Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Permanent deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

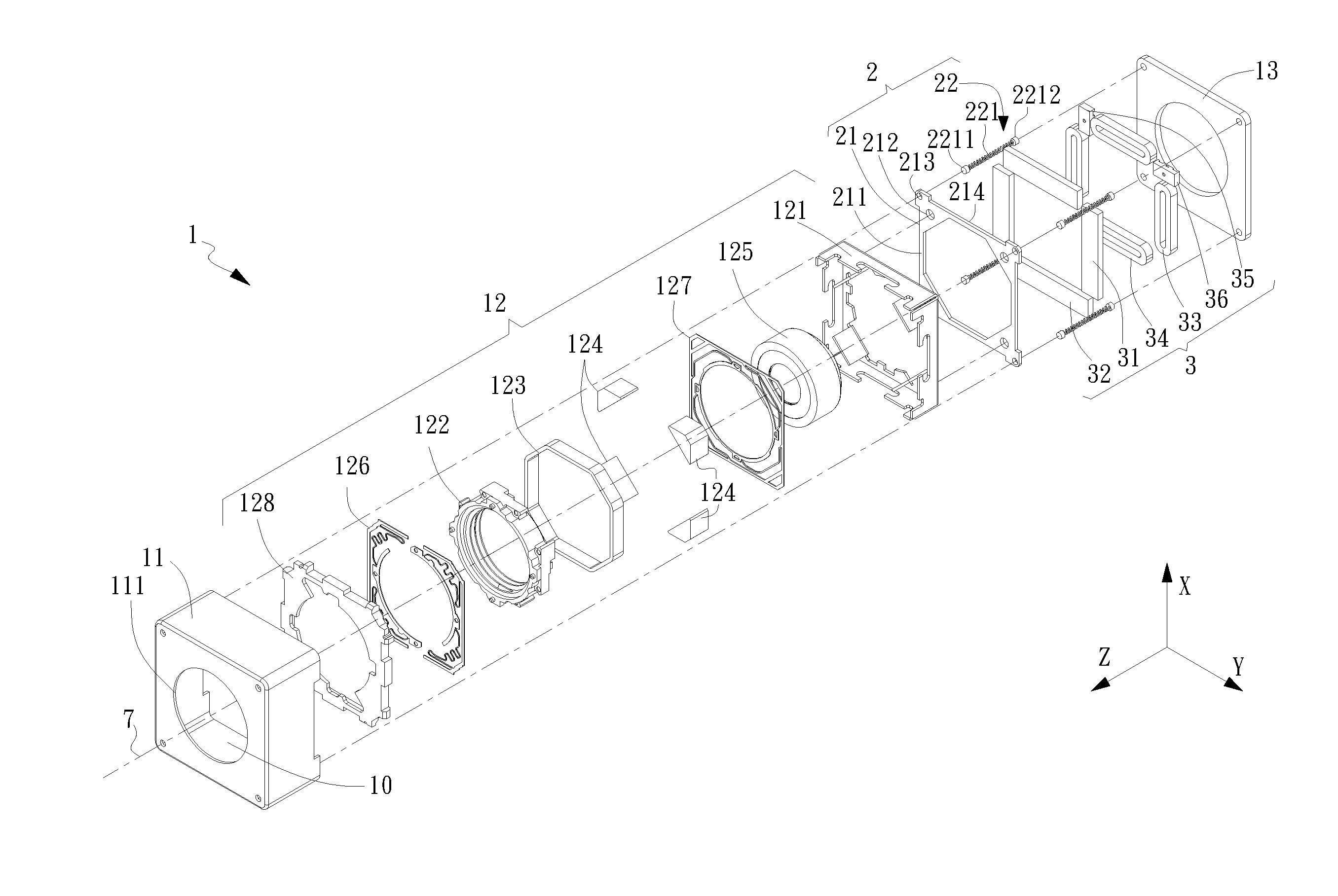

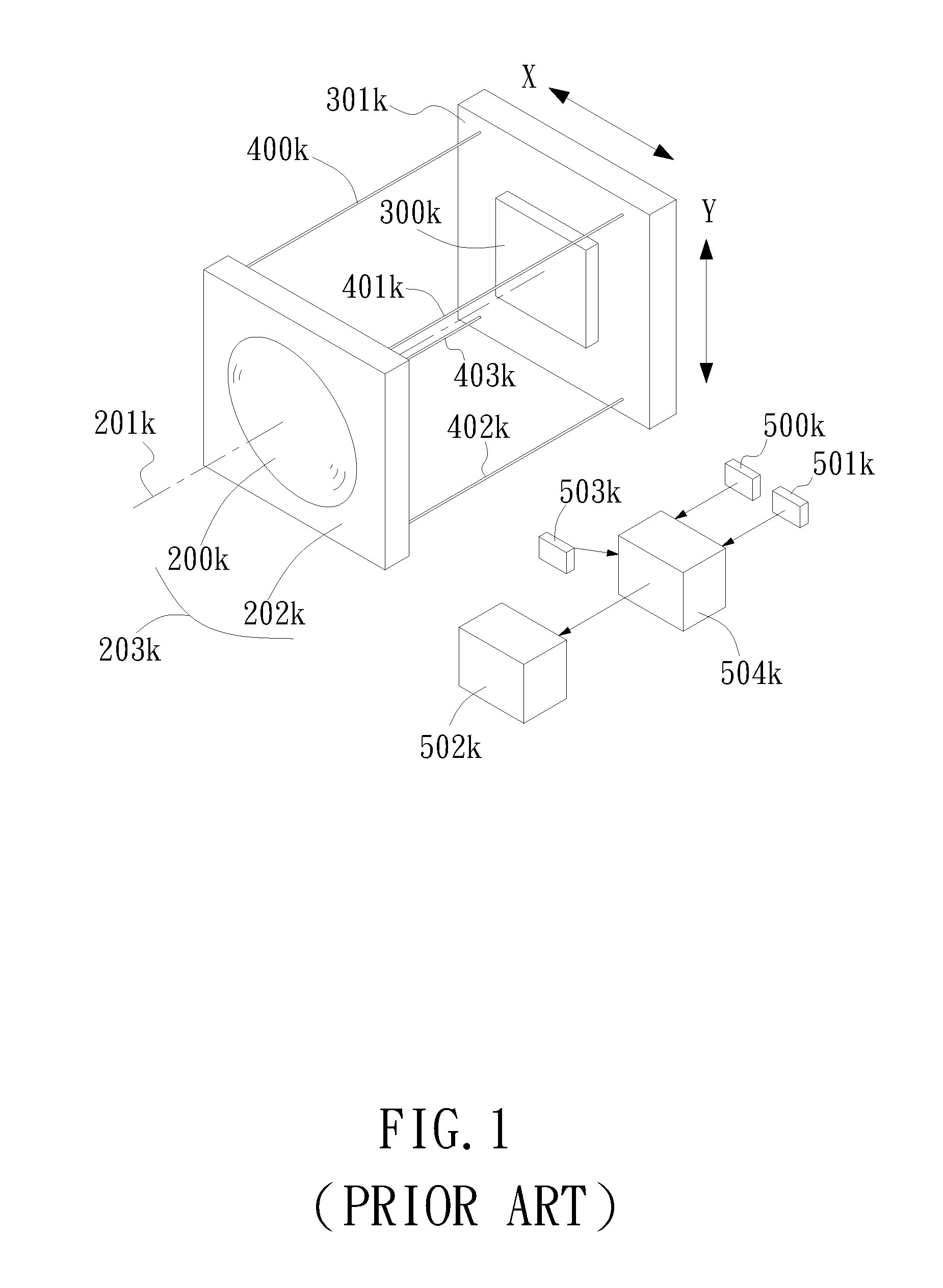

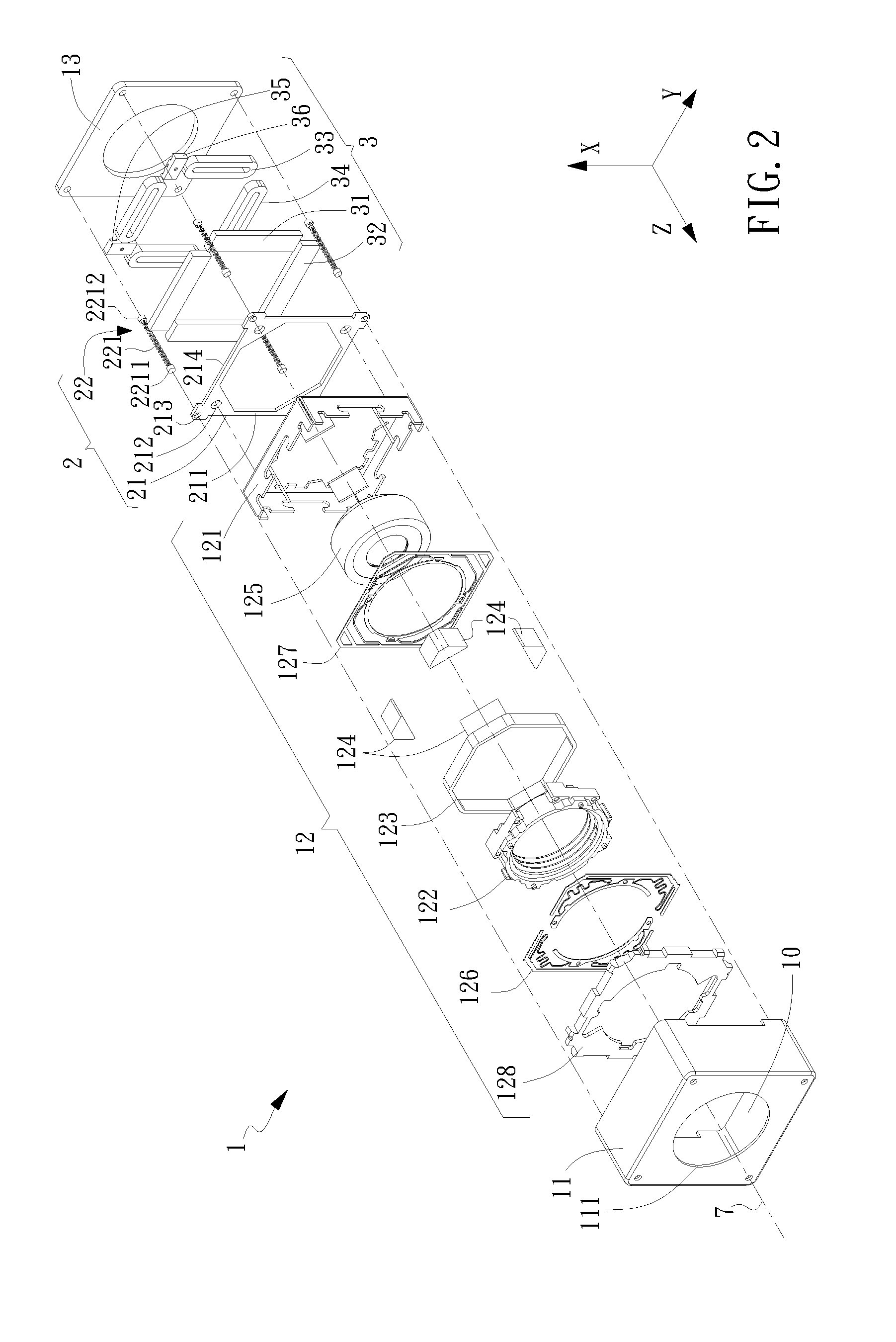

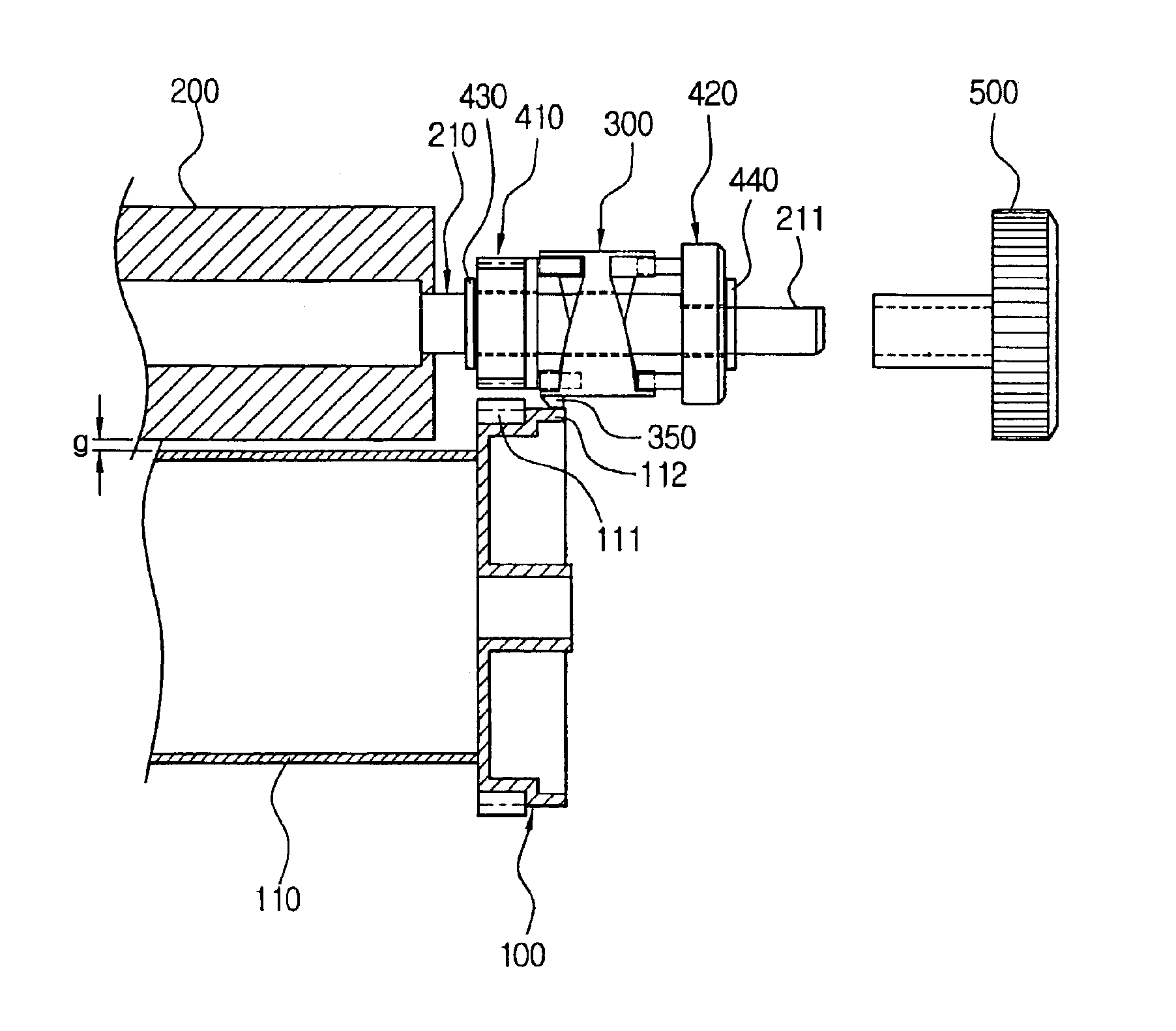

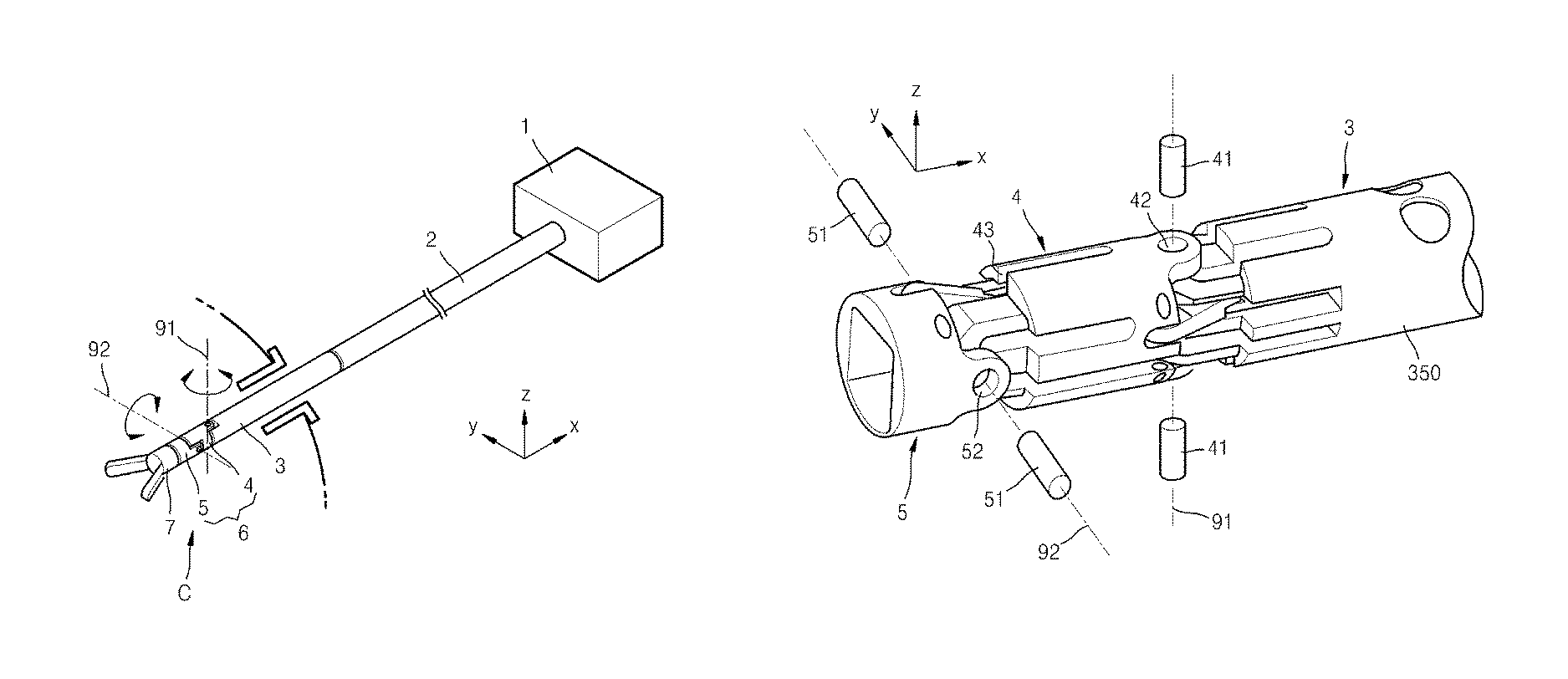

Suspension Mechanism for an Optical Image Anti-Shake Device

ActiveUS20130258475A1Permanent deformationProjector focusing arrangementCamera focusing arrangementBiomedical engineeringEngineering

An optical image anti-shake device, defined with an X-axis, a Y-axis and a Z-axis, includes a casing, a movable member and a base. A suspension mechanism furnished inside the optical image anti-shake device includes a movable-member support and a suspension module. A first surface of the movable-member support is connected to the movable member. The suspension module suspends the movable-member support together with the movable member inside an inner compartment formed between the casing and the base.

Owner:TDK TAIWAN

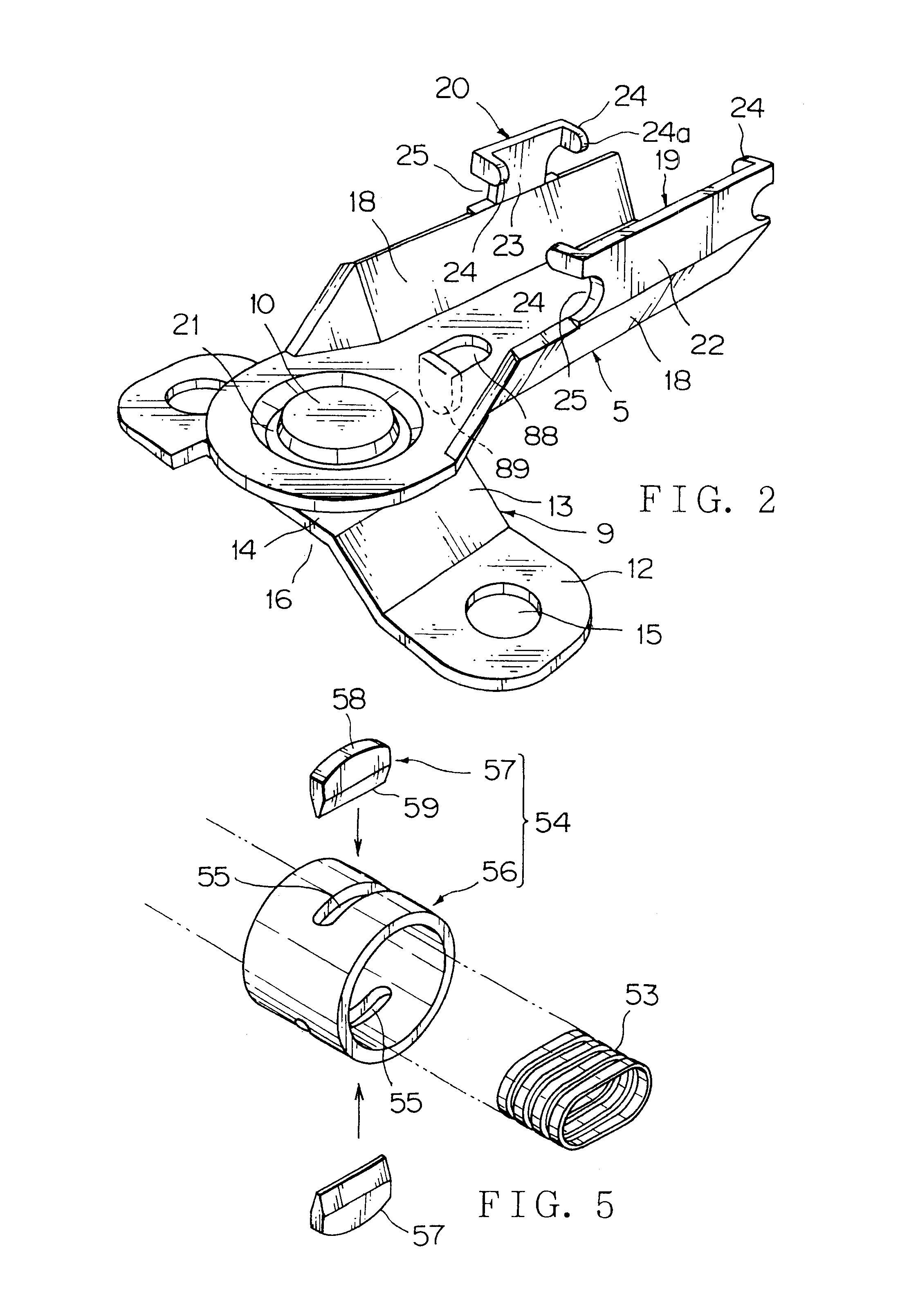

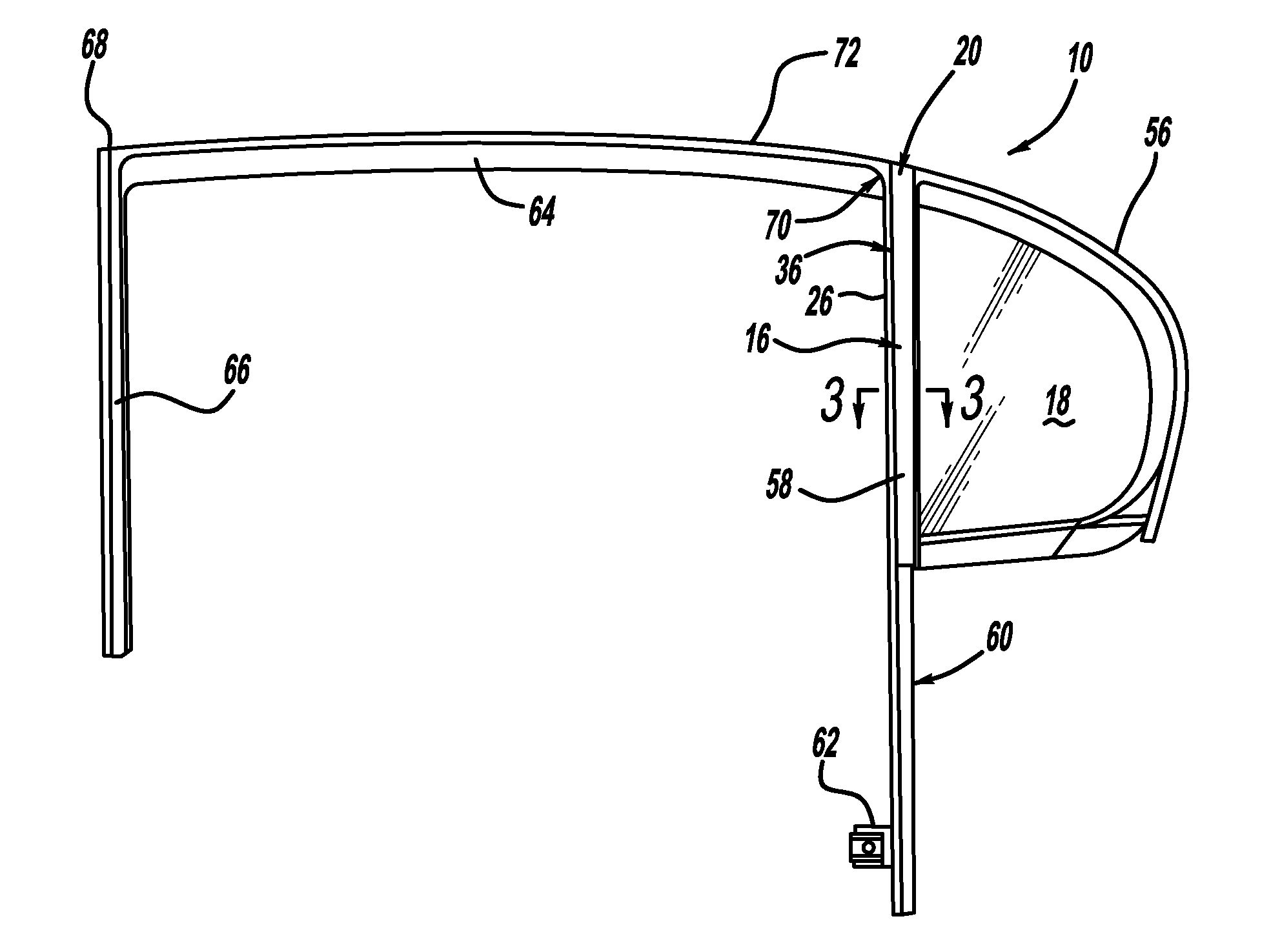

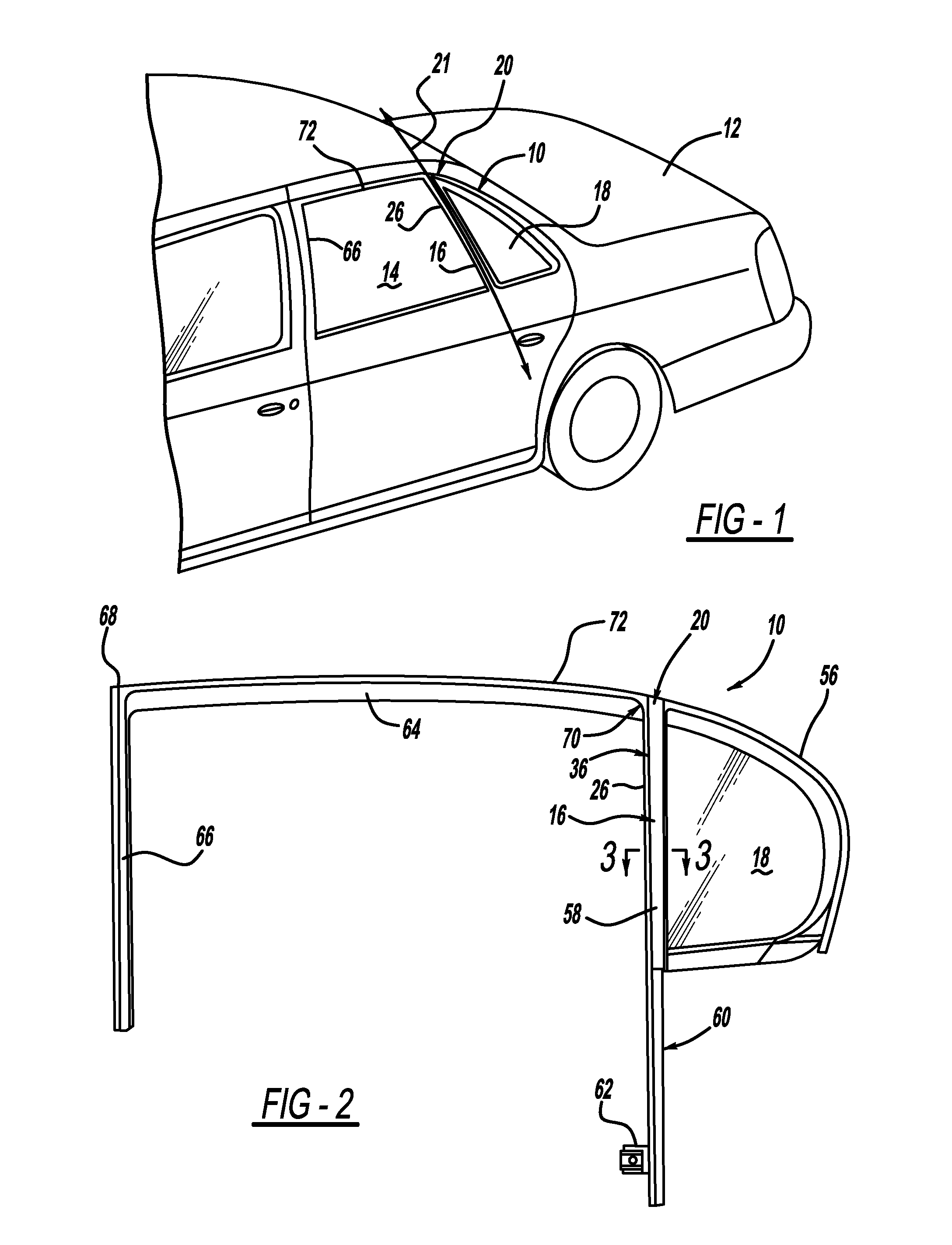

Wiring harness arrangement assembly for sliding door of car

InactiveUS6881902B2Damage permanent deformationUndesirable permanent deformationCoupling device connectionsInsulated cablesEngineeringMechanical engineering

