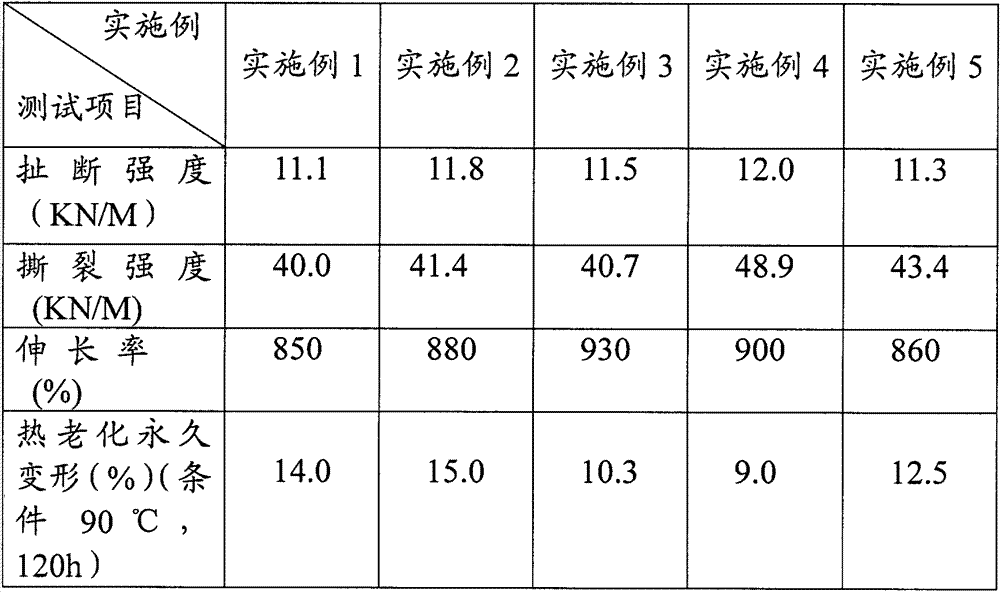

The invention relates to the field of silicone rubber materials and particularly relates to a preparation method of high-performance mould-press type mixed silicone rubber. The preparation method comprises the following steps: matching raw materials, kneading the raw materials, curing the rubber material, introducing steam, and performing vacuumizing treatment. The tensile strength, the tear strength, the elongation and other parameters of a rubber product produced by the silicone rubber after treatment by vulcanization are obviously improved, the thermal aging permanent deformation parameter is also in a relatively small range, and the comprehensive mechanical properties are further improved.

Owner:ZHEJIANG JOTEC NEW MATERIAL TECH

Preparation method for high-strength high-toughness flame-retardant polyamide

InactiveCN102492290ALittle impact on mechanical propertiesReduce total usagePolyamideAntimony trioxide

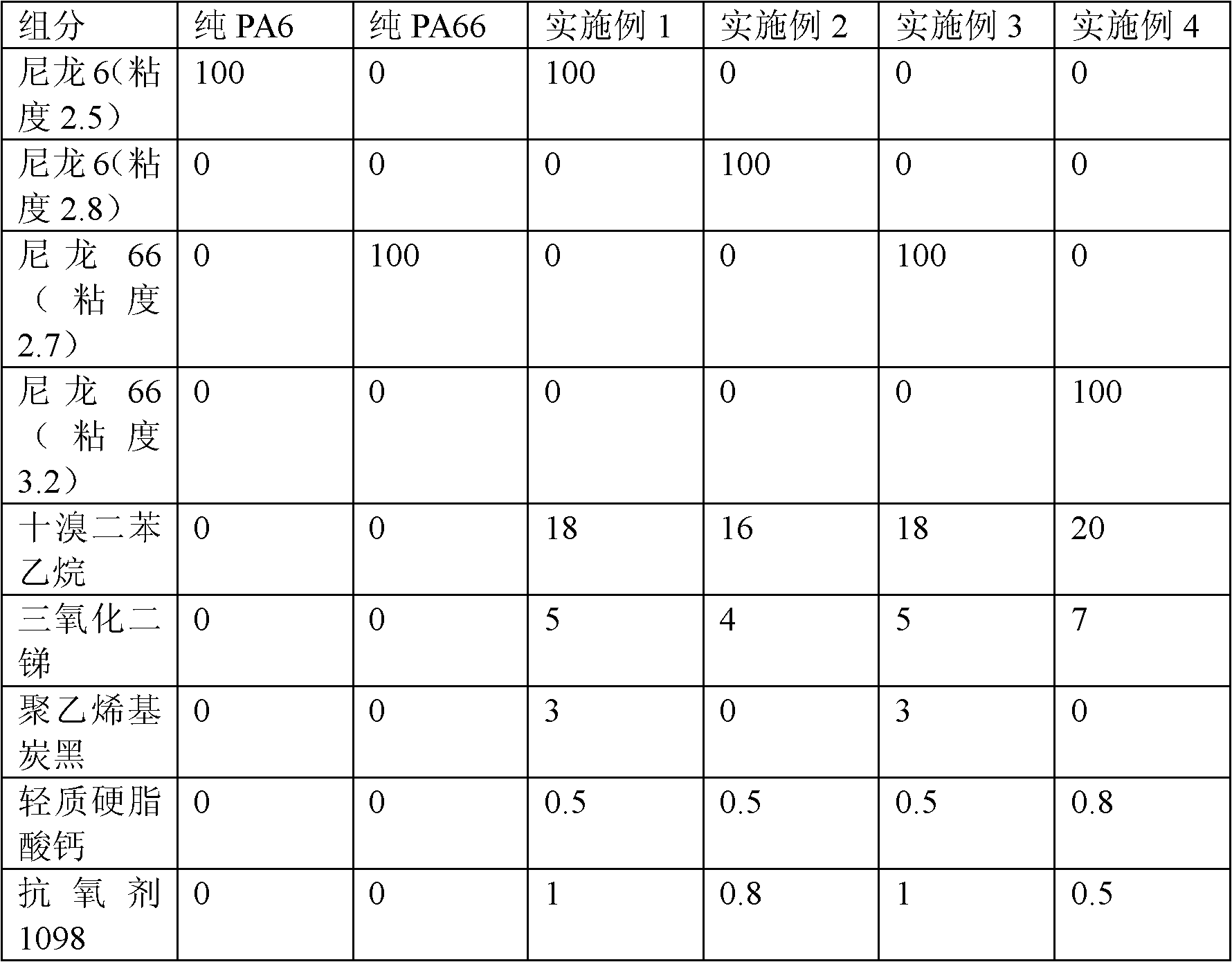

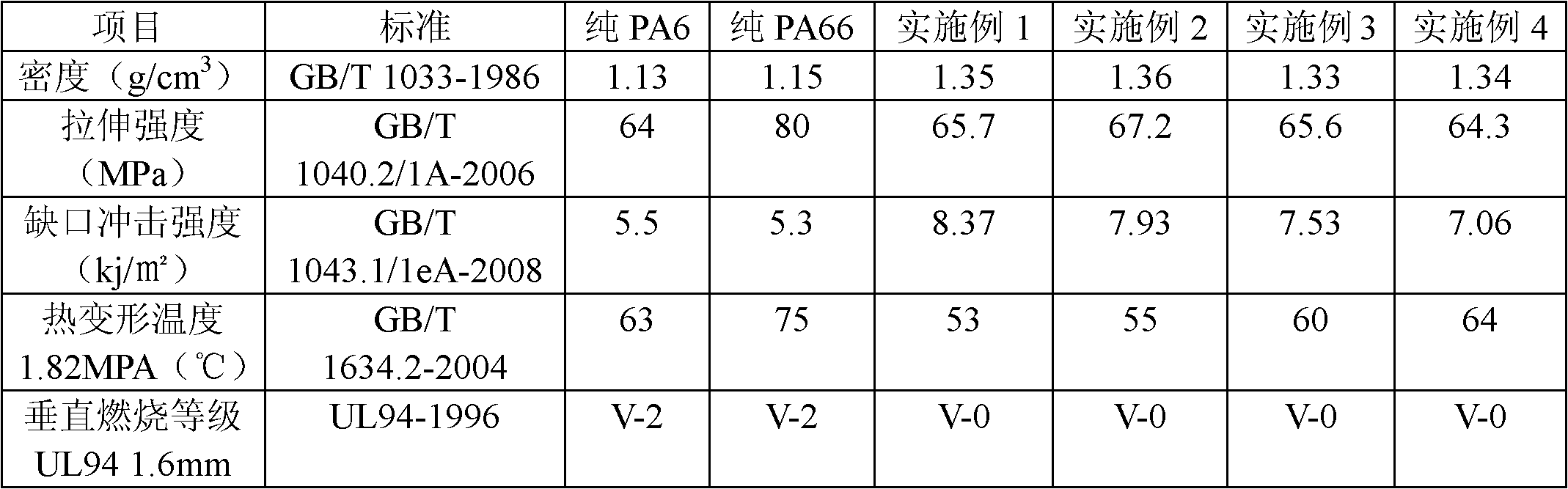

The invention relates to a preparation method for high-strength high-toughness flame-retardant polyamide. According to the method, based on 100 parts by weight of polyamide with a relative viscosity of 2.4 to 3.3, 15 to 30 parts by weight of a decabromodiphenylethane fire retardant, 3 to 10 parts by weight of an antimony oxide fire retardant, 0 to 5 parts by weight of a light stabilizer, 0.2 to 1part by weight of a heat stabilizer and 0.5 to 1 part by weight of an anti-oxidant are added so as to obtain a mixture, and the mixture is subjected to melt mixing and extrusion in virtue of a double-screw extruder and then undergoes cooling, drying and pelletizing so as to obtain the high-strength high-toughness flame-retardant polyamide. The method provided in the invention enables nylon to have improved flame retardation and aging resistance and good mechanical properties and allows a product of nylon to have good surface appearance; combined utilization of decabromodiphenylethane and antimony oxide for modification of polyamide enables purposes of the invention to be achieved.

Owner:上海华谊集团华原化工有限公司

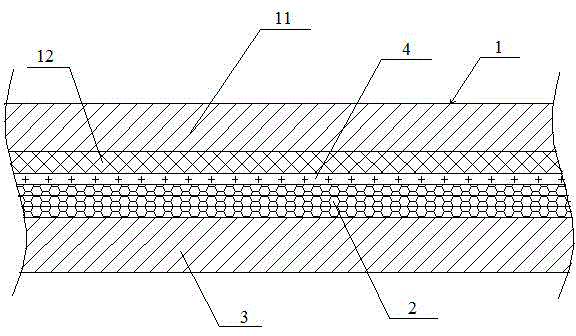

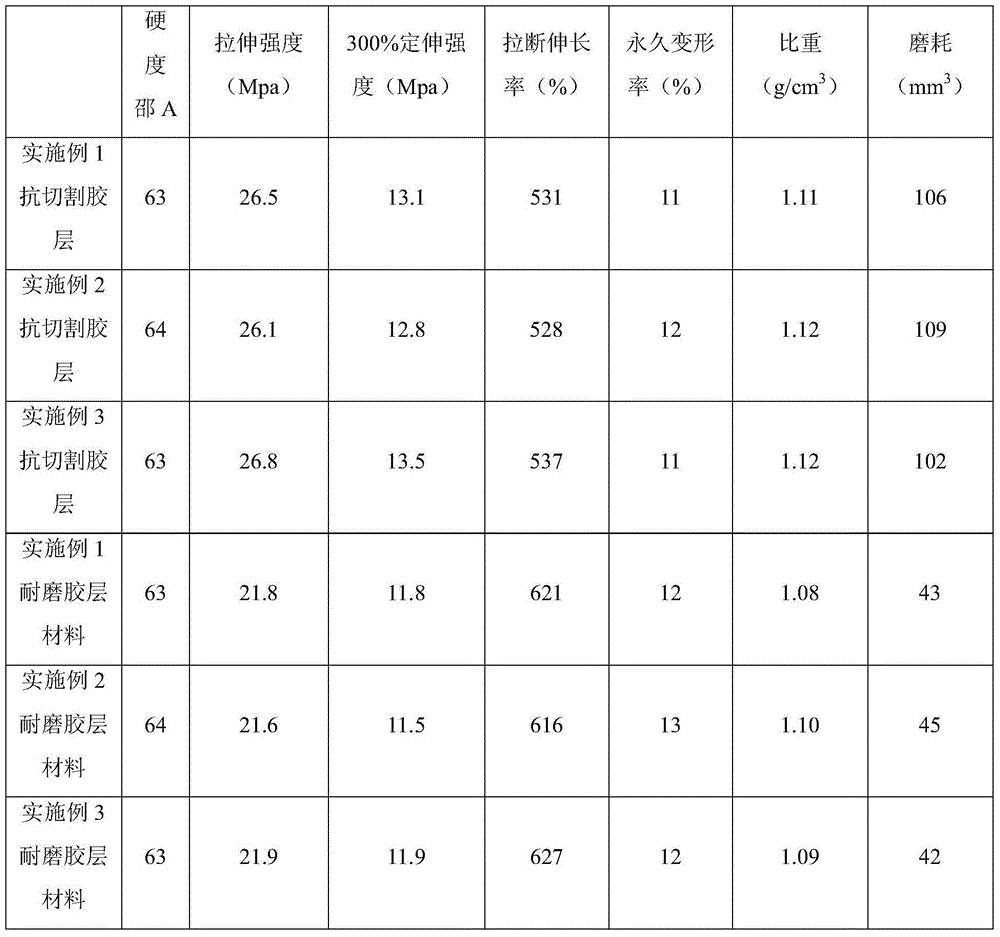

Conveyer belt with high abrasion resistance

The invention discloses a conveyer belt with high abrasion resistance. The conveyer belt comprises an upper covering adhesive layer, a belt core and a lower covering adhesive layer, wherein the upper covering adhesive layer is composed of a cutting-resistant adhesive layer and an abrasion-resistant adhesive layer; and an anti-tear skeleton layer is arranged between the abrasion-resistant adhesive layer and the belt core. The conveyer belt has good abrasion resistance, impact resistance and elasticity, and is long in service life and suitable for being used in mines and other occasions with relatively high abrasion.

