Warm mixed flame retardant asphalt, mixture containing warm mixed flame retardant asphalt and their preparation methods

An asphalt mixture and warm mix technology, which is applied in building thermal insulation materials, building components, climate change adaptation, etc., can solve the problems of high cost, affecting the anti-rutting performance of asphalt mixture, and volatile.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

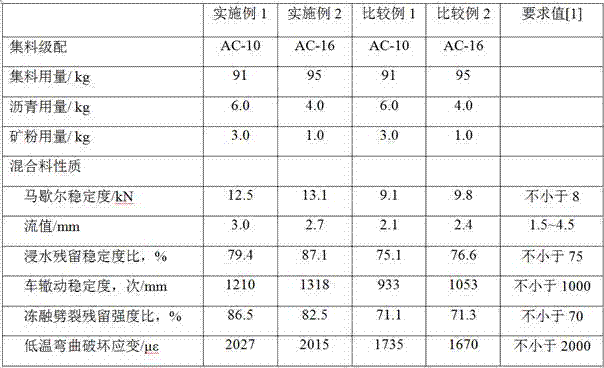

Examples

Embodiment 1

[0068] It is divided into three steps: (A) preparation of warm mix agent, (B) preparation of warm mix flame retardant asphalt, (C) preparation of warm mix flame retardant asphalt mixture.

[0069] (A) Preparation of warm mixing agent

[0070] Including (1) hydrogenation conversion and (2) sweating.

[0071] (1) Hydrogenation conversion

[0072] The wax oil product (n-paraffin content of 95.5wt%; drop melting point of 86.2°C; penetration degree (25°C) 55 dmm) from the low-temperature FT synthesis experimental device of China Petroleum and Chemical Corporation is used as raw material, and the FHJ-2 catalyst ( A Ni / Al 2 O 3 Commercial catalyst, developed and produced by Fushun Petrochemical Research Institute. The active metal content is 40% based on oxide. The catalyst is subjected to conventional reduction treatment before use) under the action of reaction pressure of 6.5MPa, reaction temperature of 220°C, and volumetric space velocity of 1.0h -1 Hydrogenation is carried out at a volu...

Embodiment 2

[0095] It is divided into three steps: (A) preparation of warm mix agent, (B) preparation of warm mix flame retardant asphalt, (C) preparation of warm mix flame retardant asphalt mixture.

[0096] (A) Preparation of warm mixing agent

[0097] This embodiment includes: (1) Hydrogenation conversion and (2) Sweating.

[0098] (1) Hydrogenation conversion

[0099] The wax oil product (normal paraffin content 90.0wt%; drop melting point 82.6°C; penetration degree (25°C) 62dmm) from the low-temperature FT synthesis experimental device of China Petroleum and Chemical Corporation is used as raw material, and the catalyst (Mo-Ni / Al 2 O 3 , The active metal content as oxide is 20%) under the action of reaction pressure 3.0MPa, reaction temperature 300℃, volumetric space velocity 2.0h -1 Hydrogenation is carried out at a volume ratio of 100:1 to hydrogen liquid to convert olefins and oxygen-containing compounds.

[0100] Hydrogenation product properties: weight content of normal alkanes 93.3%; d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com