Owner:YAZAKI CORP

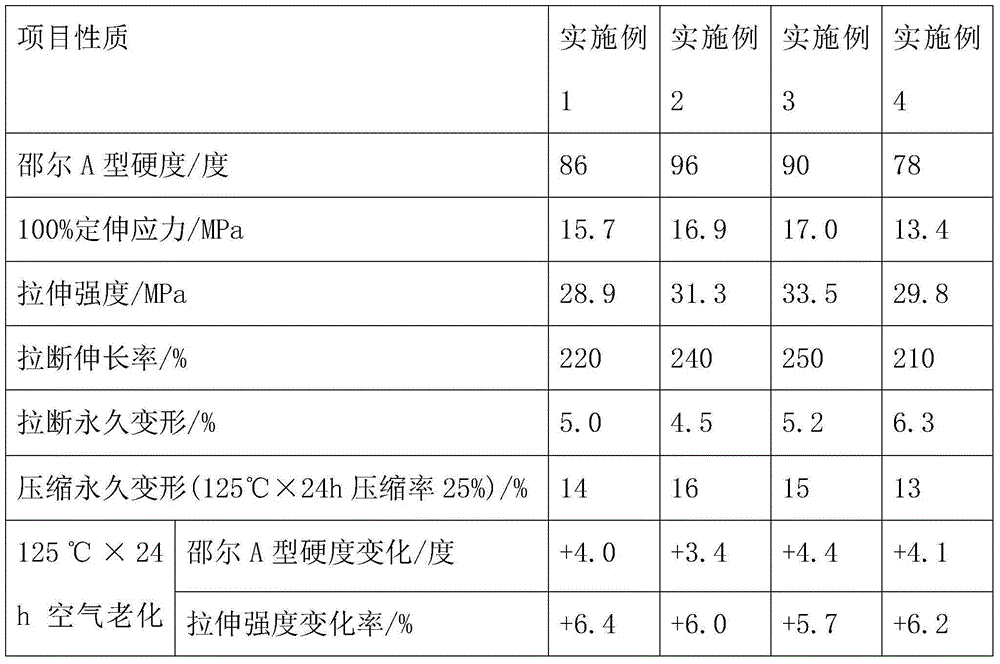

Conductive silicon rubber material with ultralow compressive deformation and low hardness and preparation method thereof

ActiveCN103160128AReduce fillingIncrease elasticityNon-conductive material with dispersed conductive materialRubber materialCarbon nanotube

The invention relates to a conductive silicon rubber material with ultralow compressive deformation and low hardness and a preparation method thereof and belongs to the technical field of conductive silicon rubber materials. The rubber material is prepared by filling conductive fillers with different shape factors so as to ensure that a network passage is formed under the condition of low-usage conductive filler. The rubber material comprises the following ingredients in parts by mass: 100 parts of silicon rubber, 1-15 parts of vulcanizing agent, 0 or 1-8 parts of vulcanizing assistant, 5-15 parts of carbon black and 0.5-5 parts of carbon nanotubes. According to the material, the material is endowed with higher conductivity under the condition that lower compression permanent deformation and lower hardness are guaranteed; the preparation process is simple, and the cost is low; and through testing the electrical and mechanical properties of the material, the conductive silicon rubber material has the following properties: the Shore A hardness is not higher than 50, the 25% constant compression permanent deformation is not higher than 10% (100 DEG C * 24 h), the instantaneous resilience performance is not lower than 60%, and the volume resistivity is not higher than 50 omega.cm.

Owner:BEIJING UNIV OF CHEM TECH

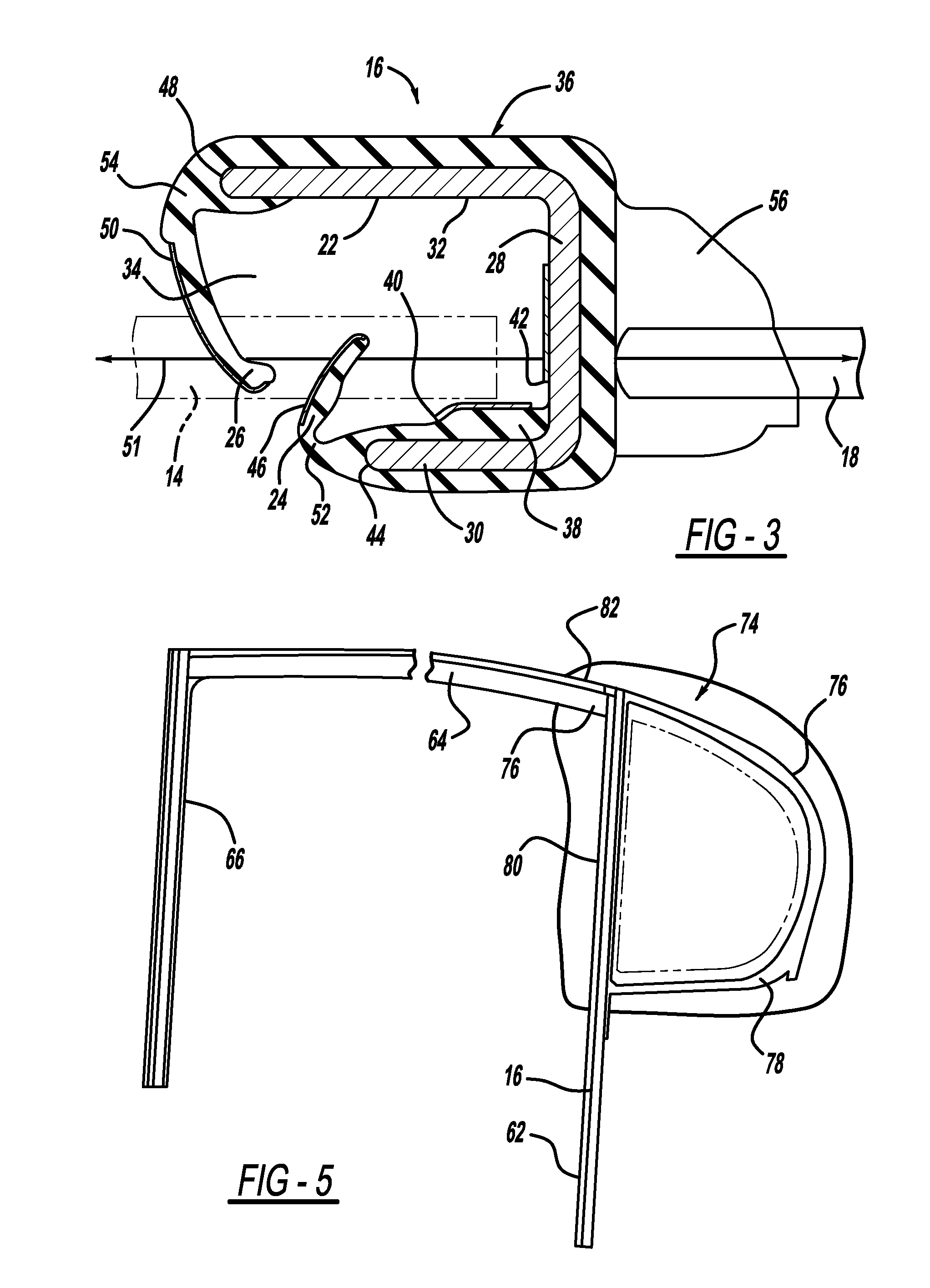

Method of forming unsupported division post for automotive glass encapsulation

InactiveUS20110109009A1Sufficient flexibilityRigid enoughMouldsDomestic slide fastenersCurve shapeHand manipulation

A method of forming a division post assembly for guiding a moveable window panel in a motor vehicle comprises: forming a body portion free of structural metal and coextruding at least one sealing wing with the body portion to form a coextruded assembly. The body portion comprises a first material and has a generally U-shaped cross-section including a base and first and second opposing walls defining a channel configured to receive at least an edge of the moveable window panel. The sealing wing projects into the channel and comprises a second material different than the first material. The body portion and the coextruded assembly exhibit sufficient flexibility for hand manipulation into a curved shape having a first radius of curvature that is substantially the same as a second radius of curvature of a mold cavity of a mold into which the coextruded assembly is configured for placement.

Owner:HUTCHINSON SEALING SYST

High-performance modified carboxylated nitrile rubber material and preparation method thereof

The invention discloses a high-performance modified carboxylated nitrile rubber material. The material comprises the following raw materials by weight: 90 to 130 parts of modified carboxylated nitrile rubber, 15 to 30 parts of natural rubber, 20 to 40 parts of carbon black N-774, 5 to 10 parts of carbon black N-990, 5 to 10 parts of antimony trioxide, 3 to 5 parts of zinc oxide, 1 to 3 parts of stearic acid, 1 to 3 parts of sulfur, 0.5 to 3 parts of tetrabenzylthiuramdisulfide, 1 to 3 parts of N-tert-butyl-2-benzothiazole sulfonamide, 2 to 6 parts of dioctyl sebacate and 4 to 8 parts of an auxiliary. The modified carboxylated nitrile rubber blending material provided by the invention has higher comprehensive mechanical property, and heat and ageing resistant properties, high-temperature and oil resistant properties and low-compression and permanent-deformation properties.

Owner:合肥市再德高分子材料有限公司

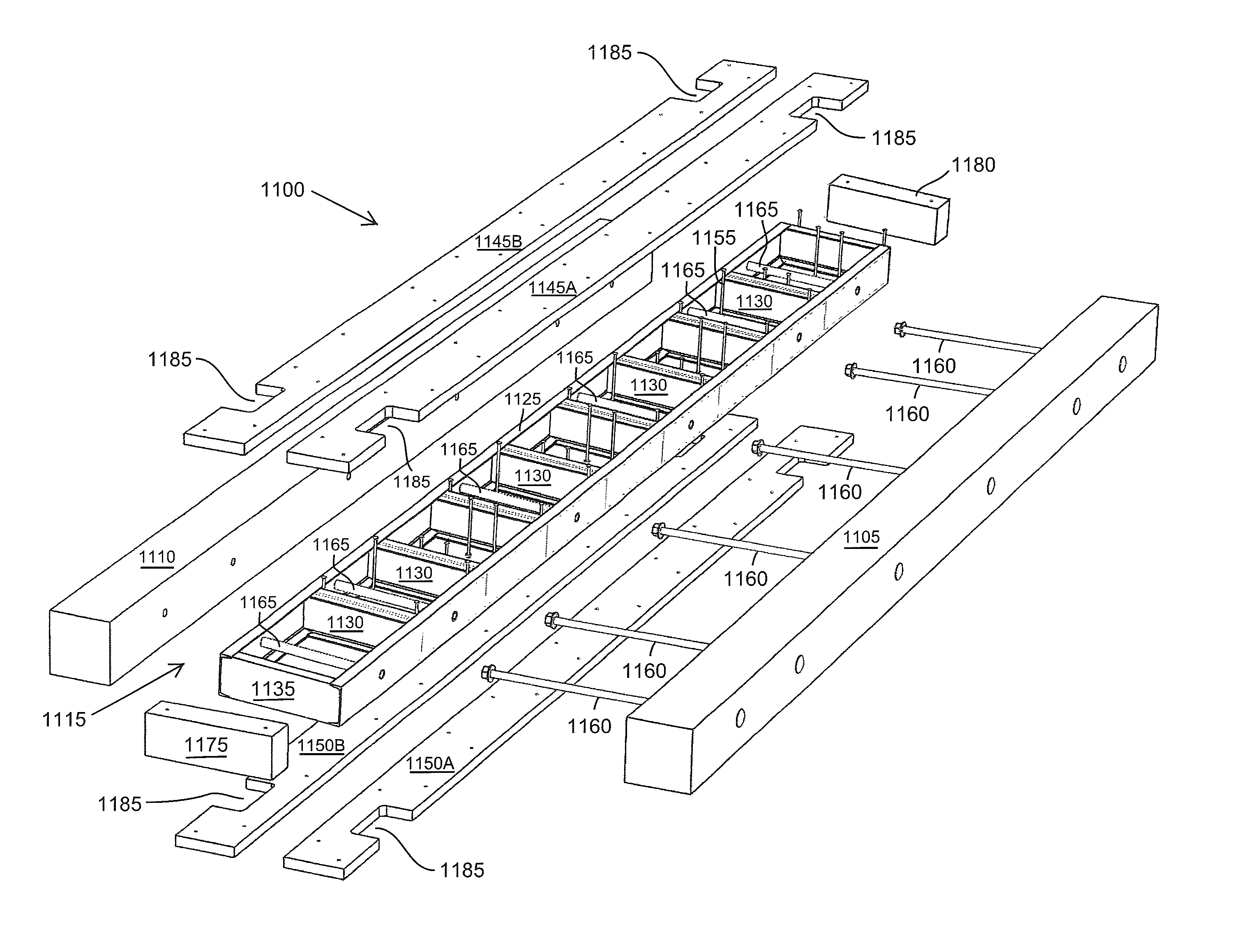

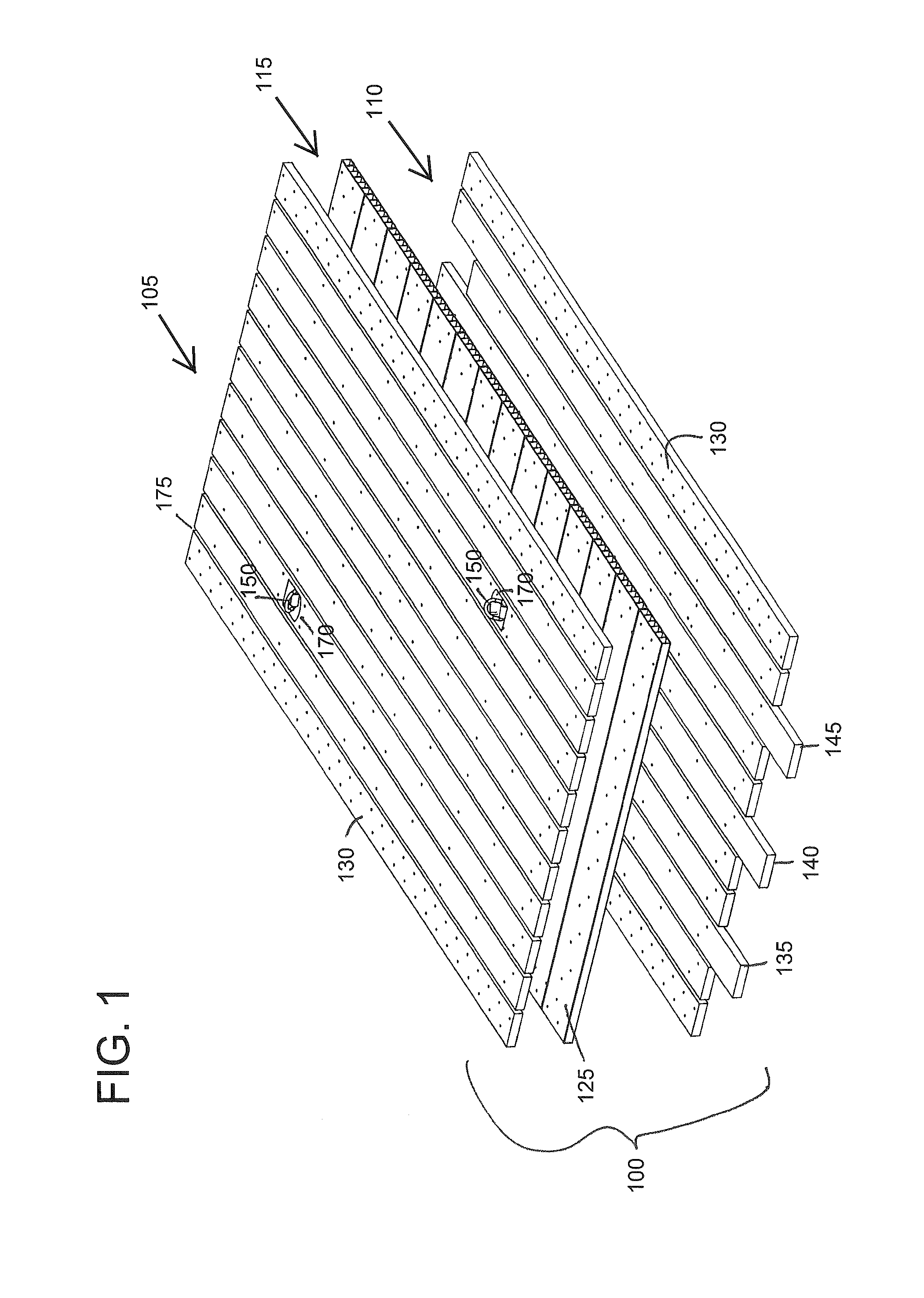

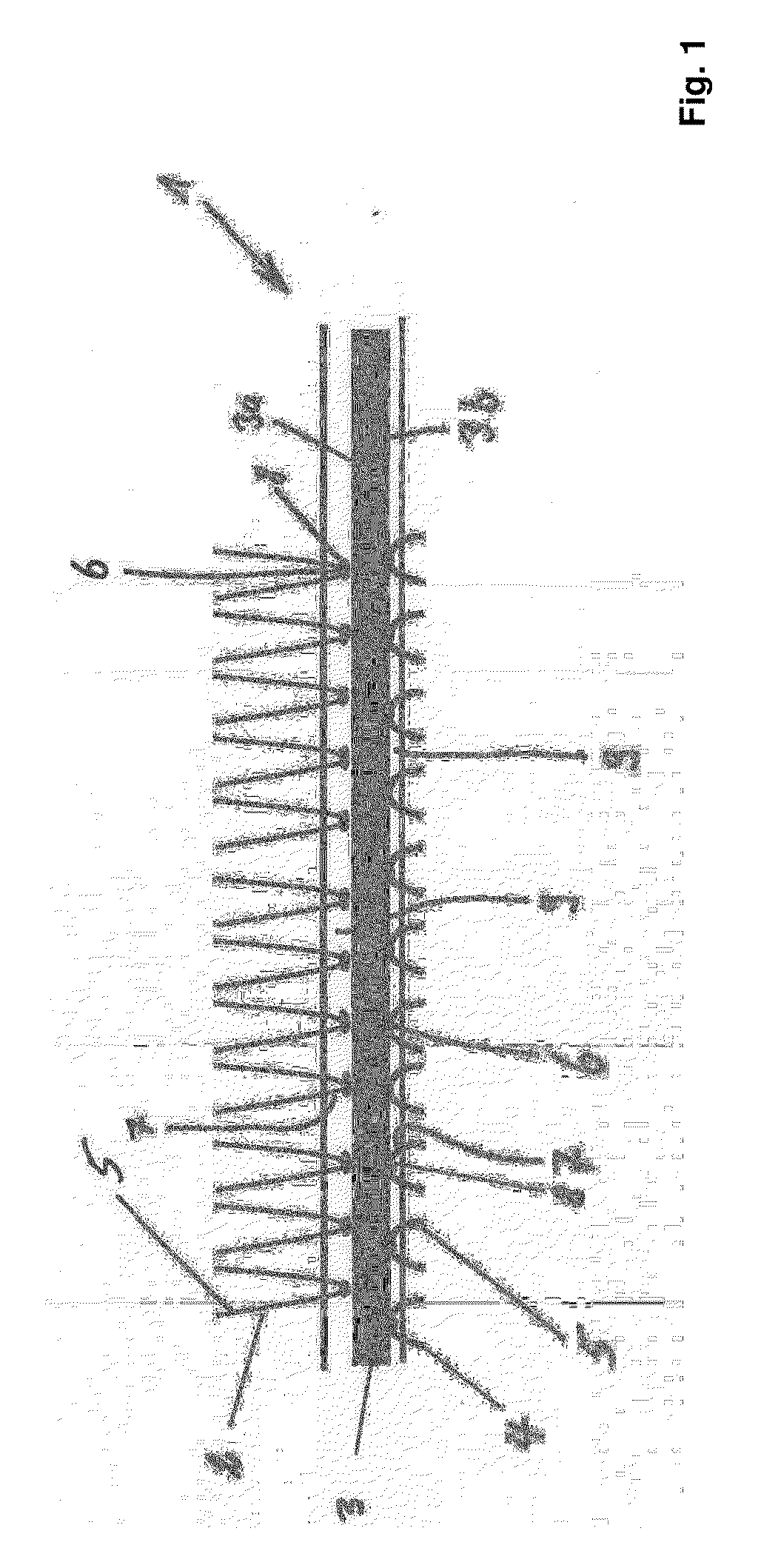

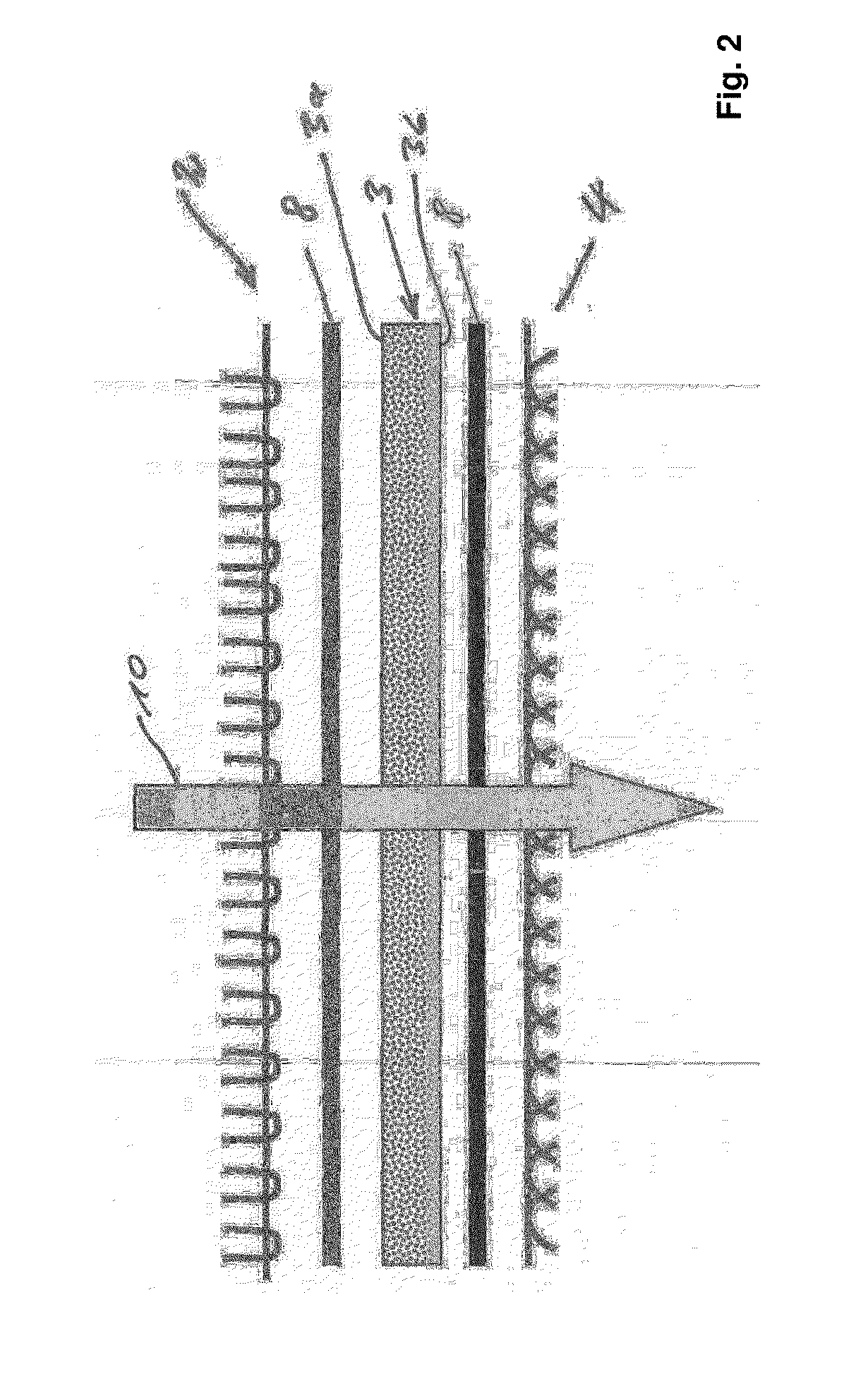

Mat construction with environmentally resistant core

ActiveUS9315949B1Permanent deformationImprove environmental resistanceSingle unit pavingsFloorsEngineeringUltimate tensile strength

A mat having a core that provides strength and rigidity to the mat, and including a structure of a sheet, elongated members, a frame, compartments, or combinations thereof and at least one outer layer associated with the core and made of a sheet, elongated members or combinations thereof. The core and outer layer(s) are integral or are joined together, and the structure of the core is made of one or more environmentally resistant materials to provide an extended service life when encountering rain, snow or other weather conditions that would eventually degrade wood. The mat has a load bearing capacity that is able to withstand a load of at least 500 to 800 psi or even 1000 psi without permanently deforming the core. Bumpers are preferably provided upon sides of the mat to protect them from damage due to transport or installation of the mat.