Owner:ZHEJIANG SANWEI RUBBER ITEM CO LTD

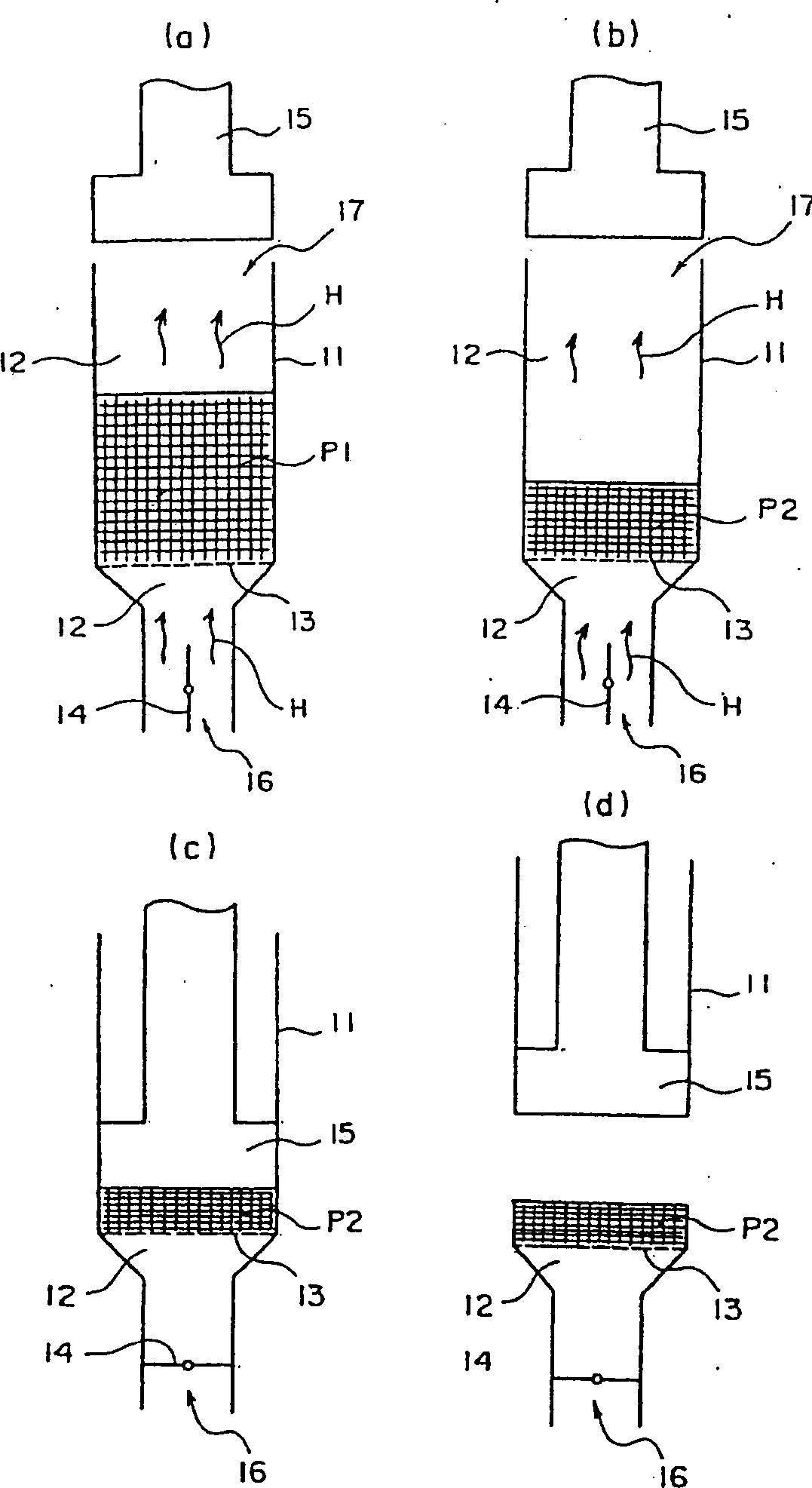

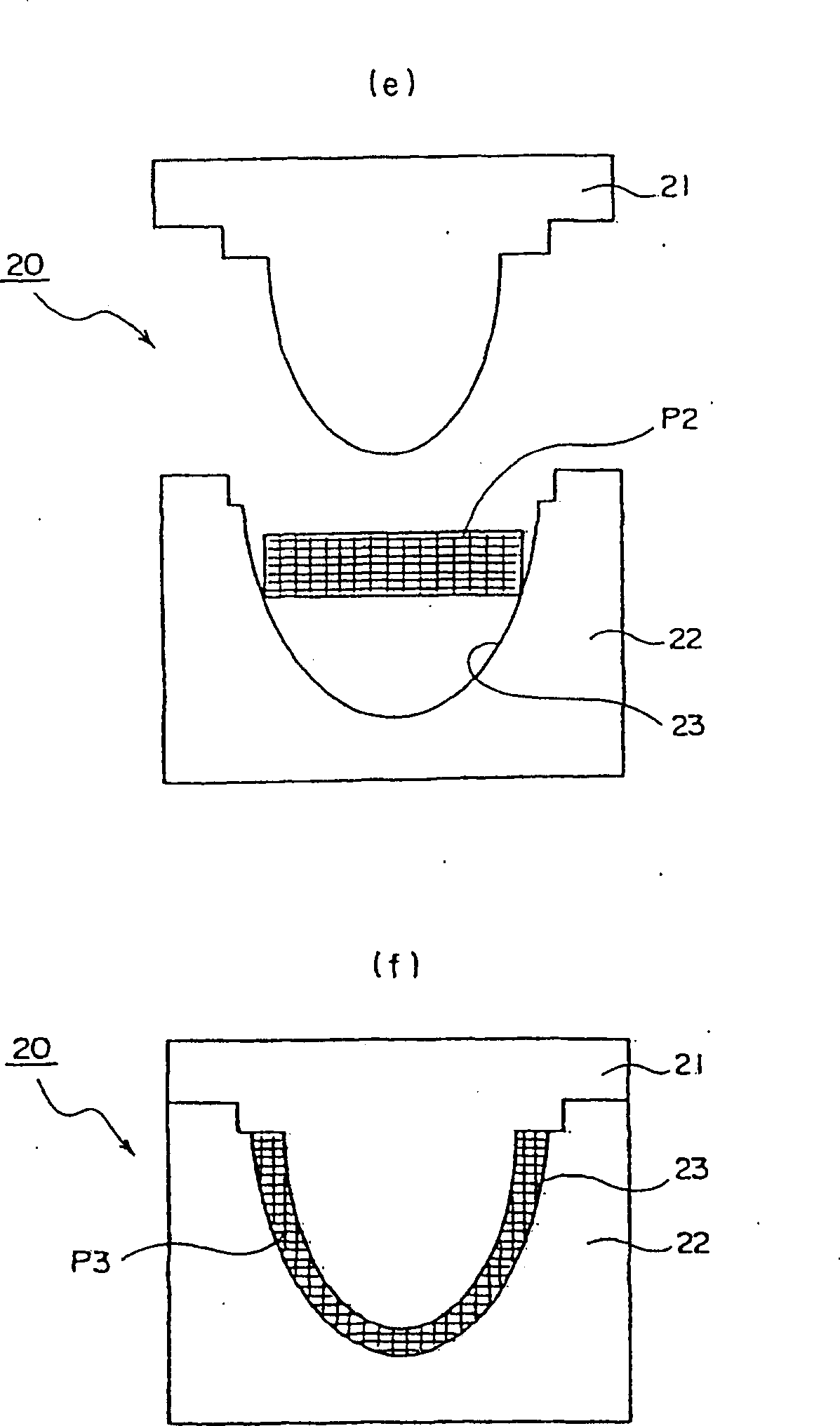

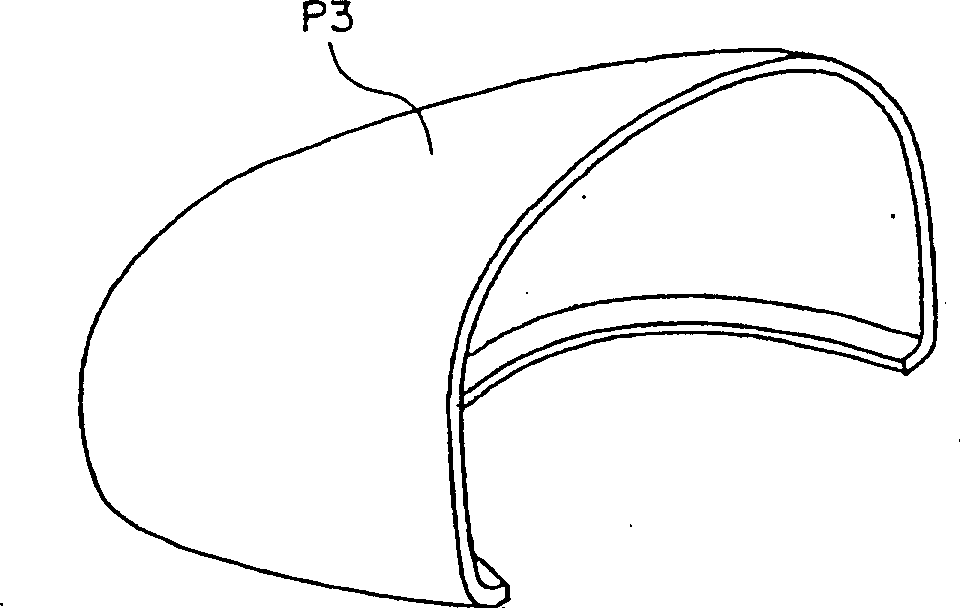

Process for producing a fiber-reinforced thermoplastic resin molded product and product thereby produced

