Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Reduce the amount of scrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

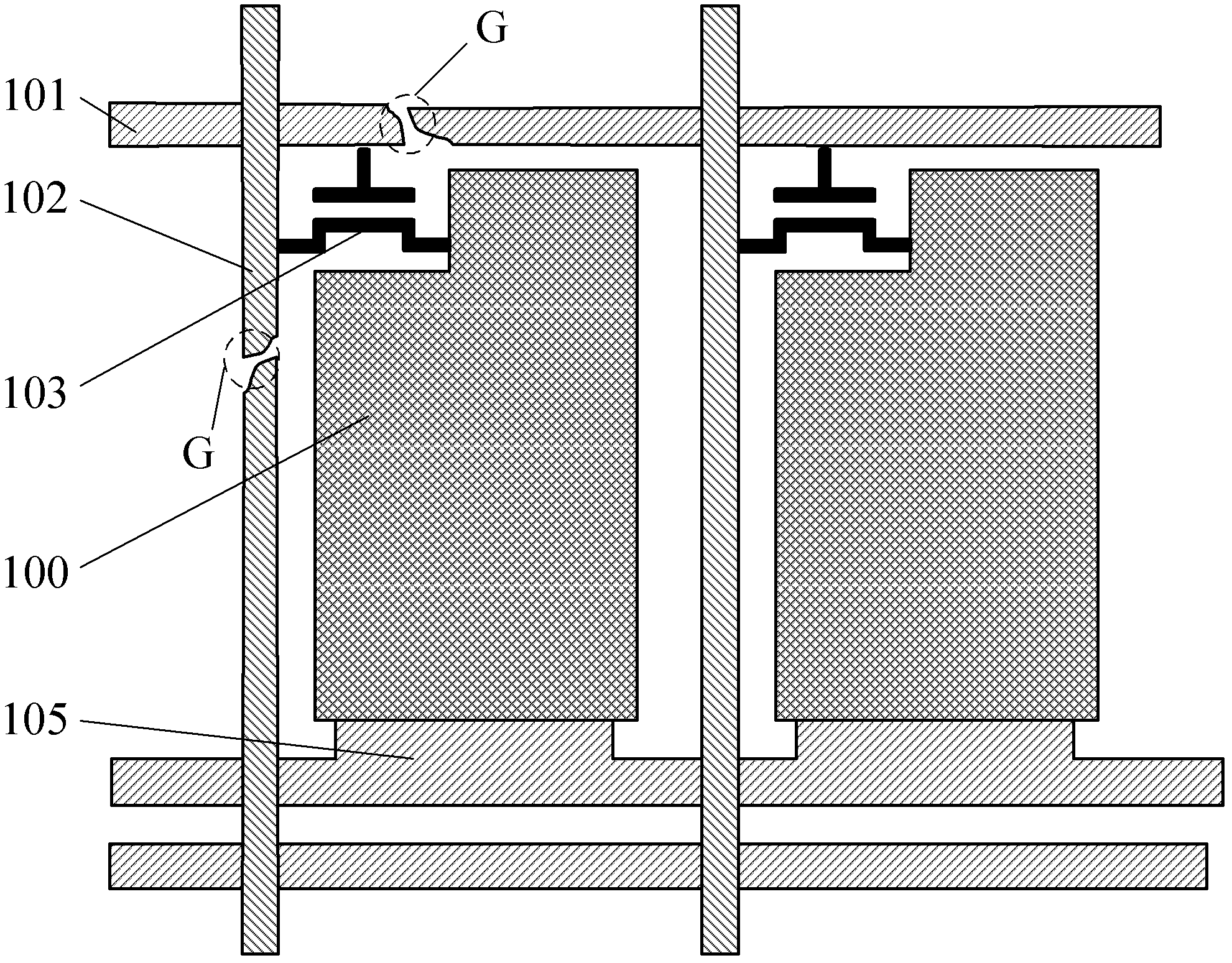

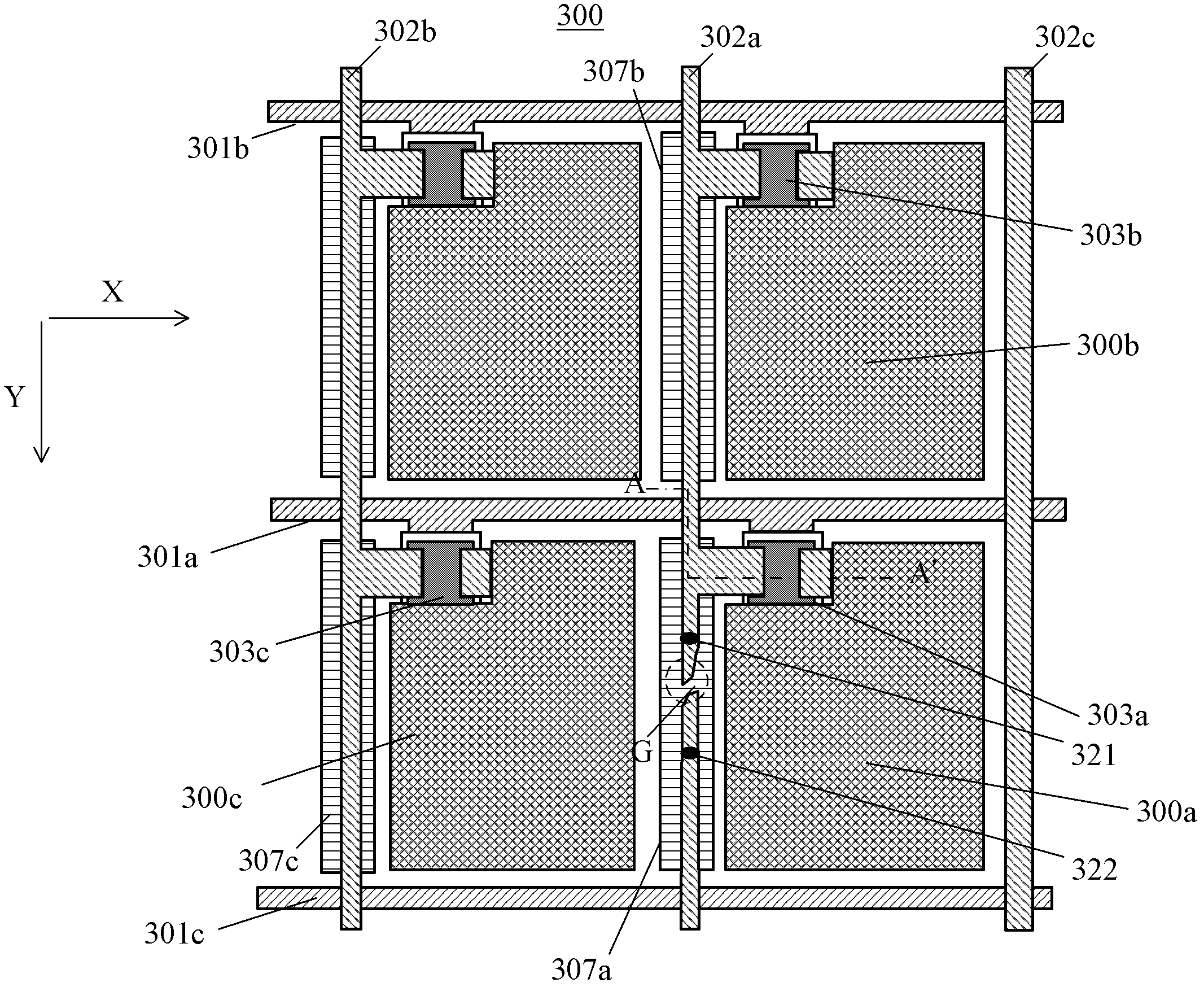

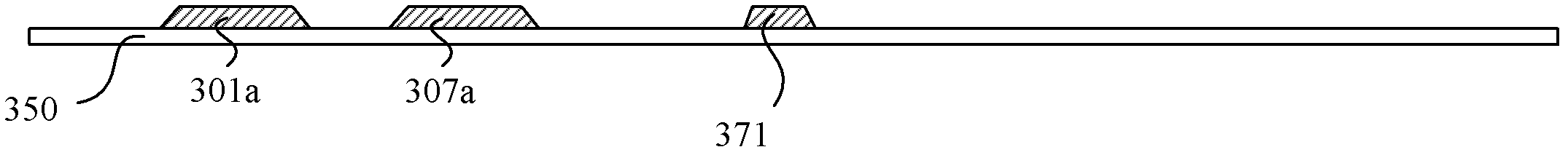

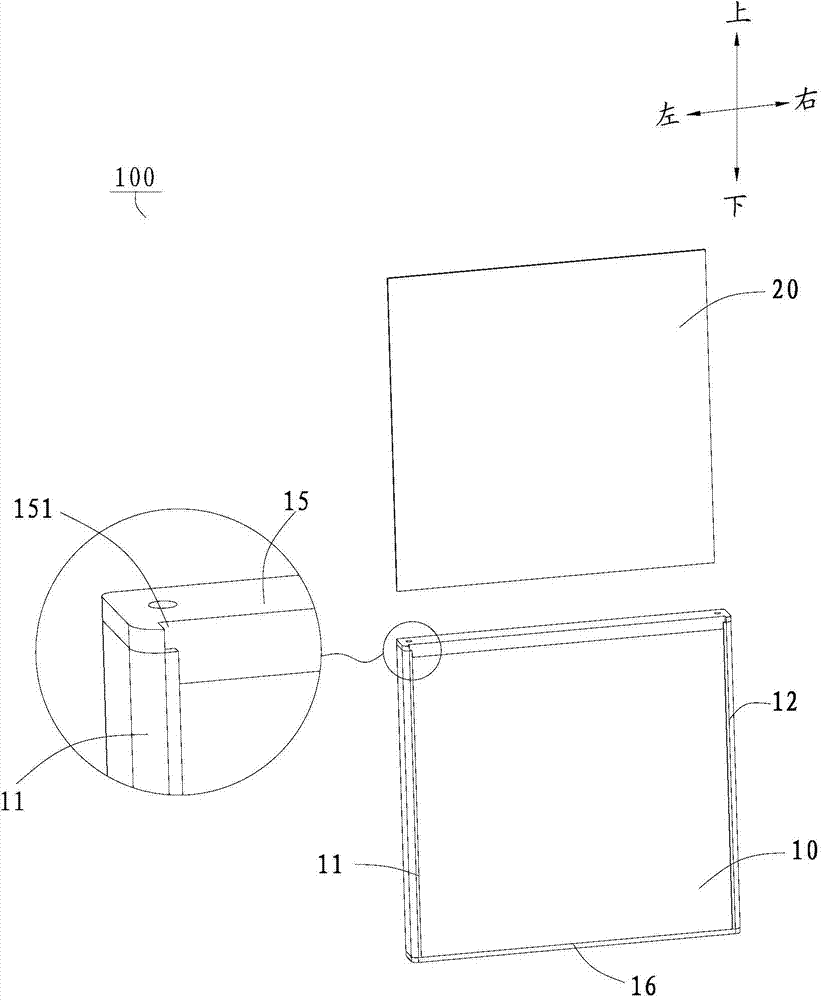

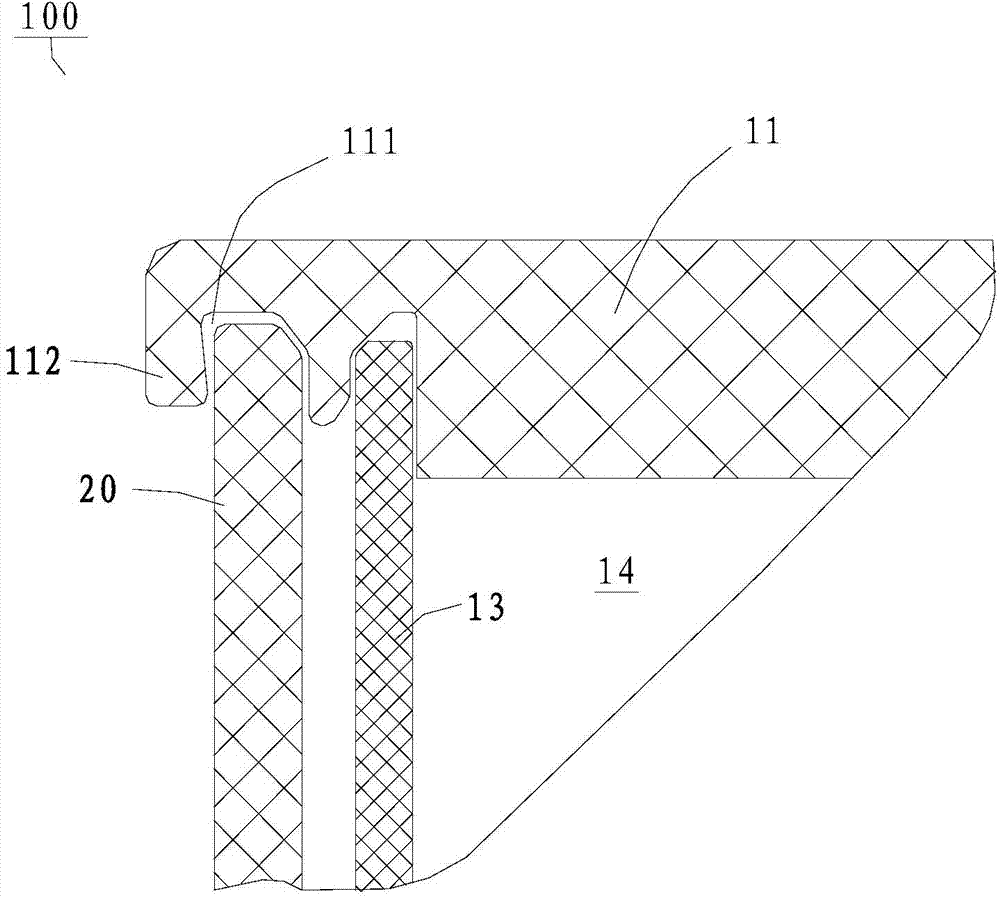

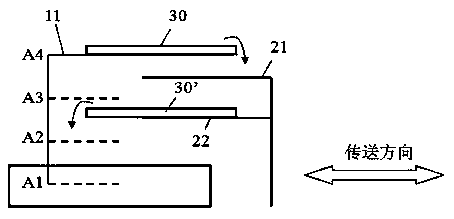

Flat display panel and repair method thereof

The invention discloses a flat display panel and a repair method thereof. The flat display panel comprises a plurality of repair lines parallel to data lines. The repair lines are disposed on one sides of pixel electrodes in a paired manner. When one of the data lines is broken, an electric route can be formed by the aid of the corresponding repair line, so that signals can be transmitted to the corresponding pixel electrodes via the electric route instead of the disconnection position of the broken data line.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

