Combined type 1-KV level transformer bushing

A transformer bushing and combined technology, applied in the direction of transformer/inductor coil/winding/connection, insulator, etc., can solve the problems of unsatisfactory sealing effect, reduce manufacturing cost, high manufacturing cost, etc., achieve compact structure and improve reliability , Easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

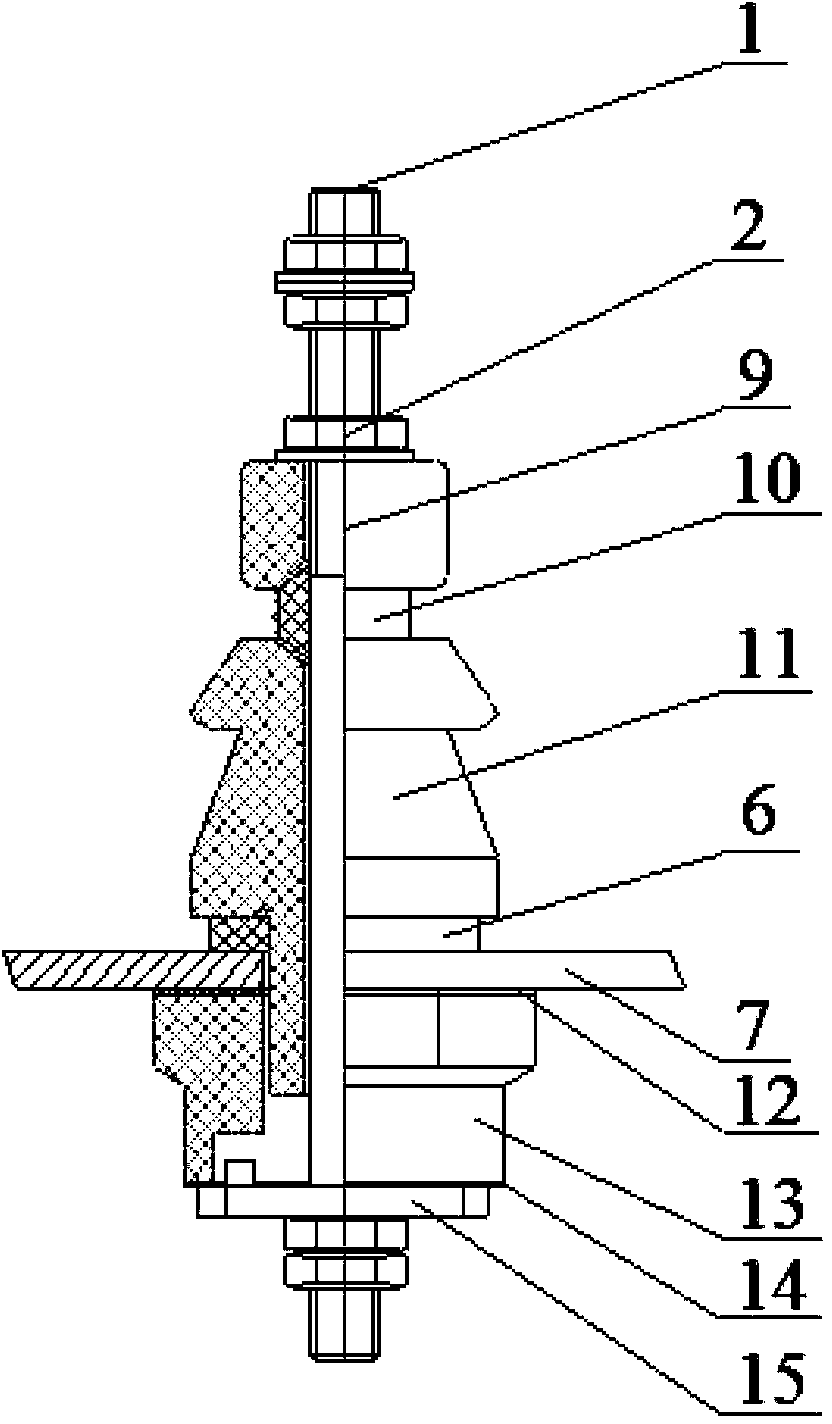

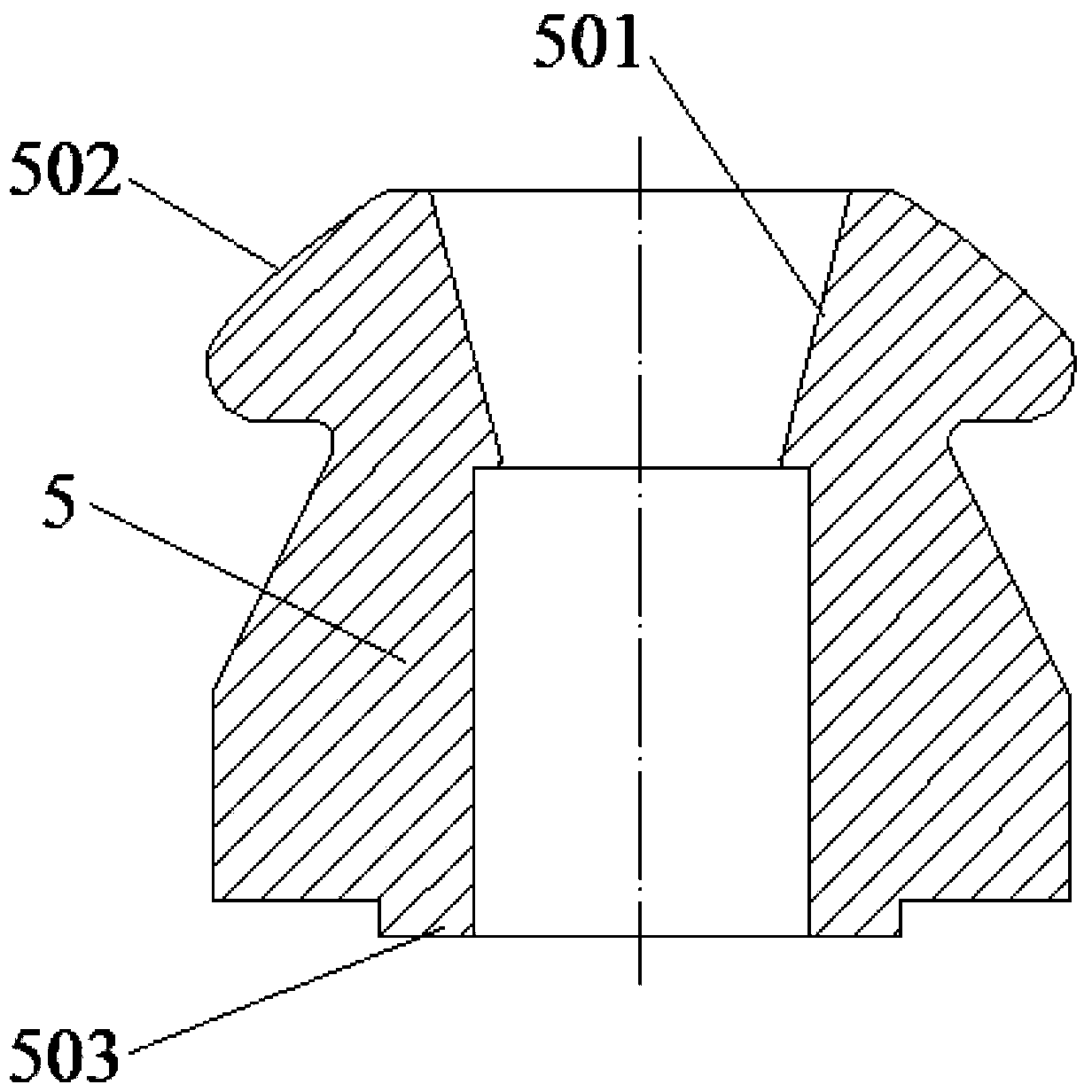

[0034] combine figure 1 , a combined 1KV transformer bushing of this embodiment, including a conductive rod 1, a nut 2, a metal gland 3, a wedge-shaped sealing bead 4, a porcelain sleeve 5, a flat sealing washer 6 and a base 8, and the conductive rod 1 One end has an external thread, which is used to connect the wire with the nut, and the other end is a flat terminal 101. The flat terminal 101 is provided with a connection hole 102. The flat terminal 101 is located in the transformer, which improves the connection reliability in the transformer. , and easy to install and operate. Such as Figure 4As shown, the base 8 is an insulating cast body, and the base 8 is combined with the end of the conductive rod 1 close to the flat terminal 101 to form an integrated structure. The base 8 includes a bearing part and a connecting part. The bearing part and the connecting part are perpendicular to each other. The bearing part is used for The supporting ceramic sleeve 5, sealing flat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com