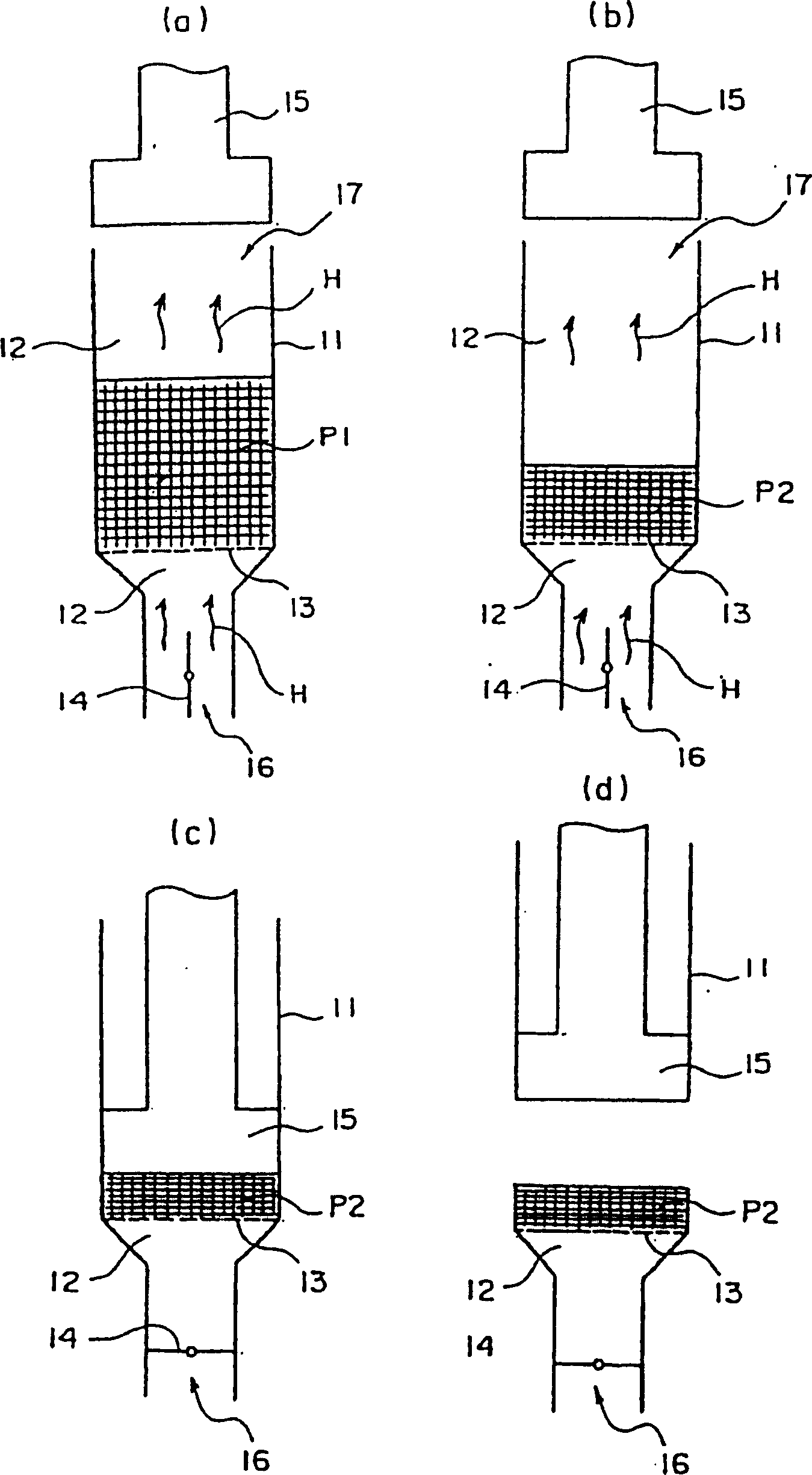

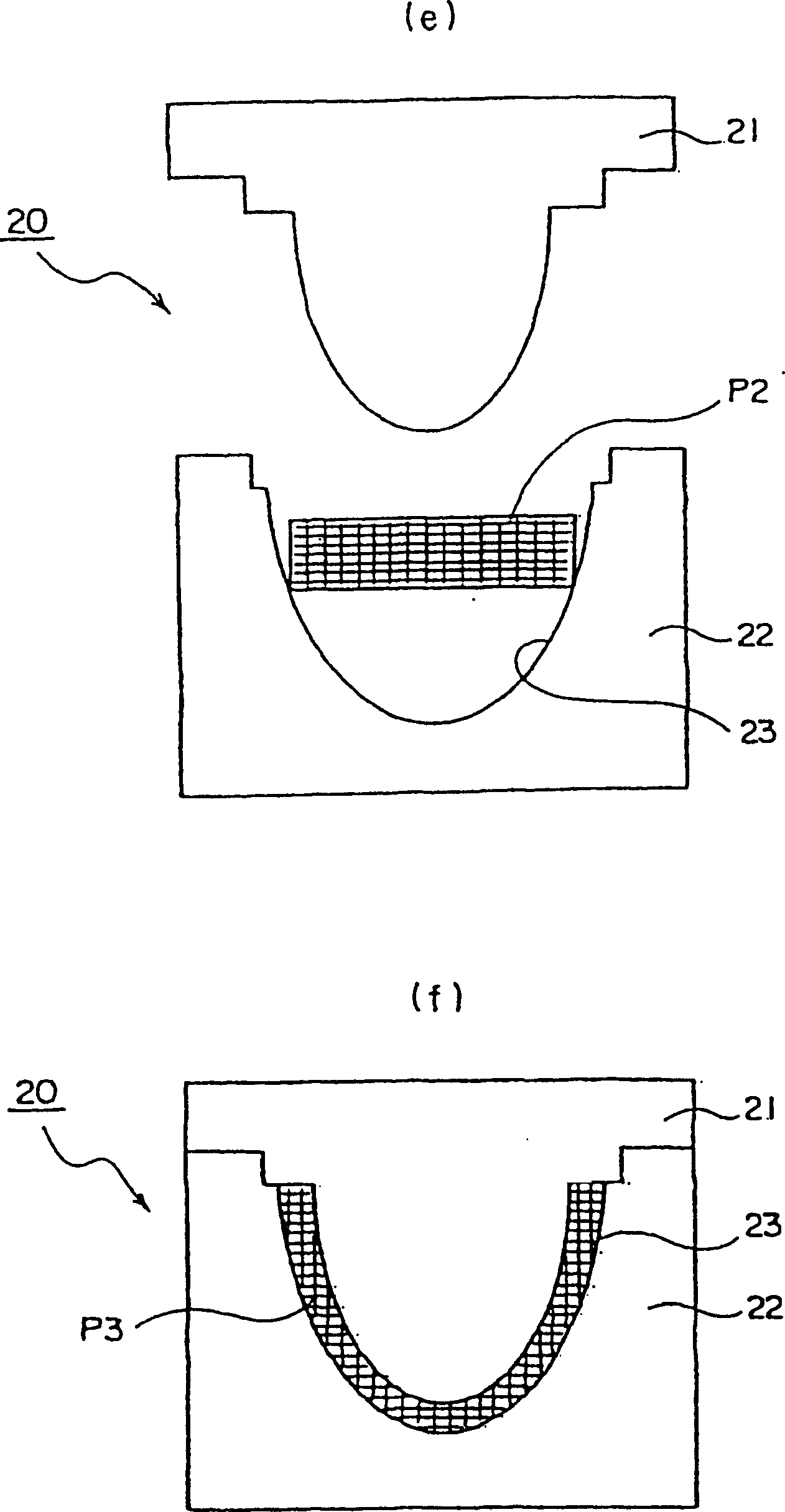

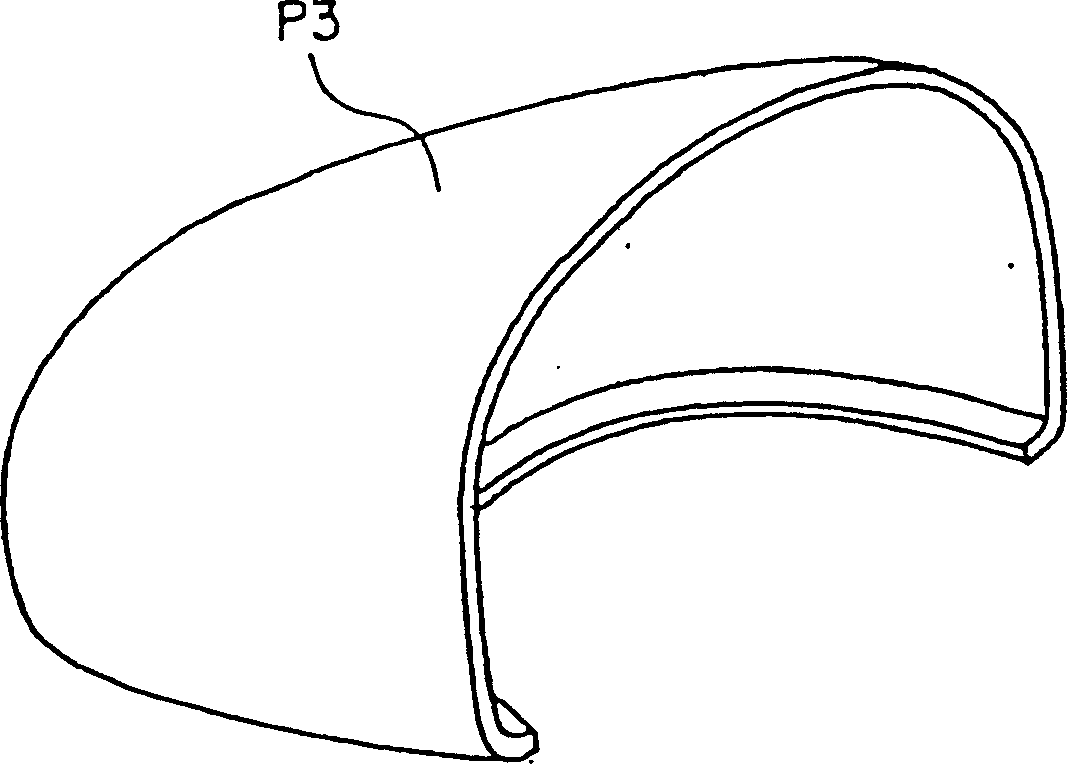

InactiveCN1314840AHigh mechanical strengthGood lookingDomestic footwearUpperShear stressVolumetric Mass Density

A new process for producing a fiber-reinforced thermoplastic resin molded product with a high mechanical strength and no heat substantial deterioration of the resin, by an efficient heating without applying shear stress to the fiber-reinforced thermoplastic resin base material and a molded product, for example, a tiptoe core for a safety shoe produced by said process are provided. The fiber-reinforced thermoplastic resin base material P1 in a string form or a tape form is scattered and accumulated in a vessel such as tube 11, and a heating gas passed to the accumulated base material to melt heat, and preferably press by a plunger 15, the base material P1, whereby a molten mass P2 is formed, and then the molten mass P2 is dislocated to a mold to be press-mold. Said base material preferably satisfies the following formula: {fraction (1 / 100<=RHO1 / rho0<= 1 / 2 , wherein rho0 means a density where said base material is scattered and accumulated and rho0 means a true density of said base material.

Owner:FIBER GLASS JAPAN

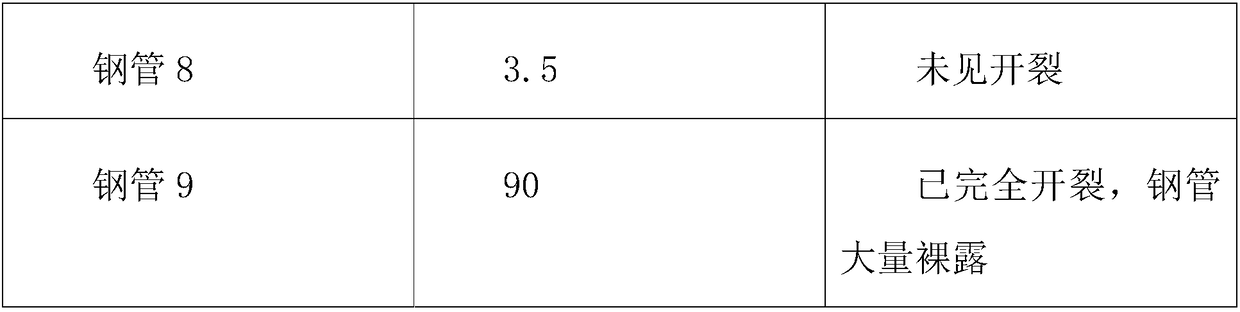

Modified asphalt waterproof coiled material and method for preparing same

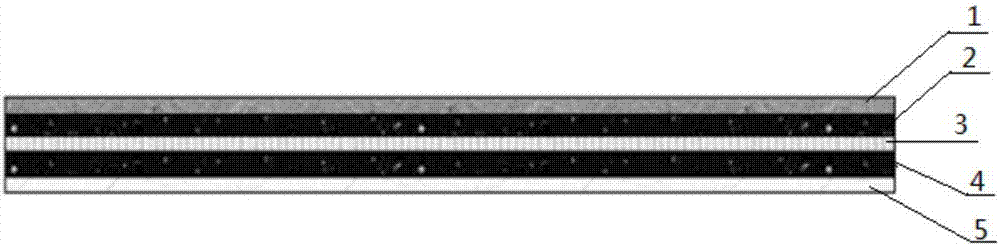

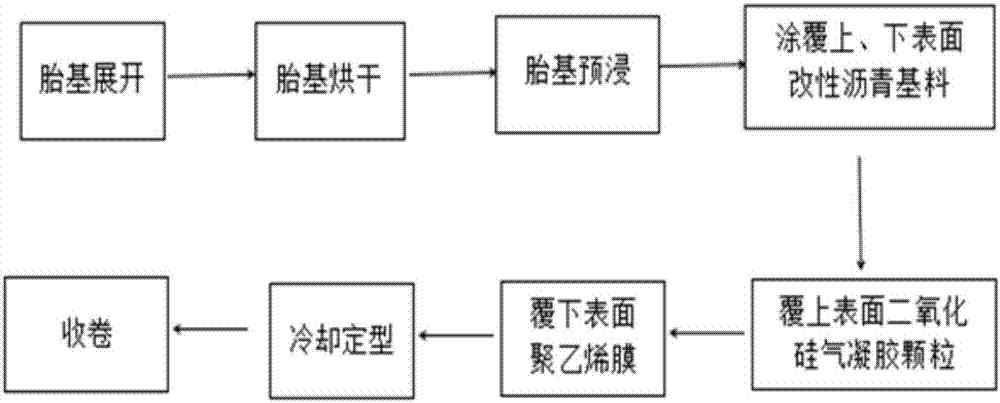

InactiveCN107053785AImprove adhesionGood heat insulationConstructions elementsBituminous layered productsThermal ageingBituminous waterproofing

The invention belongs to the field of building waterproofing, and particularly provides a modified asphalt waterproof coiled material and a method for preparing the same. The modified asphalt waterproof coiled material comprises an upper covering isolation layer, a first modified asphalt base material layer, a reinforcement layer, a second modified asphalt base material layer and a lower covering isolation layer from top to bottom. Isolation materials for the upper covering isolation layer are silicon dioxide aerogel particles. The modified asphalt waterproof coiled material and the method have the advantages that heat-insulation surfaces of the modified asphalt waterproof coiled material comprise the silicon dioxide aerogel particles, accordingly, excellent heat-insulation effects can be realized, and heat aging due to solar radiation can be reduced; the modified asphalt waterproof coiled material is exposed and accordingly can be easily constructed, and maintenance in later periods can be facilitated.

Owner:杭州东方雨虹建筑材料有限公司

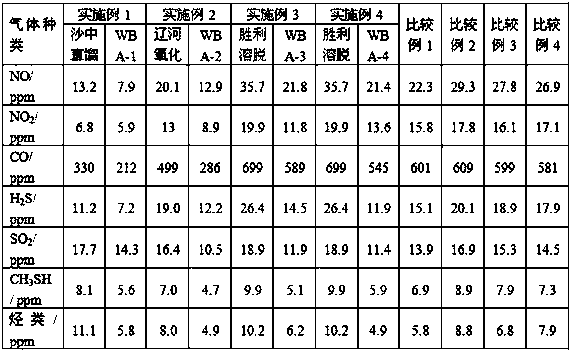

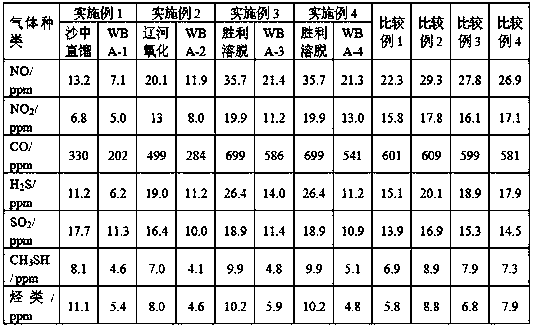

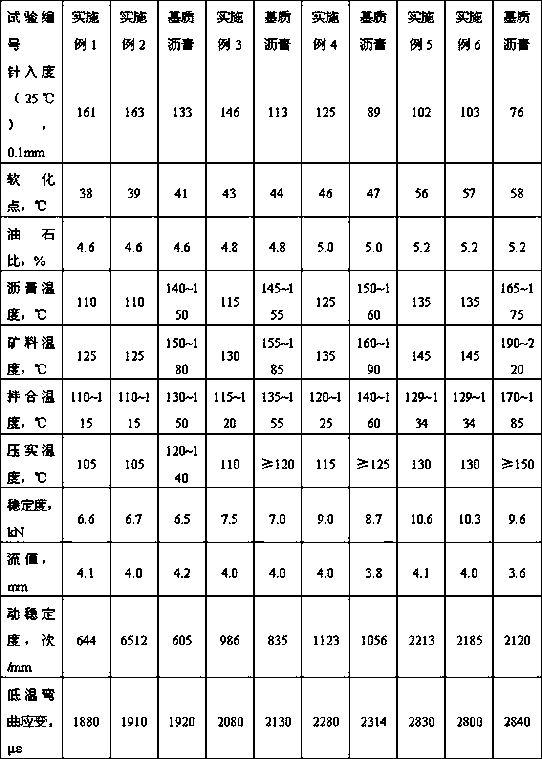

Sulfur emulsified asphalt and preparation method thereof

ActiveCN104559231ALow preparation temperatureLow viscosityClimate change adaptationBuilding insulationsSulfurAsphalt

The invention discloses sulfur emulsified asphalt and a preparation method thereof. The sulfur emulsified asphalt is in a water-in-oil type and comprises the following components by weight: 30-97% of matrix asphalt, 0.9-34% of water, 1-6% of emulsifier and 1-30% of sulfur. The preparation method comprises the following steps: the emulsifier is added into the matrix asphalt in a melted state and is uniformly mixed, a certain amount of water is slowly dripped into the matrix asphalt containing the emulsifier and is uniformly mixed, water is dispersed in the asphalt containing the emulsifier in a fine micro-ball state, and then water-in-oil emulsified asphalt is formed; then sulfur is added into the water-in-oil emulsified asphalt and mixed uniformly and has a full reaction with the asphalt to obtain the sulfur emulsified asphalt. The high-temperature stability of the sulfur emulsified asphalt is good, the preparation temperature of the sulfur emulsified asphalt and the mix temperature of an asphalt mixture are low, the anti-track performance of the mixture is good, volatilization of harmful gas and a thermal aging phenomenon of asphalt are reduced, and the sulfur emulsified asphalt and the preparation method are environment-friendly and save energy.

