High-power transmission power cable

A technology for transmitting power and high power, applied in power cables, insulated cables, flexible cables, etc., can solve the problems of large cable loss and poor heat dissipation, and achieve the effect of slowing down thermal aging, reducing size, and increasing flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

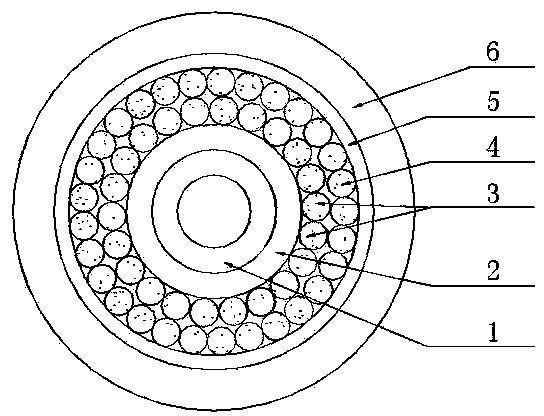

[0013] Such as figure 1 As shown, a high-power transmission power cable according to the present invention includes a combined water pipe layer from the inside to the outside, a thin copper wire harness layer 4 outside the combined water pipe layer, and a thin copper wire harness layer 4 is wrapped with an isolation layer 5 , the outermost extruded rubber layer 6; a pair of control lines 3 are also arranged in the fine copper wire harness layer 4, and the control lines 3 are close to the combined water pipe layer; the combined water pipe layer is cooled by The water pipe 1 and the cold pipe sealing layer 2 wrapped outside the cooling water pipe 1 are composed.

[0014] The above-mentioned cooling water pipe 1 adopts a metal spring pipe; the sealing layer 2 of the cold pipe is made of wear-resistant semi-conductive cross-linked polyethylene, and the insulation of the control line pair 3 is made of cross-linked polyethylene insulation, silicone rubber insulation or fluoroplastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com