High-performance modified carboxylated nitrile rubber material and preparation method thereof

A high-performance technology of carboxylated nitrile rubber, which is applied in the field of high-performance modified carboxylated nitrile rubber materials and its preparation, can solve the problems of high cost and large amount of modified raw materials, and achieve high temperature oil resistance and low compression set performance , high comprehensive mechanical properties, no harm to the environment and human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

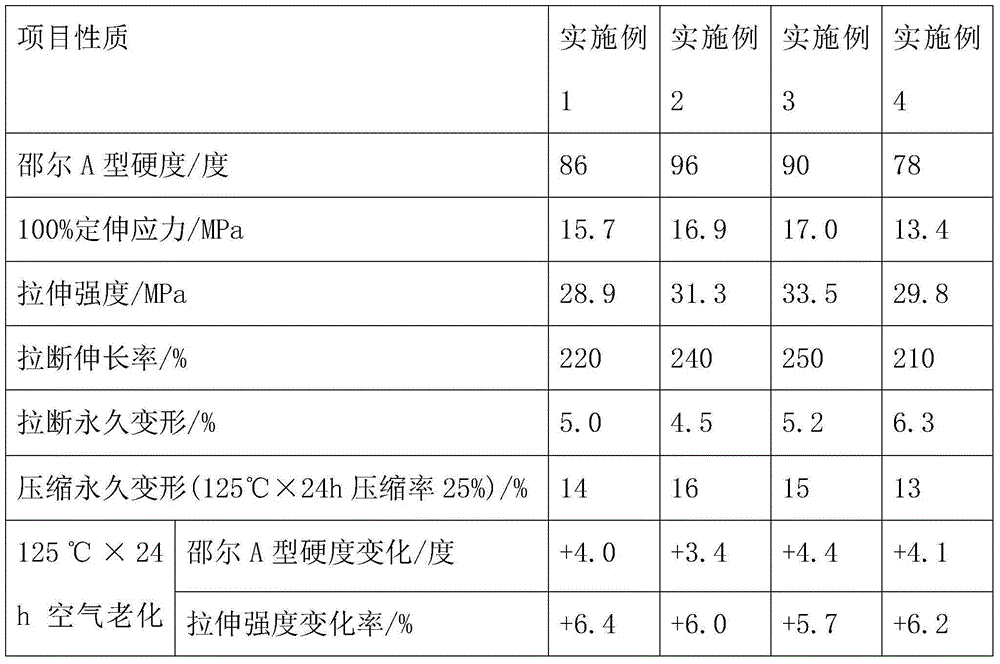

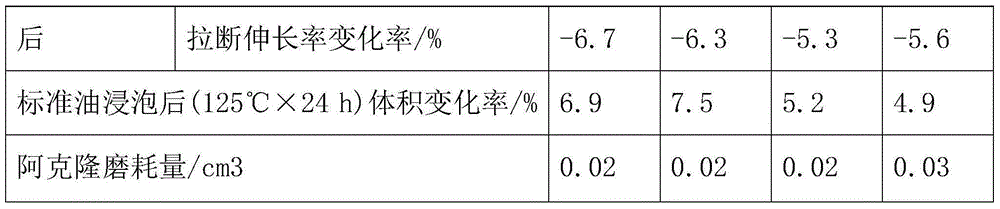

Examples

Embodiment 1

[0027] A high-performance modified carboxylated nitrile rubber material is characterized in that it comprises the following raw materials in parts by weight: 90 parts of modified carboxylated nitrile rubber, 30 parts of natural rubber, 20 parts of carbon black N-77420 parts, and 10 parts of carbon black N-99010 parts , 10 parts of antimony trioxide, 3 parts of zinc oxide, 3 parts of stearic acid, 1 part of sulfur, 3 parts of tetrabenzylthiuram disulfide, 1 part of N-tert-butyl-2-benzothiazole sulfenamide , 6 parts of dioctyl sebacate and 4 parts of auxiliary agent; Said auxiliary agent is made up of hexamethylenetetramine, magnesium oxide and lubricant that the mass proportion is 7:1:0.5;

[0028] The preparation of the modified carboxylated nitrile rubber includes: adding 55% butadiene, 34% acrylonitrile, 2.0% alkylbenzenesulfonate, 0.3% persulfate and propylbenzene to the vacuum reactor by weight percentage 0.01%, carry out free radical emulsion polymerization reaction in wa...

Embodiment 2

[0035] A high-performance modified carboxylated nitrile rubber material is characterized in that it comprises the following raw materials in parts by weight: 100 parts of modified carboxylated nitrile rubber, 25 parts of natural rubber, 30 parts of carbon black N-77430 parts, and 7 parts of carbon black N-9907 , 8 parts of antimony trioxide, 3.5 parts of zinc oxide, 2.5 parts of stearic acid, 1.5 parts of sulfur, 2 parts of tetrabenzylthiuram disulfide, 1.5 parts of N-tert-butyl-2-benzothiazole sulfenamide , 5 parts of dioctyl sebacate and 6 parts of auxiliary agent; Said auxiliary agent is made up of hexamethylenetetramine, magnesium oxide and lubricant that the mass proportion is 6:2:0.3;

[0036] The preparation of the modified carboxylated nitrile rubber comprises: adding 60% of butadiene, 30% of acrylonitrile, 2.5% of alkylbenzenesulfonate, 0.25% of persulfate and propylbenzene to the vacuum reactor by weight percentage 0.01%, carry out free radical emulsion polymerizatio...

Embodiment 3

[0043] A high-performance modified carboxylated nitrile rubber material is characterized in that it comprises the following raw materials in parts by weight: 120 parts of modified carboxylated nitrile rubber, 20 parts of natural rubber, 77427 parts of carbon black, 9908 parts of carbon black , 6 parts of antimony trioxide, 4 parts of zinc oxide, 2 parts of stearic acid, 2 parts of sulfur, 1.5 parts of tetrabenzylthiuram disulfide, 2 parts of N-tert-butyl-2-benzothiazole sulfenamide , 4 parts of dioctyl sebacate and 5 parts of auxiliary agent; Said auxiliary agent is made up of hexamethylenetetramine, magnesium oxide and lubricant that the mass proportion is 5.5:1.5:0.4;

[0044] The preparation of the modified carboxylated nitrile rubber comprises: adding 61% of butadiene, 26% of acrylonitrile, 2.75% of alkylbenzenesulfonate, 0.23% of persulfate and propylbenzene to the vacuum reactor by weight percentage 0.02%, carry out free radical emulsion polymerization reaction in water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com