Owner:CHINA PETROLEUM & CHEM CORP +1

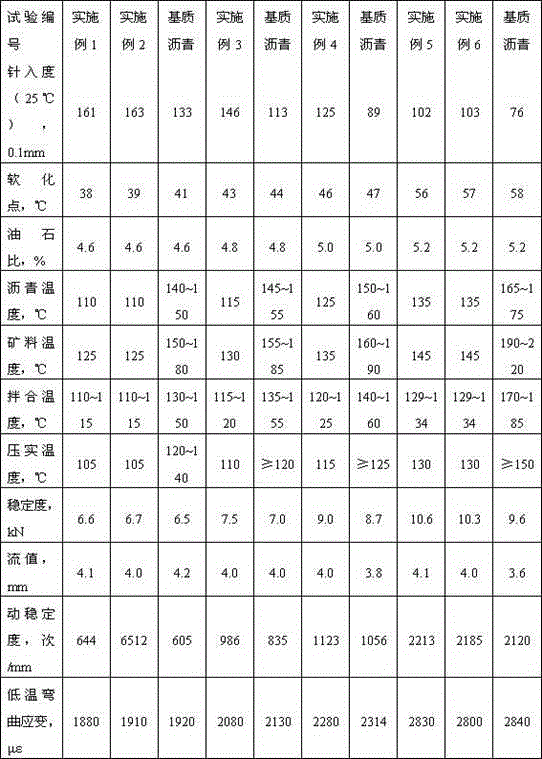

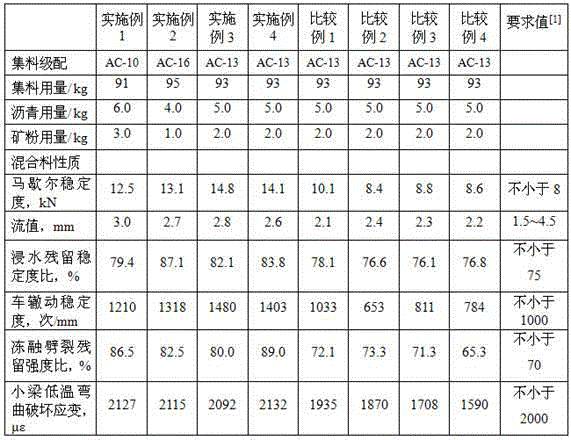

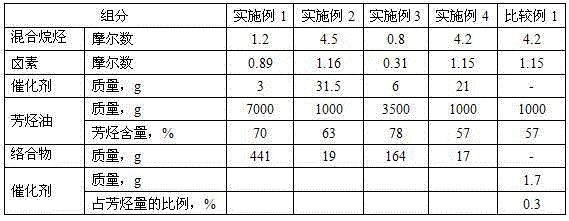

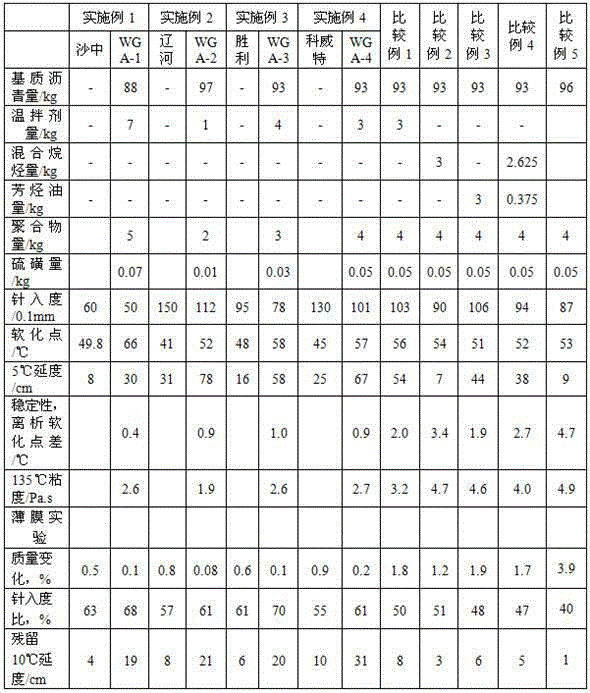

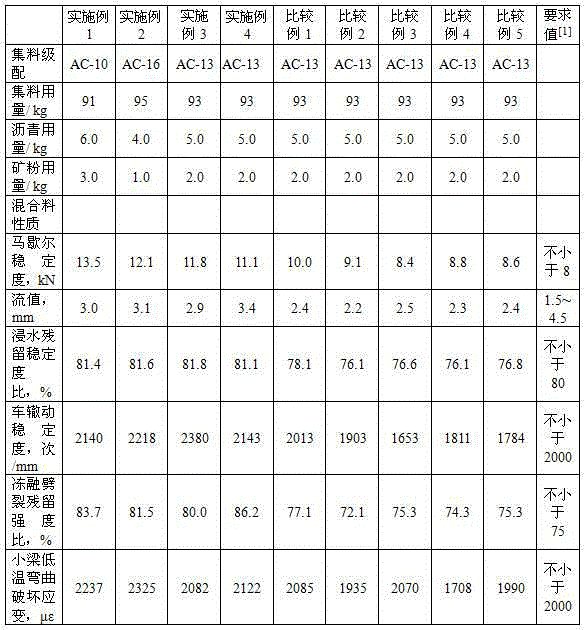

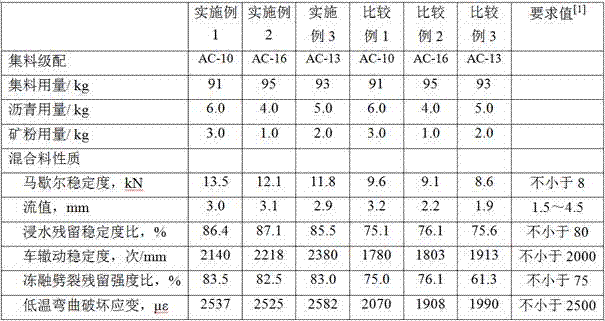

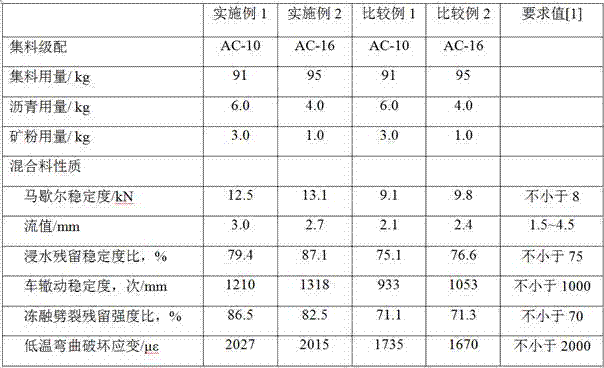

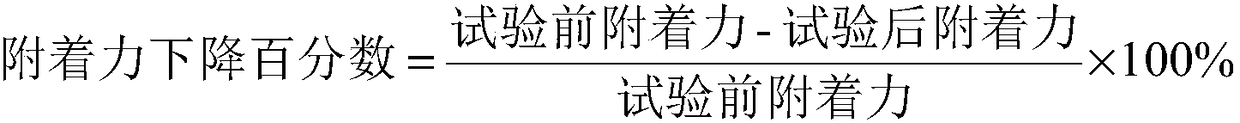

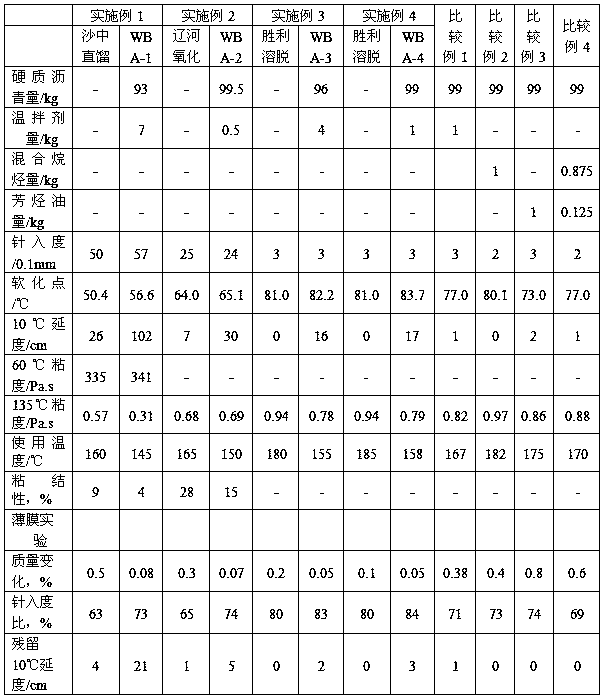

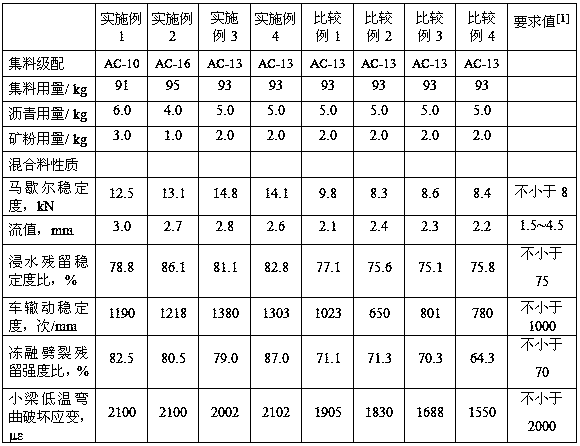

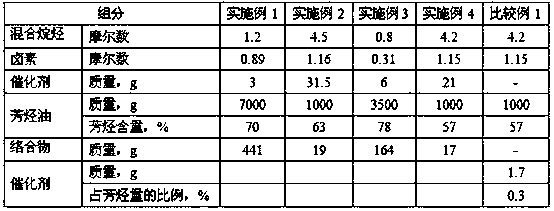

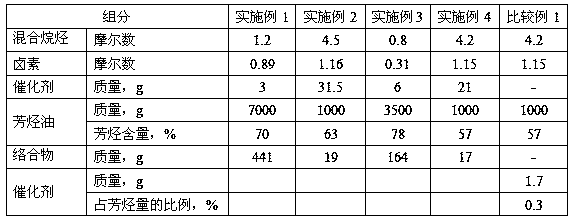

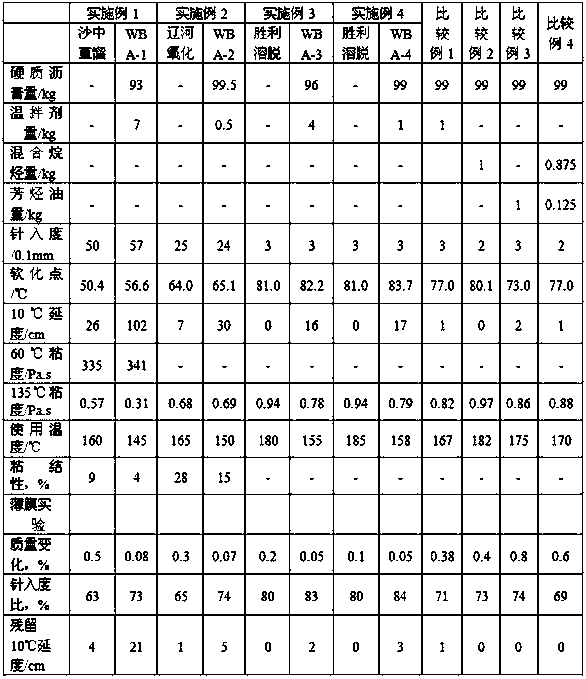

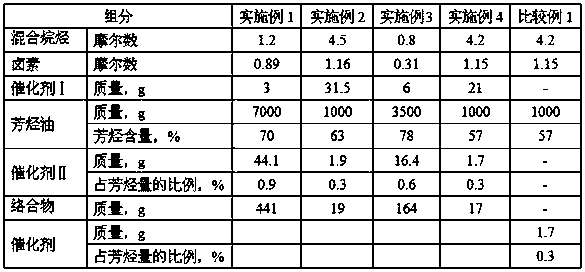

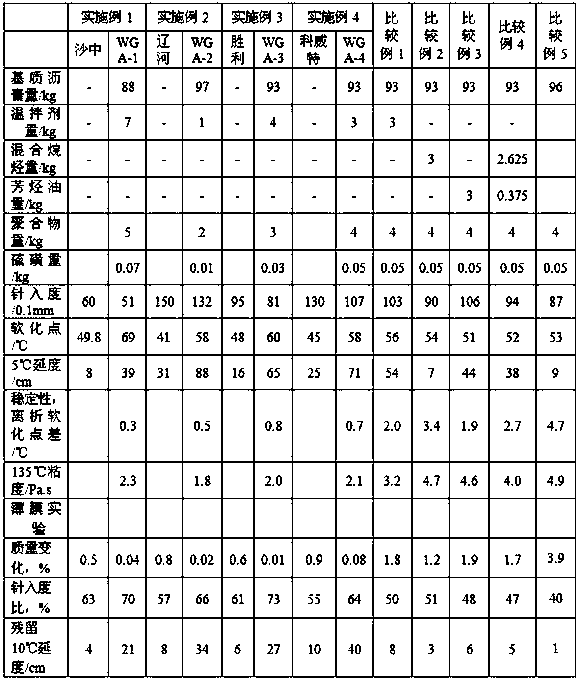

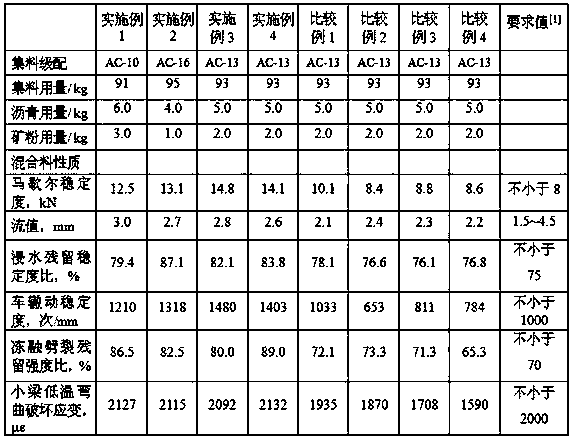

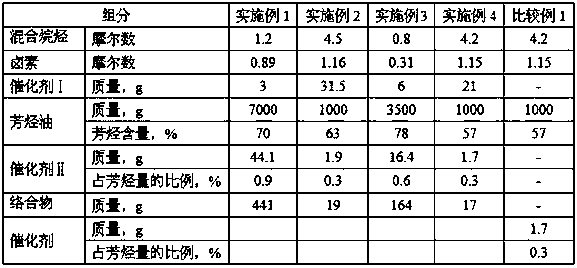

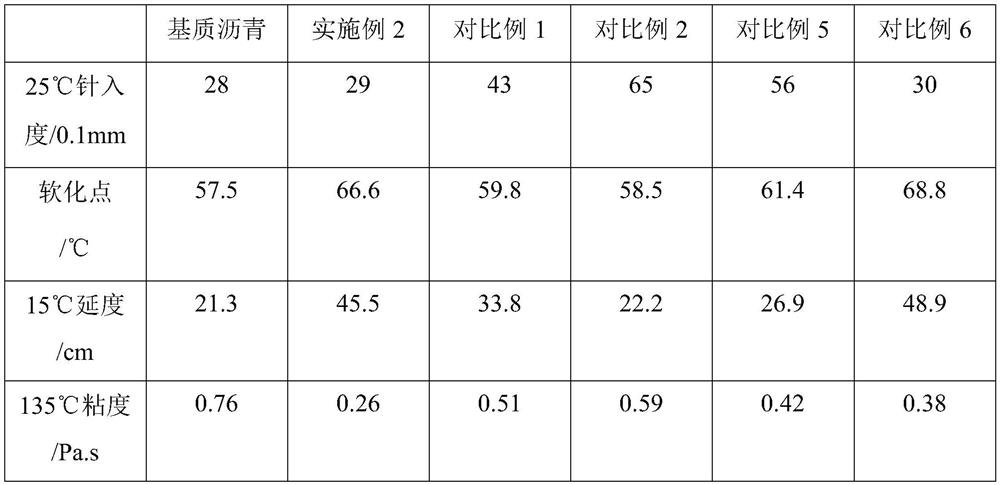

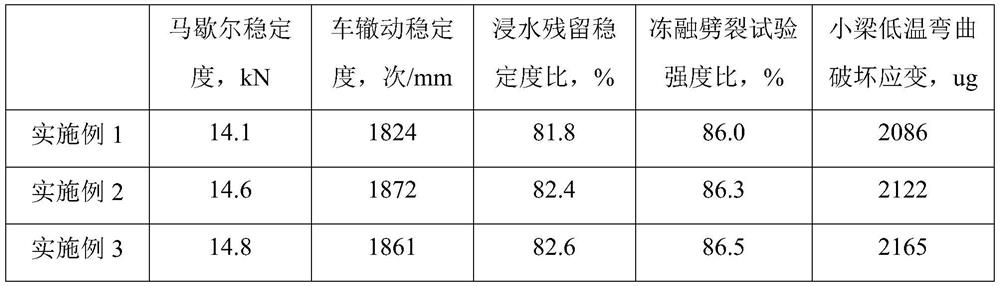

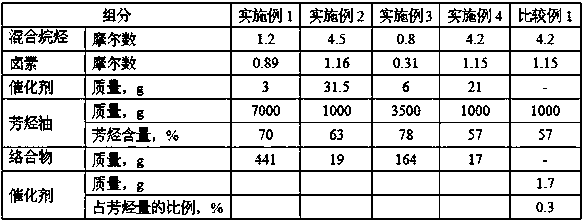

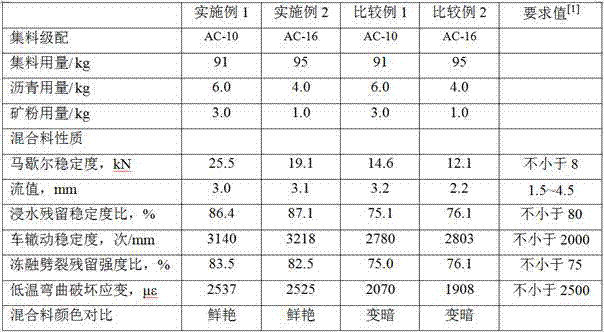

Warm mix hard asphalt mixture and preparation method thereof

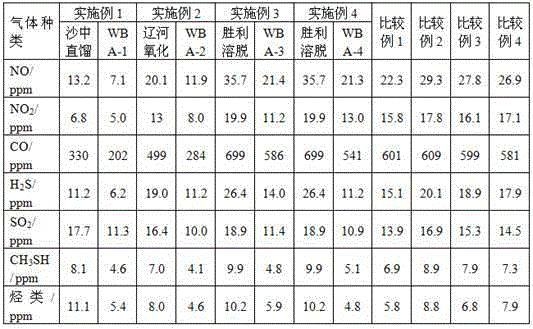

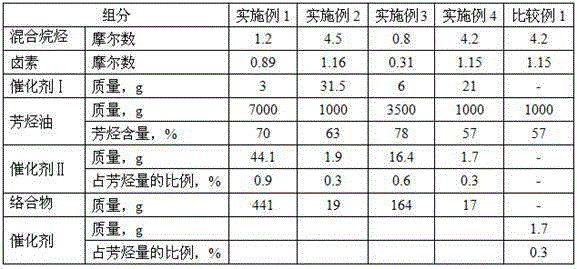

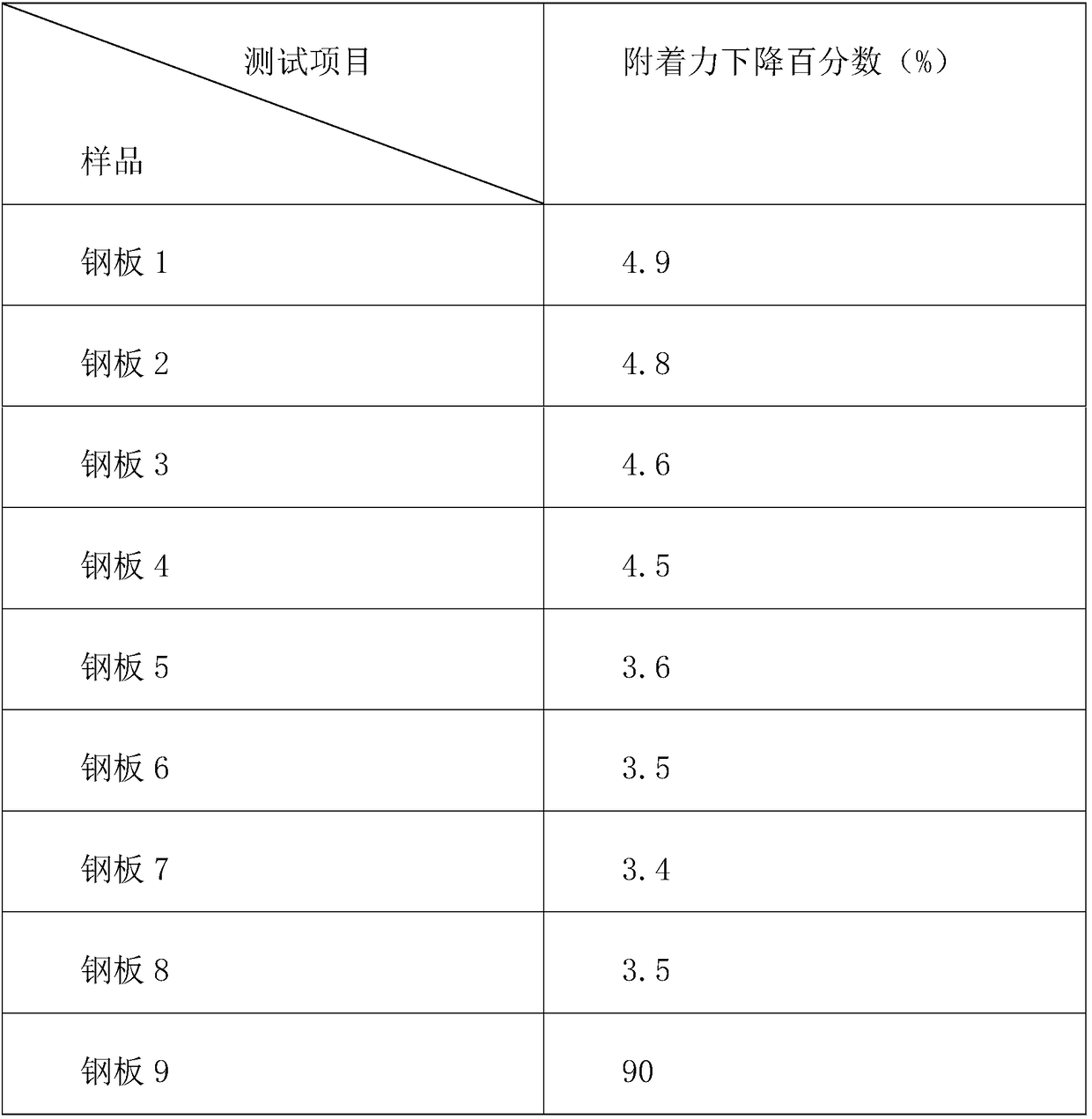

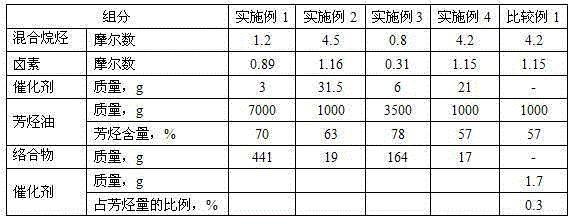

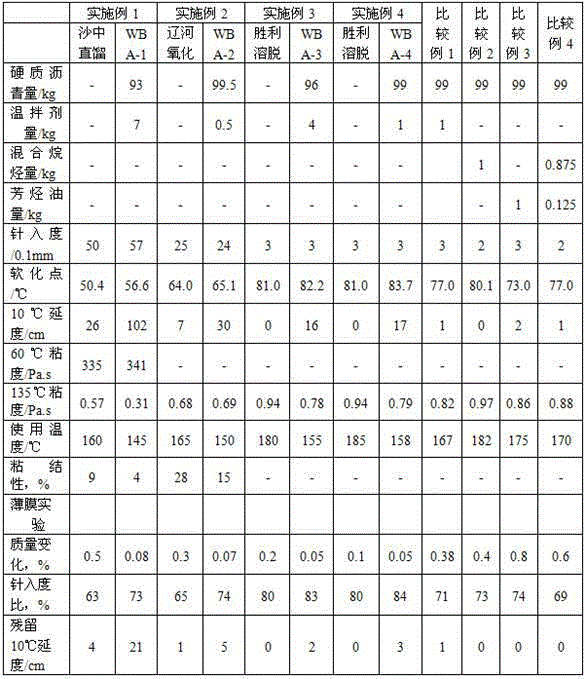

ActiveCN106630765AEasy to grasp performanceImprove performanceClimate change adaptationAlkaneHalogen

The invention discloses a warm mix hard asphalt mixture and a preparation method thereof, wherein the warm mix hard asphalt mixture comprises 4.0-6.0 parts of a warm mix hard asphalt, 1.0-3.0 parts of ore powder, and 91.0-95.0 parts of an aggregate, and the warm mix hard asphalt comprises 0.5-7 parts of a warm mix agent and 93-99.5 parts of matrix asphalt. The warm mix agent preparation method comprises: under the effect of a catalyst, carrying out a reaction on a macromolecule alkane and an elemental halogen to obtain an intermediate; carrying out a reaction on an aromatic hydrocarbon oil and a complexing compound under the effect of a catalyst to obtain an aromatic hydrocarbon complexing component; and carrying out a reaction on the aromatic hydrocarbon complexing component and the intermediate at a certain temperature, and aging to obtain the warm mix agent. According to the present invention, the warm mix hard asphalt used in the warm mix hard asphalt mixture contains the warm mix agent, such that the warm mix effect can be provided, the high temperature performance and the low temperature performance of the asphalt are considered, the harmful gas generation is reduced, the adhesion of the asphalt is improved, the thermal stability of the asphalt is improved, and the aging resistance is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