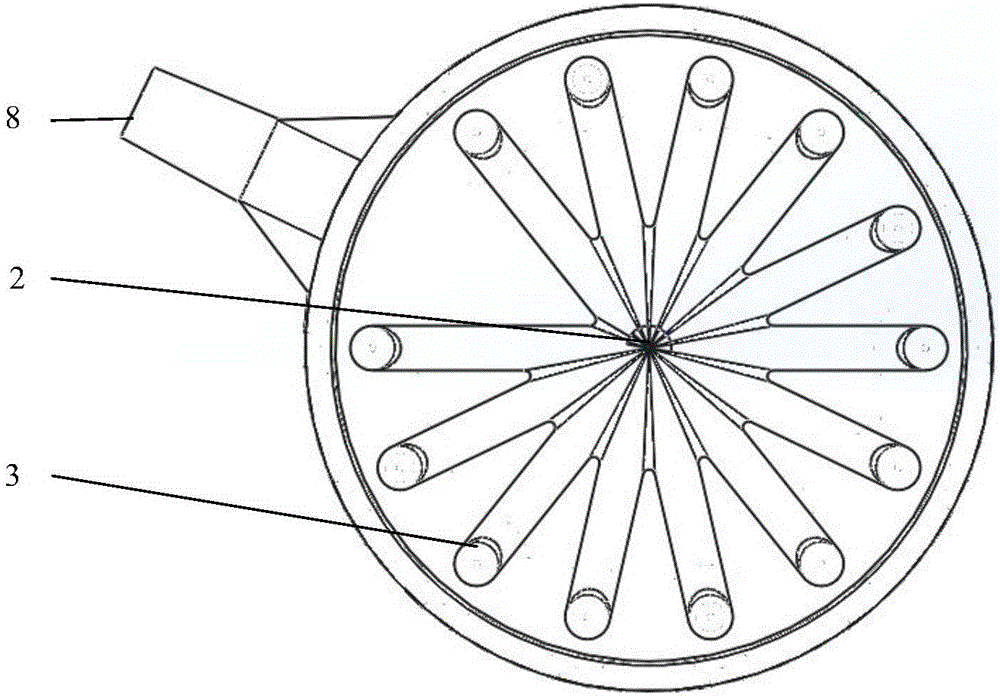

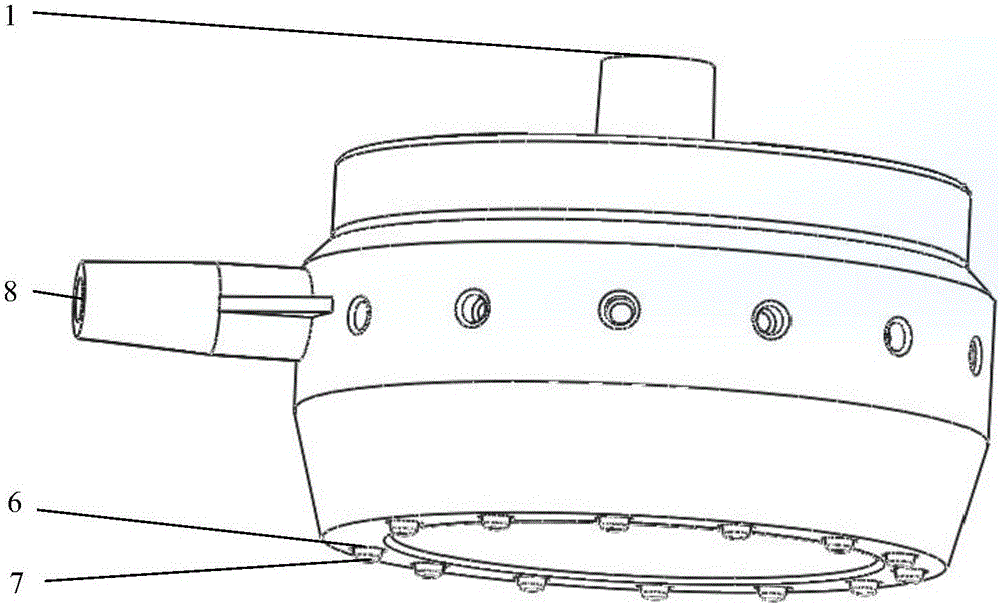

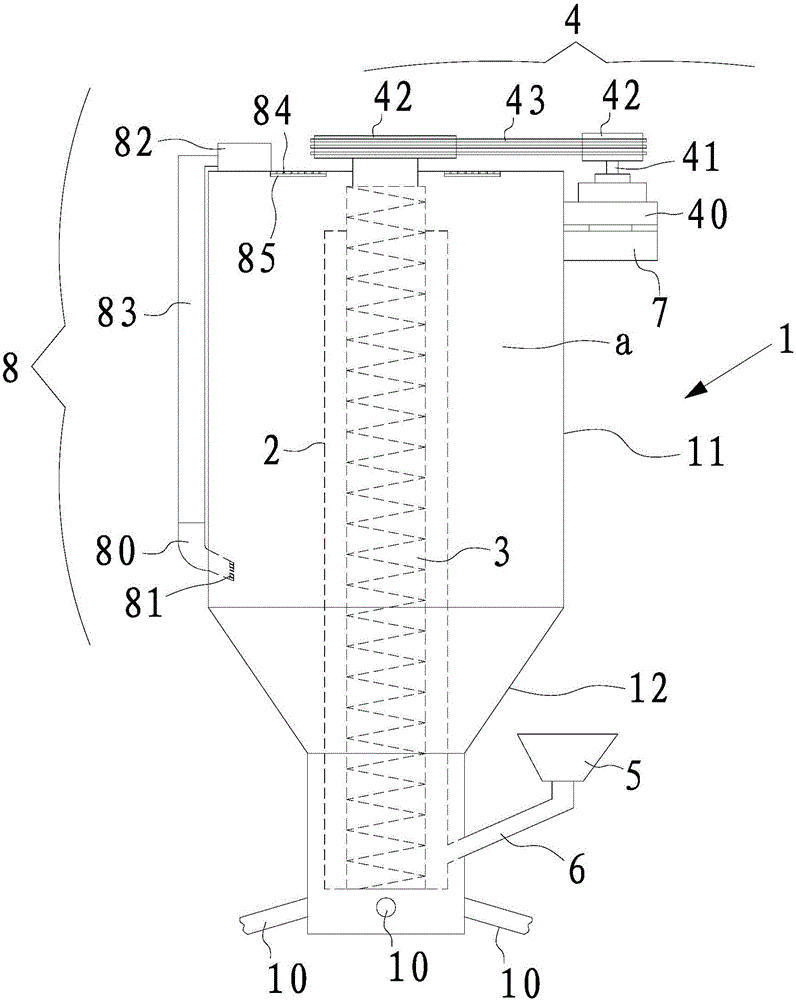

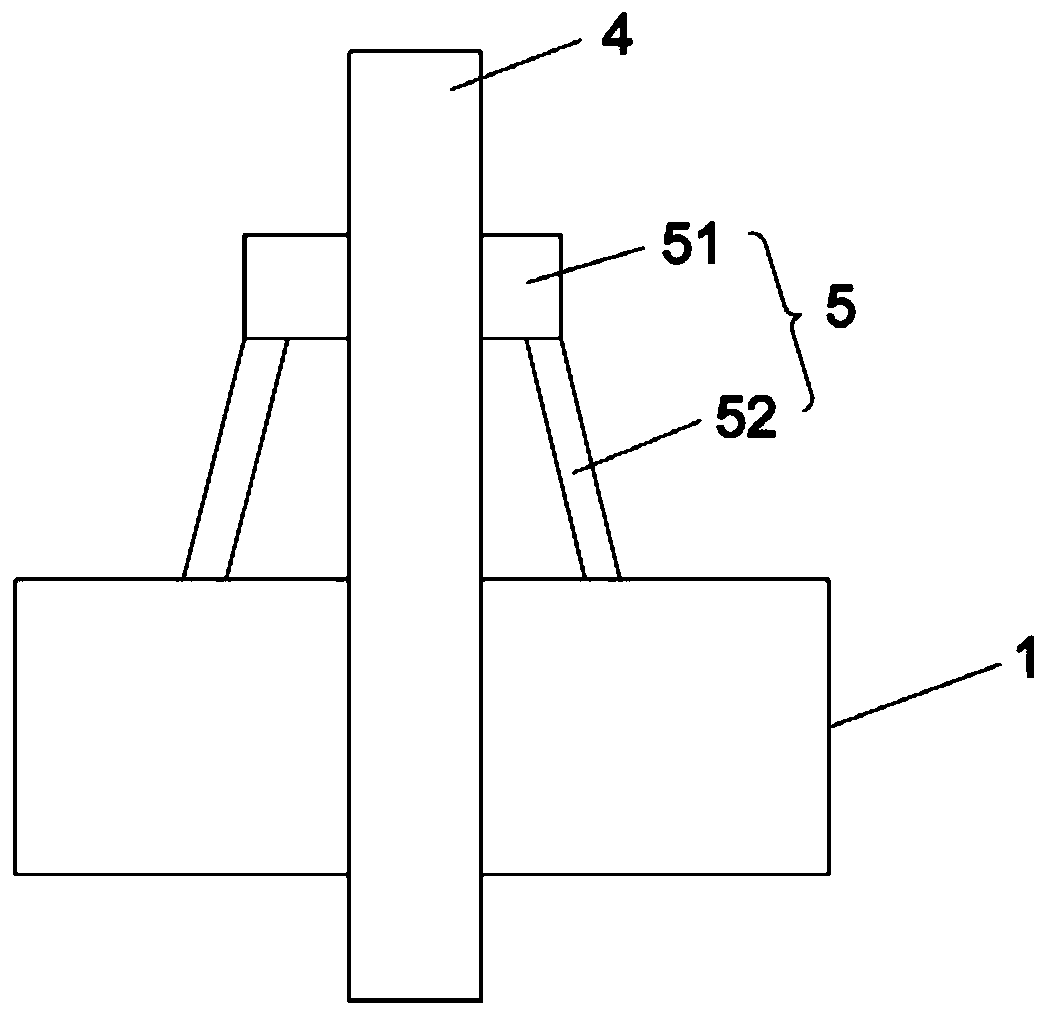

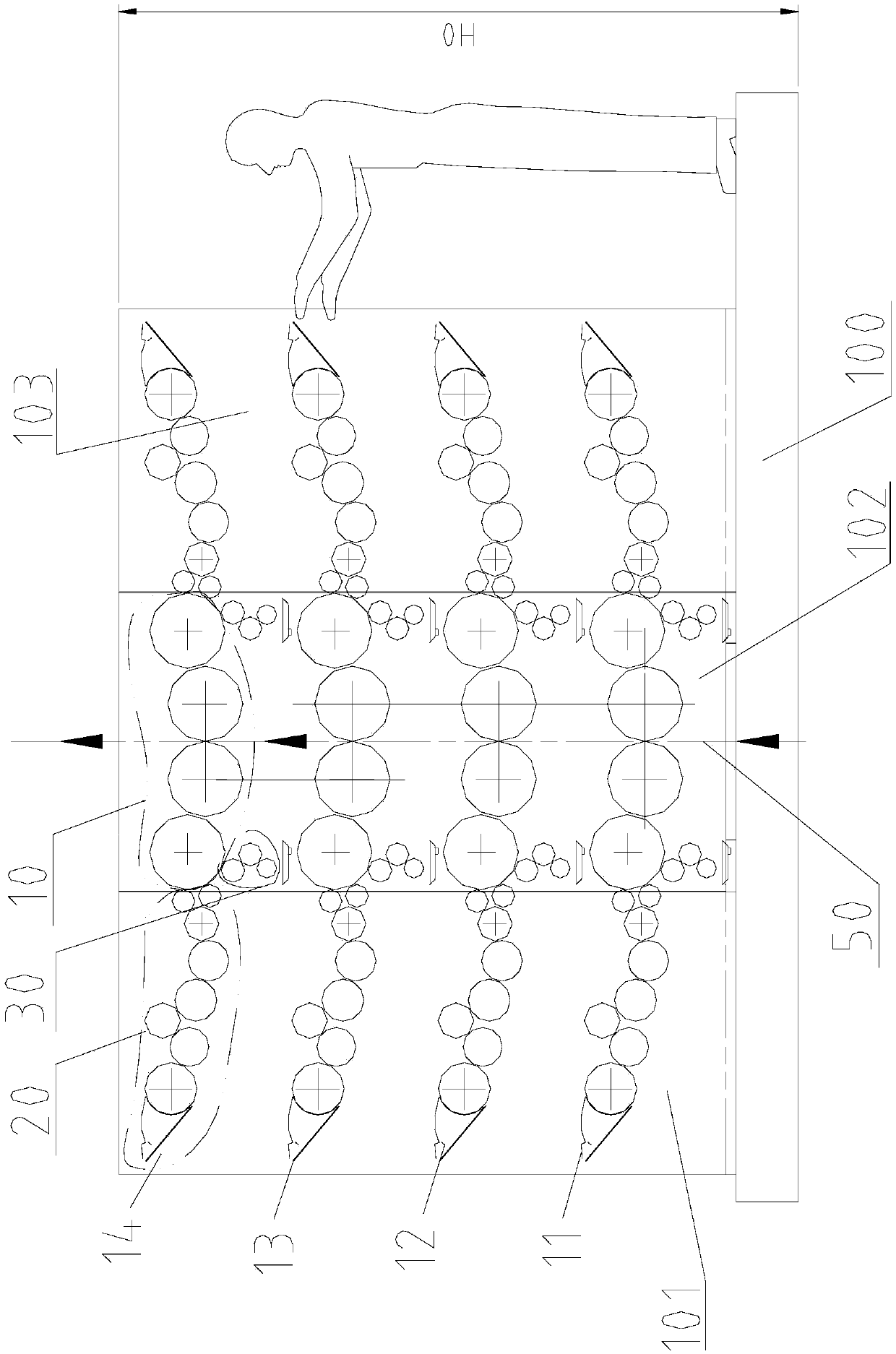

Multi-nozzle module based on 3D (three-dimensional) printing and device and technique for large-scale production of particles

InactiveCN106622413AEvenly distributedReduce the difficulty of printingAdditive manufacturing apparatusLaboratory glasswaresEnvironmental resistanceEngineering

The invention discloses a technical method for large-scale production of particles by a multi-nozzle module based on a 3D (three-dimensional) printing technique and application of the technical method. The technical method is characterized in that a single nozzle is of a coaxial annular gap air blowing structure, the middle part is provided with a fluid channel, and the coaxial annular gap is an air channel; on the basis of a two-phase flow cutting principle, liquid-phase liquid is cut by air, and liquid droplet particles are produced; by controlling air and liquid outlet pressures and flow rates, the liquid droplets with different particle sizes can be obtained; the number of nozzles can be designed according to the requirement of droplet output, and liquid and air are uniformly distributed by a distributor, so as to obtain higher droplet production efficiency. The technical method has the advantages that the preparation of 3D printing nozzle modules is simple, the material cost is low, and other complicated mechanical processing methods are not required; the prepared particles are free from the pollution by poisonous matters, such as a continuous phase and surfactants; the technical method is especially suitable for preparing high-viscosity solution and suspension droplets containing insoluble particles, is widely applied to the fields of medical care, petroleum, biology, environment protection and the like, and is suitable for large-scale industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