Owner:QUALITY MAT

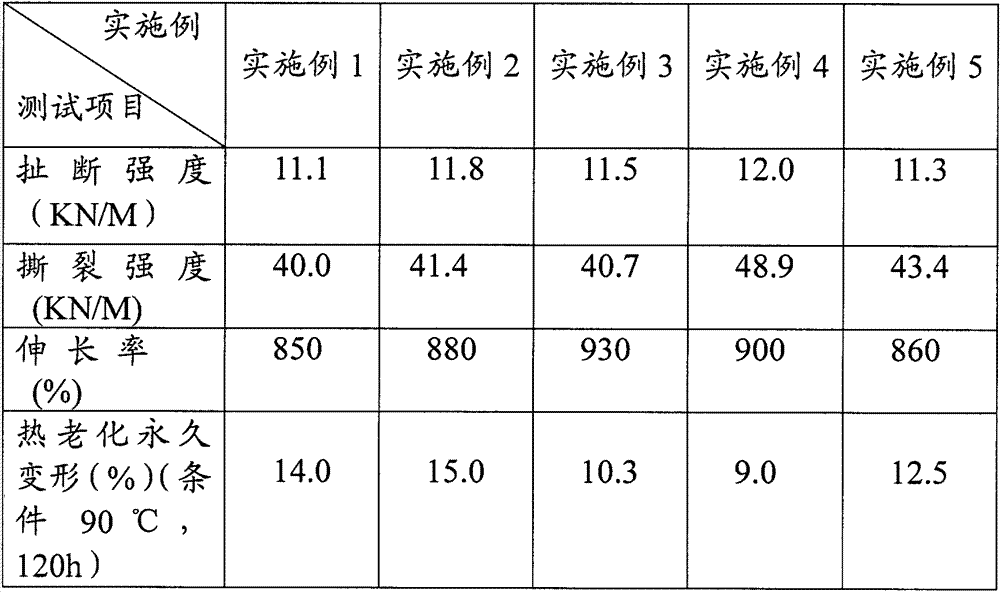

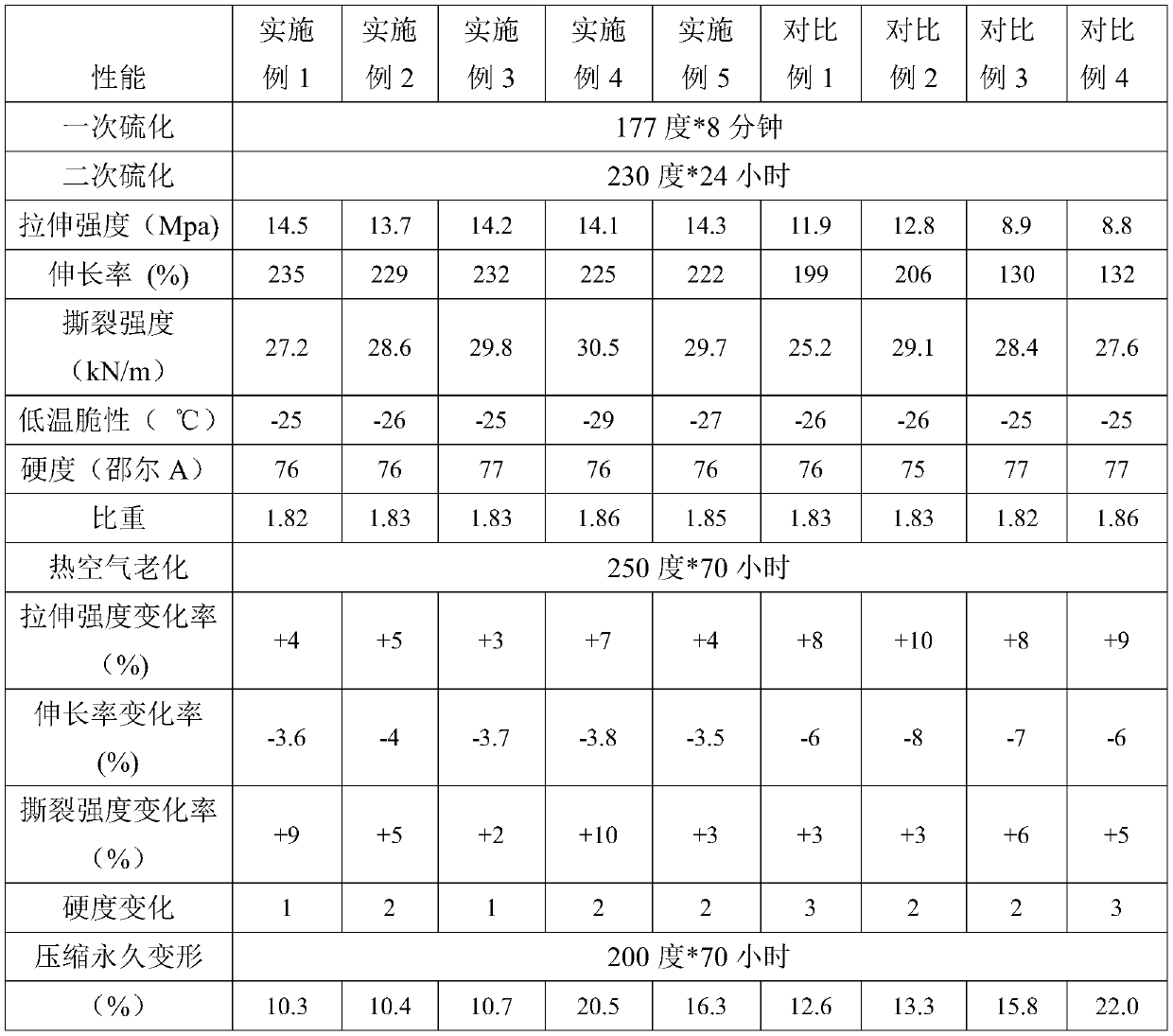

Preparation method of high-performance mould-press type mixed silicone rubber

The invention relates to the field of silicone rubber materials and particularly relates to a preparation method of high-performance mould-press type mixed silicone rubber. The preparation method comprises the following steps: matching raw materials, kneading the raw materials, curing the rubber material, introducing steam, and performing vacuumizing treatment. The tensile strength, the tear strength, the elongation and other parameters of a rubber product produced by the silicone rubber after treatment by vulcanization are obviously improved, the thermal aging permanent deformation parameter is also in a relatively small range, and the comprehensive mechanical properties are further improved.

Owner:ZHEJIANG JOTEC NEW MATERIAL TECH

High temperature resistant inner layer material for heat radiator water pipe and preparation method thereof

The present invention provides a high temperature resistant inner layer material for a heat radiator water pipe and a preparation method thereof. The high temperature resistant inner layer material can satisfy cooling liquid aging resistance under the long time action of a high temperature medium, high resistance and no zinc in the material, and can be balanced in the aspects of compression permanent deformation, extension, physical and mechanical properties, low temperature performance, resistance and the like. The high temperature resistant inner layer material includes the following variouspreparation materials: 0-80 parts by weight of ethylene-propylene copolymer, 0-150 parts by weight of ethylene-propylene diene copolymer, 50-150 parts by weight of carbon black, 20-50 parts by weightof a plasticizer, 0-20 parts by weight of precipitation method white carbon black, 0-15 parts by weight of magnesium oxide, 0-2 parts by weight of stearic acid, 1.5 to 8 parts by weight of an antioxidant, 2.5 to 10 parts by weight of crosslinking agent BIBP, 1 to 3.5 parts by weight of crosslinking agent TMPTMA and 1-8 parts by weight of other auxiliaries.

Owner:宁海建新胶管有限公司

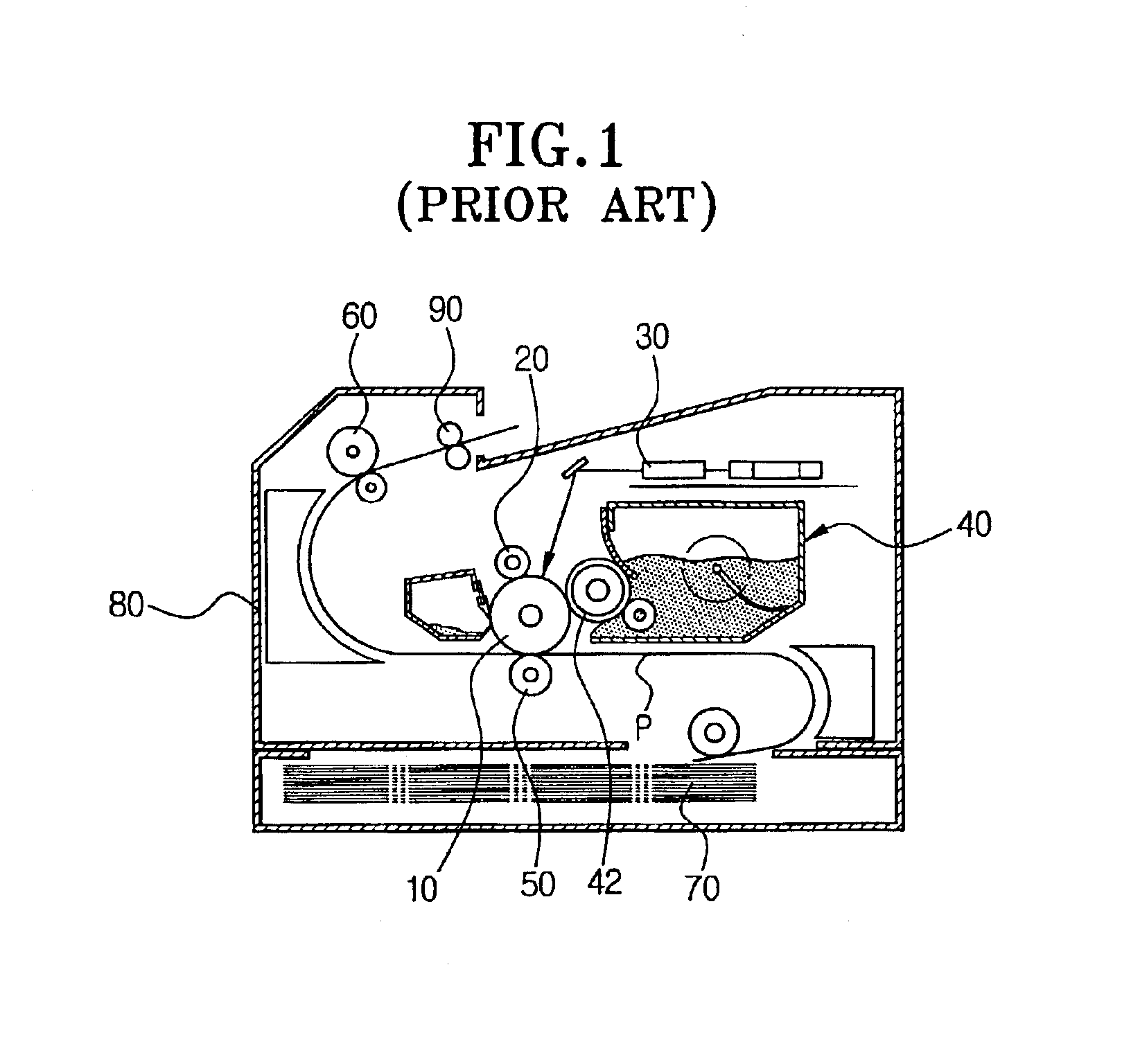

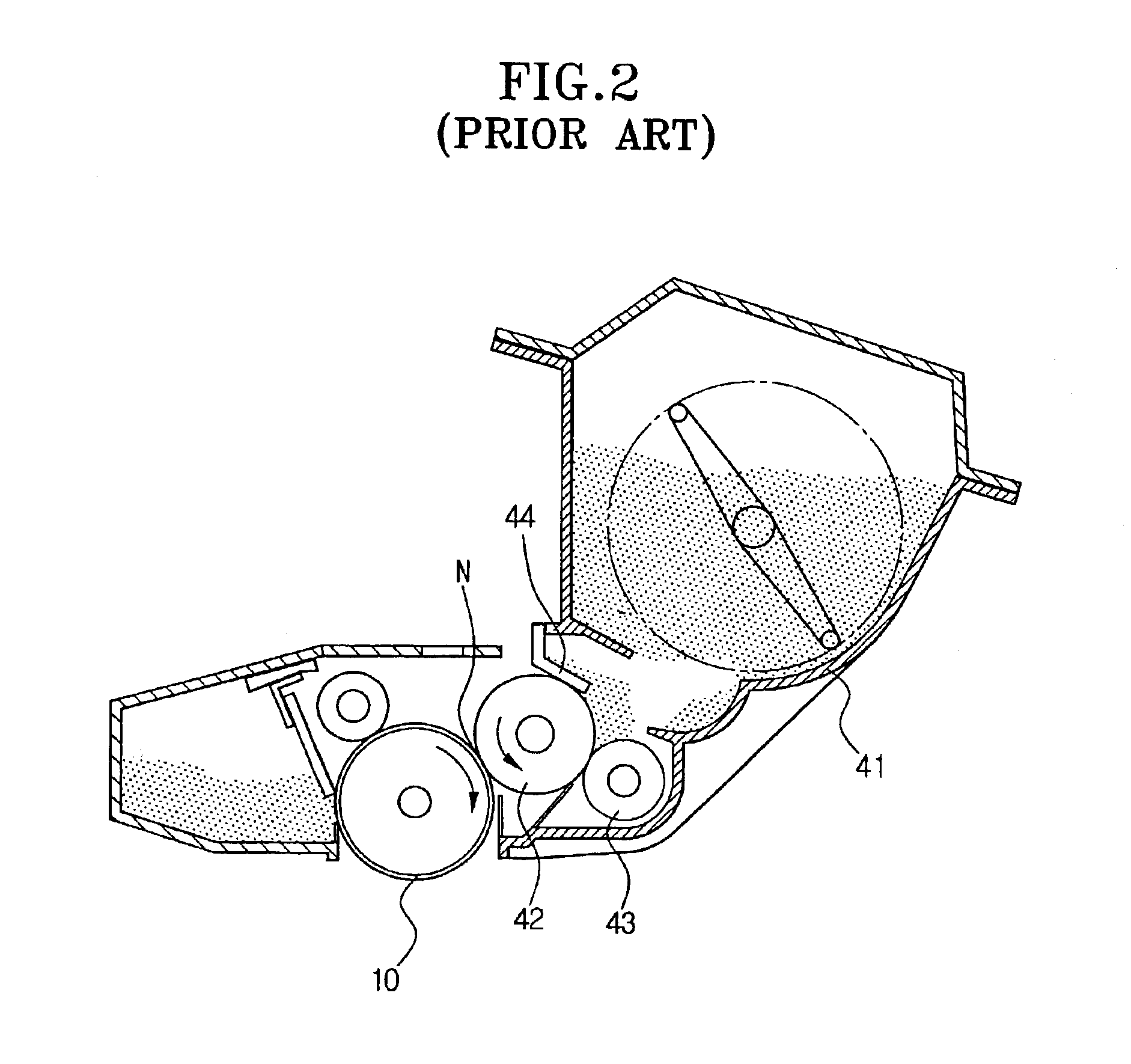

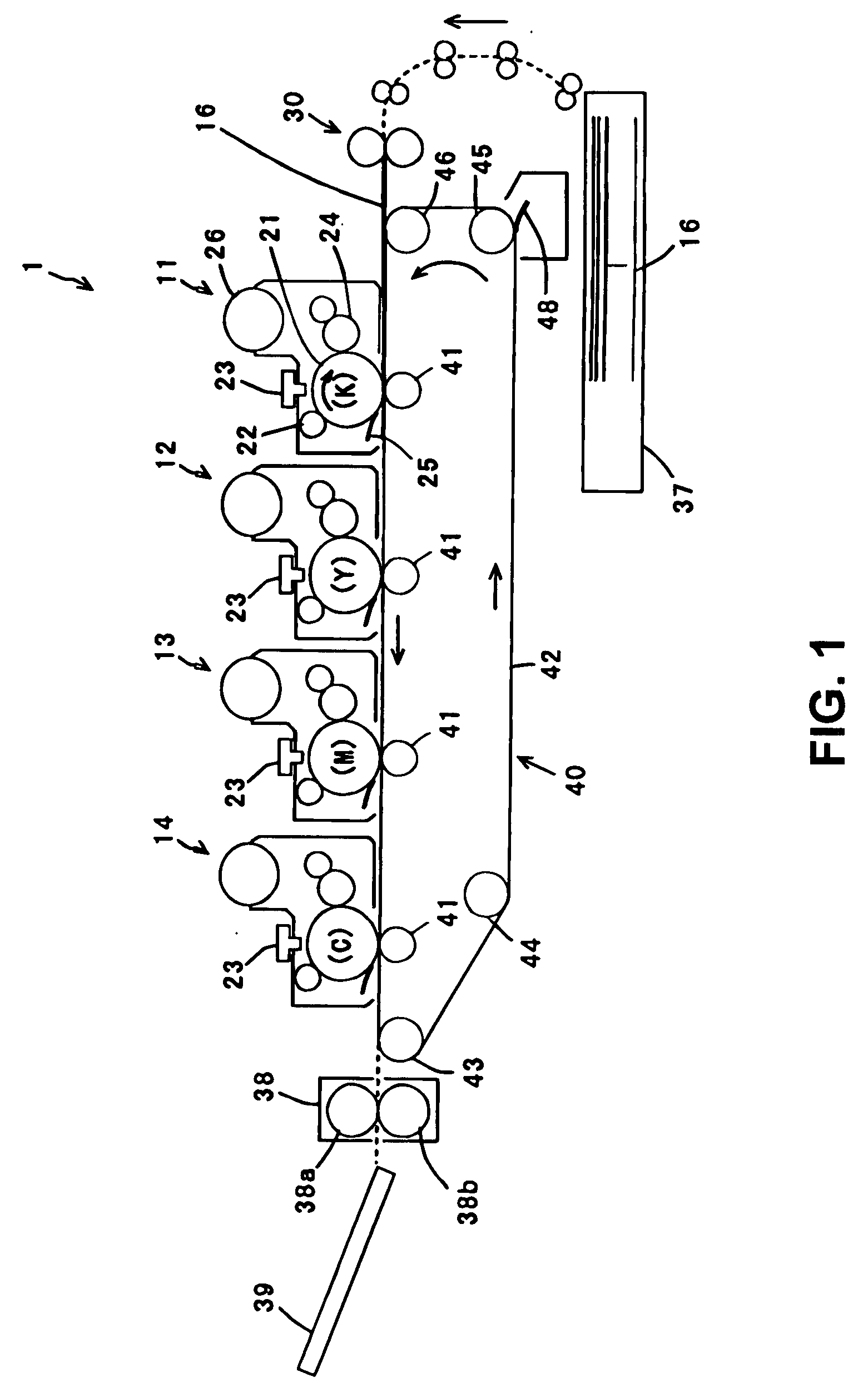

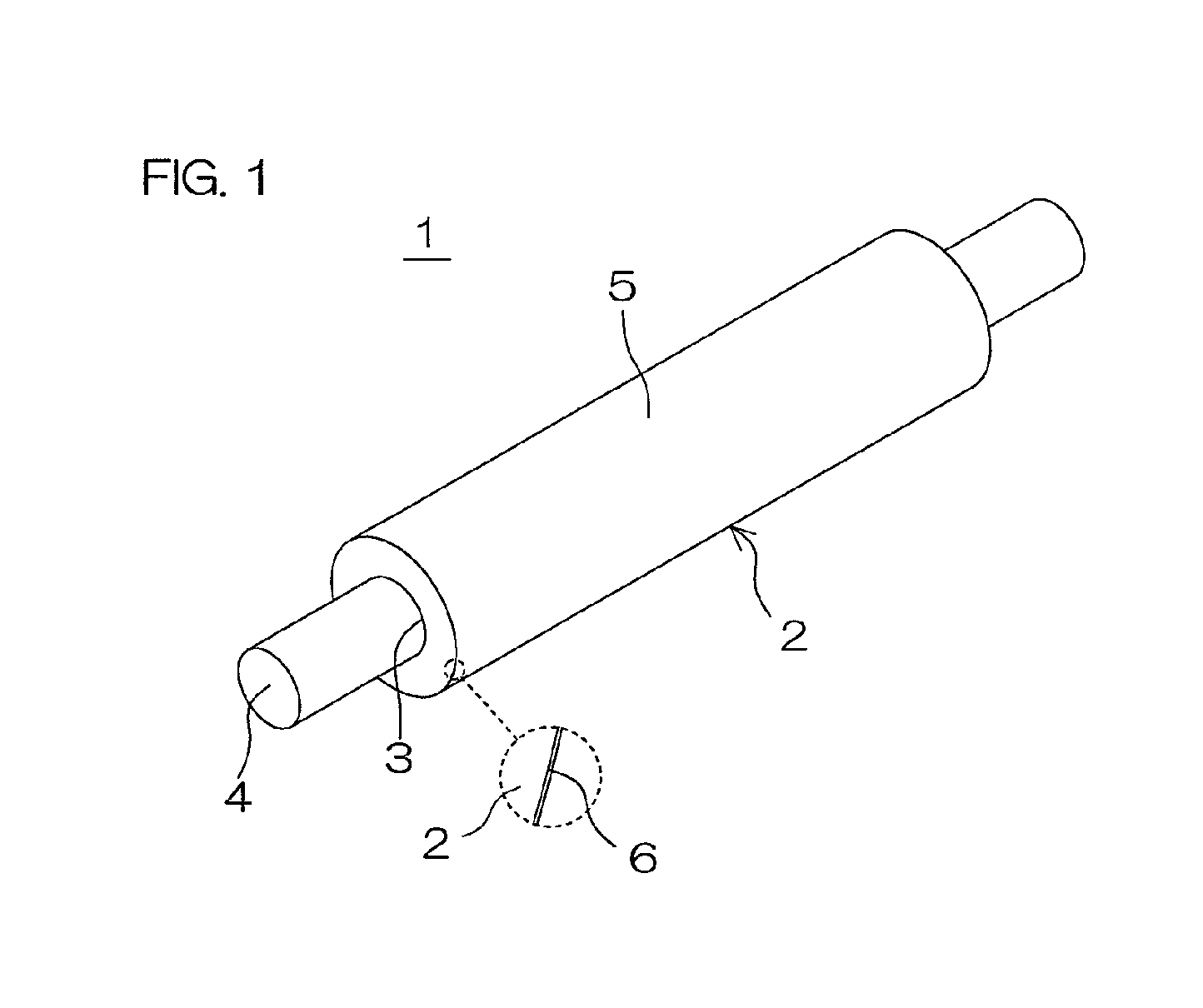

Roller spacing device

InactiveUS6882813B2High viscosityPermanent deformationElectrographic process apparatusCorona dischargeMechanical engineeringClose contact

A roller spacing device roller mechanisms having rollers in close contact under a given pressure to separate first and second rollers by a constant distance to keep the rollers from touching when roller mechanisms are not used for a long period of time. The roller spacing device comprises a spacing member shiftably mounted between first and second positions on a shaft having a partial D-cut portion and associated with one of the roller members to be separated. The spacing member has a spacing nose overlapped in the second position with an outer circumferential surface of a driving gear connected to the other roller member to separate the first roller member from the second roller member by the constant distance; and a shifting unit shifting the spacing member between first and second positions on the shaft. With this construction, the first and second roller members are separated by a constant distance to keep each roller from touching when the roller mechanism is not driven for a long period of time so as to solve several problems which may be generated when the roller members are in contact under a given pressure for a long period of time.