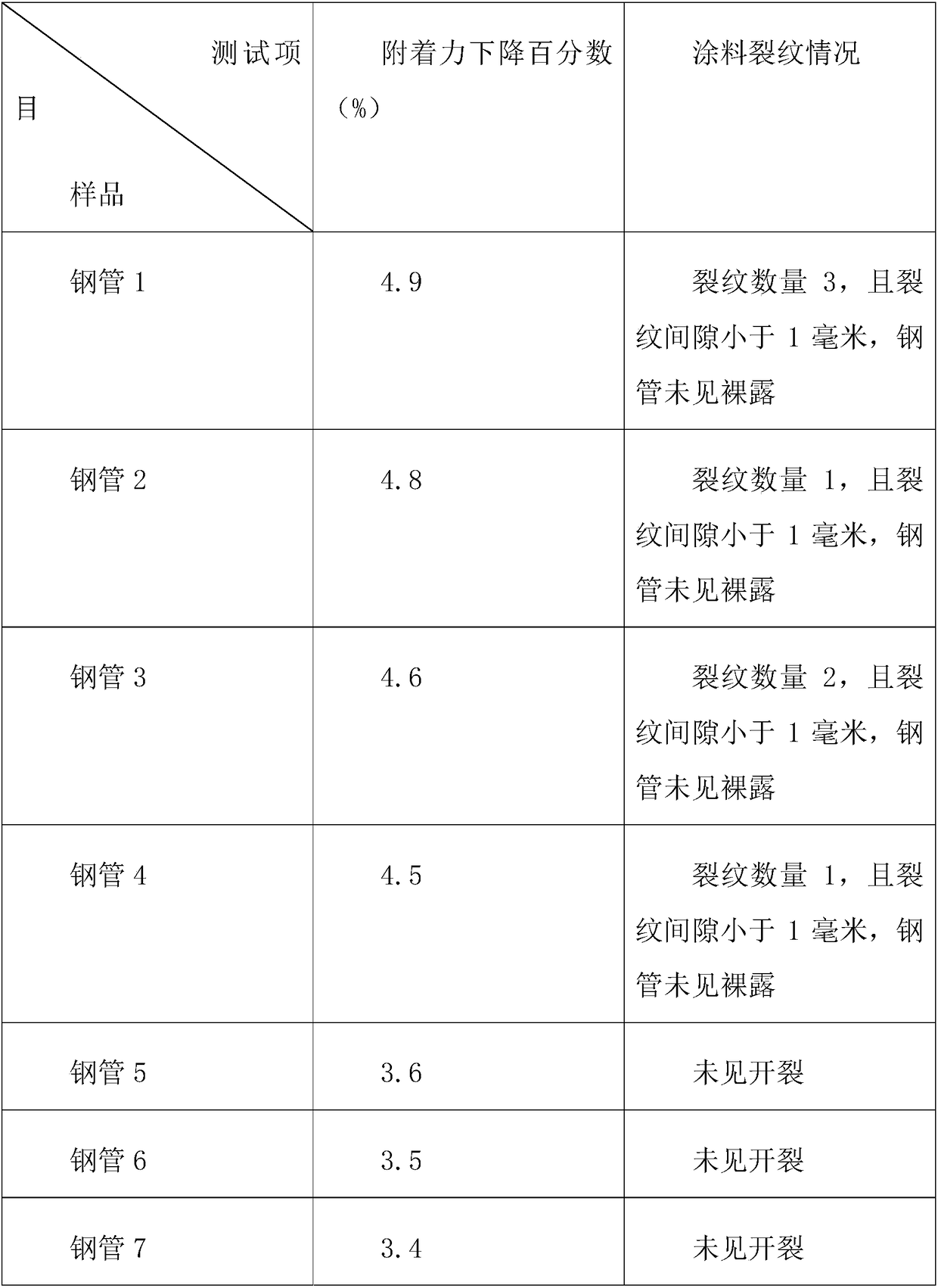

Wear-resistant anticorrosive coating, and preparation method and brushing method thereof

InactiveCN108165097ASimple and easy to prepareSimple methodFireproof paintsLiquid surface applicatorsFiberCarbon fibers

The invention provides a wear-resistant anticorrosive coating, and a preparation method and a brushing method thereof, and relates to the technical field of coatings. The wear-resistant anticorrosivecoating is mainly prepared from the following raw materials in parts by weight: 5 to 25 parts of carbon fiber, 5 to 25 parts of polyphenylene sulfide, 10 to 50 parts of an additive, 30 to 80 parts ofa first component, 50 to 100 parts of a second component and 20 to 50 parts of ceramic microspheres, wherein the additive comprises one or two selected from the group consisting of an inorganic additive and an organic additive; the first component comprises a curing agent and an aging-resistant auxiliary agent with a weight ratio of 1.5: (1-2); and the second component comprises a silane couplingagent, polyethylene glycol and epoxy resin with a weight ratio of 1: 2: (1.5-2.5). According to the invention, the stripe structure of the carbon fiber facilitates dispersing and absorbing the wear force to the coating, so the wear-resistant capacity of the coating is improved; the polyphenylene sulfide can be used as a protective layer of the carbon fiber, so bonding among carbon fibers is more stable; meanwhile, by utilization of the wear resistance of the polyphenylene sulfide, a protective layer to the carbon fiber can be constituted.

Owner:东方工建集团有限公司

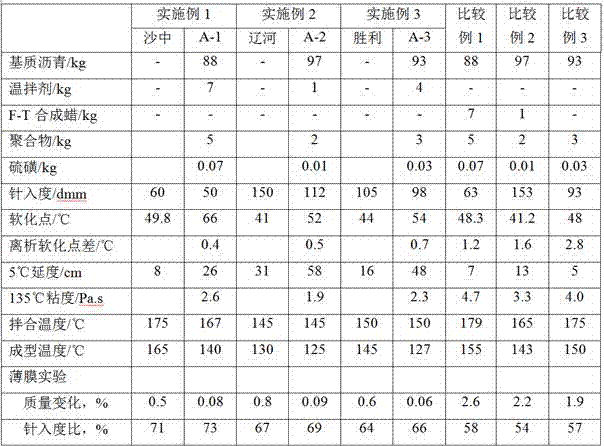

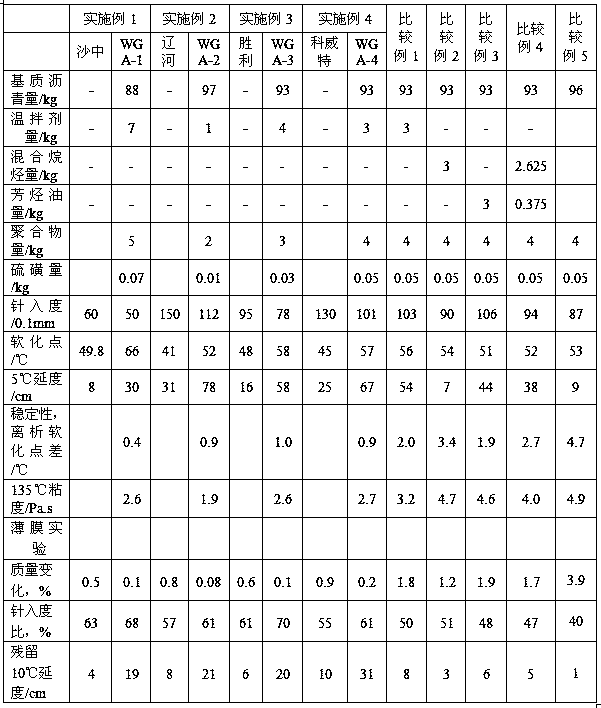

Warm mix polymer modified asphalt mixture and preparation method thereof

ActiveCN106630762AEasy to grasp performanceImprove performanceClimate change adaptationAlkanePolymer modified

The invention discloses a warm mix polymer modified asphalt mixture and a preparation method thereof, wherein the mixture comprises 4.0-6.0 parts of a warm mix polymer modified asphalt, 1.0-3.0 parts of ore powder, and 91.0-95.0 parts of an aggregate, the warm mix polymer modified asphalt comprises 1-7 parts of a warm mix agent, 2-5 parts of a polymer, 88-97 parts of matrix asphalt, and sulfur, and the sulfur accounts for 0.01-0.07% of the total mass of the warm mix agent, the polymer and the matrix asphalt. The warm mix agent preparation method comprises: under the effect of a catalyst, carrying out a reaction on a macromolecule alkane and a halogen to obtain an intermediate; uniformly mixing aromatic hydrocarbon oil and a complexing compound to obtain an aromatic hydrocarbon complexing component; and carrying out a reaction on the aromatic hydrocarbon complexing component and the intermediate at a certain temperature to obtain the warm mix agent. According to the present invention, by adding the warm mix agent to the asphalt in the mixture, the warm mix effect is provided for the asphalt, the high temperature performance and the low temperature performance of the asphalt are considered, the thermal stability of the asphalt is improved, the aging resistance is improved, the thermal aging of the asphalt is reduced, and the harmful gas generation is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly lubricating grease with high lubricating property and preparation method thereof

ActiveCN109536260AImprove the lubrication effectReduce pollutionLubricant compositionCalcium silicateLithium hydroxide

The invention discloses environment-friendly lubricating grease with high lubricating property. The environment-friendly lubricating grease is prepared from the following raw materials in parts by weight: 85 parts of base oil, 20 parts of 12-hydroxystearic acid, 8 parts of lithium hydroxide powder, 1 part of a complex heat stabilizer, 0.4 part of an auxiliary heat stabilizer, 0.5 part of carboxymethyl cellulose, 1 part of sodium dodecyl sulfate, 1 part of sodium dodecyl benzene sulfonate, 0.3 part of an antioxidant, 0.3 part of graphite and 0.3 part of glycerinum, wherein the base oil is prepared from epoxidized soybean oil and chlorinated paraffin in the mass ratio is 7:3 through mixing; the complex heat stabilizer is prepared from peanut oil and tea tree oil in the mass ratio is 2:1; theauxiliary heat stabilizer is prepared from calcium silicate, zinc oxide and aluminum oxide in the mass ratio is 3:2:2. The invention also provides a preparation method of the environment-friendly lubricating grease with the high lubricating property. The environment-friendly lubricating grease disclosed by the invention has very high lubricating property, is good in biodegradability and has smallpollution to environment.

Owner:统一石油化工有限公司

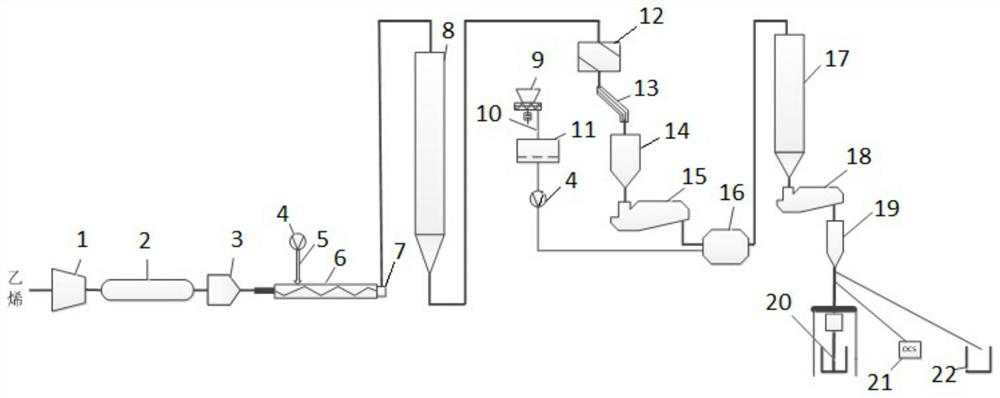

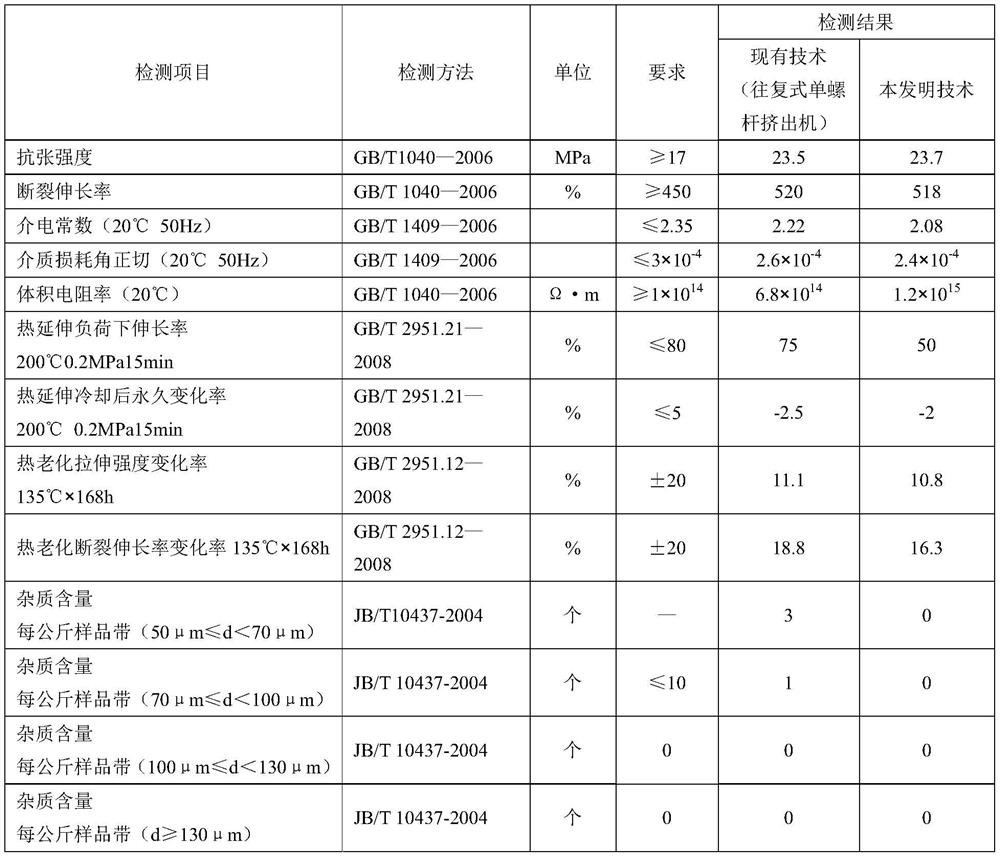

Preparation method of high-voltage and ultrahigh-voltage cable insulating material

