Thermoplastic polyurethane elastomer composition, and preparation method and application thereof

A technology of thermoplastic polyurethane and elastomer, applied in the field of thermoplastic polyurethane elastomer, can solve the problems of complex and difficult production process, high processing temperature and difficult operation, high price and cost, and achieve the effects of reducing wear, improving heat resistance and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

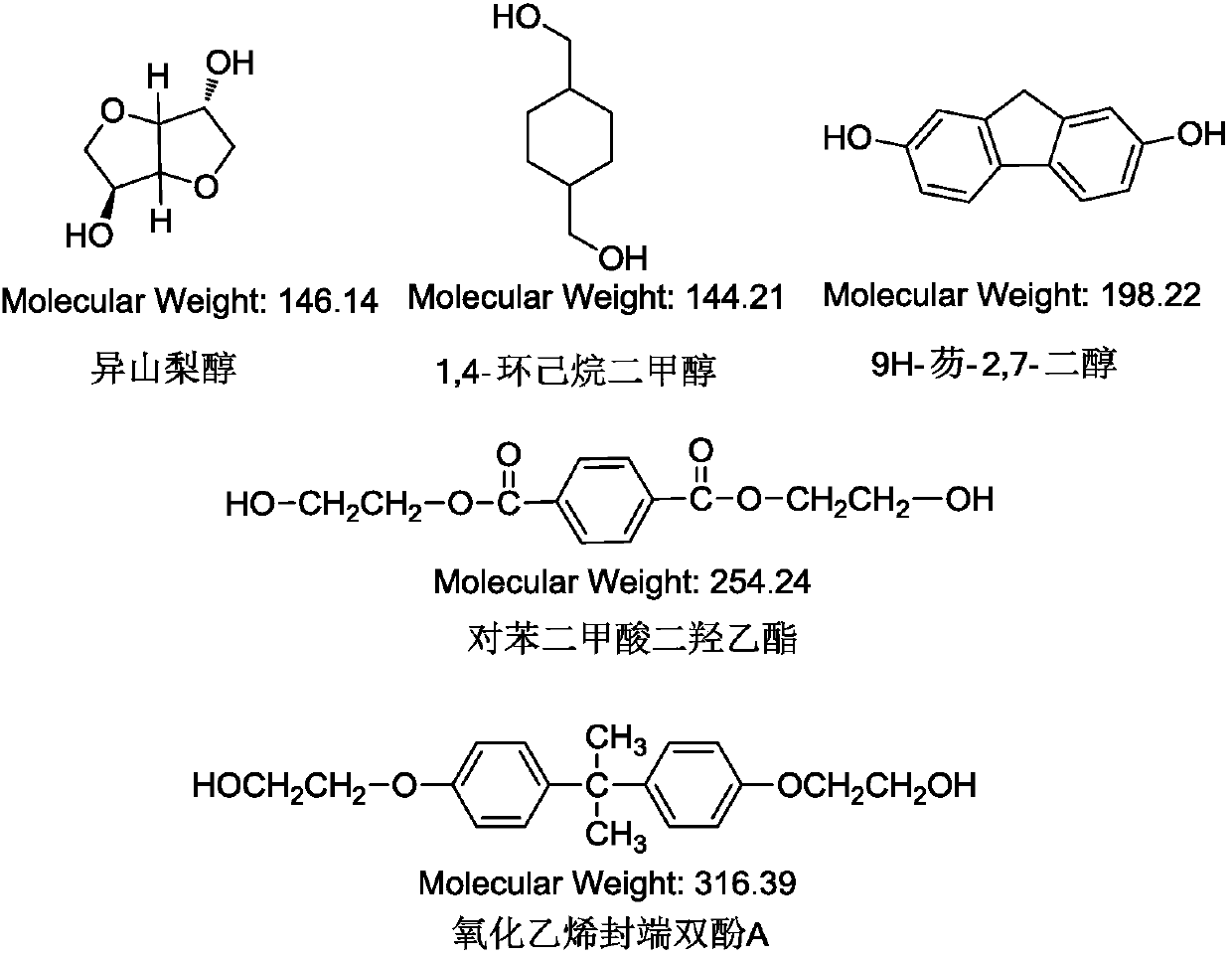

Method used

Image

Examples

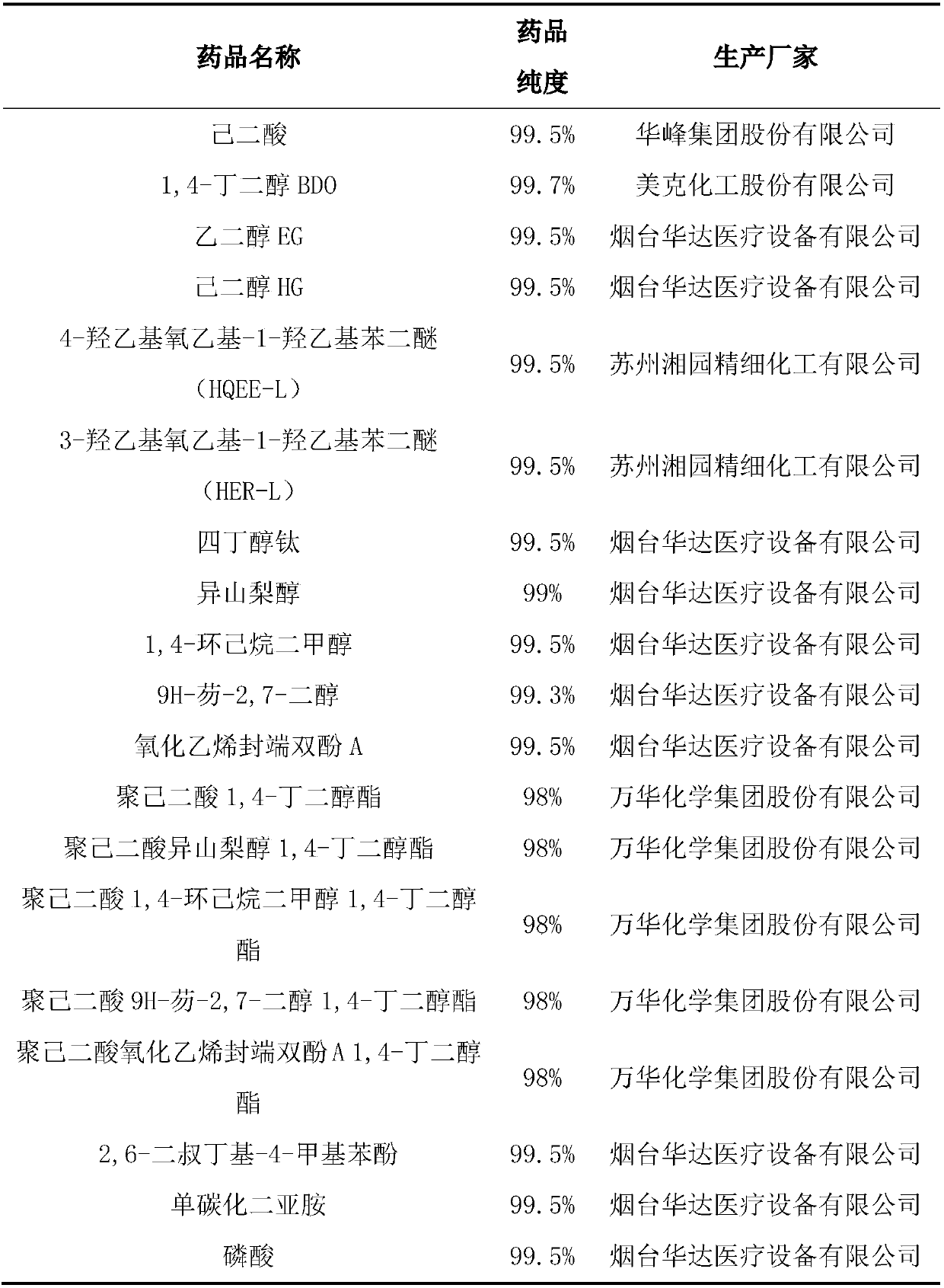

Embodiment 1

[0051] In Example 1, the thermoplastic polyurethane elastomer was synthesized by using the material dosage formula of isocyanate index R=1.20: 350g PIBA2000 polyester polyol, 118.3g ethylene glycol chain extender, 2g 2,6-di-tert-butyl-4-methyl Mix base phenol, 8g monocarbodiimide additive, 5ppm phosphoric acid catalyst at 65°C, add 531.7g MDI isocyanate, stir quickly until the temperature rises to 95°C, stop stirring, gel for 1.5min, and quickly pour into the mold In the process of aging reaction at 110°C for 10h, then crushed, injection molded test pieces of different shapes, the injection molding temperature was 215°C, the injection molded test pieces were annealed in a 90°C oven for 12h, and then taken out and placed in a standard constant temperature and humidity laboratory (23°C, 50% humidity) After standing for 24 hours, cut out different shapes of specimens for testing and evaluation.

[0052] The elevator roller made of the thermoplastic polyurethane elastomer of this ...

Embodiment 2

