Modified asphalt waterproof coiled material and method for preparing same

A technology of modified asphalt and waterproof membrane, which is applied in the direction of asphalt layered products, chemical instruments and methods, building components, etc. Handling and other issues, to achieve the effect of reducing thermal aging, good heat insulation effect, and easy maintenance in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

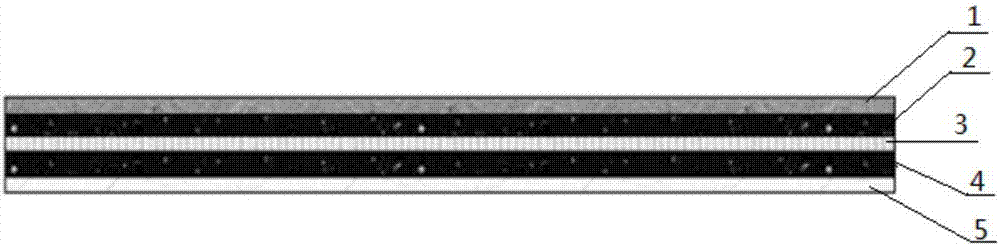

[0042] The present invention also provides a method for preparing the modified asphalt waterproof coiled material, the method comprising: applying the corresponding modified asphalt base material and isolation material sequentially on the upper surface and the lower surface of the reinforcement layer respectively, cooling and shaping, collecting rolls to form the modified bitumen waterproofing membrane.

[0043] In the present invention, "corresponding" refers to the modification of the first modified asphalt base material layer 2, the overlying surface isolation layer 1, the second modified asphalt base material layer 4, and the lower overlying surface isolation layer 2 respectively. Asphalt base material, isolation material. In addition, the modified asphalt base material and isolation materials used are as mentioned above, and will not be repeated here.

Embodiment approach

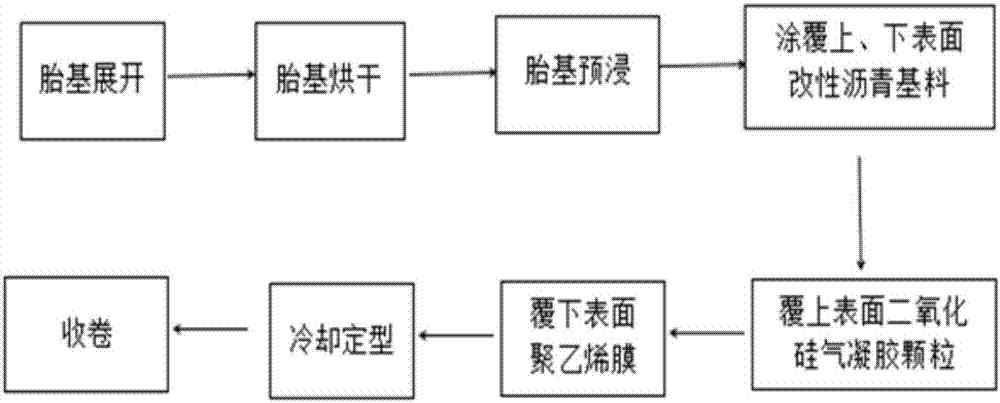

[0044] According to one embodiment, the lower covering insulation layer 5 is a polyethylene film as an example, such as figure 2 As shown, the preparation process of the modified waterproof asphalt membrane may include: unfolding, drying, and pre-impregnating the base (i.e., the reinforcement) in sequence, and then coating the modified base on the upper and lower surfaces of the base. Asphalt base material, finally on the surface of the upper modified asphalt base material (corresponding to the first modified asphalt base material layer 2) covered with aerogel particles, modified asphalt base material below (corresponding to the second modified asphalt base material layer 2) The surface of the material layer 4) is covered with a polyethylene film, then cooled and shaped, and rolled to obtain the modified asphalt waterproof coiled material.

[0045] Specifically, the upper surface isolation layer 1 is formed by spreading silica airgel particles on the first modified asphalt ba...

Embodiment 1

[0048] 1) Preparation of elastomer modified asphalt base material

[0049] Heat 6000kg 90# petroleum asphalt to 180-185°C, add 1400kg SBS803, heat up to 185-195°C, start the colloid mill, homogenize for 1.5h, then add 2600kg talcum powder, keep the temperature at 180-190°C and stir for 50min, It is standby to make elastomer II type modified asphalt base material (i.e. SBSII type modified asphalt base material);

[0050] 2) Preparation of modified asphalt waterproof membrane

[0051] With the glass fiber reinforced polyester tire as the reinforcing body, the above-mentioned SBSII modified asphalt base material is evenly coated on the upper and lower surfaces of the reinforcing body. / cm 3 Silica airgel (85% porosity, 10-20 mesh, thermal conductivity 0.013w / m·K) is evenly spread on the SBSII modified asphalt base material on the upper surface, and the thickness of the spread is 2.0mm, through the extrusion of the extrusion roller, the unbonded particles are removed to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com