Door for refrigerator and refrigerator comprising same

ActiveCN103791680AVarious shapesAvoid damageDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

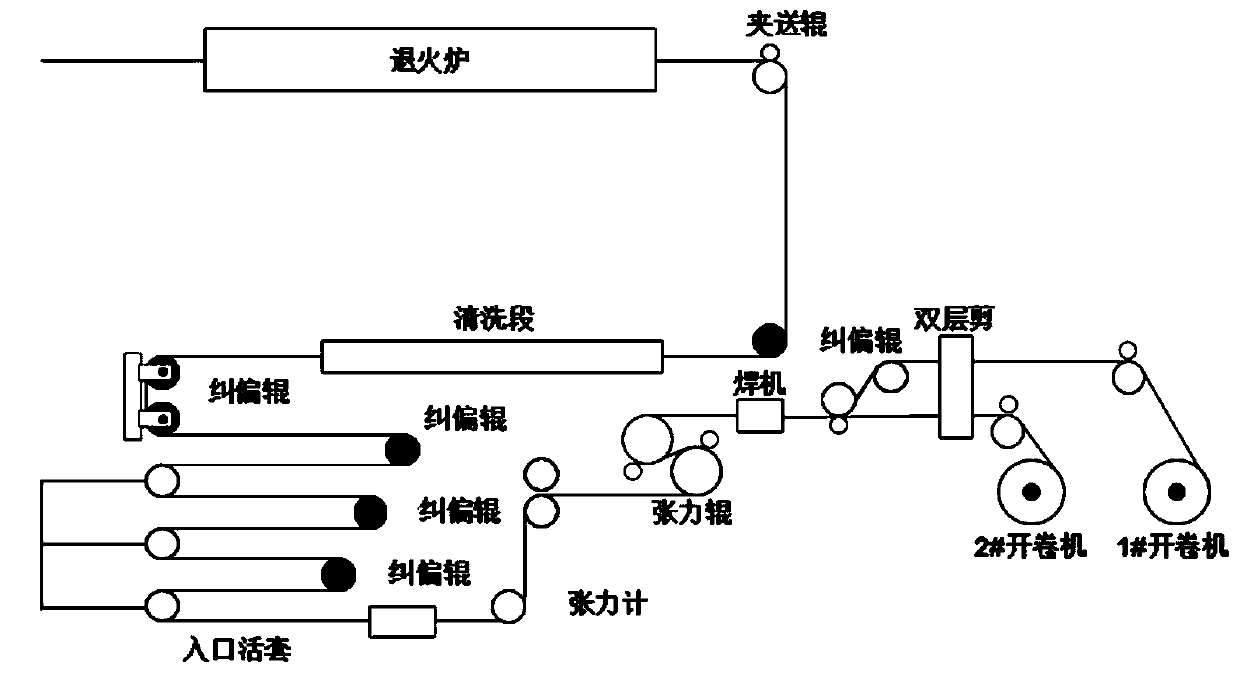

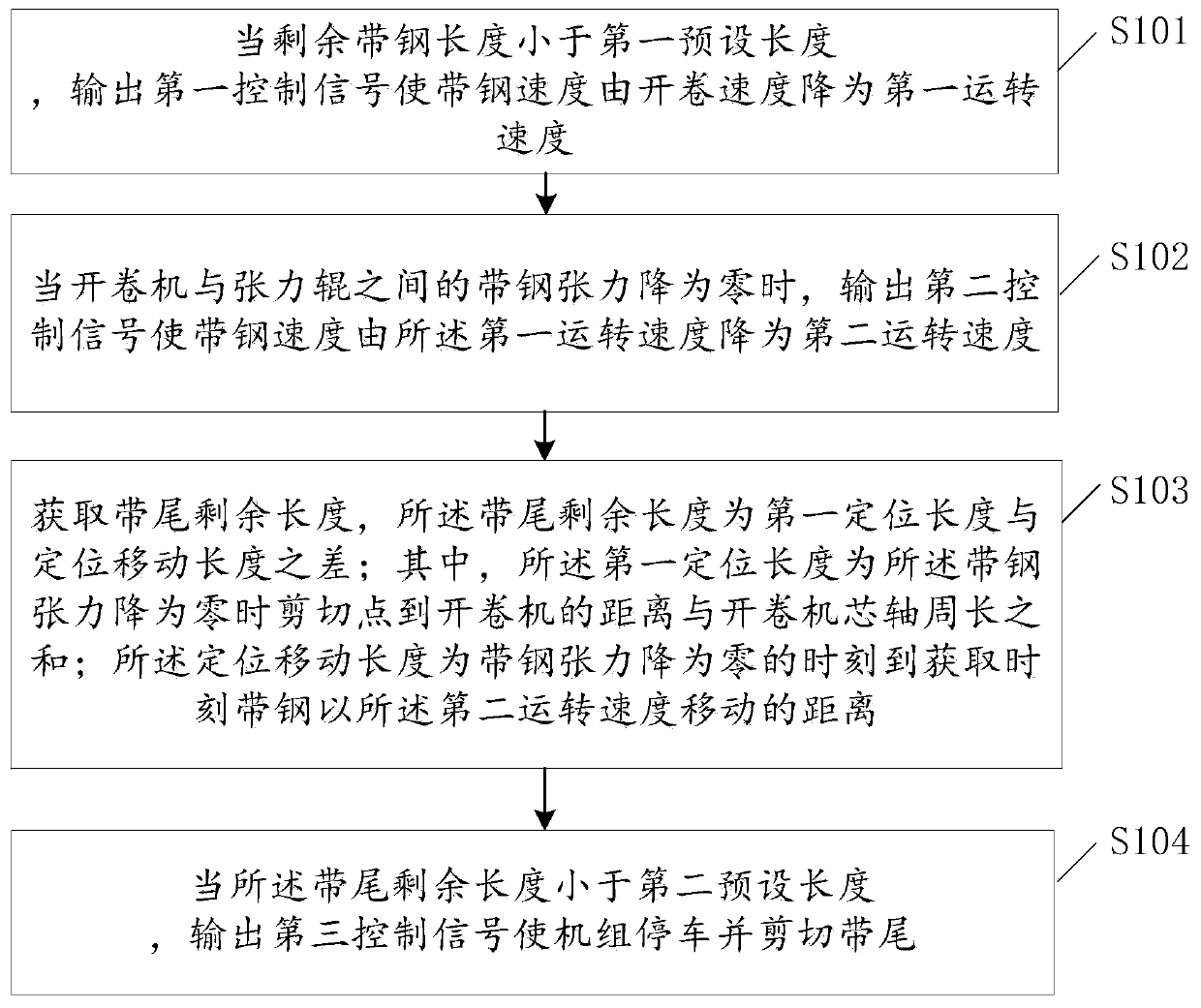

Full-automatic tail throwing control method and system for cold rolling continuous annealing unit

