Intermittent hot water circulation pressure stabilization insulation tyre vulcanization technology

A technology of hot water circulation and tire vulcanization, which is applied in the field of rubber manufacturing. It can solve the problems that the temperature is lower than the upper mold, the temperature difference even exceeds 10°C, affects the high speed and durability of the tire, and the quality of tire vulcanization is difficult to guarantee. Effects of over-curing phenomenon, reasonable optimization of vulcanization process conditions, and reduction of total vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

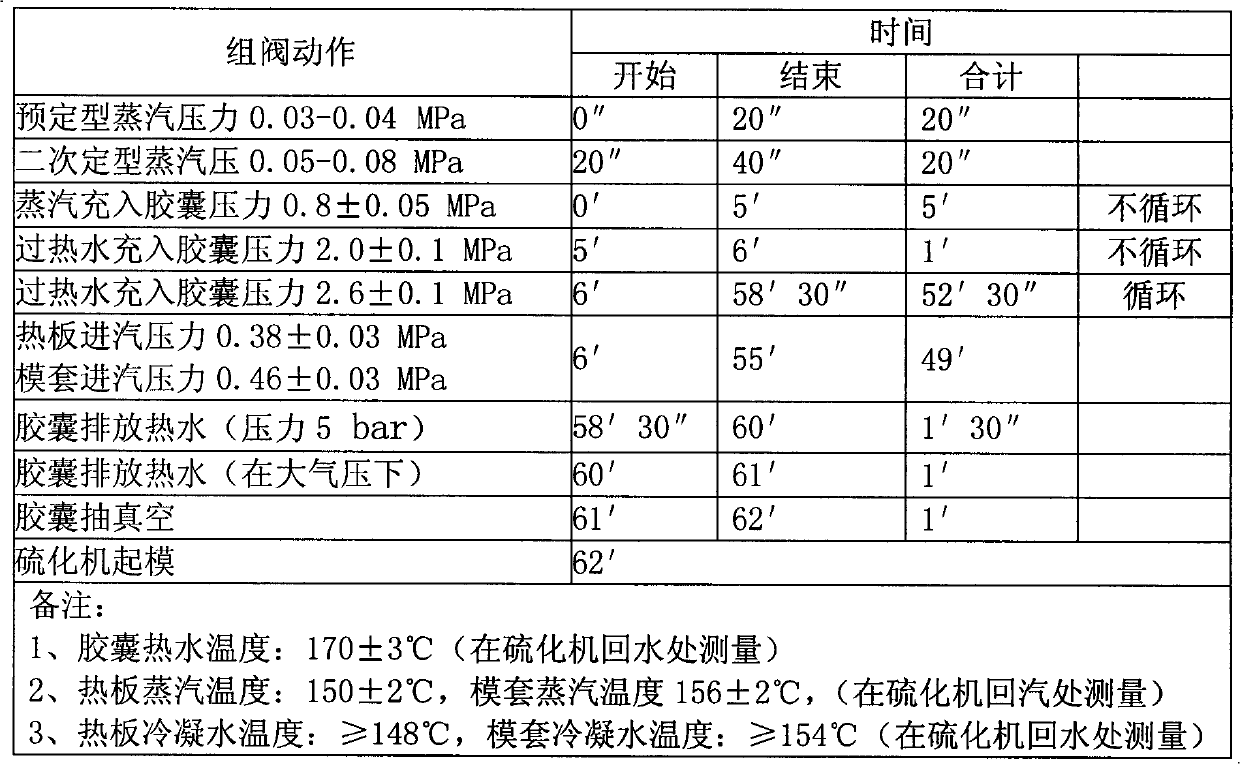

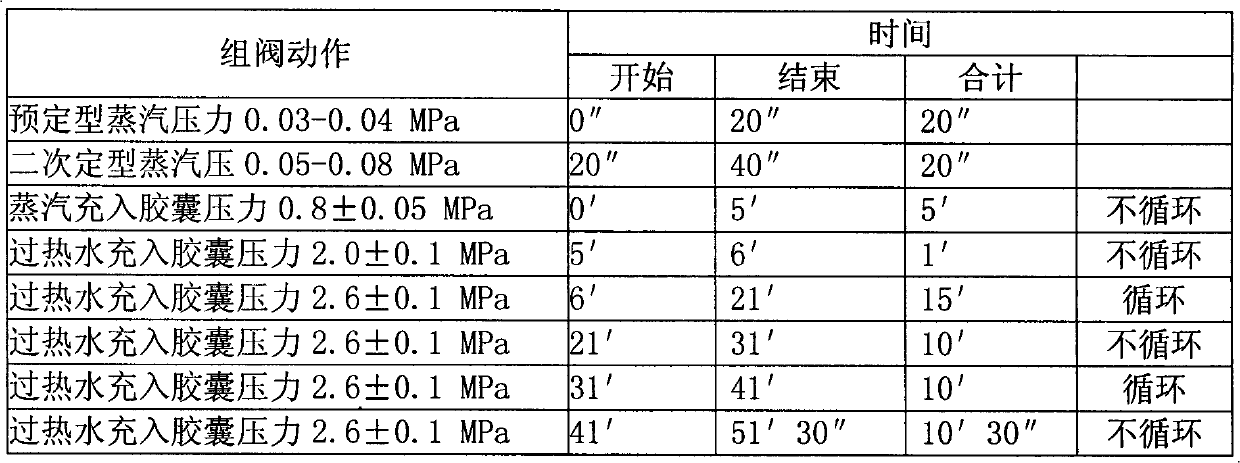

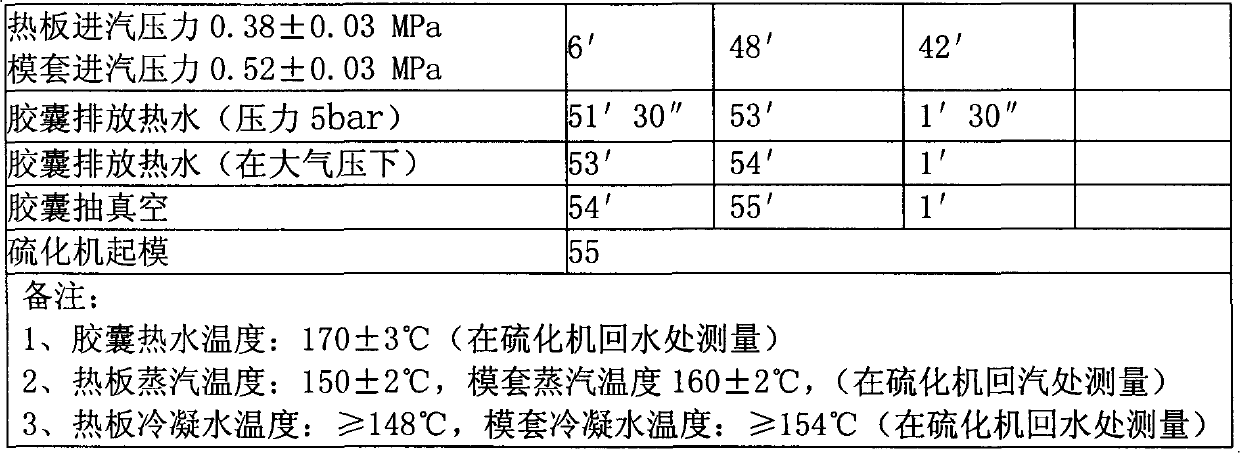

[0025] An embodiment, an intermittent hot water circulation, pressure-stabilized and heat-retaining tire vulcanization process, comprising the following steps: after the vulcanizer is closed, saturated superheated steam of 0.8 ± 0.03 MPa is injected for 5 minutes, so that the bladder is stretched rapidly and uniformly shaped;

[0026] Then inject 2.0±0.1MPa superheated water into it, keep it for 1min, quickly provide internal pressure, and make the tread rubber fill the pattern; the parts are dense to prevent pressure fluctuations, and make full use of steam heat at the same time;

[0027] The secondary superheated water is injected and circulated, the pressure is 2.6±0.1MPa, the temperature is 170±2℃, and the external pressure steam enters at the same time, the steam pressure of the side plate is 0.38±0.03MPa, the temperature is 150±2℃, and the steam pressure of the crown is 0.52±0.03MPa , the temperature is 160±2°C, heat the tire embryo, and start to vulcanize, the time is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com