PendingCN112280149AImprove cleanlinessImprove stabilityPlastic/resin/waxes insulatorsLow-density polyethyleneUltra high voltage

The invention discloses a preparation method of a high-voltage and ultrahigh-voltage cable insulating material. The preparation method comprises the following steps: (1) compressing an ethylene monomer, carrying out high-pressure polymerization in a reactor to obtain low-density polyethylene, separating by a high-pressure separator and a low-pressure separator, cooling the low-density polyethylene, directly feeding into a single-screw extruder, adding a liquid antioxidant, uniformly dispersing the liquid antioxidant into low-density polyethylene, filtering through a high-mesh filter screen, and granulating to obtain low-density polyethylene containing the antioxidant; and (2) dedusting and grading the antioxidant-containing low-density polyethylene, adding a cross-linking agent by adoptinga post-permeation method, fully stirring, putting into an absorption bin, keeping the temperature, cooling, dedusting, removing impurities, and carrying out metal filtration to obtain the high-voltage and ultrahigh-voltage cable insulating material. According to the method provided by the invention, secondary melting processing of low-density polyethylene is avoided, thermal aging of resin is reduced, the cleanliness and the stability of the insulating material are improved, and the method is high in production efficiency, low in cost and convenient to popularize and apply.

Owner:南京地中缆科技有限公司

Warm mixed modified asphalt, mixture containing warm mixed modified asphalt and their preparation methods

InactiveCN107513278AFor quick outflowEasy to separateHydrocarbon by hydrogenationPetroleum wax refiningSolid componentInorganic salts

The invention discloses warm mixed modified asphalt. The asphalt comprises a warm mixing agent, a polymer, basic asphalt and sulphur. The warm mixing agent is prepared by carrying out hydro-conversion on an F-T synthesis product as a raw material under action of a catalyst and carrying out special sweating on the hydrogenation product. Airflows pass through a material layer and carry away a liquid component in the sweating process so that separation effects of a solid component and the liquid component are improved and a separation rate is accelerated. Gas produced by inorganic salt decomposition forms micro-spaces in the material layer so that the liquid component fast outflows. The warm mixed modified asphalt has a low use temperature, high thermal stability and good heat aging resistance, reduces the heat aging of asphalt and reduces harmful gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

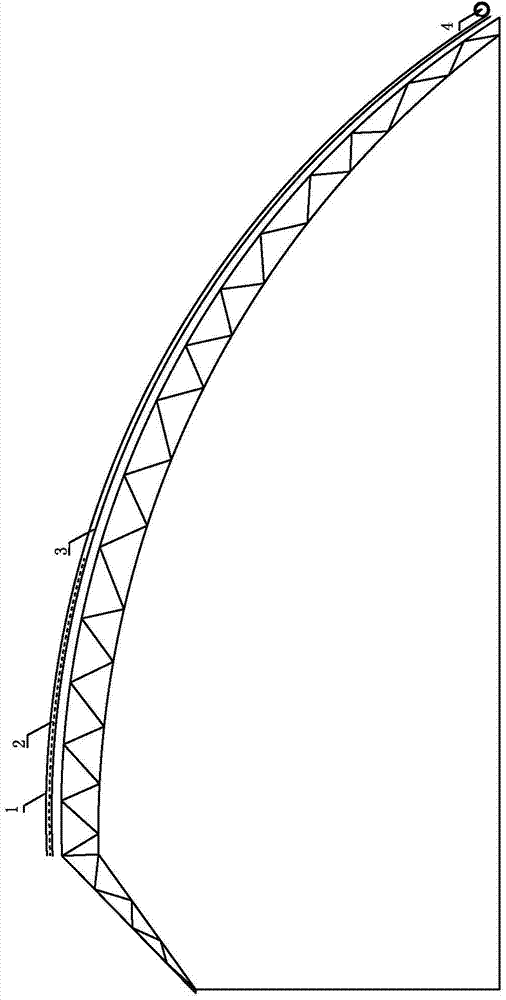

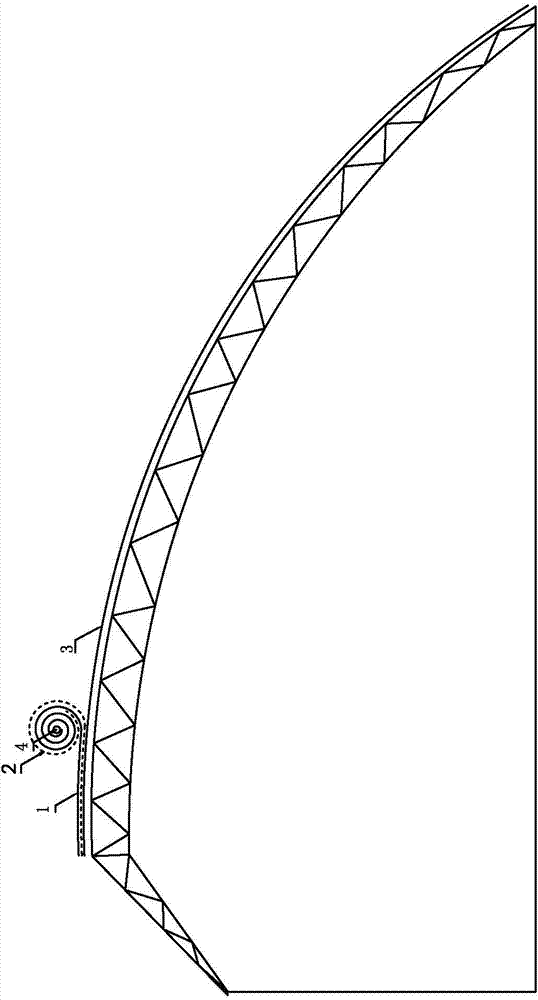

Method for prolonging service life of solar greenhouse heat preservation quilt

InactiveCN103477915AReduce thermal agingReduce photoagingClimate change adaptationGreenhouse cultivationUv blockingSolar greenhouse

The invention relates to a greenhouse heat preservation device and in particular relates to a method for prolonging the service life of a solar greenhouse heat preservation quilt. An ultraviolet barrier layer (2) is paved between the heat preservation quilt (1) and a greenhouse coverage material (3); the ultraviolet barrier layer (2) can be rolled up together with the heat preservation quilt (1) when the heat preservation quilt (1) is rolled up; the width of the ultraviolet barrier layer (2) at least ensures that the ultraviolet barrier layer (2) can completely cover all exposed parts of the heat preservation quilt (1) when the heat preservation quilt (1) is totally rolled up. Due to the ultraviolet barrier layer (2), thermal ageing and light aging of the heat preservation quilt (1) are alleviated, so that the service life of the heat preservation quilt can be greatly prolonged; by the method, the service life of the heat preservation quilt can be greatly prolonged at low cost.

Owner:CHINA AGRI UNIV

Warm mixed flame retardant asphalt, mixture containing warm mixed flame retardant asphalt and their preparation methods

InactiveCN107513280ALiquid enhancementFor quick outflowClimate change adaptationBuilding insulationsInorganic saltsSolid component

The invention discloses warm mixed flame retardant asphalt. The asphalt comprises a warm mixing agent, basic asphalt and a fire retardant. A preparation method of the warm mixing agent comprises carrying out hydro-conversion on an F-T synthesis product as a raw material and carrying out special sweating on the hydrogenation product. Airflows pass through a material layer and carry away a liquid component in the sweating process so that separation effects of a solid component and the liquid component are improved and a separation rate is accelerated. Gas produced by inorganic salt decomposition forms micro-spaces in the material layer so that the liquid component fast outflows. The warm mixed flame retardant asphalt has good flame retardant effects, a low service temperature, high thermal stability and good heat aging resistance and obviously reduces harmful gas during the asphalt construction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anticorrosive coating, and preparation method and brushing method thereof

InactiveCN108165129ASimple and easy to prepareSimple methodAnti-corrosive paintsPolyether coatingsEpoxyMicrosphere

The invention provides an anticorrosive coating, and a preparation method and a brushing method thereof, and relates to the technical field of coatings. The anticorrosive coating is mainly prepared from the following raw materials in parts by weight: 10 to 50 parts of an additive, 30 to 80 parts of a first component, 50 to 100 parts of a second component and 20 to 50 parts of ceramic microspheres,wherein the additive comprises one or two selected from the group consisting of an inorganic additive and an organic additive; the organic additive is one or two selected from the group consisting ofan ethylene-methacrylic acid copolymer and an ethylene-acrylic acid copolymer; the inorganic additive is one or more selected from the group consisting of TiO2, silicon-based oxides and A12O3; the first component comprises a curing agent and an aging-resistant auxiliary agent with a weight ratio of 1.5: (1-2); and the second component comprises a silane coupling agent, polyethylene glycol and epoxy resin with a weight ratio of 1: 2: (1.5-2.5). According to the invention, the epoxy resin is uniformly coated by a mesh structure, so the time of complete covering of a substrate with the coating is greatly prolonged, and the coating has more durable anticorrosive capacity.

Owner:东方工建集团有限公司

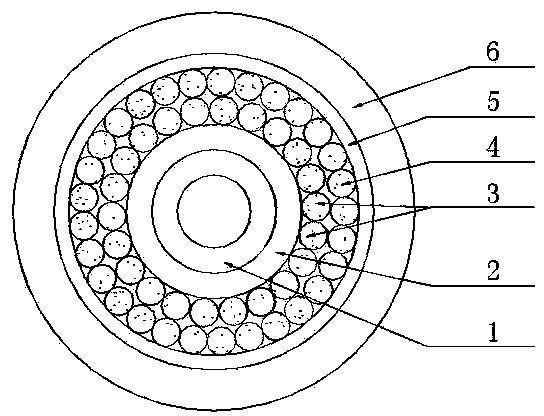

High-power transmission power cable

InactiveCN103474157ASmall sizeImprove bendabilityPower cablesFlexible cablesThermal ageingPower cable

The invention discloses a high-power transmission power cable. The high-power transmission power cable sequentially comprises a combined water passing pipe layer, a fine copper wire harness layer, an isolating layer and a rubber layer from inside to outside, wherein the fine copper wire harness layer is arranged outside the combined water passing pipe layer, the isolating layer is arranged outside the fine copper wire harness layer in winding and coating modes, and the rubber layer is arranged on the outermost layer of the high-power transmission power cable in squeezing and coating modes. Control pairs are further arranged inside the fine copper wire harness layer, and the control pairs are tightly attached to the combined water passing pipe layer. The combined water passing pipe layer is composed of a cooling water pipe and a cold pipe closing layer which is arranged outside the cooling water pipe in a coating mode. The high-power transmission power cable is in the state of external natural cooling and center forced cooling in the working process, the control pairs are tightly attached to the cooling water pipe, insulating strength can be better maintained, thermal ageing is slowed down, and the stress is small when the cable is bent.

Owner:YUANCHENG CABLE CO LTD

Warm mix hard asphalt, and preparation method thereof

ActiveCN106633943AEasy to grasp performanceImprove performanceClimate change adaptationBuilding insulationsHalogenAging resistance

The invention provides a warm mix hard asphalt, and a preparation method thereof. The warm mix hard asphalt comprises, by mass, 0.5 to 7 parts of a warm mixing agent, and 93 to 99.5 parts of matrix asphalt. The preparation method comprises following steps: under the action of a catalyst, a high-molecular alkane is reacted with a halogen elementary substance at a certain temperature under a certain pressure so as to obtain an intermediate; an aromatic hydrocarbon oil and a complex are uniformly mixed so as to obtain an aromatic hydrocarbon complex compound; the aromatic hydrocarbon complex compound and the intermediate are reacted at a certain temperature so as to obtain the warm mixing agent. The warm mixing agent added in the warm mix hard asphalt is capable of realizing warm mixing of asphalt, giving consideration to the high and low temperature performance of asphalt, increasing thermal stability of asphalt, improving aging resistance, reducing application temperature of asphalt, reducing generation amount of harmful gas, and improving the cohesiveness of asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy-duty anticorrosive paint as well as preparation method and painting method thereof

InactiveCN108129945AImprove anti-corrosion abilityAnti-corrosion expiration date increasedLiquid surface applicatorsAnti-corrosive paintsSilane couplingAdjuvant

The invention provides heavy-duty anticorrosive paint as well as a preparation method and a painting method thereof, relating to the technical field of paint. The heavy-duty anticorrosive paint is prepared from the following raw materials in parts by weight: 10-25 parts of imvite, 5-15 parts of graphite, 5-15 parts of lithium cobalt oxide, 10-50 parts of additives, 30-80 parts of first ingredients, 50-100 parts of second ingredients and 20-50 parts of ceramic microbeads. The graphite and lithium cobalt oxide are both inserted between imvite layers. The additives is prepared from an inorganic additive and / or an organic additive. The first ingredients are prepared from a curing agent and an anti-aging adjuvant in a weight ratio of 1.5: (1 to 2). The second ingredients are prepared from a silane coupling agent, polyethylene glycol and epoxy resin in a weight ratio of 1 to 2 to (1.5-2.5). The imvite subjected to layer insertion can form multiple interlaced protection layers in the paint, various corrosive fluids can be prevented from invading into an inner layer of the paint to reach the surface of a base material to cause corrosion in a severe environment, and the anticorrosive capacity of the paint is improved.