Owner:S PRINTING SOLUTION CO LTD

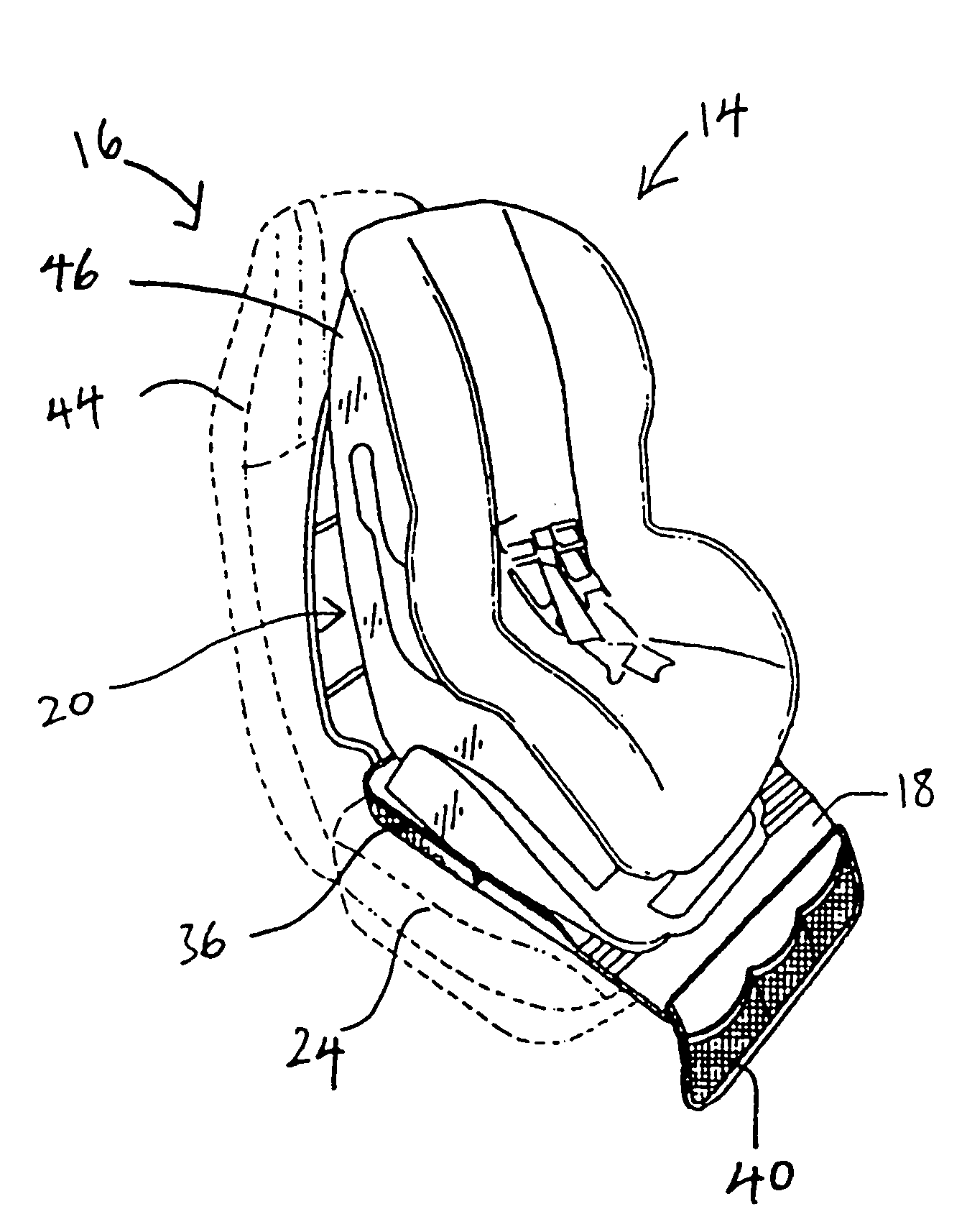

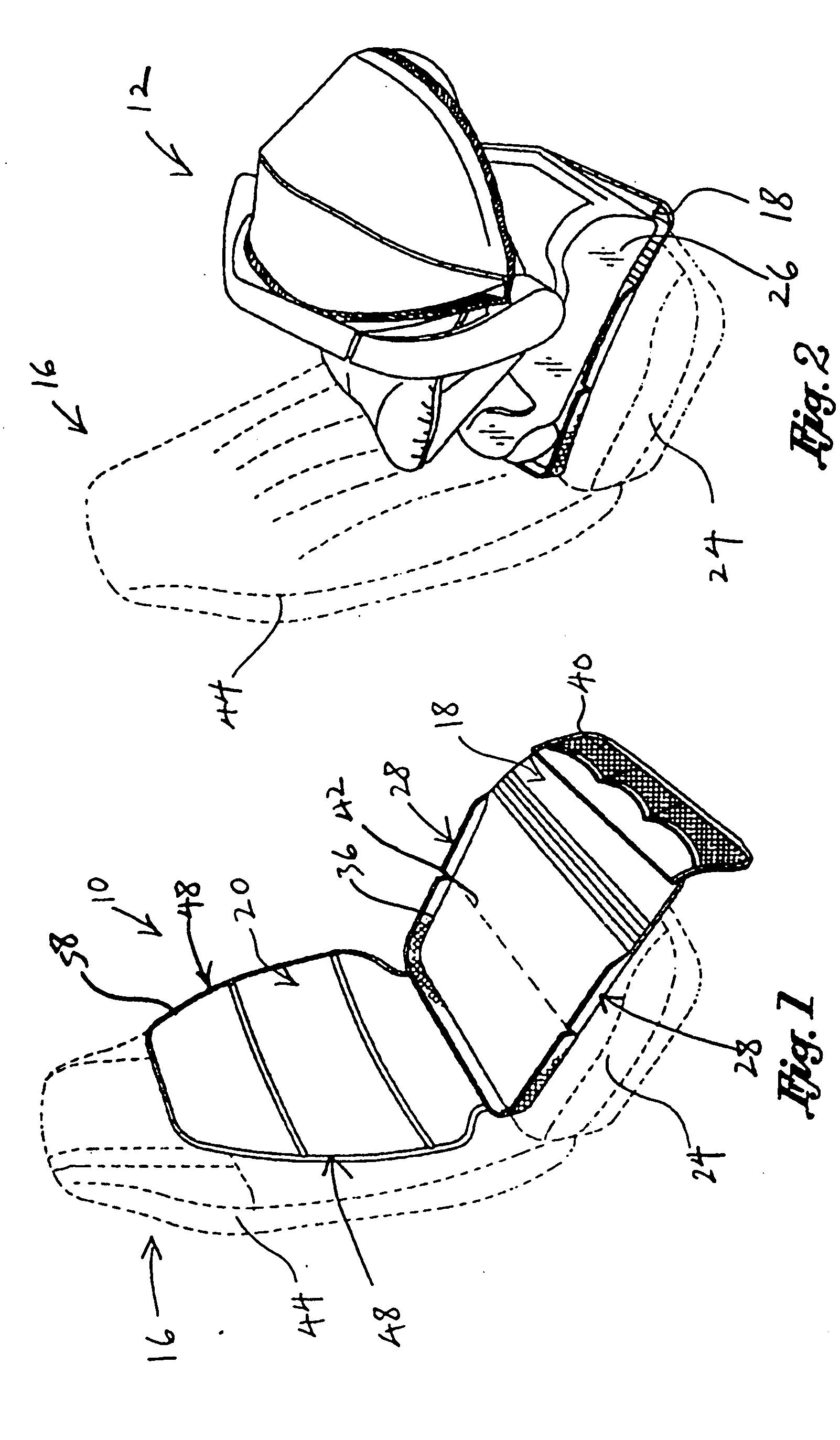

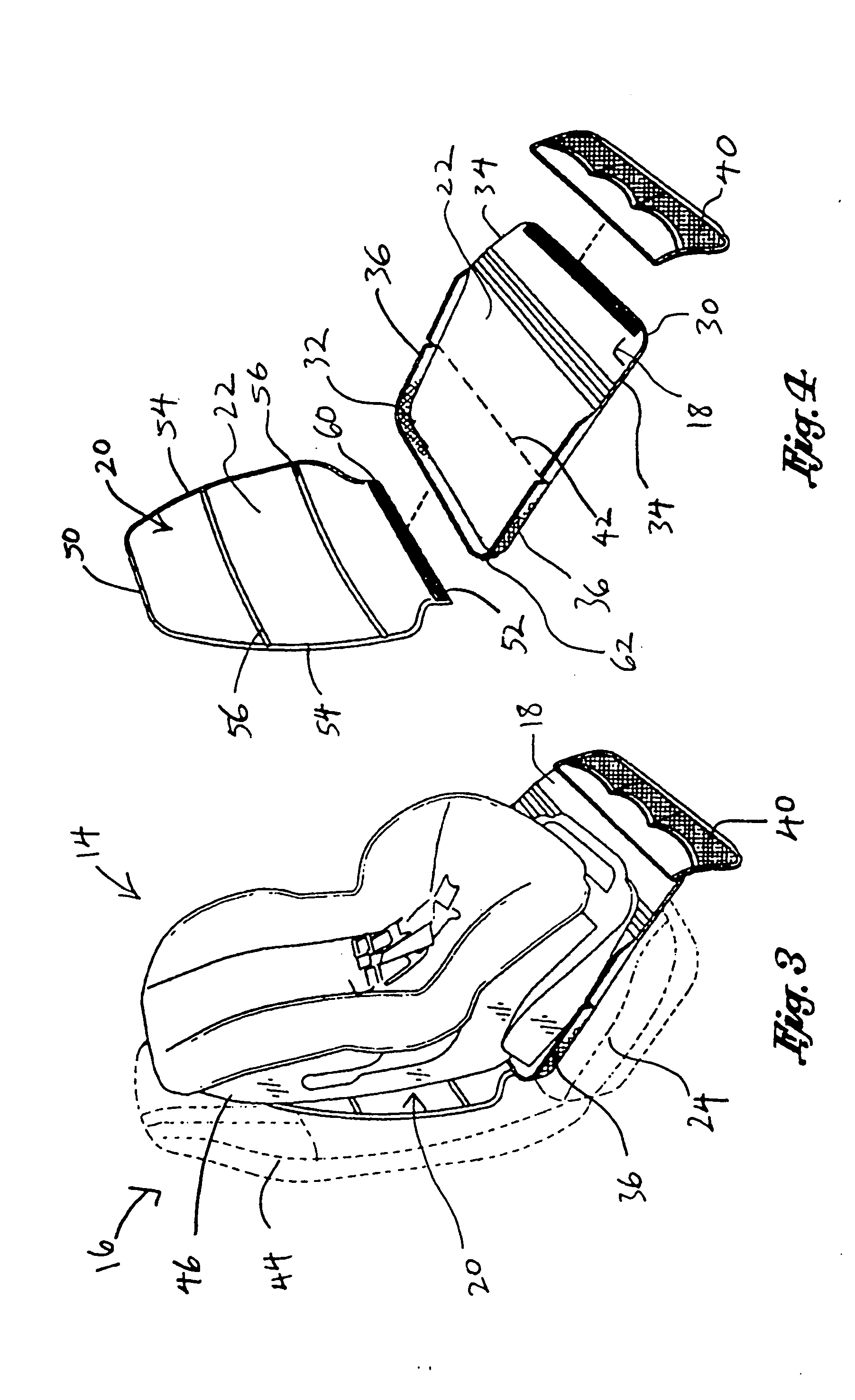

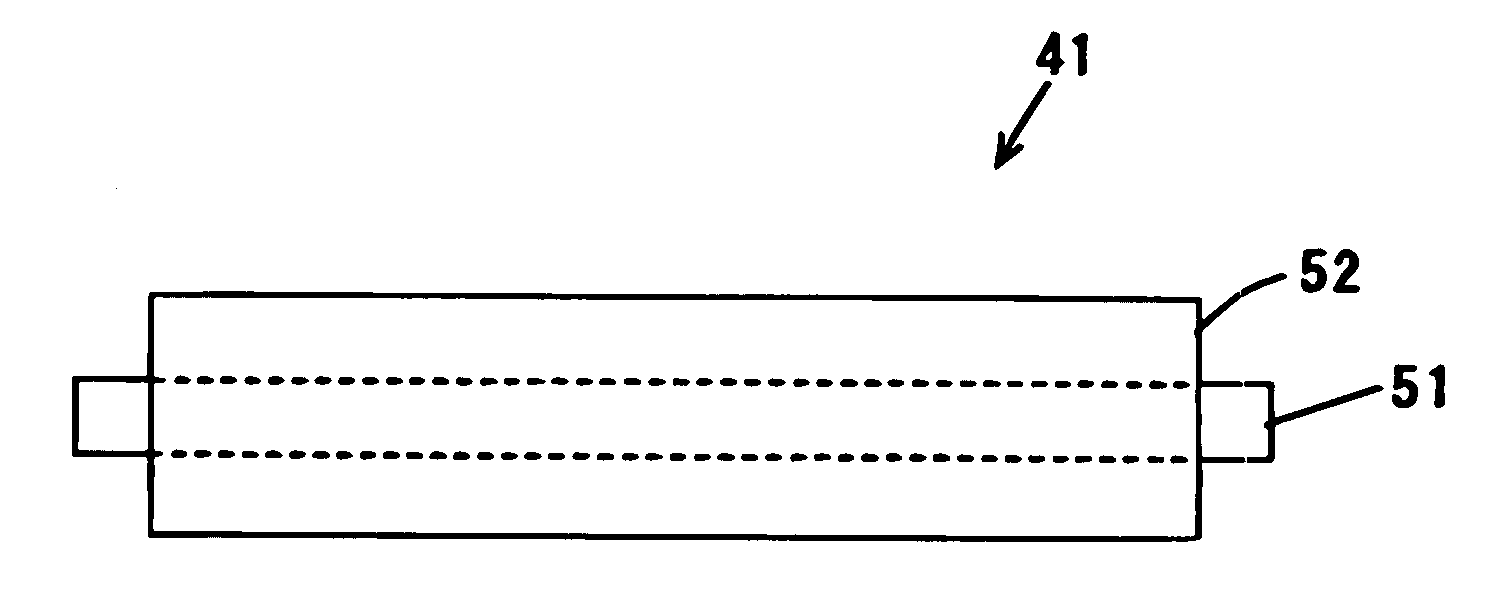

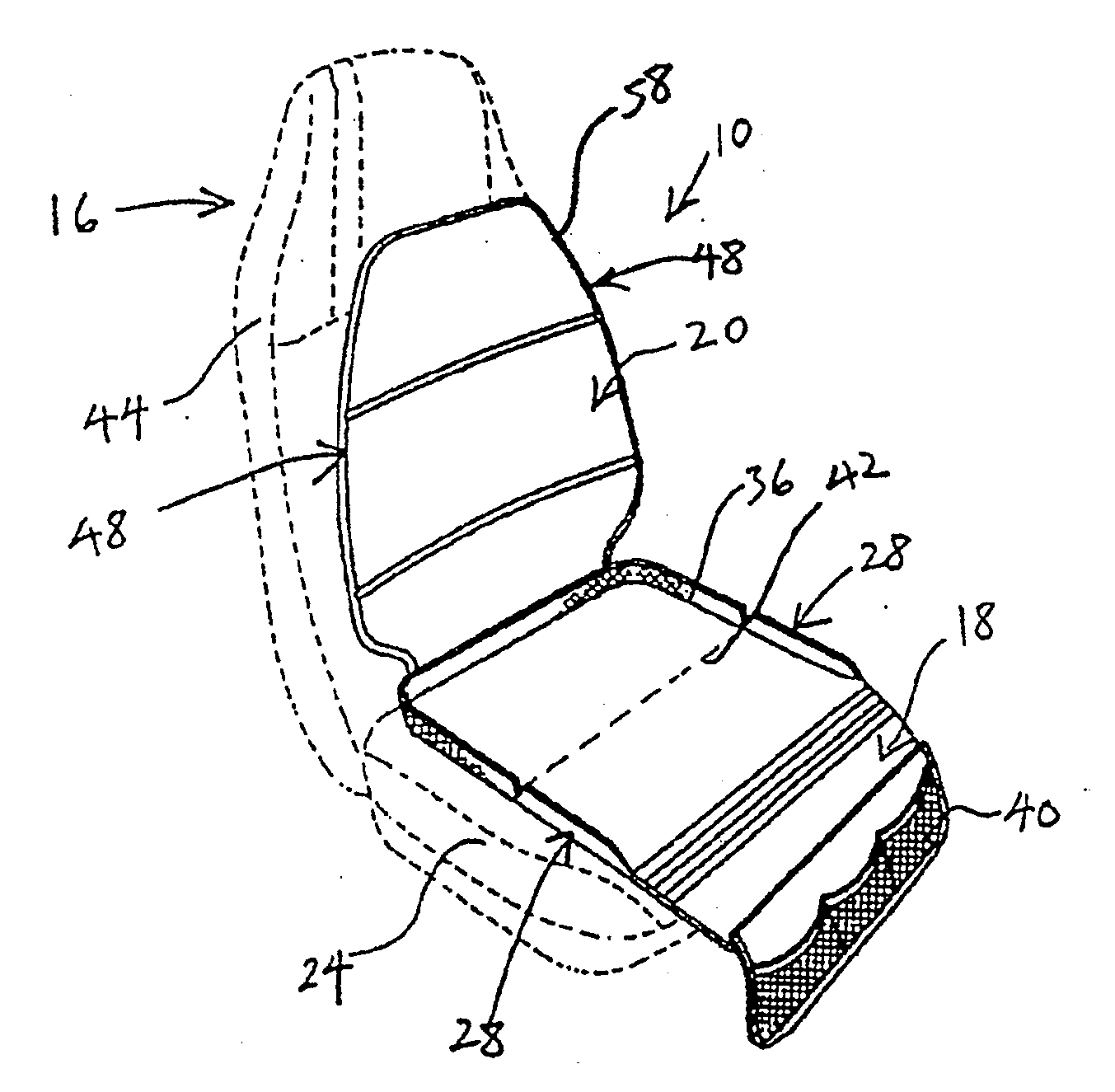

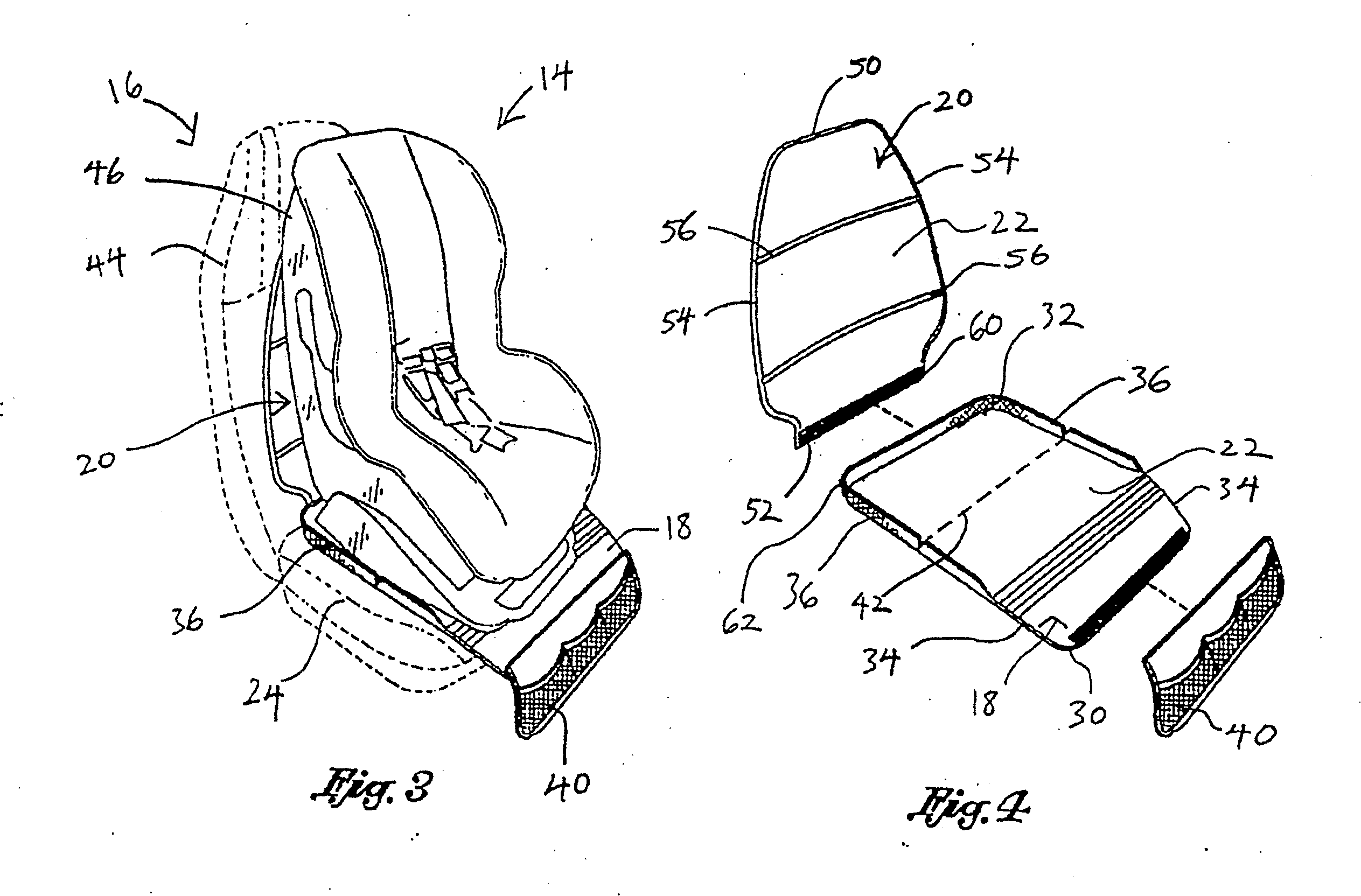

Two-stage protective car seat cover for child and infant safety chairs

InactiveUS20060082196A1Equally distributedEasily and conveniently be attachableSeat coveringsKids chairsCar seatBack rests

There is provided a seat cover for accommodating a child safety chair upon a seat. The seat cover comprises a lower protective member which is disposable upon a seating portion of the seat. This lower member can accommodate the child safety chair when positioned in a rearward-facing direction to prevent it from permanently compressing the seating portion. The seat cover further comprises an upper protective member that is disposable against a seat-back portion of the seat. This upper member is selectively attachable with and detachable from the lower member. By doing so, the upper member can further prevent the chair from permanently compressing the seat-back portion when it is repositioned in a forward-facing direction and placed in contact therewith.

Owner:PRINCE LIONHEART

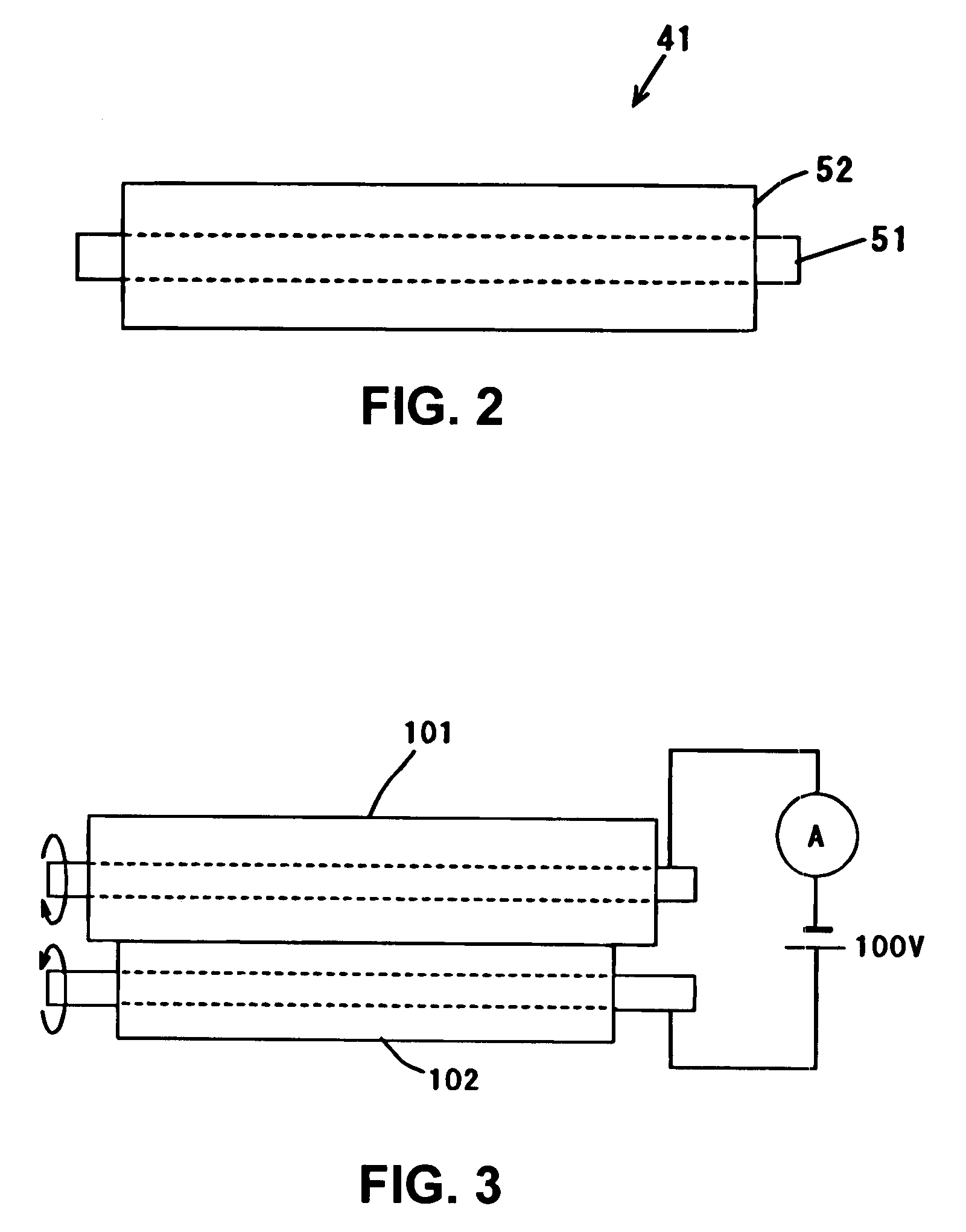

Conductive foamed roller, method of producing the same, and image forming apparatus

InactiveUS20080056766A1Reduce environmental loadReduce permanent compressive deformationElectrographic process apparatusCorona dischargeImage formationMetal

A conductive foamed roller includes a metal shaft portion and a conductive foamed rubber portion. The conductive foamed roller has a permanent compressive strain of equal to or less than 1.75%.

