FAM-B-methanol-gasoline-resistant low-temperature-resistant low-compressive-deformation ethylene-acrylate rubber material and preparation method thereof

A technology for changing ethylene acrylate and methanol gasoline is used in the field of environmentally friendly ethylene acrylate rubber materials for automotive engine thermostats, which can solve problems such as poor performance and achieve low compression set, small swelling, and excellent resistance to FAMB methanol gasoline. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

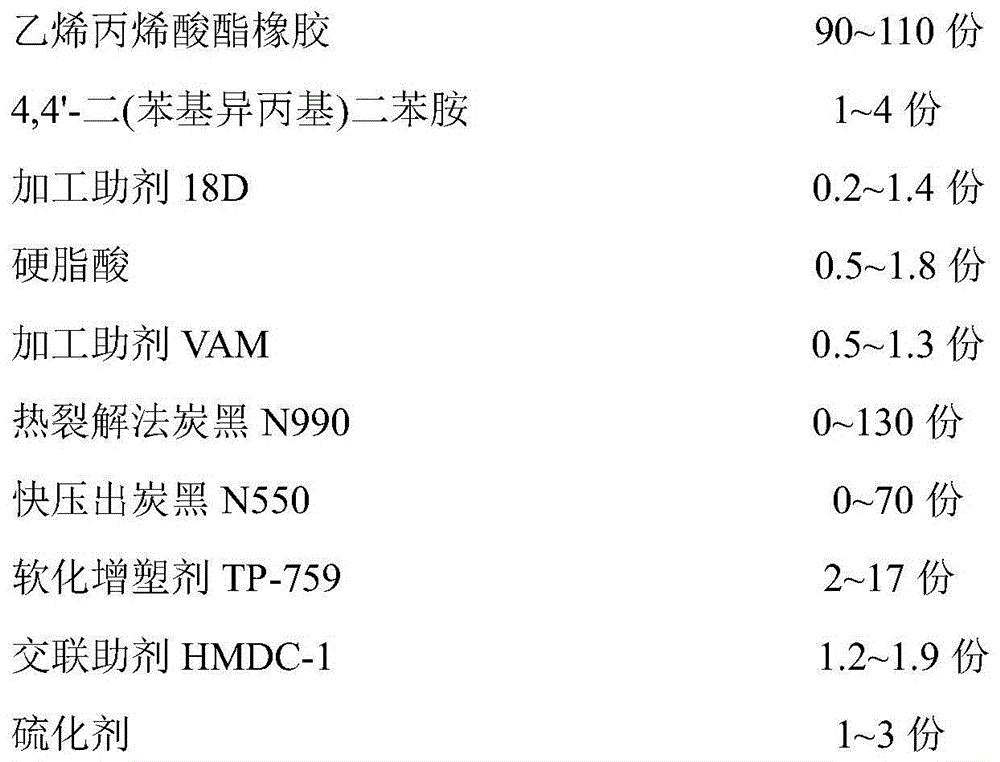

[0028] A kind of resistance to FAM B methanol gasoline of the present embodiment, the low-pressure variable ethylene acrylate rubber material of low temperature resistance, comprises following component:

[0029]

[0030] Acrylate raw rubber in this embodiment is ethylene acrylate rubber produced by DuPont, the U.S., and the quick-extrusion carbon black is N550 quick-extrusion carbon black produced by Cabot Company; the thermal cracking carbon black is Maple Leaf brand N990 produced in Canada Carbon black; stearic acid was produced by Malaysia Southern Oil Company; 4,4'bis(phenylisopropyl)diphenylamine was anti-aging agent 445 (CAS No.: 10081-67-1) produced by Jiangsu Huada Chemical Group Co., Ltd. ); processing aid VAM (CAS No.: 63231-60-7), processing aid 18D (CAS No.: 124-30-1), softening plasticizer TP-795 (CAS No.: 141-17-3), Cross-linking aid HMDC-1 (CAS No.: 143-06-6) and vulcanizing agent 1,8-diazabicyclo[5.4.0]undec-7-ene (CAS No.: 6674-22-2) The suppliers are Sha...

