Conveyer belt with high abrasion resistance

A conveyor belt, high wear-resistant technology, applied in the field of conveyor belts, can solve the problems of reducing the impact and wear strength of the covering rubber layer, the overall toughness and tear resistance, and the impact on the life of the conveyor belt, so as to avoid loss of belt core, Improve dispersion and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

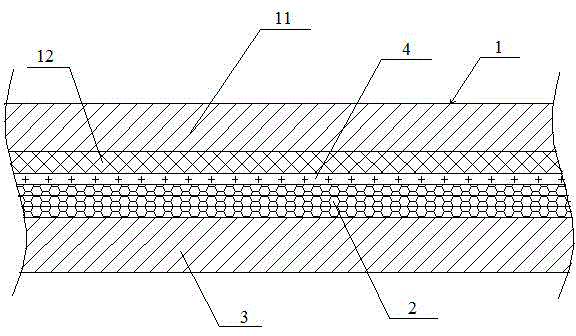

[0034] Such as figure 1Shown, a kind of high wear-resisting conveyer belt comprises upper cover adhesive layer 1, belt core (canvas) 2 and lower cover adhesive layer 3, and described upper cover adhesive layer 1 is made of anti-cut adhesive layer (thickness 3mm) 11 and resistant The wear-resistant rubber layer (thickness 3mm) 12 is composed of a tear-resistant skeleton layer 4 between the wear-resistant rubber layer 12 and the belt core 2 . The tear-resistant skeleton layer is composed of two layers of steel mesh with a thickness of about 2mm. The specification of the steel mesh is: the diameter of the steel wire is 1mm, and the mesh size of the steel mesh is 10mm×10mm. The lower cover adhesive layer 3 material is the same as the wear-resistant adhesive layer.

[0035] The material formulation of the anti-cut adhesive layer is as follows in parts by weight:

[0036] 85 parts of smoked sheet rubber, 35 parts of butadiene rubber (butadiene rubber br9000, commercially available...

Embodiment 2

[0044] Such as figure 1 Shown, a kind of high wear-resisting conveyer belt comprises upper cover adhesive layer 1, belt core (canvas) 2 and lower cover adhesive layer 3, and described upper cover adhesive layer 1 is made of anti-cut adhesive layer (thickness 3mm) 11 and resistant The wear-resistant rubber layer (thickness 6mm) 12 is composed of a tear-resistant skeleton layer 4 between the wear-resistant rubber layer 12 and the belt core 2 . The tear-resistant skeleton layer is composed of two layers of steel mesh with a thickness of about 2mm. The specification of the steel mesh is: the diameter of the steel wire is 1mm, and the mesh size of the steel mesh is 10mm×10mm. The lower cover adhesive layer 3 material is the same as the wear-resistant adhesive layer.

[0045] The material formulation of the anti-cut adhesive layer is as follows in parts by weight:

[0046] 95 parts of smoked sheet rubber, 25 parts of butadiene rubber, 50 parts of carbon black N110 (commercially av...

Embodiment 3

[0053] Such as figure 1 Shown, a kind of high wear-resisting conveyer belt comprises upper cover adhesive layer 1, belt core (canvas) 2 and lower cover adhesive layer 3, and described upper cover adhesive layer 1 is made of anti-cut adhesive layer (thickness 3mm) 11 and resistant The wear-resistant rubber layer (thickness 5mm) 12 is composed of a tear-resistant skeleton layer 4 between the wear-resistant rubber layer 12 and the belt core 2 . The tear-resistant skeleton layer is composed of two layers of steel mesh with a thickness of about 2mm. The specification of the steel mesh is: the diameter of the steel wire is 1mm, and the mesh size of the steel mesh is 10mm×10mm. The lower cover adhesive layer 3 material is the same as the wear-resistant adhesive layer.

[0054] The material formulation of the anti-cut adhesive layer is as follows in parts by weight:

[0055] 90 parts of smoked sheet rubber, 30 parts of butadiene rubber (butadiene rubber br9000, commercially availabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com