Owner:OKI DATA CORP

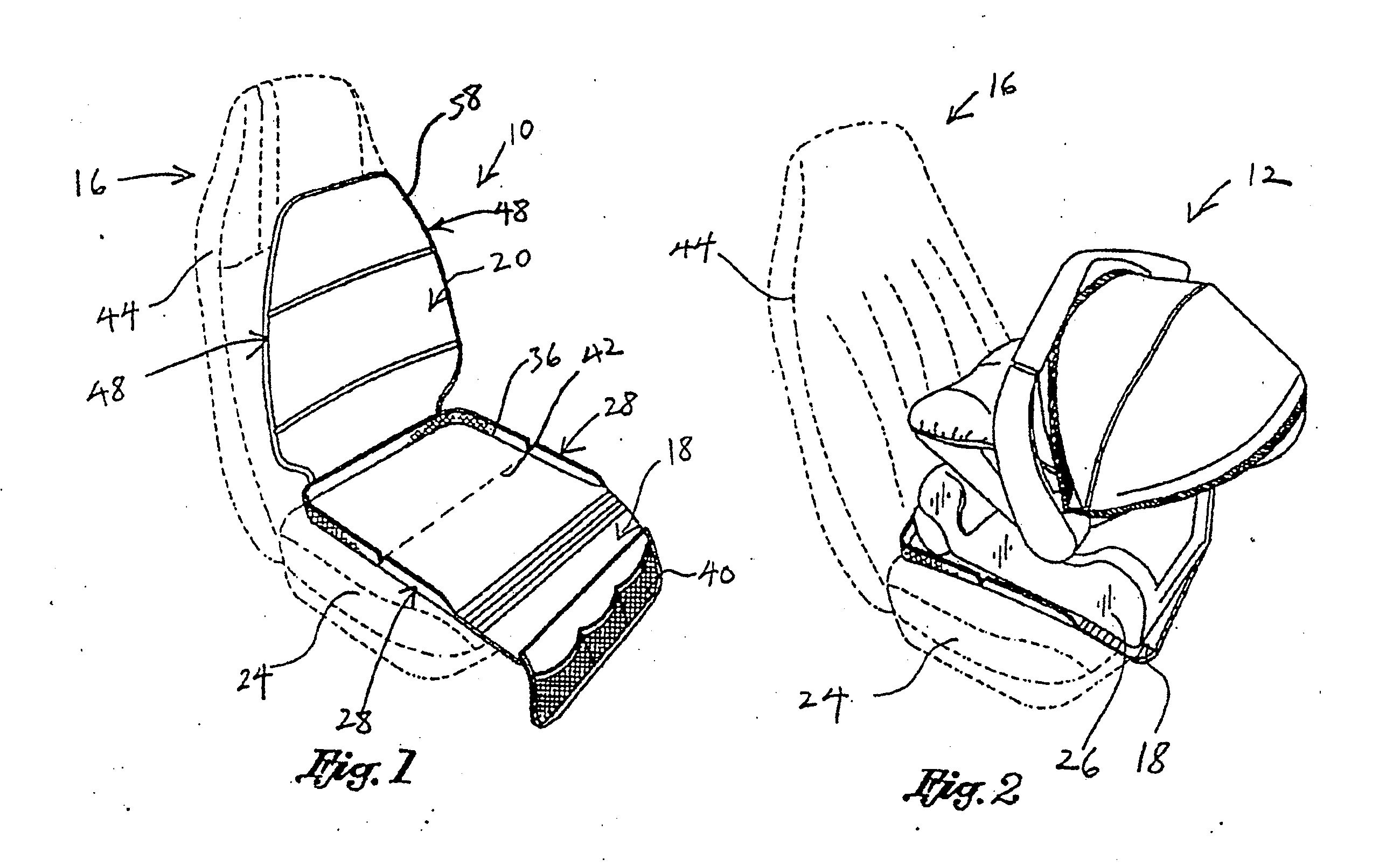

Two-stage protective car seat cover for child and infant safety chairs

InactiveUS20070210627A1Alleviates the above-referenced deficienciesEasily alternateSeat coveringsStuffed mattressesCar seatBack rests

Owner:PRINCE LIONHEART

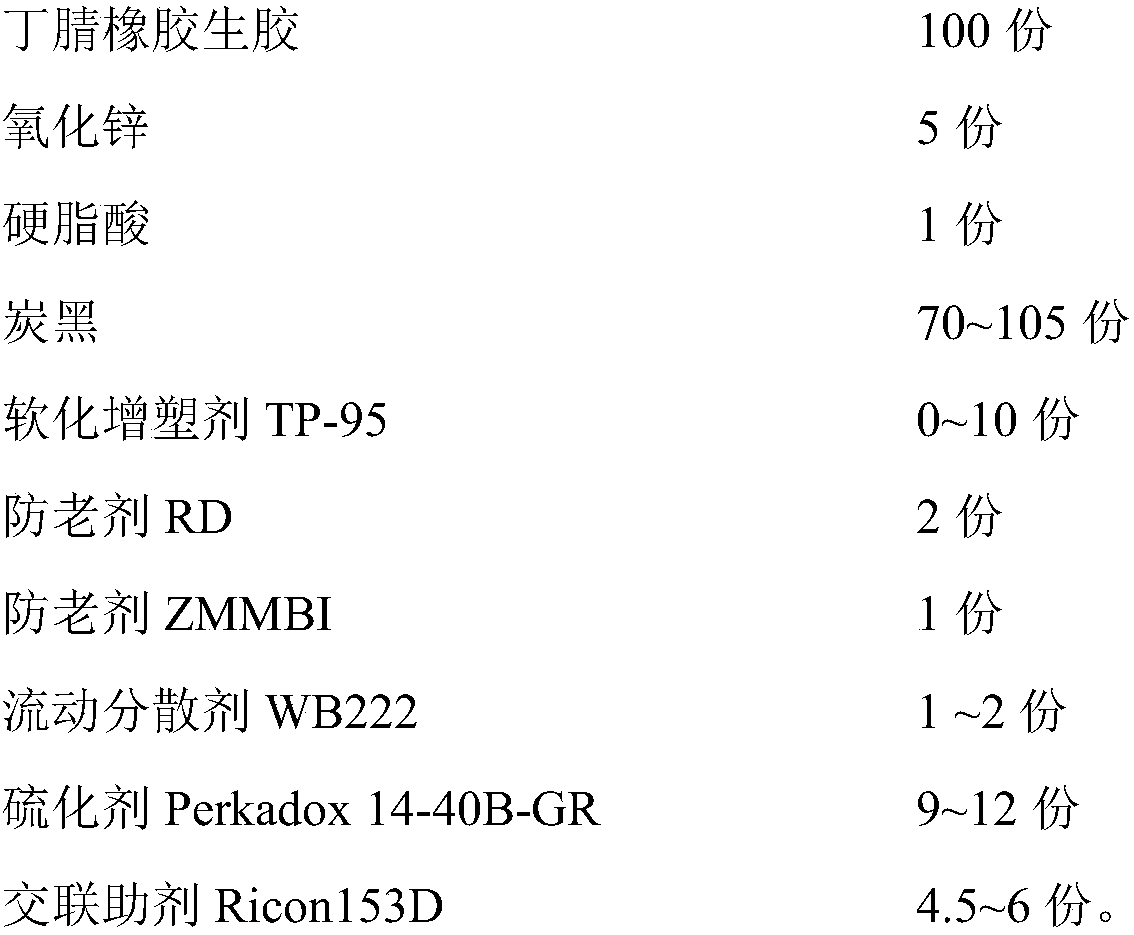

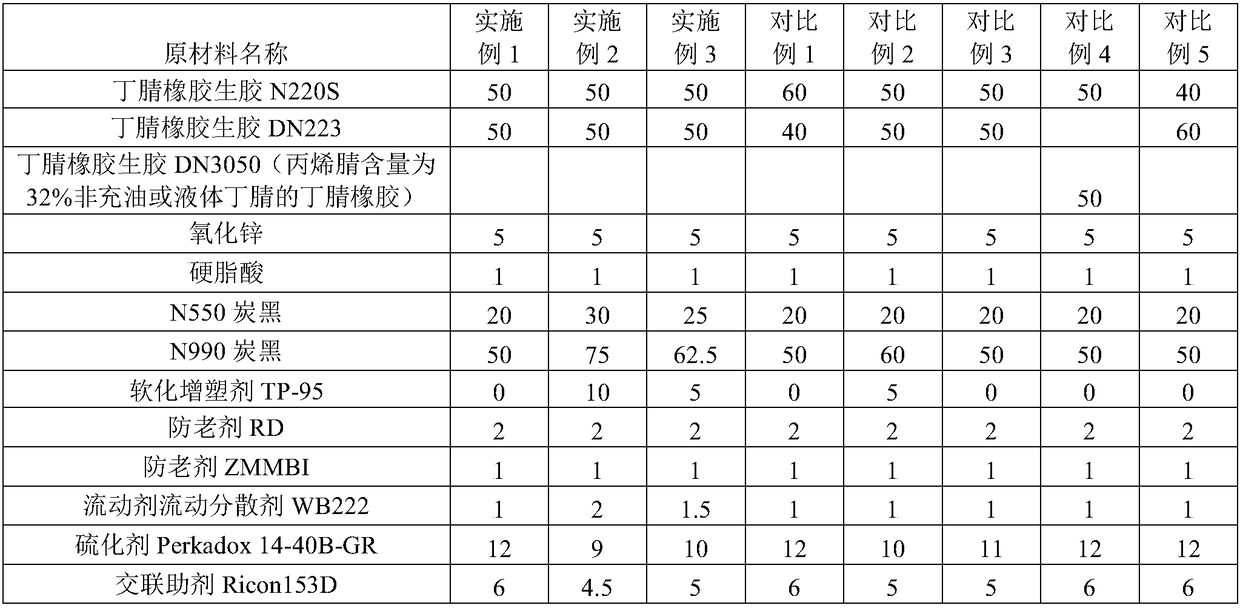

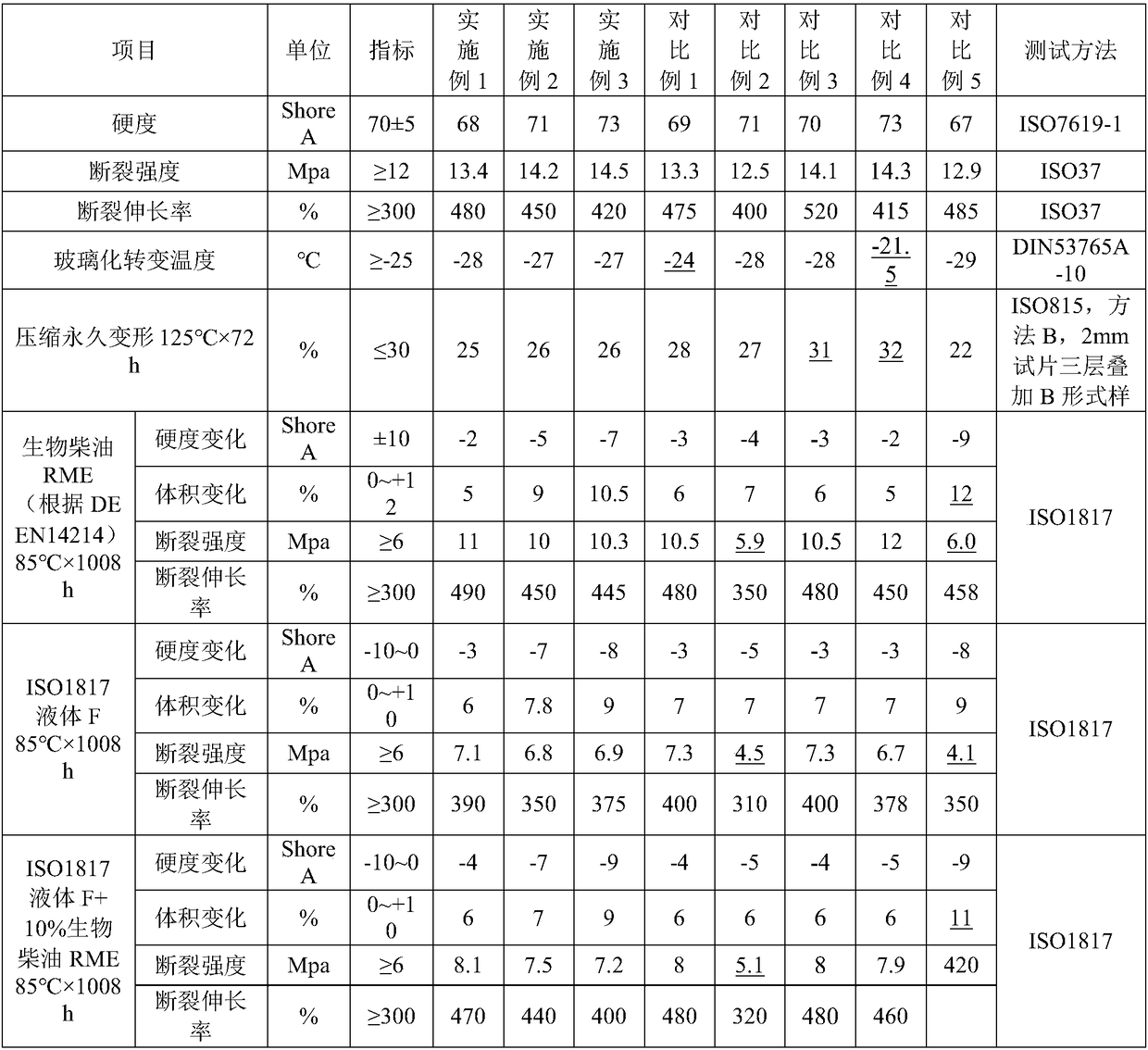

Diesel oil-resisting low pressure change nitrile rubber material and preparation method thereof

ActiveCN108424557AGood oil resistanceResistance to erosion and swellingRubber materialPolymer science

The invention discloses a diesel oil-resisting low pressure change nitrile rubber material and a preparation method thereof and belongs to the technical field of rubber. The rubber material is prepared from the following components: 100 parts of raw nitrile rubber, 5 parts of zinc oxide, 1 part of stearic acid, 70 to 105 parts of carbon black, 0 to 10 parts of a softened plasticizer TP-95, 2 partsof an antiager RD, 1 part of an antiager ZMMBI, 1 to 2 parts of a flow dispersant WB222, 9 to 12 parts of a vulcanizing agent Perkadox 14-40B-GR and 4.5 to 6 parts of a crosslinking agent Ricon153D.According to the preparation method disclosed by the invention, by reasonably matching the components of the raw nitrile rubber, nitrile rubber with high-content acrylonitrile is combined with the rawnitrile rubber filled with liquid nitrile and containing middle-content acrylonitrile; and the prepared nitrile rubber material has the characteristics of excellent diesel oil resistance, low compaction set and low temperature resistance.

Owner:南京金三力高分子科技有限公司

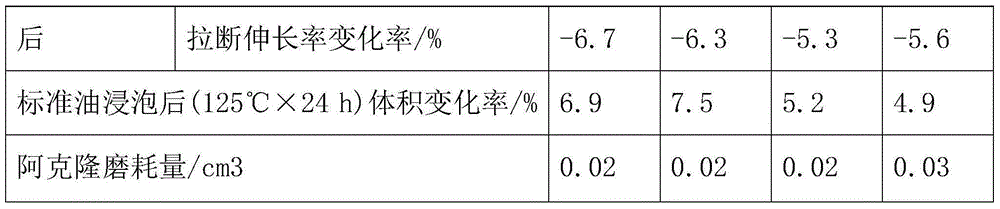

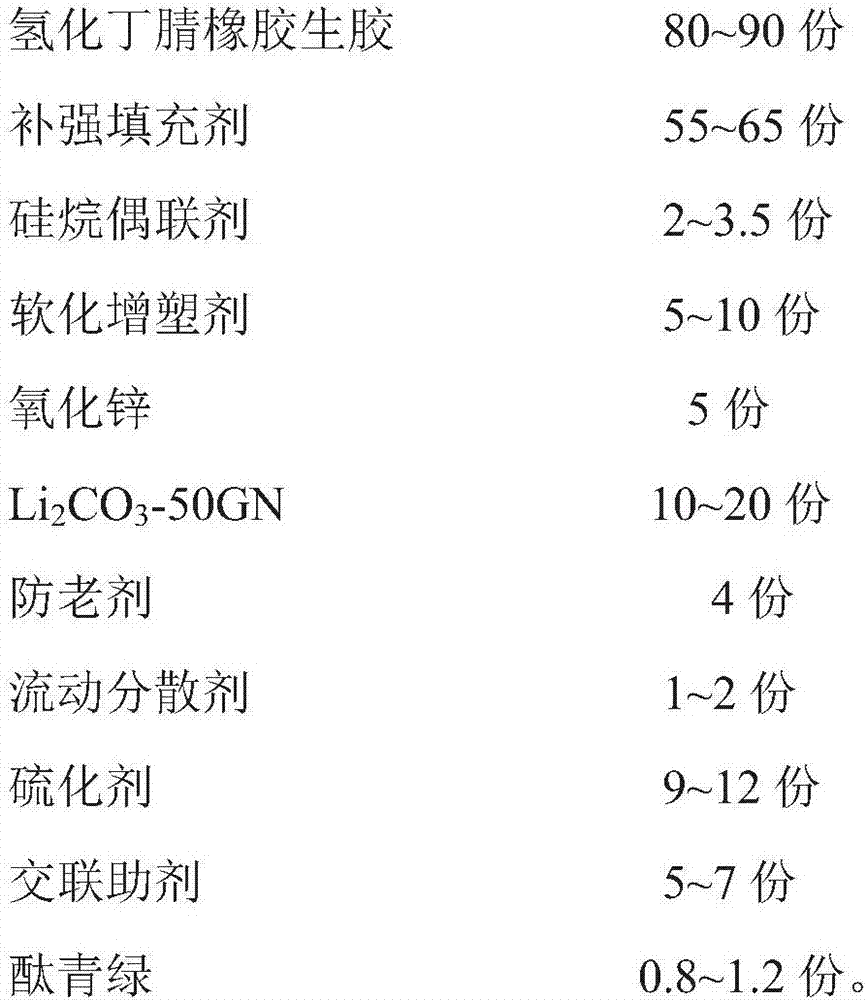

High temperature resistant color hydrogenated butadiene-acrylonitrile rubber material and preparing method thereof

The invention discloses a high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material and a preparing method thereof, and belongs to the technical field of rubber. The high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material is prepared from, by weight, 80-90 parts of hydrogenated butadiene-acrylonitrile rubber crude rubber, 55-65 parts of reinforcing filler, 2-3.5 parts of silane coupling agent, 5-10 parts of softening plasticizer, 5 parts of zinc oxide, 10-20 parts of Li2CO3-50 GN, 4 parts of anti-aging agent, 1-2 parts of flowing dispersing agent, 9-12 parts of vulcanizing agent, 5-7 parts of crosslinking agent and 0.8-1.2 parts of phthalocyanine green. The high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material has the advantages of being excellent in temperature resistant performance and oil resistant performance, resistant to low temperature, and low in compression deformation at the same time.

Owner:南京金三力高分子科技有限公司

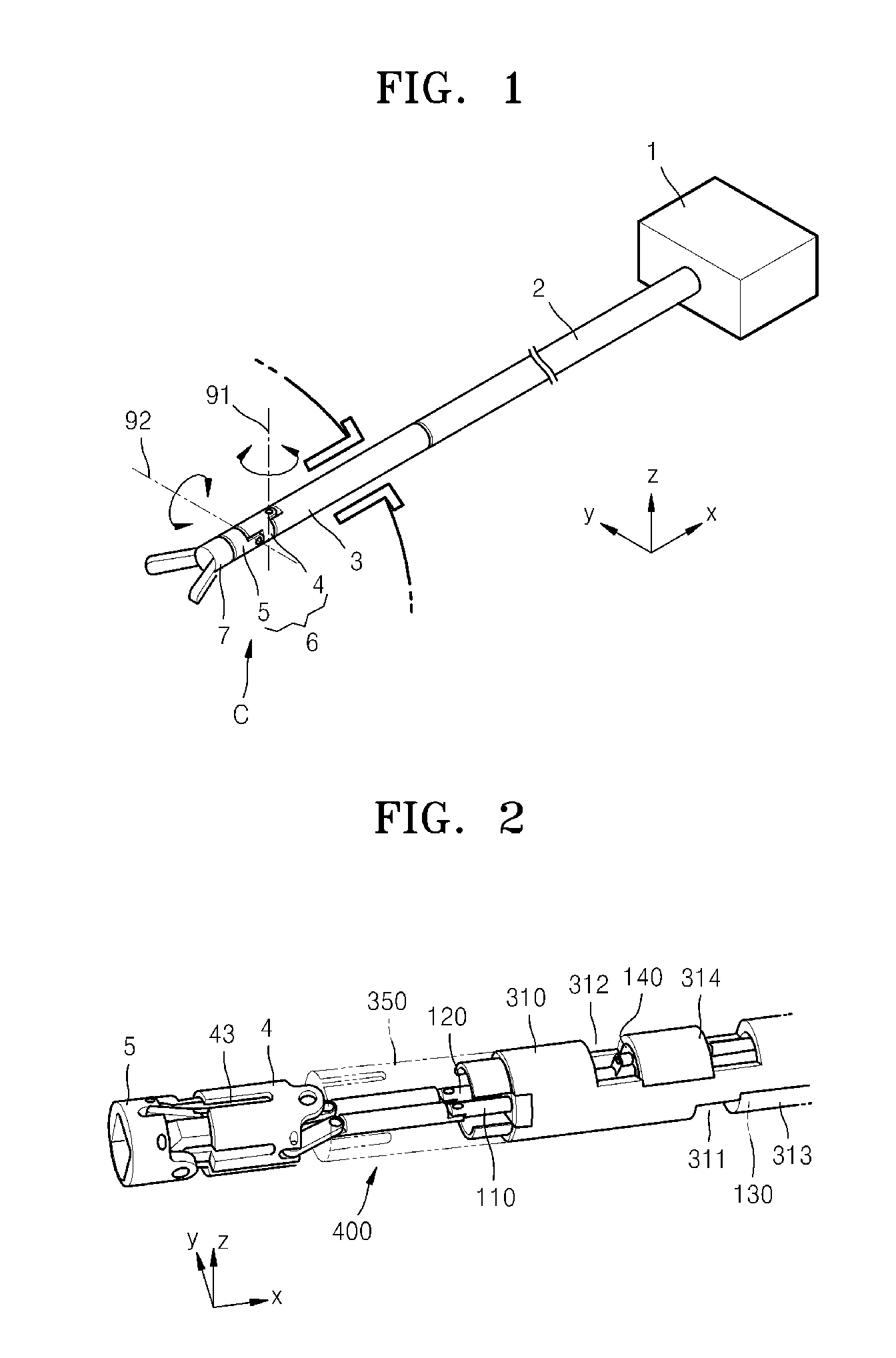

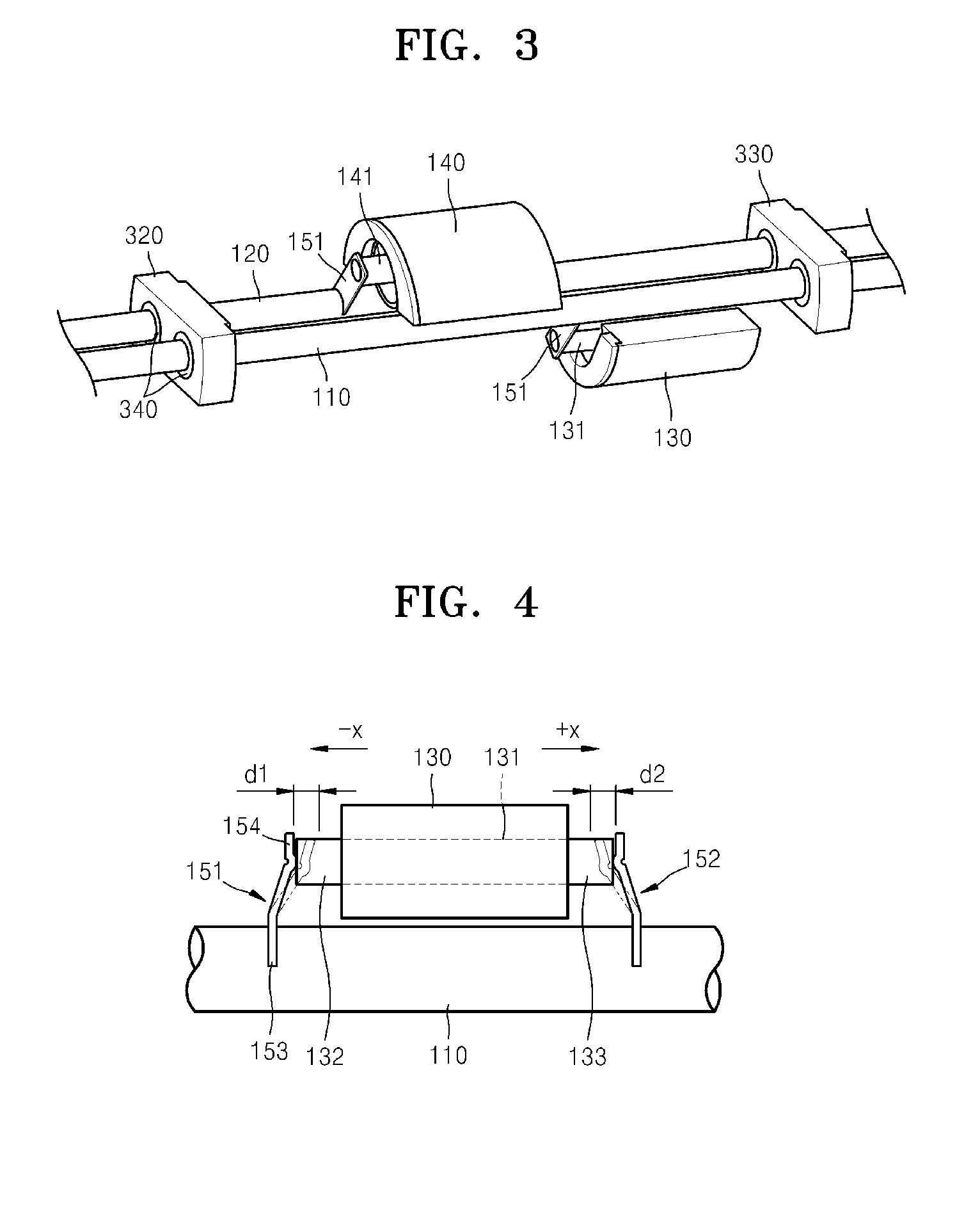

Surgical device

ActiveUS9579162B2Increase the number ofCrosstalk between the joint parts may further increaseProgramme-controlled manipulatorJointsEngineeringMechanical engineering

A surgical device including first and second joint parts that are connected in series is provided. The surgical device includes a plurality of link arms that pass through an inner portion of the first joint part so as to drive the second joint part. The link arms are serially connected so as to rotate with respect to each other, and are rotatably connected to a driving unit for driving the plurality of link arms.

Owner:SAMSUNG ELECTRONICS CO LTD

Shaft end O-shaped permanent compression set resisting rubber sealing ring

The invention discloses a shaft end O-shaped permanent compression set resisting rubber sealing ring. Raw materials of the shaft end O-shaped permanent compression set resisting rubber sealing ring comprise, by weight, 30-60 parts of tetrapropyl fluoro rubber, 10-20 parts of nitrile butadiene rubber, 10-20 parts of polyether polyurethane rubber, 15-25 parts of styrene butadiene rubber, 1.2-2.5 parts of dicumyl peroxide, 2.5-4 parts of trimethylolpropane triacrylate, 0.8-1.7 parts of N,N'-p-phenylbimaleimide, 50-75 parts of modified nanometer montmorillonite, 20-45 parts of white carbon black, 20-40 parts of polytetrafluoroethylene, 5-12 parts of nanometer silica, 5-12 parts of nanometer kaolin, 5-12 parts of graphite powder, 5-12 parts of glass fibers, 0.8-1.6 parts of di(dioctylpyrophosphato)ethylene titanate, 0.9-1.8 parts of triphenyl phosphate, 0.9-1.8 parts of dibutyl phthalate, 0.9-1.8 parts of microcrystalline paraffin and 0.5-1.5 parts of an antioxidant.