[0054] In Example 2, the material dosage formula of isocyanate index R=1.30 is adopted to synthesize thermoplastic polyurethane elastomer, 700g PCBA5000 polyester polyol, 83.6g hexanediol chain extender, 15g tetrakis (4-hydroxyl 3,5-tert-butyl Phenyl propionate) pentaerythritol ester, 1g polycarbodiimide additive, 1ppm stannous octoate catalyst, stir and mix evenly at 75°C, add 216.4gMDI isocyanate, stir rapidly until the temperature rises to 100°C, stop stirring, and the gel is 1.0 min, quickly poured into the mold, aged and reacted at 90°C for 16h, then crushed, injection molded test pieces of different shapes, the injection temperature was 200°C, and the injection molded test pieces were annealed in an oven at 80°C for 12h, then taken out and placed in a standard After placing in a constant temperature and humidity laboratory (23°C, 50% humidity) for 24 hours, cut out different shape specimens for testing and evaluation.

[0055] The high-pressure hydraulic seal made of the...

Embodiment 3

[0057] In Example 3, the thermoplastic polyurethane elastomer was synthesized by using the material dosage formula of isocyanate index R=1.35. 550g PFBA1000 polyester polyol, 101.9g HQEE-L chain extender, 5g 2,6-di-tert-butyl-4-methanol Mix base phenol, 6g polycarbodiimide additive, and 5ppm phosphoric acid catalyst at 65°C to mix evenly, add 348.1g MDI isocyanate, stir quickly until the temperature rises to 100°C, stop stirring, gel for 1.5min, and quickly pour into the mold 100°C aging reaction for 12 hours, then crushed, injection molded test pieces of different shapes, the injection molding temperature was 210°C, the injection molded test pieces were annealed in a 90°C oven for 12 hours, and then taken out and placed in a standard constant temperature and humidity laboratory (23°C, 50% humidity) After standing for 24 hours, cut out different shapes of specimens for testing and evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com