Embodiment 2

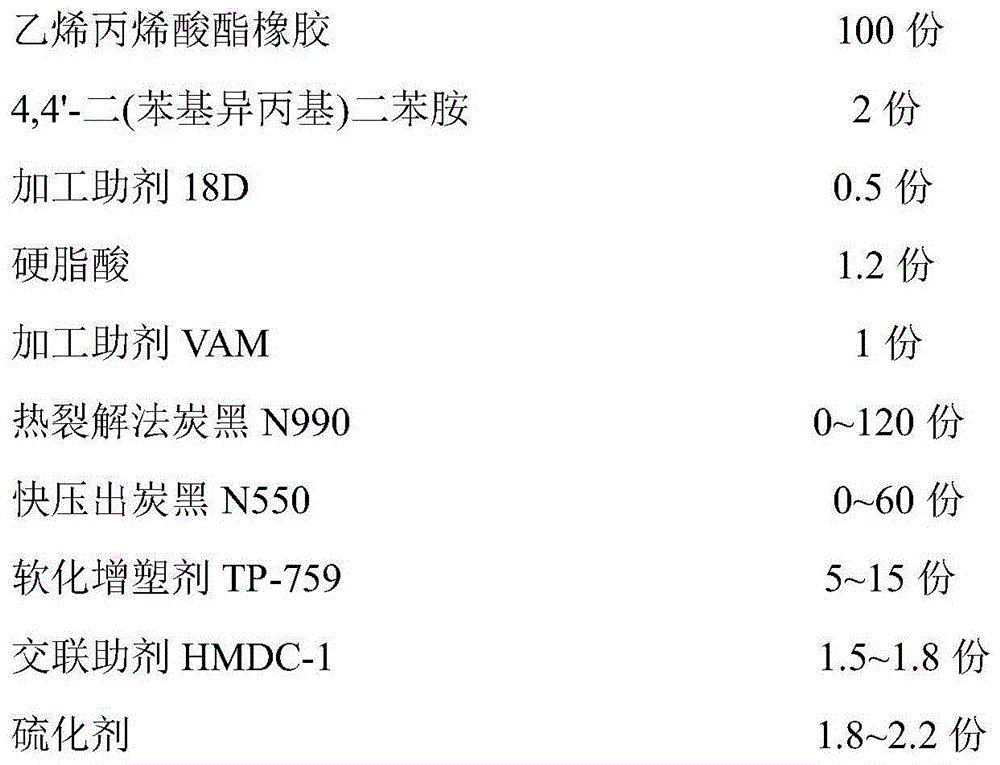

[0043] A kind of resistance to FAM B methanol gasoline of the present embodiment, the low-pressure variable ethylene acrylate rubber material of low temperature resistance, comprises following component:

[0044]

[0045] The source of each component raw material of this embodiment is the same as that of Example 1.

[0046] The process of preparing the low-pressure variable ethylene acrylate rubber material resistant to FAM B methanol gasoline and low temperature resistance in this embodiment is as follows:

[0047] Step 1. Masterbatch mixing: send the raw materials except crosslinking aid HMDC-1 and vulcanizing agent 1,8-diazabicyclo[5.4.0]undec-7-ene to Put it into the internal mixer for internal mixing to obtain the masterbatch;

[0048] Step 2. Put the masterbatch that has been parked for 8 hours, the crosslinking aid HMDC-1, and the vulcanizing agent 1,8-diazabicyclo[5.4.0]undec-7-ene into the internal mixer together Carry out two-stage mixing, and discharge the glue...

Embodiment 3

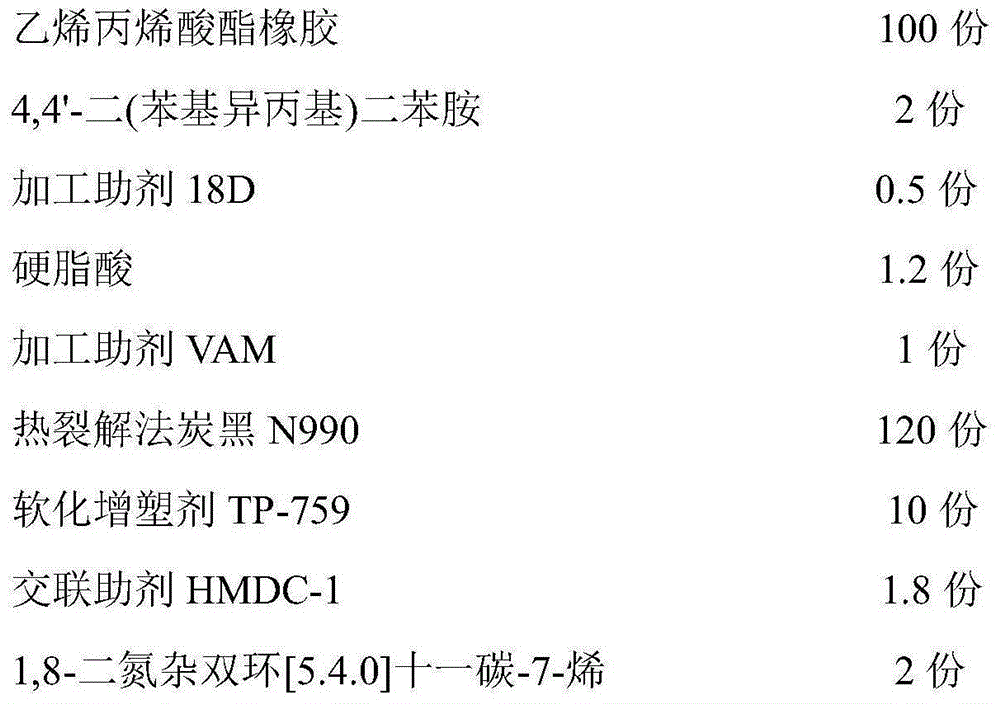

[0057] A kind of resistance to FAM B methanol gasoline of the present embodiment, the low-pressure variable ethylene acrylate rubber material of low temperature resistance, comprises following component:

[0058]

[0059]

[0060] The source of each component raw material of this embodiment is identical with embodiment 1.

[0061] The process of preparing the low-pressure variable ethylene acrylate rubber material resistant to FAM B methanol gasoline and low temperature resistance in this embodiment is as follows:

[0062] Step 1. Masterbatch mixing: send the raw materials except crosslinking aid HMDC-1 and vulcanizing agent 1,8-diazabicyclo[5.4.0]undec-7-ene to Put it into an internal mixer for internal mixing to obtain a masterbatch.

[0063] Step 2. Put the masterbatch that has been parked for 8 hours, the crosslinking aid HMDC-1, and the vulcanizing agent 1,8-diazabicyclo[5.4.0]undec-7-ene into the internal mixer together Carry out two-stage mixing, and discharge t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com