Owner:崇夕山

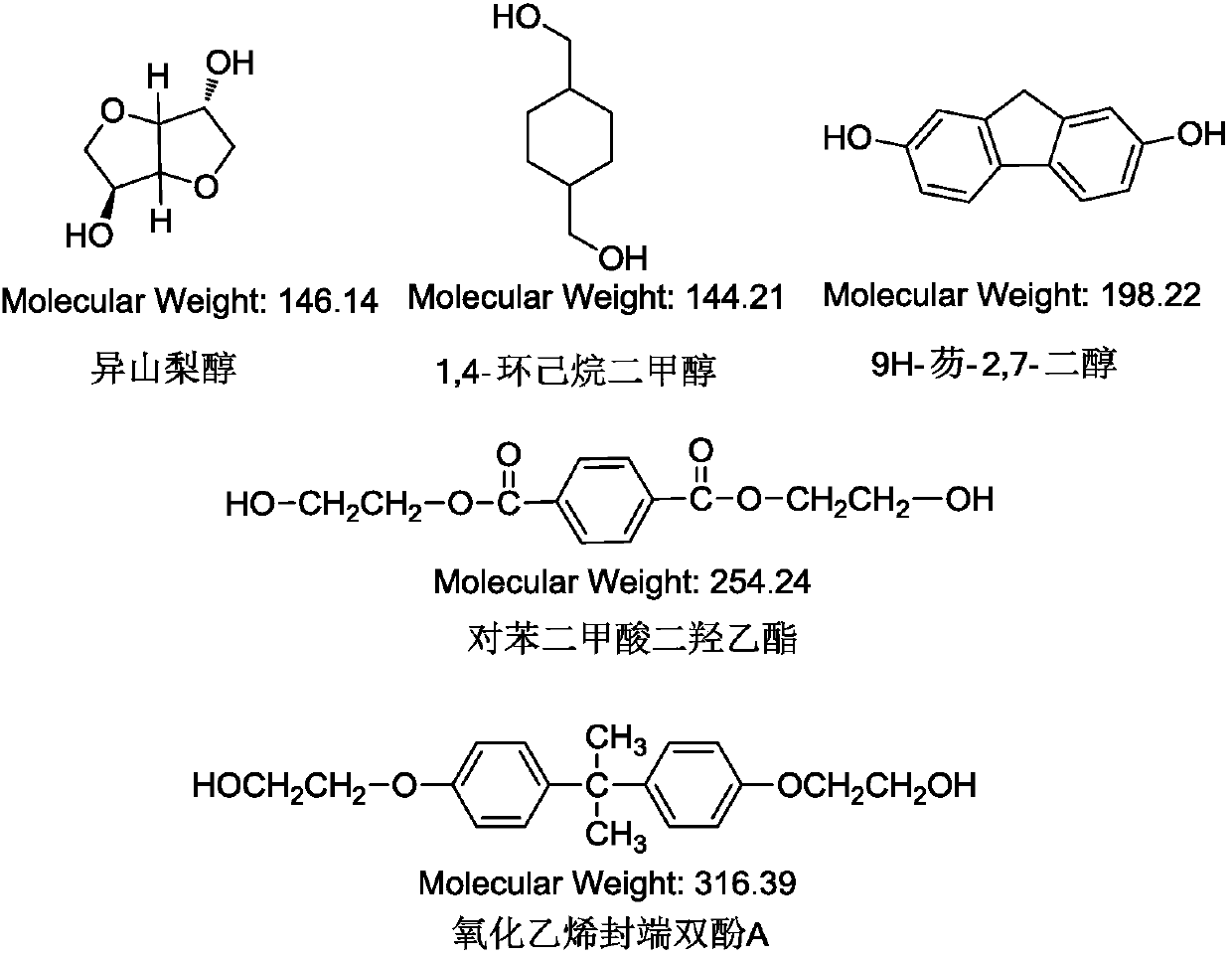

Thermoplastic polyurethane elastomer composition, and preparation method and application thereof

The invention relates to a thermoplastic polyurethane elastomer (TPU) composition and a preparation method thereof. The TPU composition has very excellent compression strength, compression permanent deformation, wear resistance and fatigue resistance. The TPU composition mainly comprises the following raw materials: (1) 33-72 parts by mass of polyhydric alcohol, (2) 3-20 parts by mass of a chain extender, and (3) 18-56 parts of diisocyanate. The TPU composition can be prepared by a one-step method. The TPU provided by the invention is suitable for high-pressure hydraulic sealing elements, high-performance elevator rollers, escalator rollers, lifting door rollers and the like.

Owner:WANHUA CHEM GRP CO LTD

Electrically conductive rubber composition, developing roller, and image forming apparatus

ActiveUS20140103262A1Excellent in toner load reduce effectReduce effectConductive materialNon-conductive material with dispersed conductive materialElectrically conductiveEpichlorohydrin

The electrically conductive rubber composition contains a rubber component including an SBR, an epichlorohydrin rubber and a CR, and the proportion of the SBR is 40 to 80 parts by mass based on 100 parts by mass of the rubber component. The rubber composition further contains 1.0 to 1.5 parts by mass of a sulfur crosslinking agent, 0.2 to 0.6 parts by mass of a thiourea accelerating agent, 0.1 to 0.5 parts by mass of a thiuram accelerating agent, and 1.0 to 2.0 parts by mass of a thiazole accelerating agent based on 100 parts by mass of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

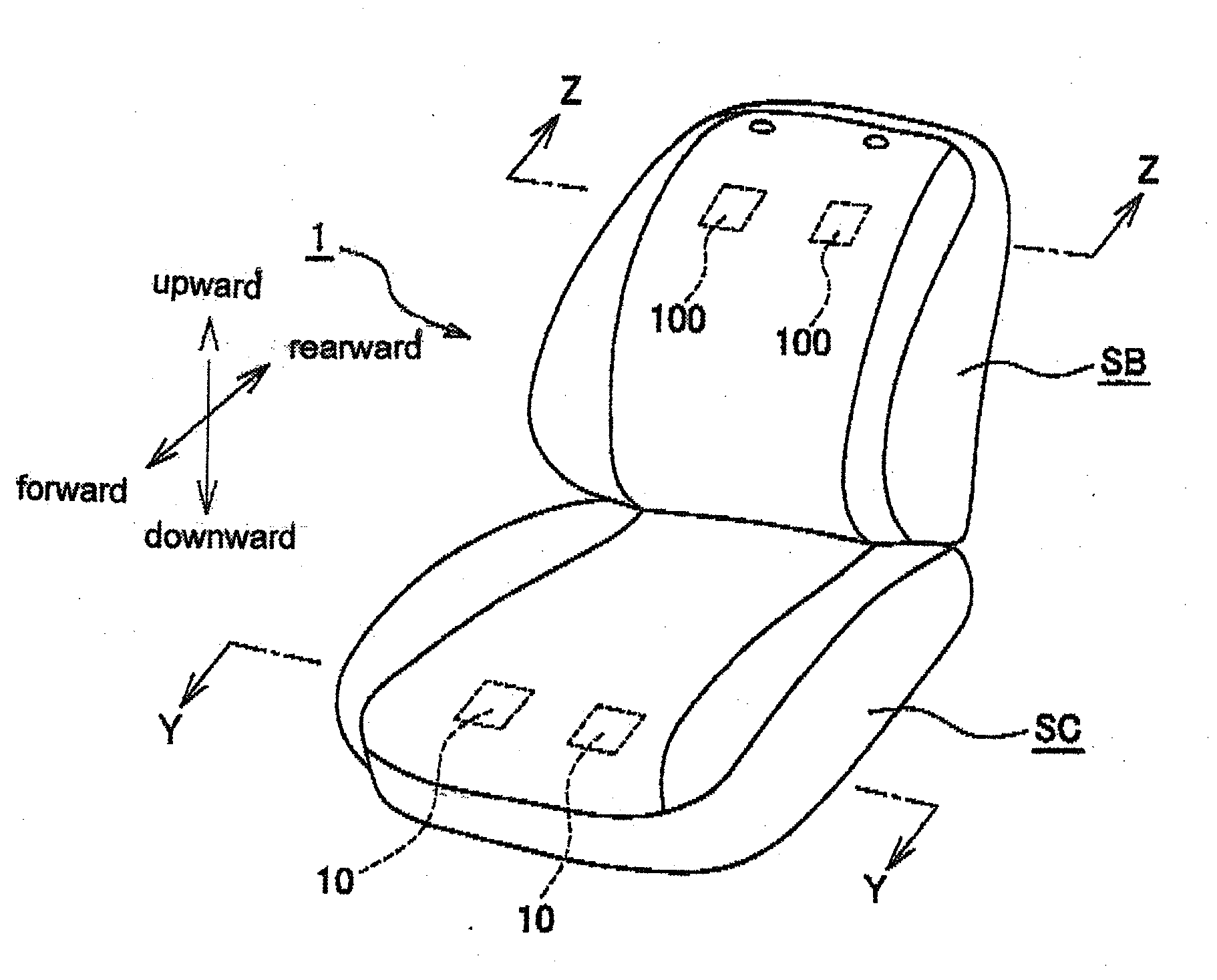

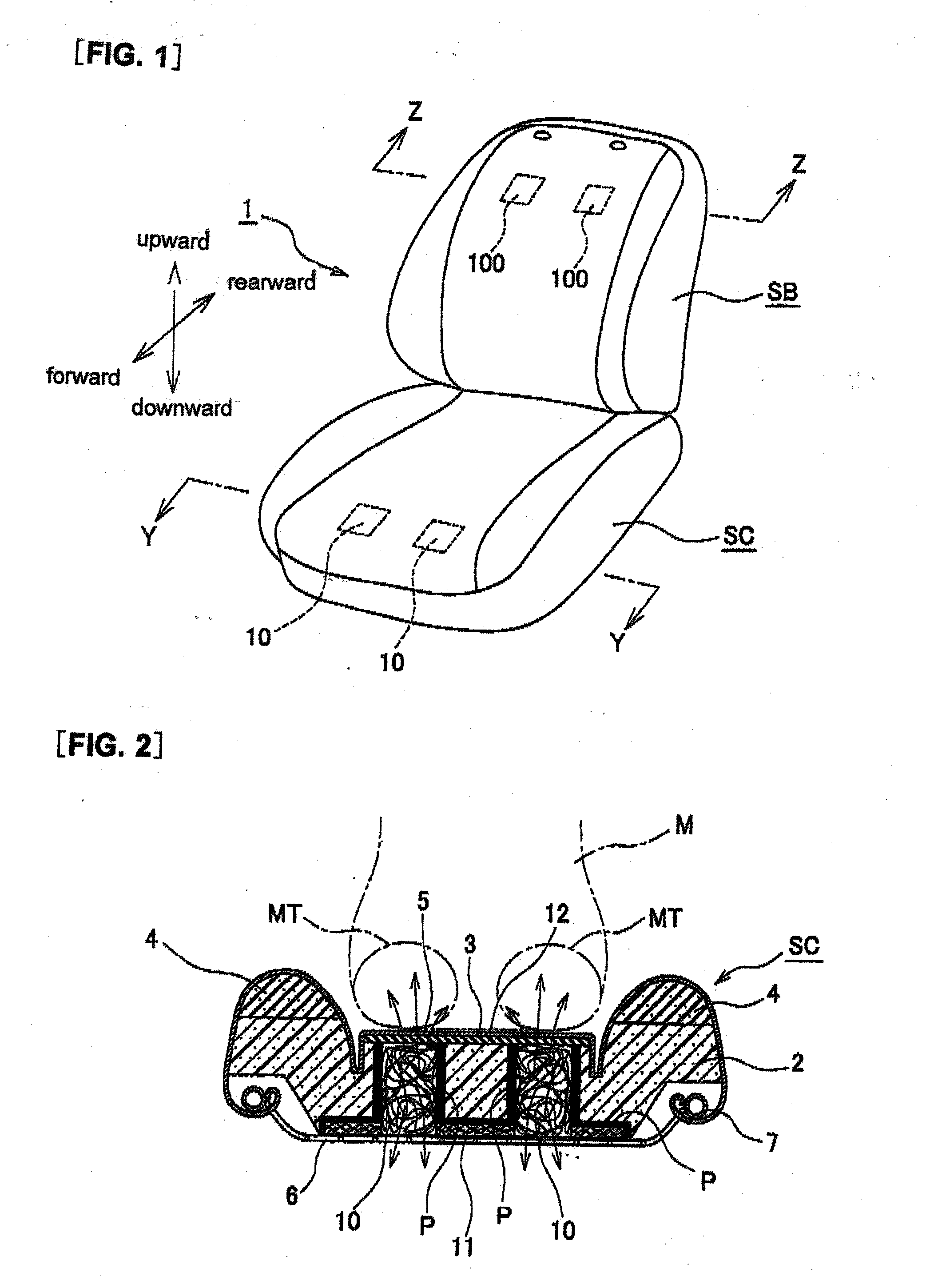

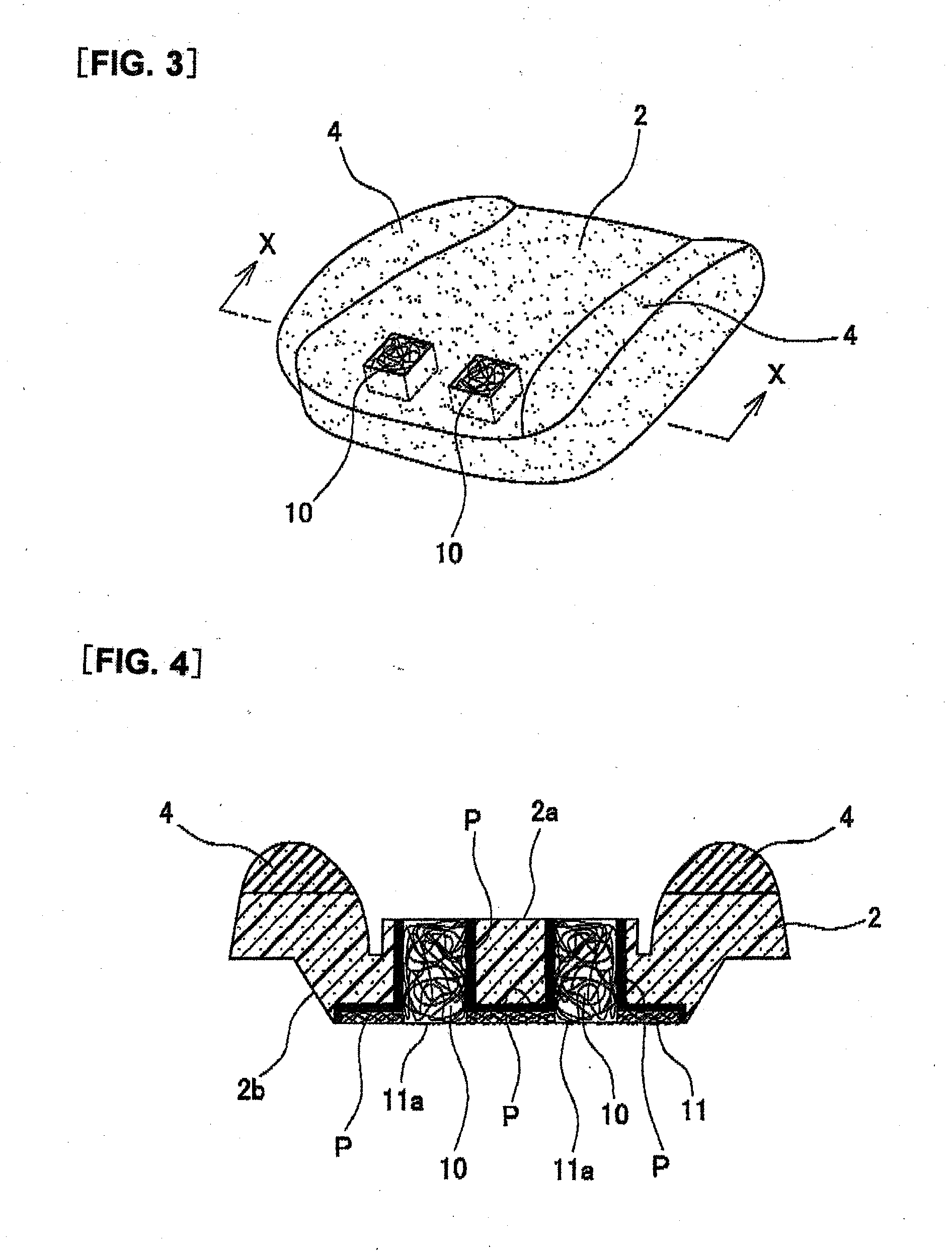

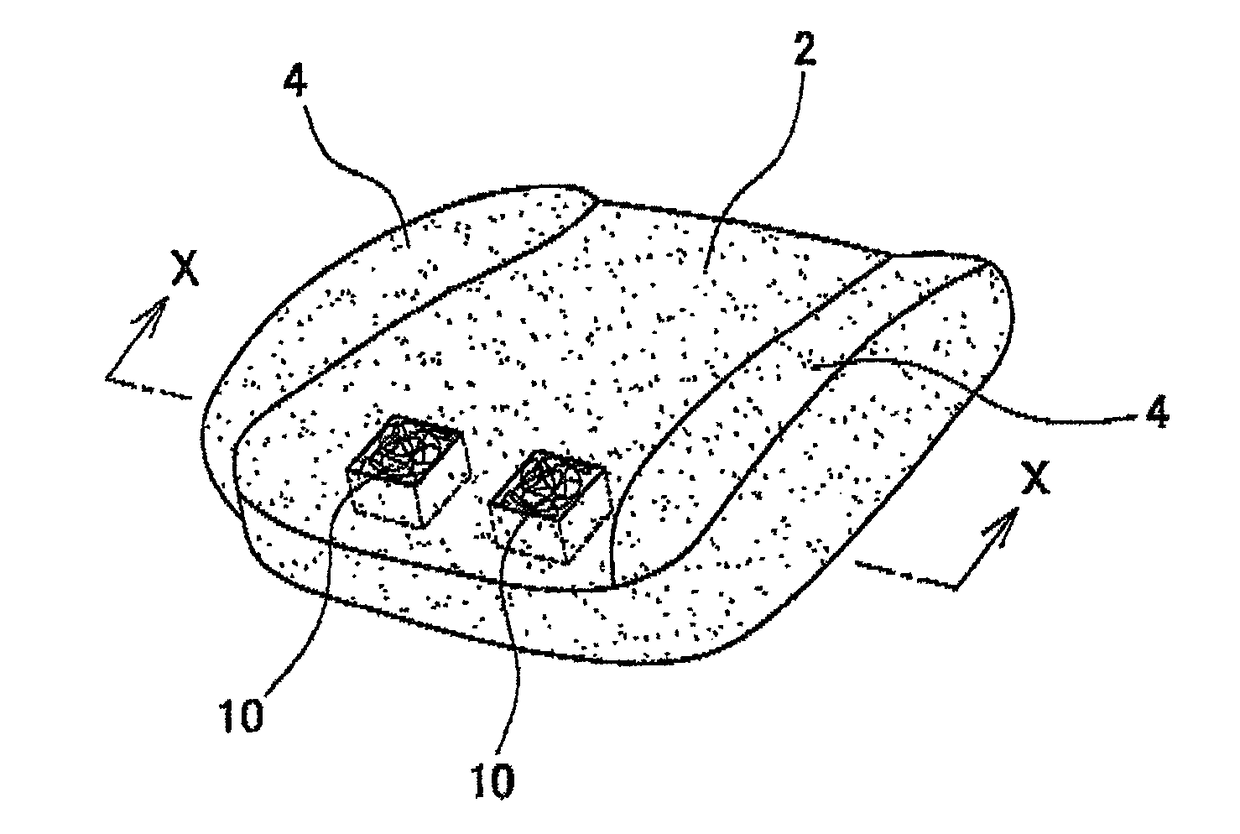

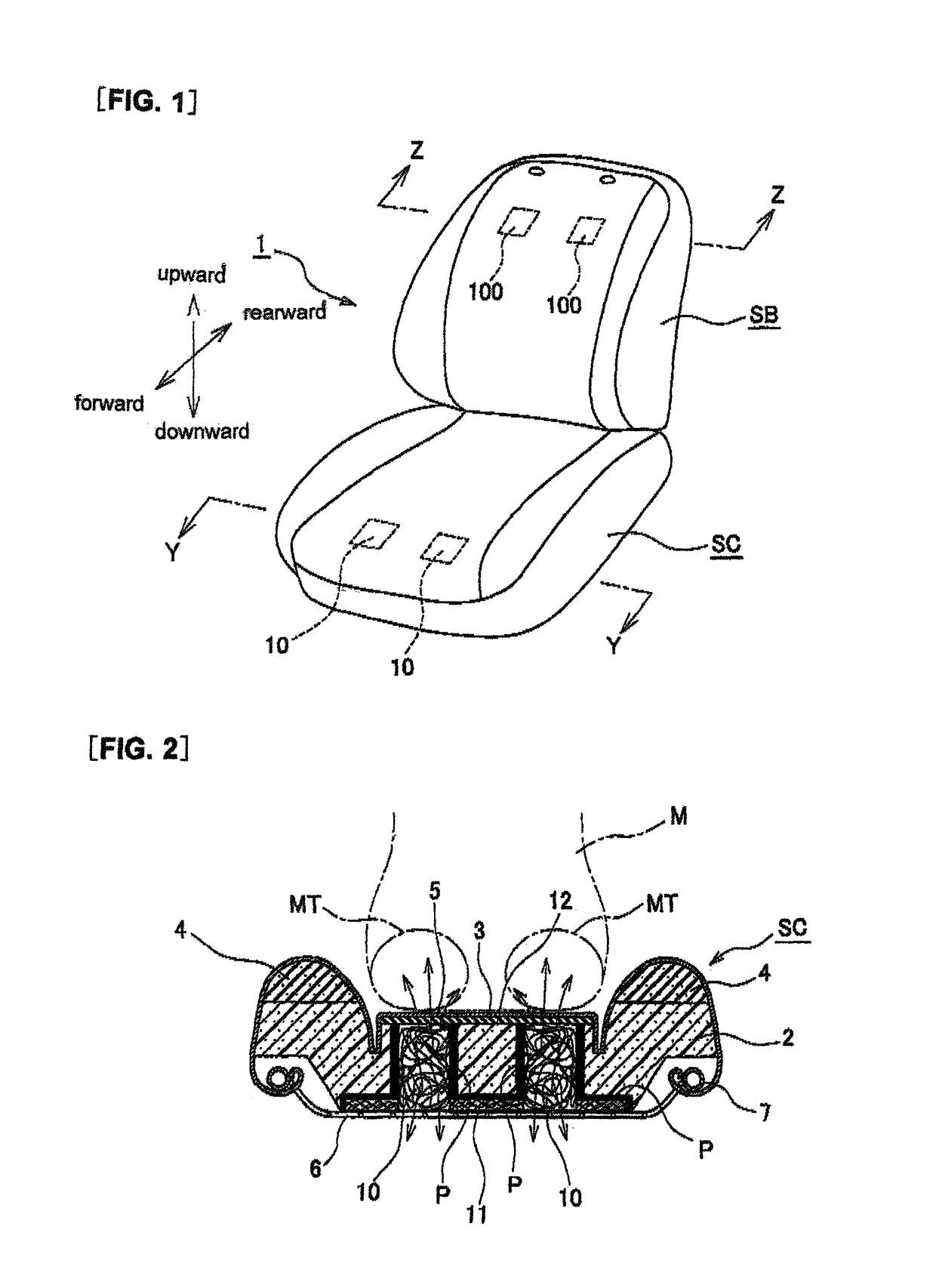

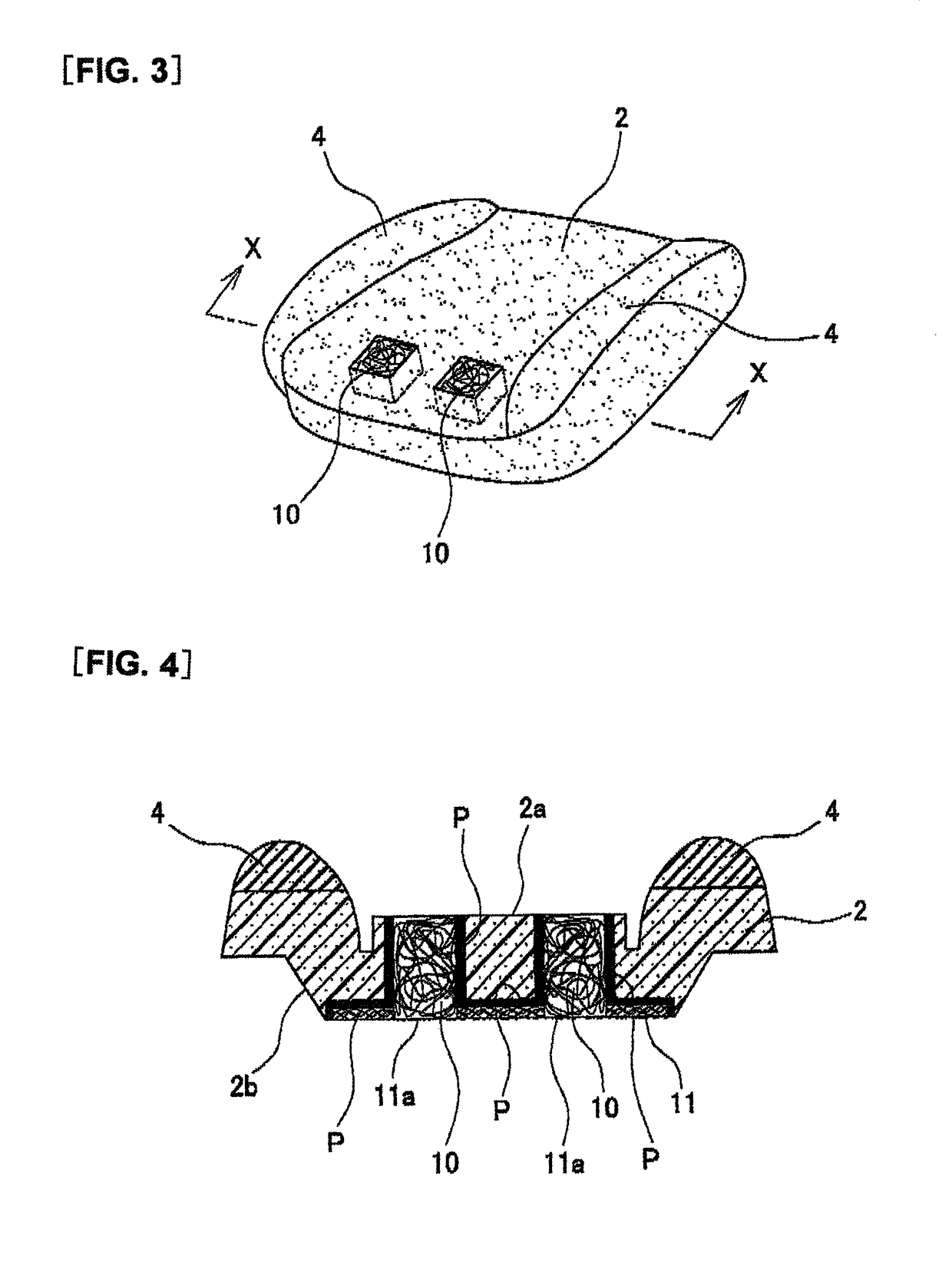

Seat with ventilative property

ActiveUS20160220028A1Prevent permanent settlingAvoid deformationVehicle seatsStuffed mattressesRight ThighEngineering

To provide a seat with ventilative property, which can eliminate or minimize the possibility of its being permanently deformed and settled into an unrecoverable deformed state. In the seat with ventilative property, left and right three-dimensional network cushion elements are provided in a forwardly-facing region of a seat cushion of the seat, in a manner independent of each other, such that the left and right three-dimensional network cushion elements are respectively situated at: one location on which a left thigh portion of a seat occupant is to be contacted; and the other location on which a right thigh portion of the seat occupant is to be contacted. This arrangement can almost completely prevent a direct application of a weight of the seat occupant to the two three-dimensional network cushion elements. Therefore, the present invention has the effect that a permanent downward settling of the seat cushion SC can be prevented, so that a short life of the seat due to such permanent settling may be substantially avoided.