ActiveCN110732557AReduce the amount of scrapRoll mill control devicesMetal rolling arrangementsControl signalControl engineering

The invention discloses a full-automatic tail throwing control method and system for a cold rolling continuous annealing unit. The method comprises the steps that when the length of remaining strip steel is smaller than a first preset length, a first control signal is output to enable the strip steel speed to be reduced from the uncoiling speed to the first running speed; when the strip steel tension between an uncoiling machine and a tension roller is reduced to zero, a second control signal is output to enable the strip steel speed to be reduced from the first running speed to the second running speed; the remaining strip tail length is obtained and is the difference between a first positioning length and a positioning moving length, wherein the first positioning length is the sum of thedistance between a shearing point and the uncoiling machine when the strip steel tension is reduced to zero and the perimeter of a mandrel of the uncoiling machine, and the positioning moving lengthis the distance between the moment when the strip steel tension is reduced to zero and the moment when the strip steel moves at the second running speed; and when the remaining strip tail length is smaller than a second preset length, a third control signal is output to enable the unit to stop and shear a strip tail. According to the method, the strip tail cutting waste delivery amount in the tailthrowing link can be greatly reduced, and the yield of the unit is increased.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

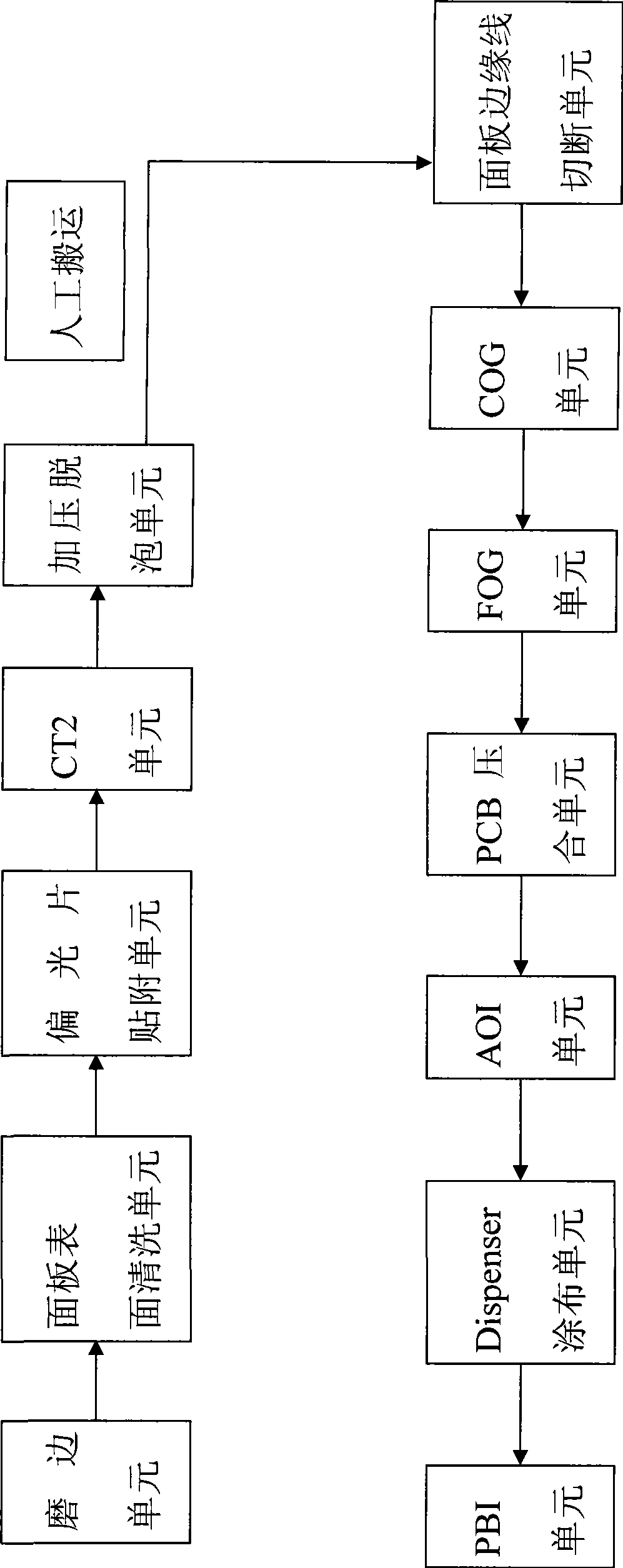