Owner:东方工建集团有限公司

Process for producing a fiber-reinforced thermoplastic resin molded product and product thereby produced

InactiveCN1137815CHigh mechanical strengthGood lookingDomestic footwearUpperShear stressVolumetric Mass Density

Owner:FIBER GLASS JAPAN

Environmentally friendly grease with high lubricating performance and preparation method thereof

ActiveCN109536260BImprove the lubrication effectReduce pollutionLubricant compositionCalcium silicateLithium hydroxide

Owner:统一石油化工有限公司

Warm-mix hard asphalt mixture and preparation method thereof

ActiveCN106630764BEasy to grasp performanceImprove performanceClimate change adaptationAlkaneHalogen

The invention discloses a warm mixing hard asphalt mixture and a preparation method thereof. The warm mixing hard asphalt mixture comprises the following components in parts by weight: 4.0-6.0 parts of warm mixing hard asphalt, 1.0-3.0 parts of mineral powder and 91.0-95.0 parts of aggregates. The warm mixing hard asphalt comprises the following components in parts by weight: 0.5-7 parts of a warm mixing agent and 93-99.5 parts of matrix asphalt. The preparation method of the warm mixing agent comprises the following steps: under the effect of a catalyst, reacting macromolecular alkane with halogen simple substances to obtain a midbody; evenly mixing aromatic oil with a complex to obtain an aromatic complex component; and reacting the aromatic complex component and the midbody at a certain temperature to obtain the warm mixing agent used in the invention. The warm mixing hard asphalt used in the warm mixing hard asphalt mixture contains the warm mixing agent, the warm mixing effect can be achieved, the high-temperature performance and low-temperature performance of the asphalt are considered, the generation amount of harmful gas is reduced, the caking property of the asphalt is improved, the heat stability of the asphalt can be improved, and the anti-ageing performance is also improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Maleic anhydride-grafted polyphenyl ether modified epoxy resin composite used for LED packaging and preparation method thereof

The invention discloses a maleic anhydride-grafted polyphenyl ether modified epoxy resin composite used for LED packaging. A polyphenyl ether material obtained after grafting by raw materials like maleic anhydride and nanometer titanium dioxide maintains excellent low dielectric performance, low loss and high heat resistance and has improved compatibility with epoxy resin, so the defects of the epoxy resin as a packaging material are effectively improved; blended talcum powder having undergone surface roughening by hydrofluoric acid has a greater contact surface with the resin and better adsorptivity and can improve ultraviolet resistance and toughness of the composite; and added nanometer zirconia further improves the thermal conduction speed of the composite, enhances thermal oxidation resistance of the resin and alleviates thermal ageing. The composite prepared in the invention has excellent mechanical properties and dielectric properties, long service life, economic performance and durability when used as an LED packaging material.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

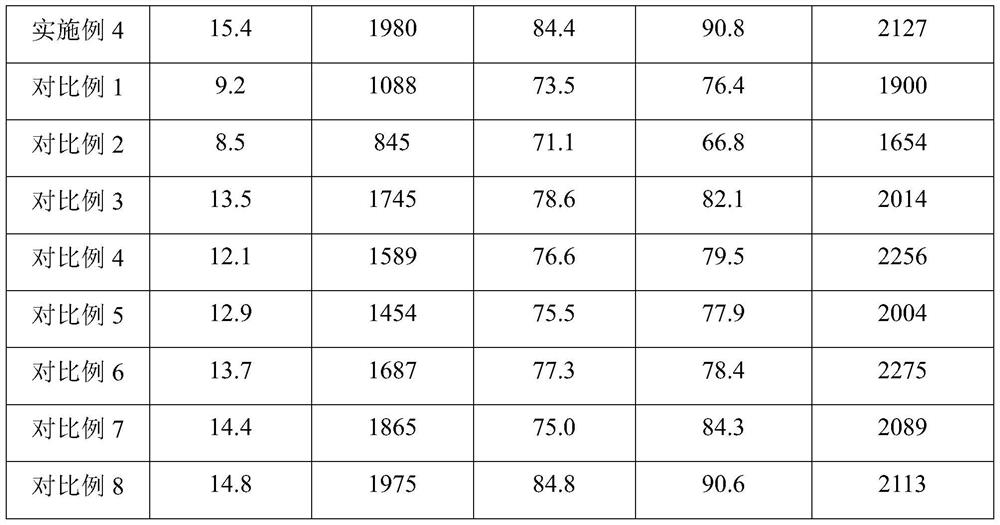

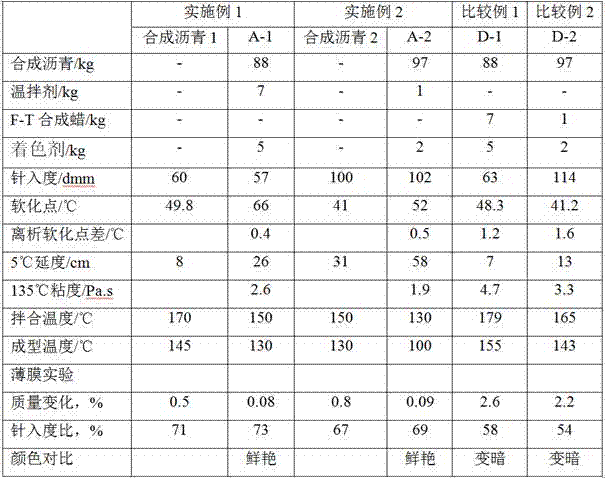

A kind of warm mixed colored synthetic asphalt and its preparation method

ActiveCN108624066BLow production temperatureReduce the use temperatureClimate change adaptationBuilding insulationsAlkanePolymer science

The invention provides warm-mixed colorful synthetic asphalt and a preparation method thereof. The warm-mixed colorful synthetic asphalt is prepared from the following components in parts by mass: 1-7parts of warm mixing agent, 88-97 parts of synthetic asphalt and 2-5 parts of a coloring agent. A preparation method of the warm mixing agent comprises the following steps: firstly, enabling high molecular alkane to react with a halogen element in presence of a first catalyst to obtain an intermediate; evenly mixing first aromatic hydrocarbon oil with a complex to obtain an aromatic hydrocarbon complex component; then, mixing the aromatic hydrocarbon complex component with the intermediate for carrying out a reaction to obtain the warm mixing agent. The warm0mixed colorful synthetic asphalt is not only low in use temperature, but also can improve the heat stability and heat aging resistance of the asphalt, so that colorful asphalt pavement is bright in colorful, and the service life of the colorful asphalt pavement is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of warm mix hard asphalt and preparation method thereof

ActiveCN106633943BEasy to grasp performanceImprove performanceClimate change adaptationBuilding insulationsAlkaneHalogen

The invention provides a warm mix hard asphalt, and a preparation method thereof. The warm mix hard asphalt comprises, by mass, 0.5 to 7 parts of a warm mixing agent, and 93 to 99.5 parts of matrix asphalt. The preparation method comprises following steps: under the action of a catalyst, a high-molecular alkane is reacted with a halogen elementary substance at a certain temperature under a certain pressure so as to obtain an intermediate; an aromatic hydrocarbon oil and a complex are uniformly mixed so as to obtain an aromatic hydrocarbon complex compound; the aromatic hydrocarbon complex compound and the intermediate are reacted at a certain temperature so as to obtain the warm mixing agent. The warm mixing agent added in the warm mix hard asphalt is capable of realizing warm mixing of asphalt, giving consideration to the high and low temperature performance of asphalt, increasing thermal stability of asphalt, improving aging resistance, reducing application temperature of asphalt, reducing generation amount of harmful gas, and improving the cohesiveness of asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

Warm mix polymer modified asphalt and its preparation method

ActiveCN106633948BEasy to grasp performanceImprove performanceClimate change adaptationBuilding insulationsAlkanePolymer modified

The invention discloses a warm mix polymer modified asphalt and a preparation method thereof, wherein the warm mix polymer modified asphalt comprises, by mass, 1-7 parts of a warm mix agent, 2-5 parts of a polymer, 88-97 parts of matrix asphalt, and sulfur, and the sulfur accounts for 0.01-0.07% of the total mass of the warm mix agent, the polymer and the matrix asphalt. The warm mix agent preparation method comprises: under the effect of a catalyst, carrying out a reaction on a macromolecule alkane and an elemental halogen at a certain temperature under a certain pressure to obtain an intermediate; carrying out a reaction on an aromatic hydrocarbon oil and a complexing compound under the effect of a catalyst to obtain an aromatic hydrocarbon complexing component; and carrying out a reaction on the aromatic hydrocarbon complexing component and the intermediate at a certain temperature, and aging to obtain the warm mix agent. According to the present invention, with the warm mix agent, the warm mix effect is provided for the asphalt, the high temperature performance and the low temperature performance of the asphalt are considered, the thermal stability of the asphalt is improved, the aging resistance is improved, the thermal aging of the asphalt is reduced, and the harmful gas generation is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Warm hard asphalt mixture and preparation method thereof

ActiveCN106630765BEasy to grasp performanceImprove performanceClimate change adaptationHalogenAging resistance

The invention discloses a warm mix hard asphalt mixture and a preparation method thereof, wherein the warm mix hard asphalt mixture comprises 4.0-6.0 parts of a warm mix hard asphalt, 1.0-3.0 parts of ore powder, and 91.0-95.0 parts of an aggregate, and the warm mix hard asphalt comprises 0.5-7 parts of a warm mix agent and 93-99.5 parts of matrix asphalt. The warm mix agent preparation method comprises: under the effect of a catalyst, carrying out a reaction on a macromolecule alkane and an elemental halogen to obtain an intermediate; carrying out a reaction on an aromatic hydrocarbon oil and a complexing compound under the effect of a catalyst to obtain an aromatic hydrocarbon complexing component; and carrying out a reaction on the aromatic hydrocarbon complexing component and the intermediate at a certain temperature, and aging to obtain the warm mix agent. According to the present invention, the warm mix hard asphalt used in the warm mix hard asphalt mixture contains the warm mix agent, such that the warm mix effect can be provided, the high temperature performance and the low temperature performance of the asphalt are considered, the harmful gas generation is reduced, the adhesion of the asphalt is improved, the thermal stability of the asphalt is improved, and the aging resistance is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hard asphalt mixture and preparation method thereof

The invention discloses a hard asphalt mixture, which is made of the following components in parts by weight: 4.2-4.8 parts of modified hard asphalt, 92-94 parts of aggregate, 1.0-1.2 parts of mineral powder, modified hard asphalt Asphalt is made of modifier and base asphalt in a weight ratio of 3:7, and the modifier is prepared by the following steps: 1 weight part of nanometer hydrotalcite powder is added to 5 weight parts of ethylene glycol to disperse, and the pH value is adjusted to 4.0 , to obtain a slurry; 2 parts by weight of benzoic acid were dissolved in 5 parts by weight of ethylene glycol, the slurry was added dropwise, stirred and reacted at 130°C for 2h, filtered with suction, the supernatant was washed with water until neutral, and dried to obtain Modified nano hydrotalcite powder: Mix modified nano hydrotalcite powder, phenolic resin and oxidized polyethylene wax in a weight ratio of 2:7:3, extrude through a twin-screw extruder, and granulate to obtain the product. The invention has the advantages of reducing the mixing temperature of the hard asphalt mixture, improving high and low temperature performance, and the like.

Owner:CHINA ROAD & BRIDGE

A kind of warm mix polymer modified asphalt and preparation method thereof

ActiveCN106633947BEasy to grasp performanceImprove performanceClimate change adaptationBuilding insulationsThermal ageingAlkane

The invention provides warm-mixed polymer modified asphalt and a preparation method thereof. The asphalt is prepared from components in parts by mass as follows: 1-7 parts of a warm-mixing agent, 2-5 parts of a polymer, 88-97 parts of substrate asphalt as well as sulfur accounting for 0.01%-0.07% of the total mass of the three components. The warm-mixing agent is prepared with the following method: under the action of a catalyst, high polymer alkane firstly reacts with elementary halogen at a certain temperature and under certain pressure to produce an intermediate; aromatic oil and a complex are uniformly mixed to form an aromatic complex component; then the aromatic complex component reacts with the intermediate at a certain temperature to produce the warm-mixing agent. The warm-mixing agent used in the warm-mixed polymer modified asphalt can have a warm-mixing effect on asphalt, considers high / low-temperature performance of asphalt and can improve the thermal stability of asphalt, improve aging resistance, reduce thermal ageing of asphalt and decrease harmful gas production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Warm mixed colorized synthetic asphalt, mixture containing warm mixed colorized synthetic asphalt and their preparation methods

InactiveCN107513276AFor quick outflowEasy to separateClimate change adaptationPetroleum wax refiningSolid componentInorganic salts

The invention discloses warm mixed colorized synthetic asphalt. The asphalt comprises a warm mixing agent, synthetic asphalt and a colorant. The warm mixing agent is prepared by carrying out hydro-conversion on an F-T synthesis product as a raw material under action of a catalyst and carrying out sweating on the hydrogenation product. Airflows pass through a material layer and carry away a liquid component in the sweating process so that separation effects of a solid component and the liquid component are improved and a separation rate is accelerated. Gas produced by inorganic salt decomposition forms micro-spaces in the material layer so that the liquid component fast outflows. The warm mixed colorized synthetic asphalt has a low use temperature, high thermal stability and high heat aging resistance, provides a bright color for the colorized asphalt pavement and prolongs a service life of the colorized asphalt pavement.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of sulfur emulsified asphalt and preparation method thereof

ActiveCN104559231BLow preparation temperatureLow viscosityClimate change adaptationBuilding insulationsSulfurAsphalt

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com