Owner:TACHI S CO LTD +1

Rubber composition, application to foam products and production method

ActiveCN108299744AImprove melt strengthPermanent deformationBicycle tyresNon-inflatable tyresElastomerCarbon number

The invention discloses rubber composition, a processing method thereof, an application of the composition to foam product production and a method. The rubber composition is prepared from a rubber matrix and essential components, wherein the rubber matrix contains a parts of branched polyethylene and b parts of EPM rubber and EPDM rubber, a is larger than 0 and smaller than or equal to 100 parts,and b is larger than or equal to 0 and smaller than 100 parts; the essential components comprise 0.5-10 parts of a crosslinking agent and 1.5-25 parts of a foaming agent. The rubber composition applies to processing of sponge sealing strips, foam materials with high foaming ratio, damping foam rubber boards, light-color high-strength foam boards, foam solid compound sealing strips as well as solidtires filled with foam elastomers. The rubber composition has the beneficial effects as follows: branched polyethylene not only contains short branch chains of methyl, ethyl, propyl, butyl, amyl andthe like, but also contains long branch chains with carbon number larger than 6, by replacing ethylene propylene rubber in the foam rubber composition partially or completely with branched polyethylene, melt strength of the rubber composition can be improved, foamability, especially pre-foamability of the composition is improved, and the obtained rubber products have lower compression set.

Owner:HANGZHOU XINGLU TECH CO LTD +1

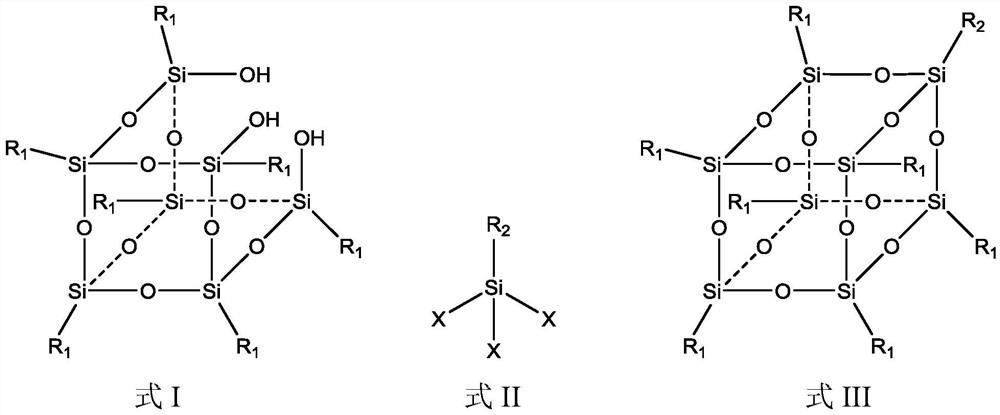

Silicone Elastomer Composition

ActiveUS20120263959A1Increase flexibilityIncrease elasticityPretreated surfacesOrganic dyesHydrogen atomHydrogen

The present invention has an objective to provide a silicone elastomer composition in which a cured product thereof is flexible, which provides a silicone elastomer with a small hardness change even due to thermal aging, and in which superior adhesive properties with respect to other silicone elastomers and superior curing properties are exhibited. The objective of the present invention can be achieved by a silicone elastomer composition comprising: (A) an organopolysiloxane having two or more silicon atom-bonded alkenyl groups on average in a molecule, in which the content of the alkenyl group is less than 0.2% by weight with respect to the amount of component (A); (B) an organopolysiloxane having two or more silicon atom-bonded hydrogen atoms on average in a molecule, in which the amount of the silicon atom-bonded hydrogen atoms in component (B) ranges from 2.5 to 10 mol with respect to one mol of the silicon atom-bonded alkenyl group in component (A); (C) a platinum-group metal-based catalyst, in a specified amount; and (D) a phthalocyanine compound, in which the amount thereof ranges from 5 to 50 mol with respect to one mol of the platinum-based metal in component (C).

Owner:DOW TORAY CO LTD

Layered rubber product

InactiveCN101031415AExcellent mechanical propertiesExcellent ozone resistanceSynthetic resin layered productsThin material handlingCross-linkPolymer science

A rubber laminate comprised of a cross-linked rubber layer containing a carboxyl-group containing nitrile copolymer rubber (A), a carboxyl-group containing acryl-based polymer (B), and a specific phosphonium salt and a fluorine-based polymer layer. Preferably, the carboxyl-group content per 100 grams of the (A) ingredient is 210 -3 to 110 -1 equivalents and the carboxyl-group content per 100 grams of the (B) ingredient is 410 -4 to 110 -1 equivalents, the (A) ingredient and (B) ingredient are in a weight ratio of 40:60 to 90:10, and the phosphonium salt content in the cross-linked rubber layer is 0.5 to 10 parts by weight per 100 parts by weight of the total of the (A) ingredient and (B) ingredient. According to the present invention, there is provided a rubber laminate excellent in oil resistance and gasoline permeation resistance plus tensile strength, low compression set, and other mechanical characteristics, ozone resistance, and interlayer adhesion.

Owner:ZEON CORP

FAM-B-methanol-gasoline-resistant low-temperature-resistant low-compressive-deformation ethylene-acrylate rubber material and preparation method thereof

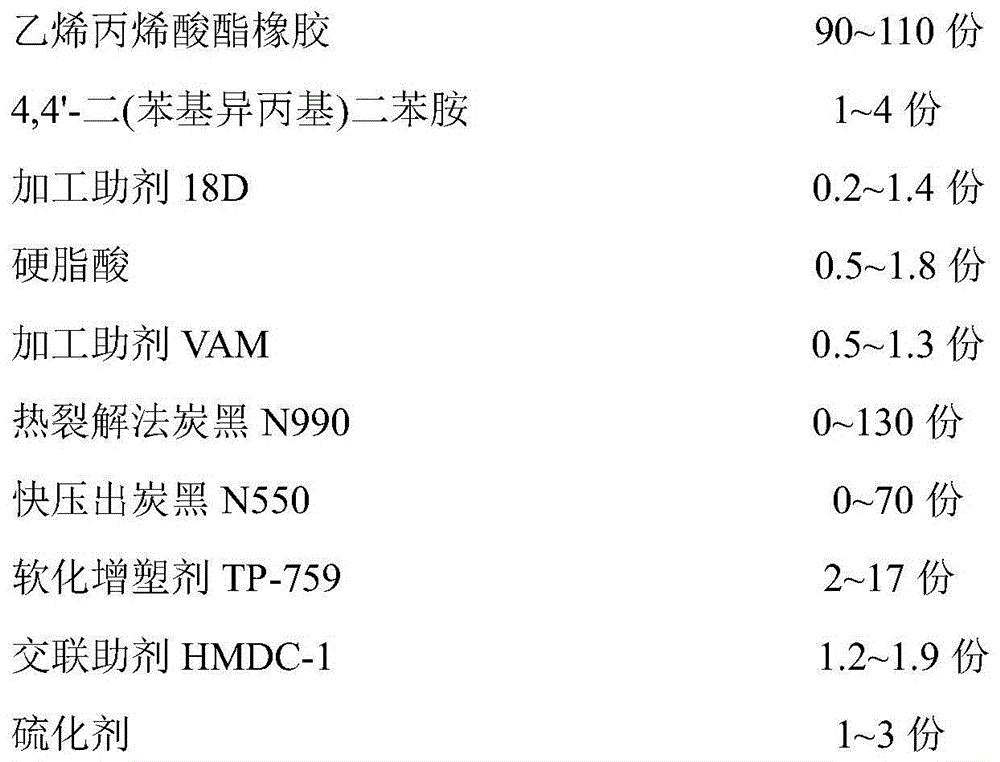

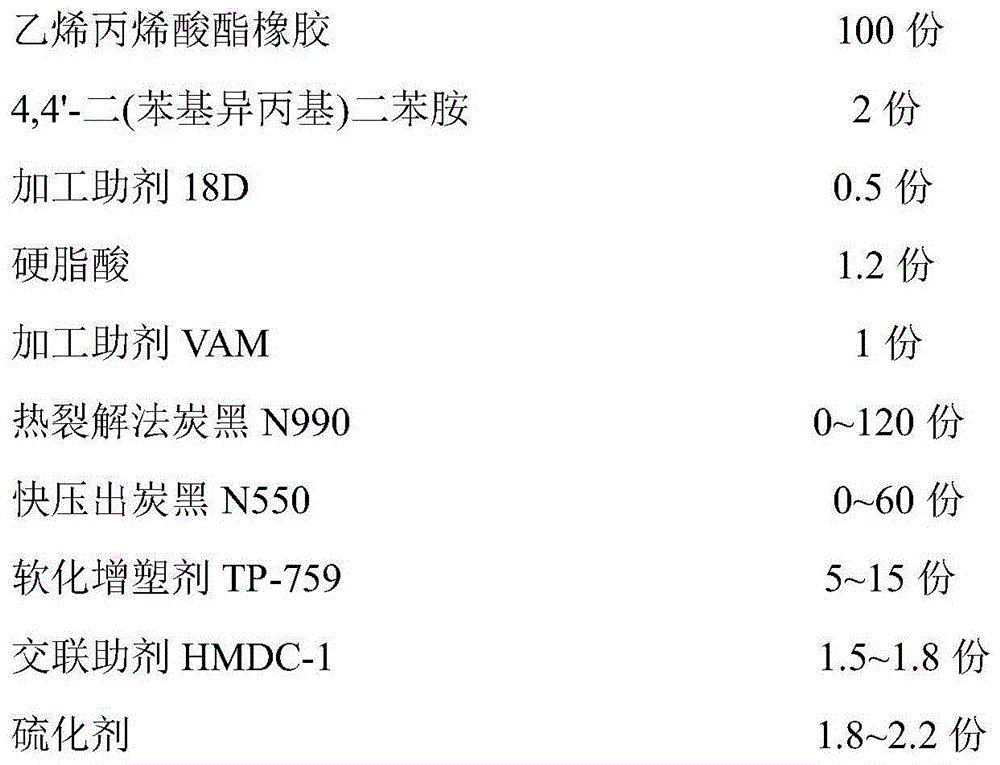

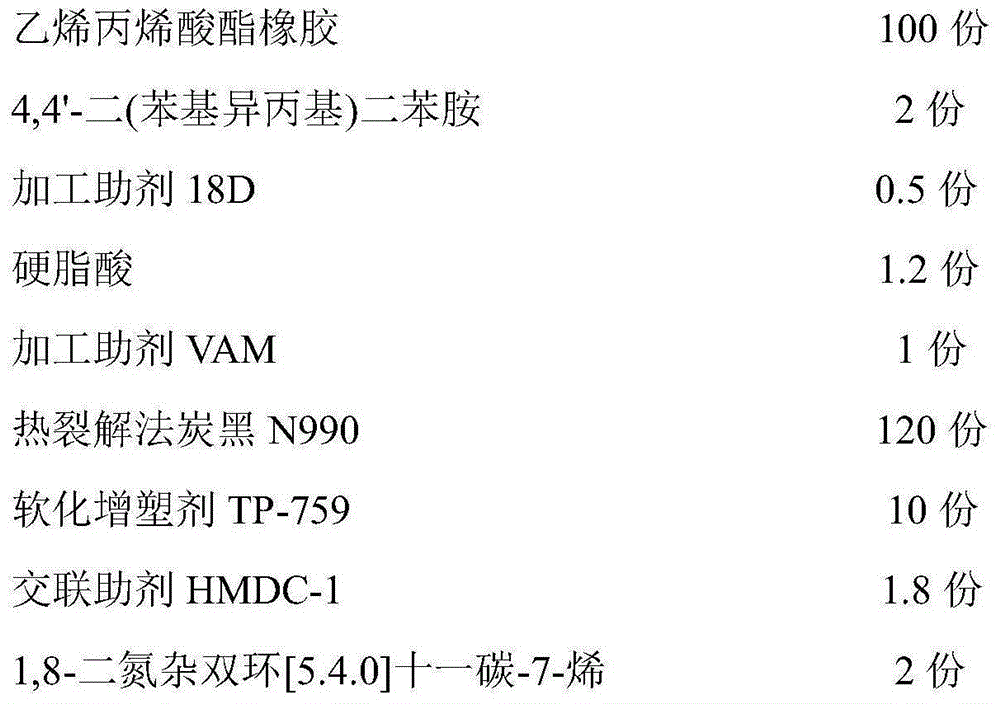

The invention discloses an FAM-B-methanol-gasoline-resistant low-temperature-resistant low-compressive-deformation ethylene-acrylate rubber material and a preparation method thereof, belonging to the technical field of rubber preparation. The preparation method comprises the following steps: sending 90-110 parts of ethylene-acrylate rubber, 1-4 parts of 4,4'-di(phenylisopropyl)diphenylamine, 0.2-1.4 parts of processing assistant 18D, 0.5-1.8 parts of stearic acid, 0.5-1.3 parts of processing assistant VAM, 0-130 parts of thermo-cracking carbon black N990, 0-70 parts of quick-extrusion carbon black N550 and 2-17 parts of softening and plasticizing agent TP-759 into a Banbury mixer, and banburying to obtain a master batch; and sending the master batch, 1.2-1.9 parts of crosslinking assistant HMDC-1 and 1-3 parts of vulcanizing agent into the Banbury mixer, carrying out secondary compounding, discharging the rubber when the temperature reaches 100 DEG C, and finally, carrying out molding, primary vulcanization and secondary vulcanization. The rubber material has the advantages of excellent FAM B methanol gasoline resistance, low temperature resistance and low compressive permanent deformation.

Owner:南京金三力高分子科技有限公司

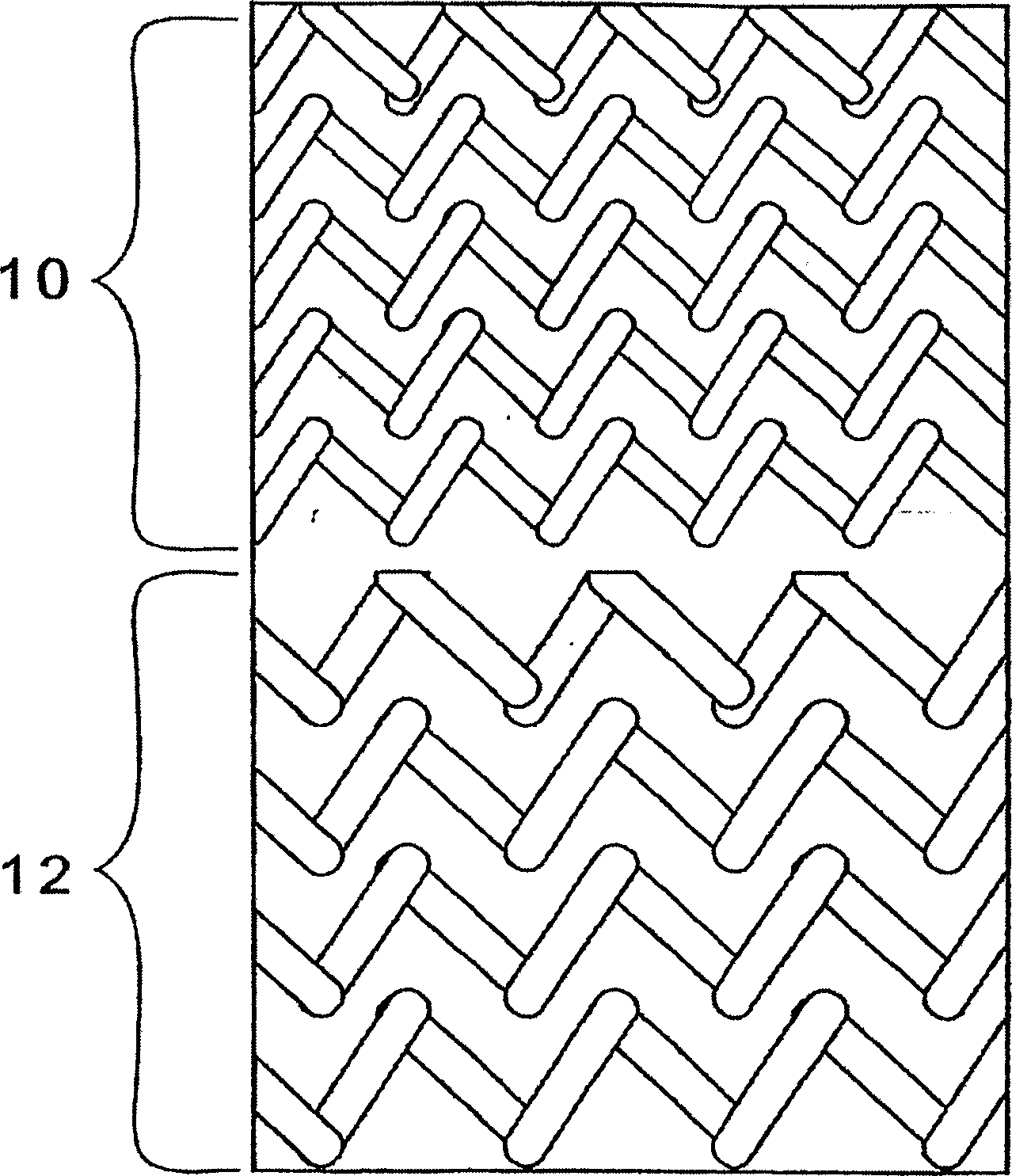

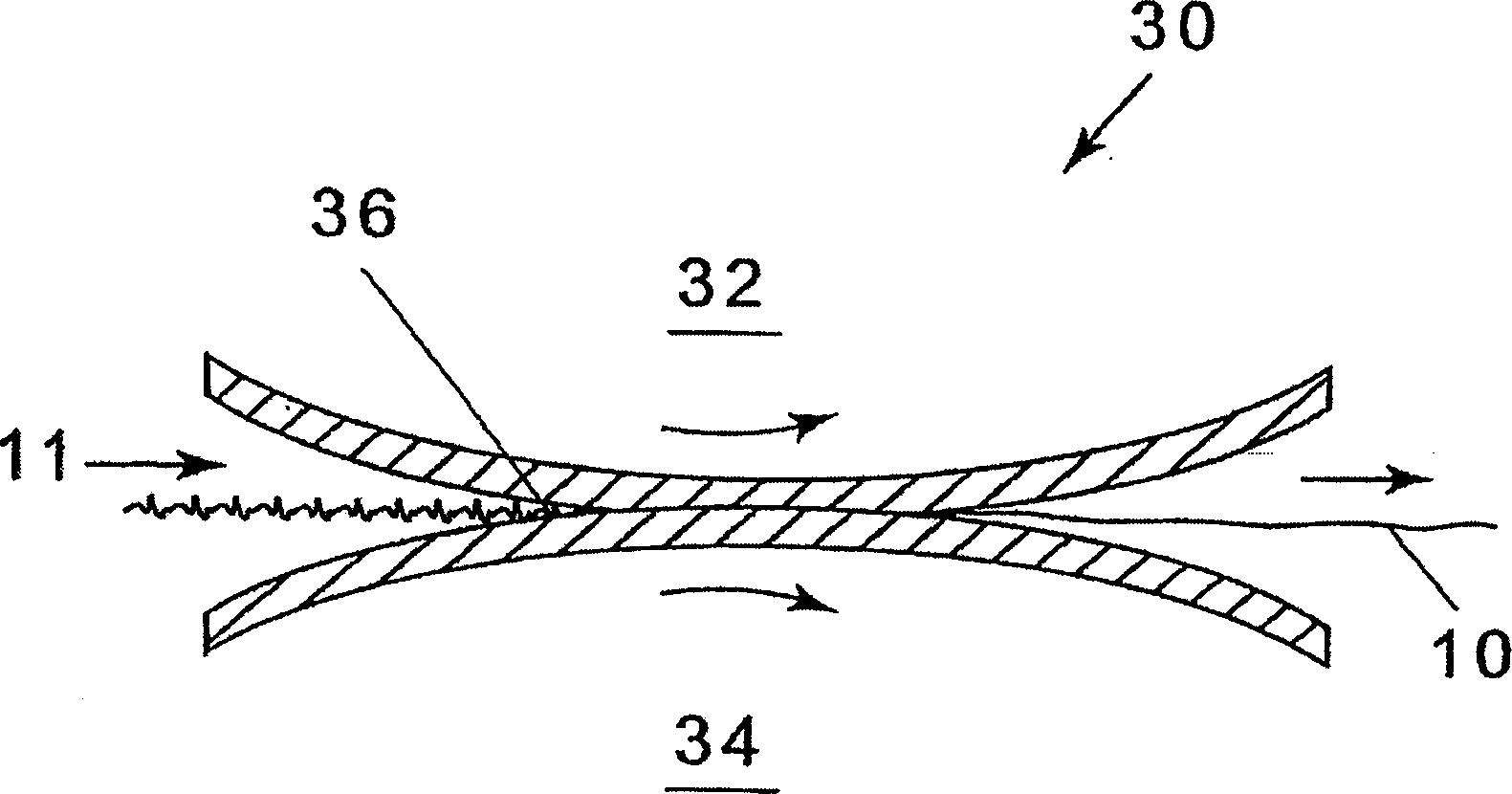

Calendered industrial process fabric

InactiveCN1732306APermanent deformationMaintain durabilityCalendersPaper/cardboardProcess engineeringPaper machine

Owner:ALBANY INT CORP

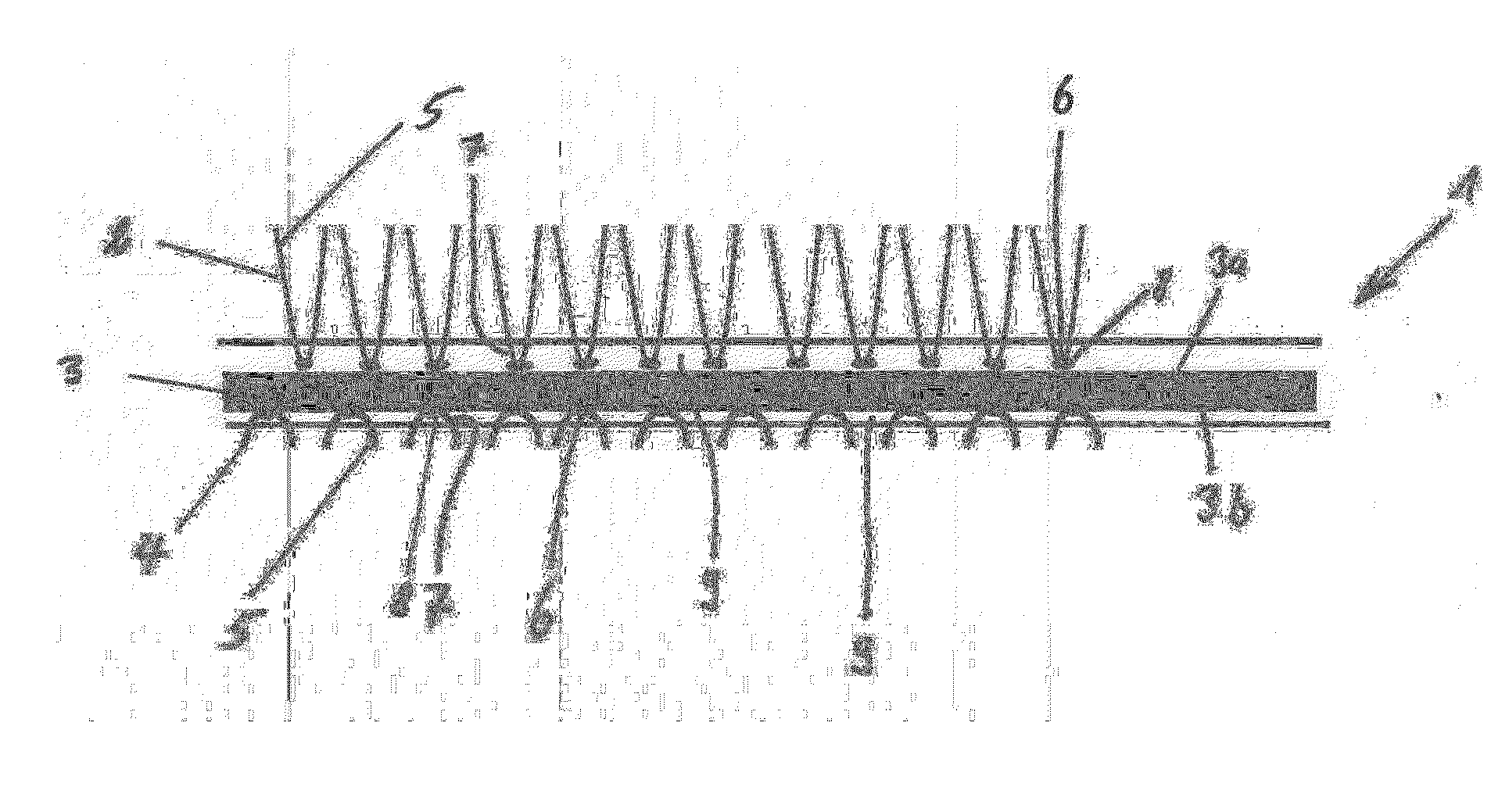

Insert mat for motor vehicles for placing onto a wall-to-wall carpet structure of the motor vehicle

InactiveUS20150125648A1Permanent deformationImprove breathabilityLiquid surface applicatorsVehicle arrangementsMobile vehicleEngineering

An insert mat for motor vehicles for placing onto a sound-absorbing wall-to-wall carpet structure of the motor vehicle, having an at least three-layer structure, in which the structure has a decorative layer, which is oriented toward the interior of the vehicle in the proper position of the insert mat and is attached to a top surface of a support layer, which surface is oriented toward the interior of the vehicle in the proper position, and a gripping layer, which in the proper position of the insert mat, is attached to a bottom surface of the support layer and is embodied to achieve a hooking interaction with a wall-to-wall carpet of a vehicle, in which the entire structure is embodied to be air permeable, wherein the decorative layer is a tuft, the support layer is a nonwoven, and the gripping layer is a tuft.

