Rubber composition, application to foam products and production method

A rubber composition and foaming agent technology, applied to rubber compositions, can solve the problems of decreased tensile strength and tear strength, difficulty in achieving vulcanization and foaming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

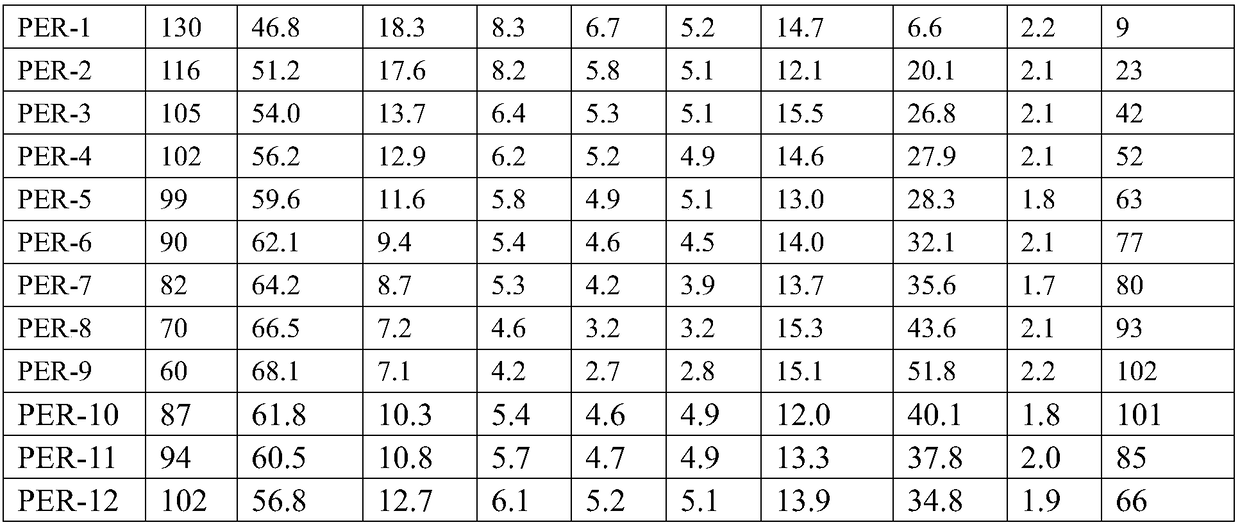

[0111] The number of branched polyethylene used is PER-9.

[0112] The processing steps of rubber composition are as follows:

[0113] (1) Rubber mixing: set the temperature of the internal mixer to 90°C, and the rotor speed to 50 rpm, add 90 parts of EPDM rubber and 10 parts of branched polyethylene for pre-compression mixing for 90 seconds; add 10 parts of oxidized Zinc and 2 parts of stearic acid, kneaded for 1 minute; then added 5 parts of calcium oxide and 2 parts of polyethylene glycol PEG4000, kneaded for 1 minute; then added 50 parts of carbon black N550, Mix 20 parts of carbon black N765, 50 parts of calcium carbonate and 70 parts of paraffin oil SUNPAR2280 for 4 minutes; finally add 3 parts of crosslinking agent dicumyl peroxide (DCP), 1 part of auxiliary crosslinking agent triallyl isocyanide Urate ester (TAIC), 20 parts of foaming agent azodicarbonamide (AC) and 2 parts of foaming agent urea, after mixing for 3 minutes, discharge glue. Thinly pass the mixed rubbe...

Embodiment 2

[0116] The branched polyethylene code used is PER-2.

[0117] The processing steps of rubber composition are as follows:

[0118] (1) Rubber mixing: set the temperature of the internal mixer to 90°C, the rotor speed to 50 rpm, add 20 parts of binary ethylene propylene rubber, 50 parts of EPDM rubber and 30 parts of branched polyethylene for pre-compression mixing Refining for 90 seconds; adding 10 parts of zinc oxide and 2 parts of stearic acid, kneading for 1 minute; then adding 5 parts of calcium oxide and 2 parts of polyethylene glycol PEG4000, kneading for 1 minute; Add 75 parts of carbon black N550, 50 parts of carbon black N765, 75 parts of calcium carbonate and 90 parts of paraffin oil SUNPAR2280 and mix for 4 minutes; finally add 6 parts of cross-linking agent dicumyl peroxide (DCP), 2 parts of cross-linking agent Linking agent triallyl isocyanurate (TAIC), 8 parts of co-crosslinking agent liquid 1,2-polybutadiene, 20 parts of blowing agent azodicarbonamide (AC) and 2...

Embodiment 3

[0121] The number of branched polyethylene used is PER-5.

[0122] The processing steps of rubber composition are as follows:

[0123] (1) Rubber mixing: set the temperature of the internal mixer to 90°C, and the rotor speed to 50 rpm, add 50 parts of EPDM rubber and 50 parts of branched polyethylene for pre-compression mixing for 90 seconds; add 10 parts of oxidized Zinc and 2 parts of stearic acid, kneaded for 1 minute; then added 5 parts of calcium oxide and 2 parts of polyethylene glycol PEG4000, kneaded for 1 minute; then added 75 parts of carbon black N550, Mix 50 parts of carbon black N765, 75 parts of calcium carbonate and 70 parts of paraffin oil SUNPAR2280 for 4 minutes; finally add 3 parts of crosslinking agent dicumyl peroxide (DCP), 1 part of auxiliary crosslinking agent triallyl isocyanide Urate ester (TAIC), 22 parts of foaming agent azodicarbonamide (AC) and 3 parts of foaming agent urea, after mixing for 3 minutes, discharge the rubber, and put the mixed rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| compression set | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com