Owner:IDEAL AUTOMOTIVE OELSNITZ GMBH

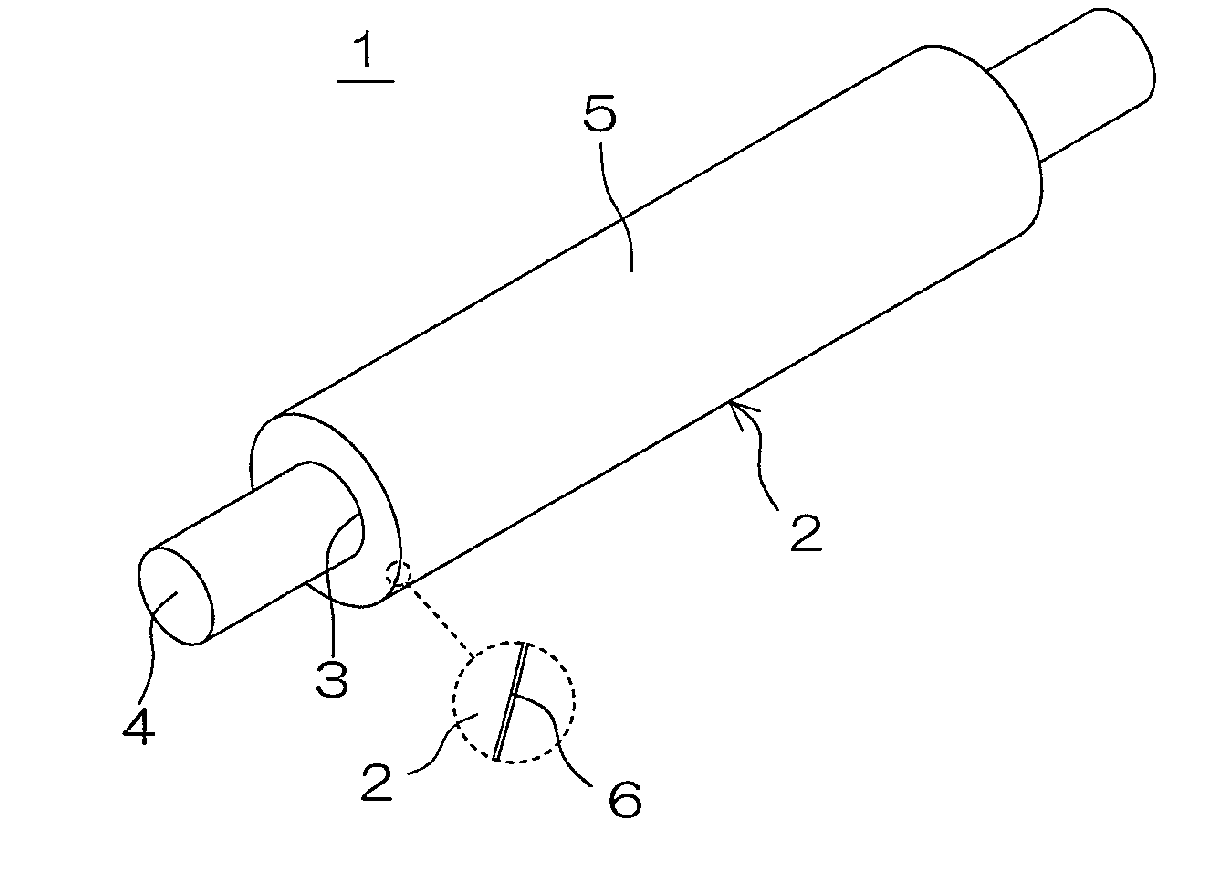

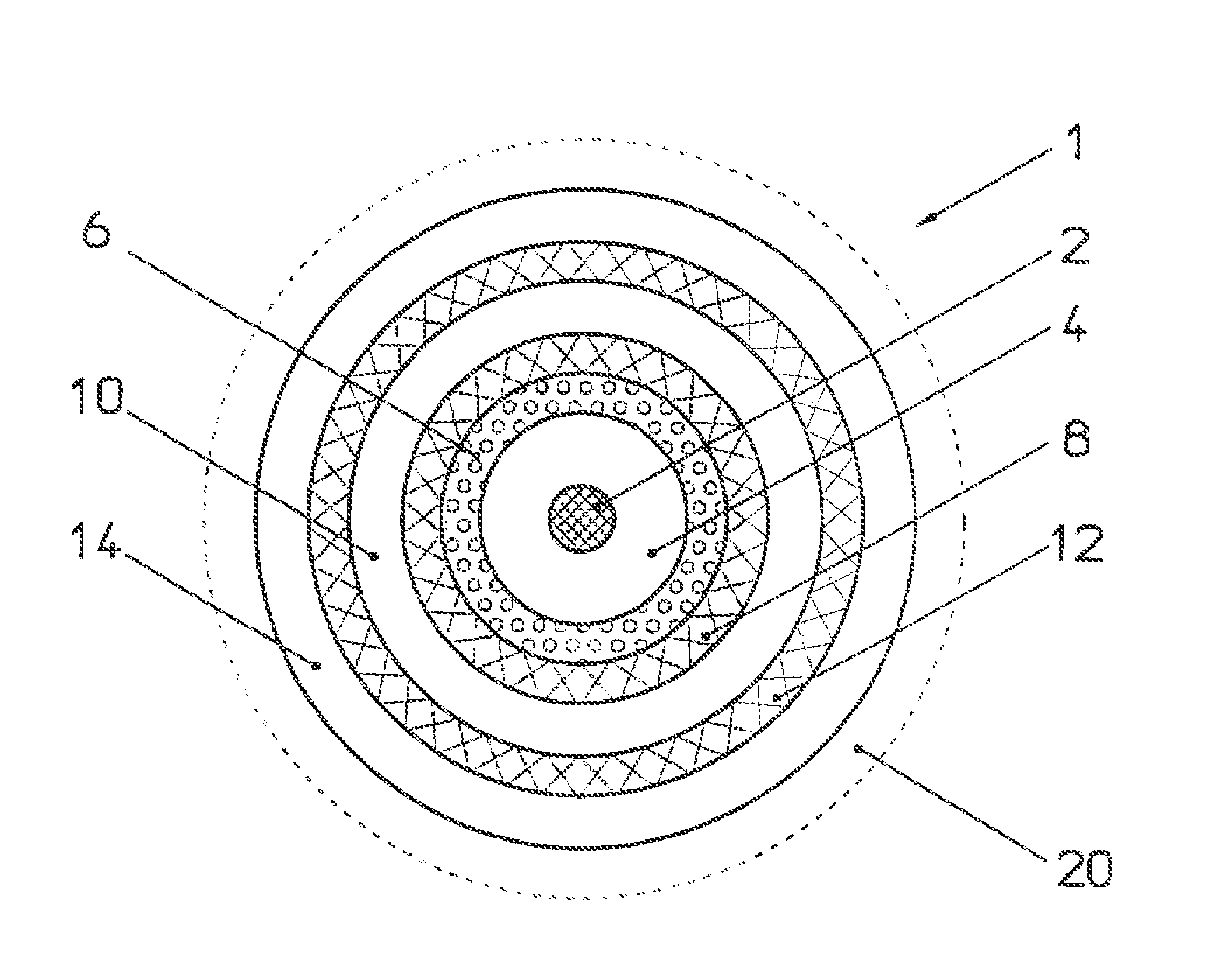

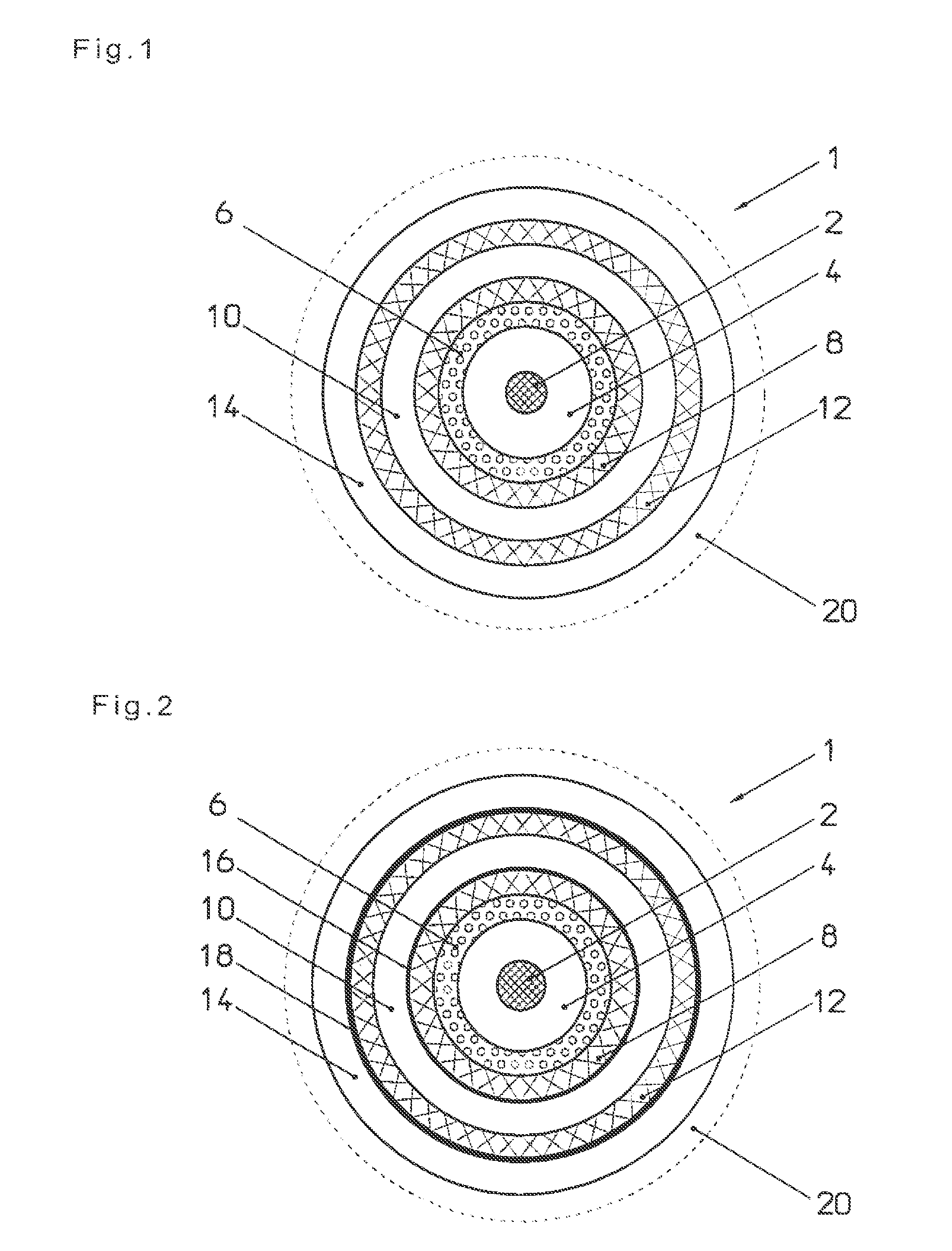

Cable with electrical conductor included therein

ActiveUS20110132660A1Optimize locationPermanent deformationElectrically conductive connectionsRope making machinesElectrical conductorCompound (substance)

Owner:HELUKABEL

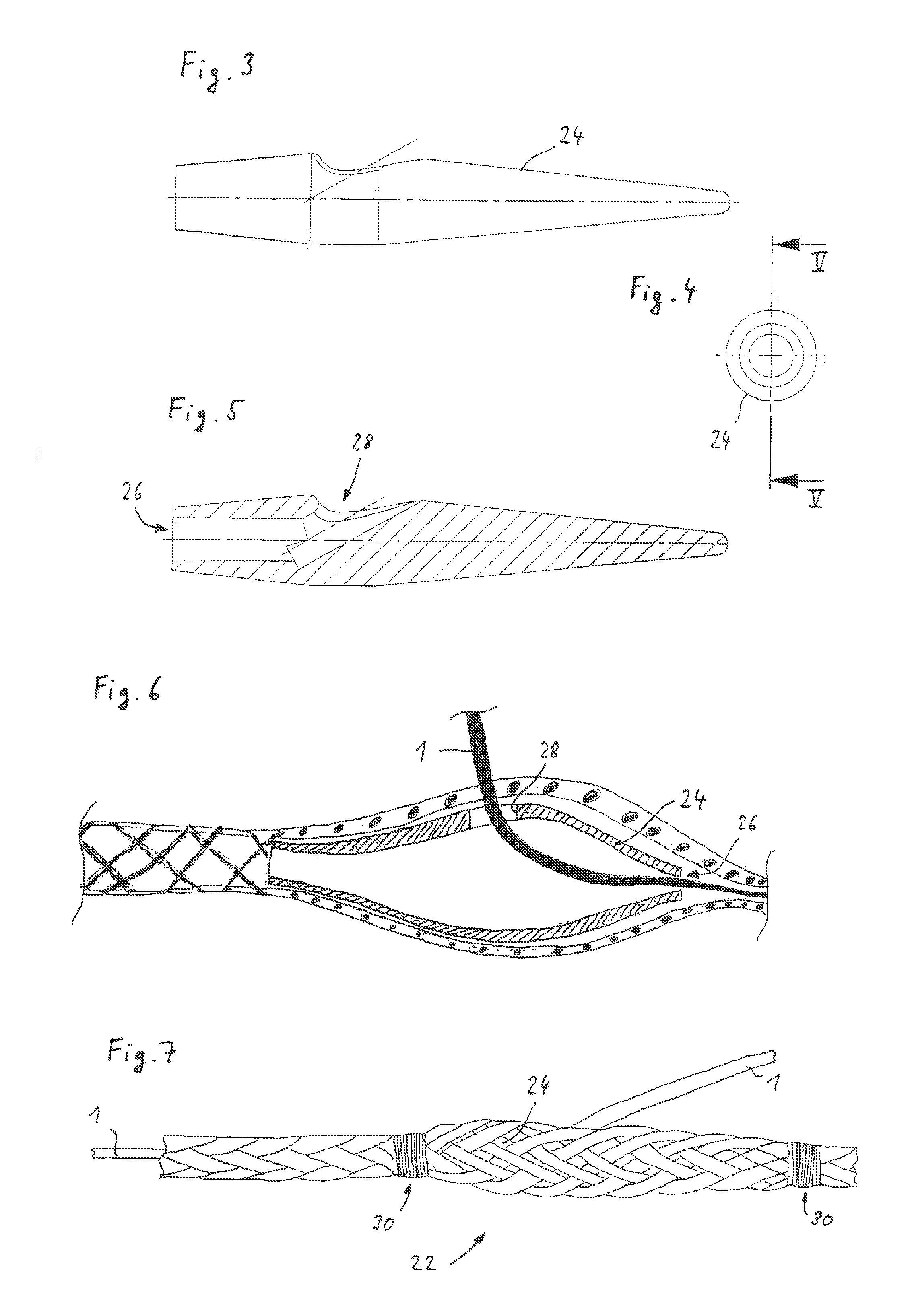

Vulcanizing agent system for fluororubber, fluororubber compound and application

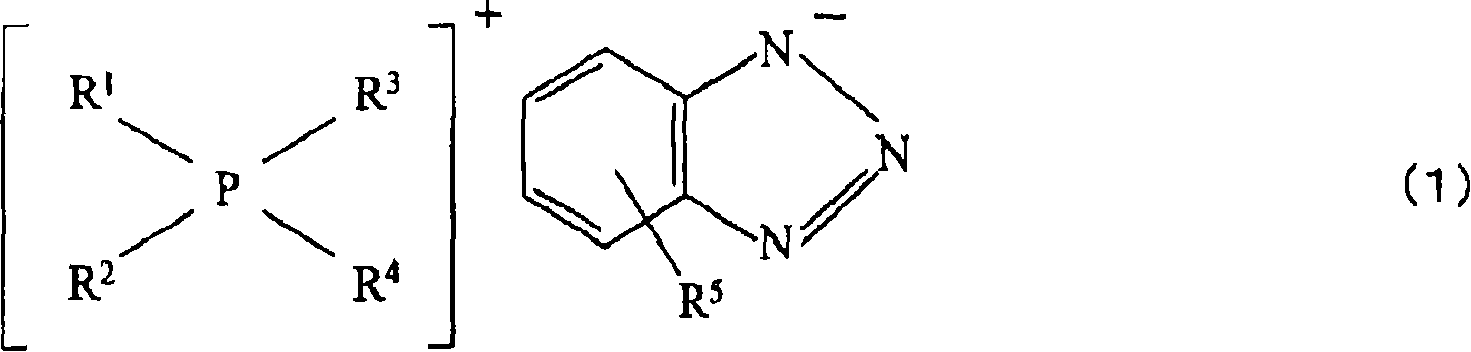

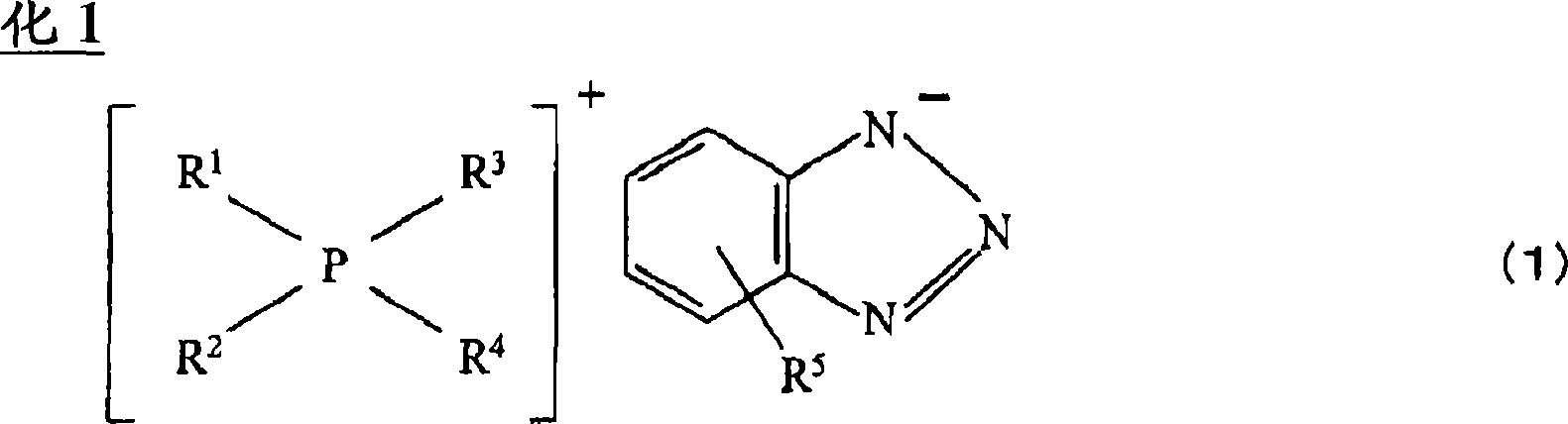

The invention discloses a vulcanizing agent system for fluororubber. The vulcanizing agent system comprises bisphenol AF, an onium compound and a fluorinated polyphenol hydroxyl compound. The invention also discloses a fluororubber compound. The fluororubber compound comprises the following raw materials in parts by mass: 100 parts of raw fluororubber, 6 to 10 parts of an acid acceptor, 20 to 40 parts of a coloring filling material, 0.5 to 1.5 parts of a release agent, 1 to 2 parts of the bisphenol AF, 0.16 to 0.5 part of benzyltriphenylphosphonium chloride BPP and 0.2 to 0.6 part of 1,1,1-tri(4-hydroxyphenyl)trifluoroethane. The invention also provides an application of the fluororubber compound in sealing products. The vulcanizing agent system provided by the invention is used for the fluororubber compound; and the prepared fluororubber compound and a sealing product have lower compression set, better chemical resistance and better comprehensive mechanical properties.

Owner:HAINING JIACHENG RUBBER CO LTD

Seat with ventilative property

ActiveUS9901181B2Reduce humidityPermanent deformationSeat heating/ventillating devicesStuffed mattressesRight ThighEngineering

To provide a seat with ventilative property, which can eliminate or minimize the possibility of its being permanently deformed and settled into an unrecoverable deformed state. In the seat with ventilative property, left and right three-dimensional network cushion elements are provided in a forwardly-facing region of a seat cushion of the seat, in a manner independent of each other, such that the left and right three-dimensional network cushion elements are respectively situated at: one location on which a left thigh portion of a seat occupant is to be contacted; and the other location on which a right thigh portion of the seat occupant is to be contacted. This arrangement can almost completely prevent a direct application of a weight of the seat occupant to the two three-dimensional network cushion elements. Therefore, the present invention has the effect that a permanent downward settling of the seat cushion SC can be prevented, so that a short life of the seat due to such permanent settling may be substantially avoided.

Owner:TACHI S CO LTD +1

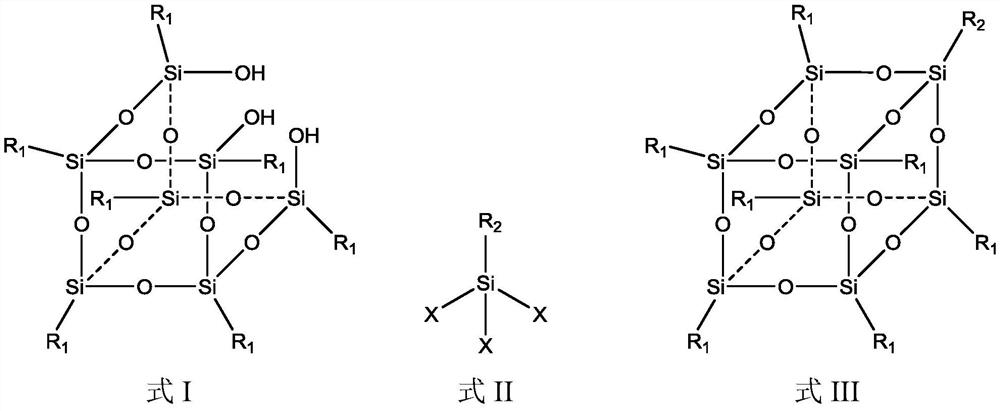

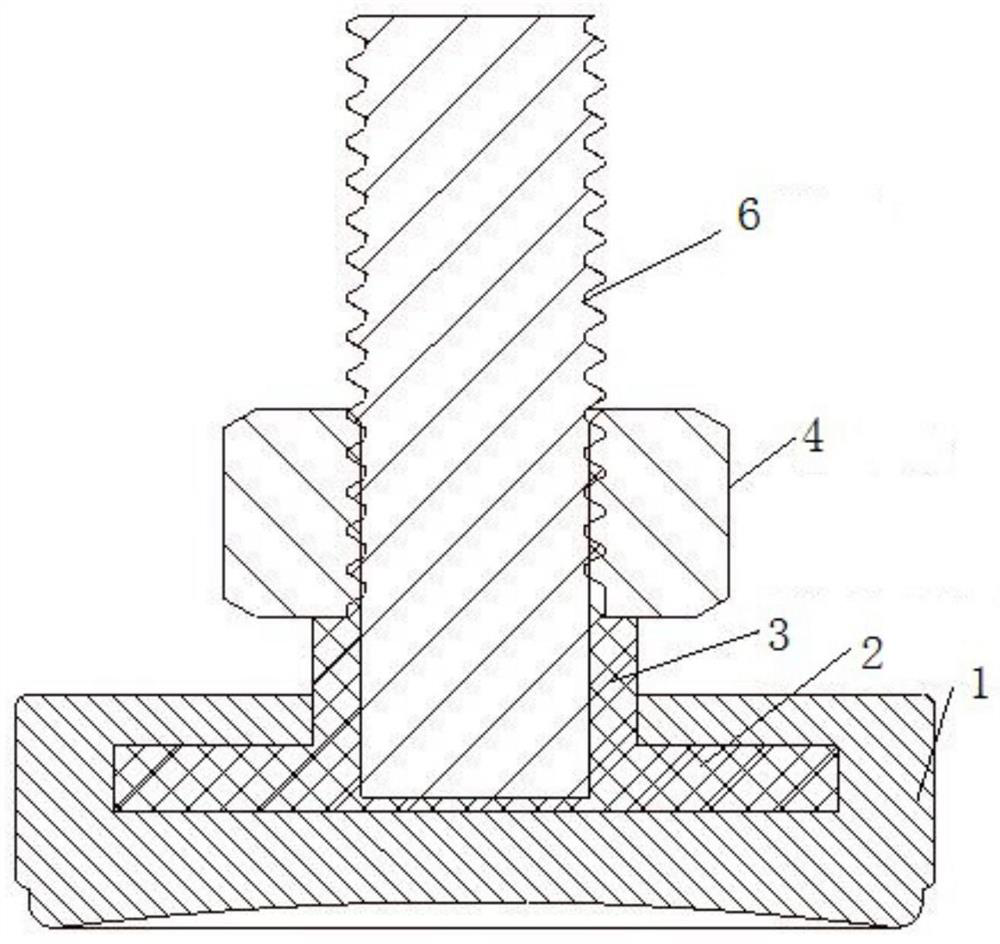

Thermoplastic polyurethane elastomer foam material composition and foam material

The invention relates to a thermoplastic polyurethane elastomer foam material composition and a foam material. The composition is prepared from the following components in parts by weight: 25-98 partsof a thermoplastic polyurethane elastomer, 2-75 parts of an unsaturated compound containing carbon-carbon double bonds, 0.1-25 part of a foaming agent and 0.1-15 part of a cross-linking agent, wherein the sum of the parts by weight of the thermoplastic polyurethane elastomer and the unsaturated compound containing the carbon-carbon double bonds is 100 parts. The thermoplastic polyurethane elastomer foam material can be prepared from the composition through mixing, mould pressing or ejection foaming. The foam material has the advantages of good wear resistance, high resilience, excellent slipresistance and the like.

Owner:WANHUA CHEM GRP CO LTD +1

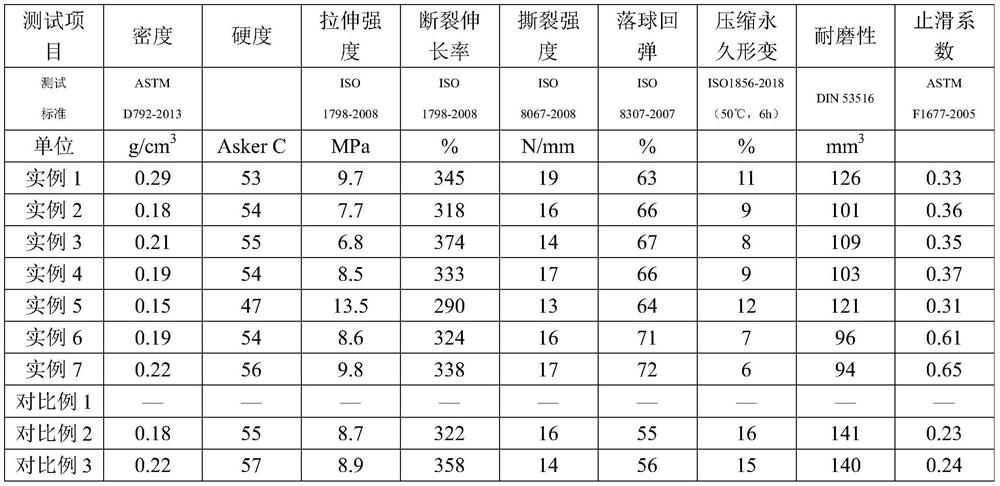

Washing machine footing and technique

ActiveCN111692275ASo as not to damageHigh strengthNon-rotating vibration suppressionOther washing machinesLaundry washing machineSupport surface

The invention discloses a washing machine footing. The footing comprises a supporting piece used for supporting on a supporting surface; the supporting piece comprises a rigid polyurethane member andan elastic polyurethane member which are integrally formed, and the elastic polyurethane member is in contact with the support surface. The washing machine footing is integrally formed by the rigid polyurethane member and the elastic polyurethane member. The structure of the washing machine footing is a whole with high strength, so that the washing machine footing cannot be damaged when being dragged; the elastic polyurethane material can generate larger deformation force under the condition of slight transverse expansion, and larger grip force is generated; and the polyurethane material has small permanent deformation. The washing machine footing makes full use of the polyurethane technology, the overall system safety of a washing machine and durability of the washing machine footing areimproved, better shock absorption and noise reduction effects are brought, and better use experience is provided for users.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com