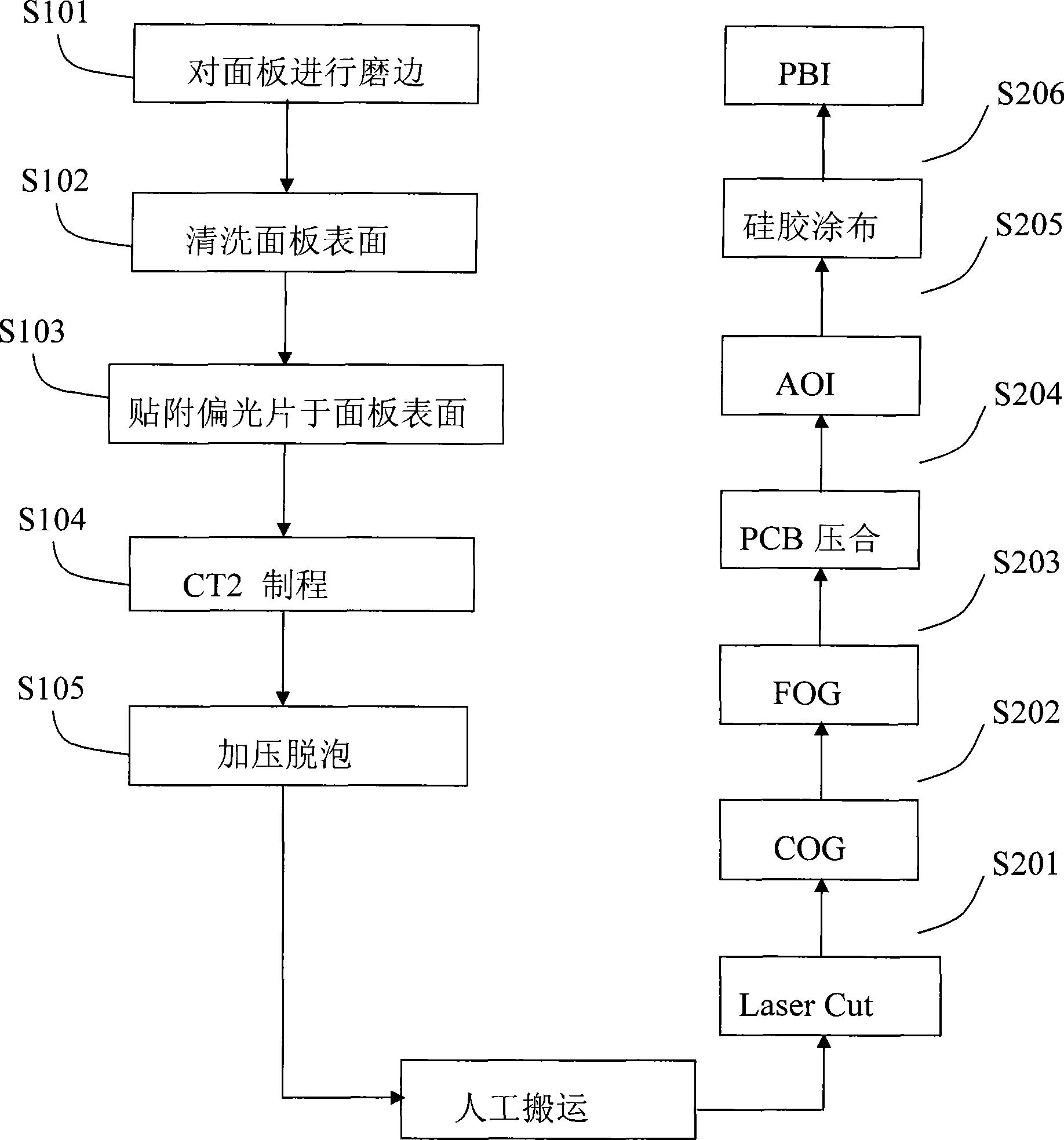

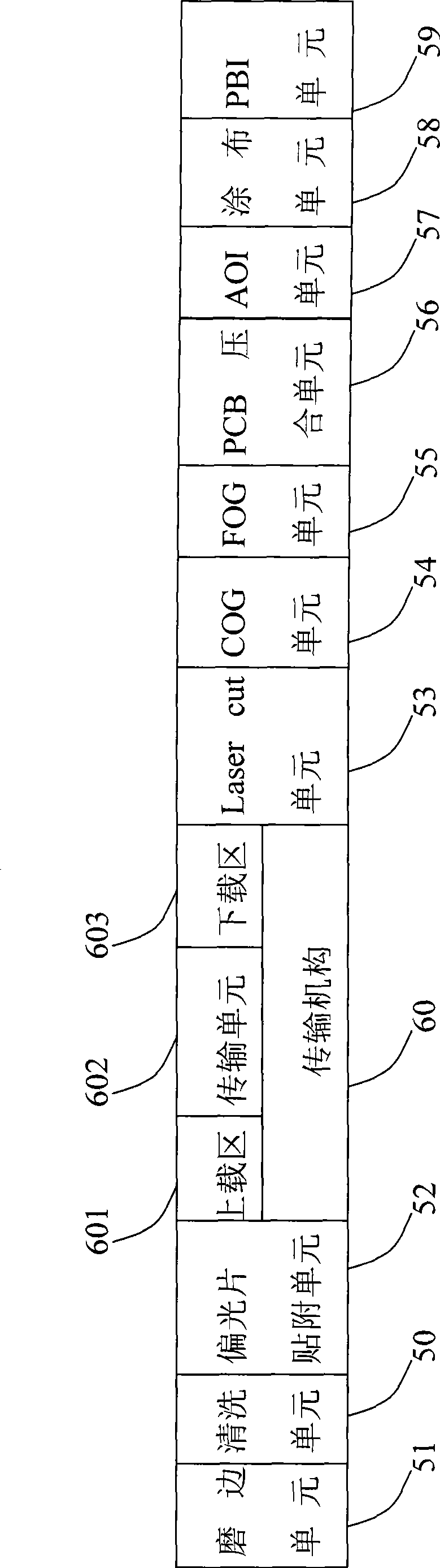

Connecting line production equipment and method for LCD device

ActiveCN101464583AReduce the amount of scrapEasy to produceNon-linear opticsProduction lineLiquid-crystal display

The invention provides a connecting production device for a liquid crystal display device and a production method of a liquid crystal display device adopting the connecting production device. The connecting production device comprises an assemblage process production line, a module process production line and a transmission mechanism. The assemblage process production line is used for forming a liquid crystal panel; the module process production line is used for assembling the panel and various parts; the transmission mechanism comprises an upload area, a transmission unit and a download area; the upload area is directly connected with the tail end of the assemblage process production line; the download area is directly connected with the front end of the module process production line; and the panel is transmitted from the upload area to the download area by the transmission unit, thereby connecting the assemblage process production line and the module process production line into a connecting production line, wherein, both the assemblage process production line and the module process production line are the connecting production line. The production process of the liquid crystal display device is integrated into a continuous production line, thereby improving the yield of the panel, simplifying the production flow, and improving the work efficiency.

Owner:AU OPTRONICS (XIAMEN) CORP +1

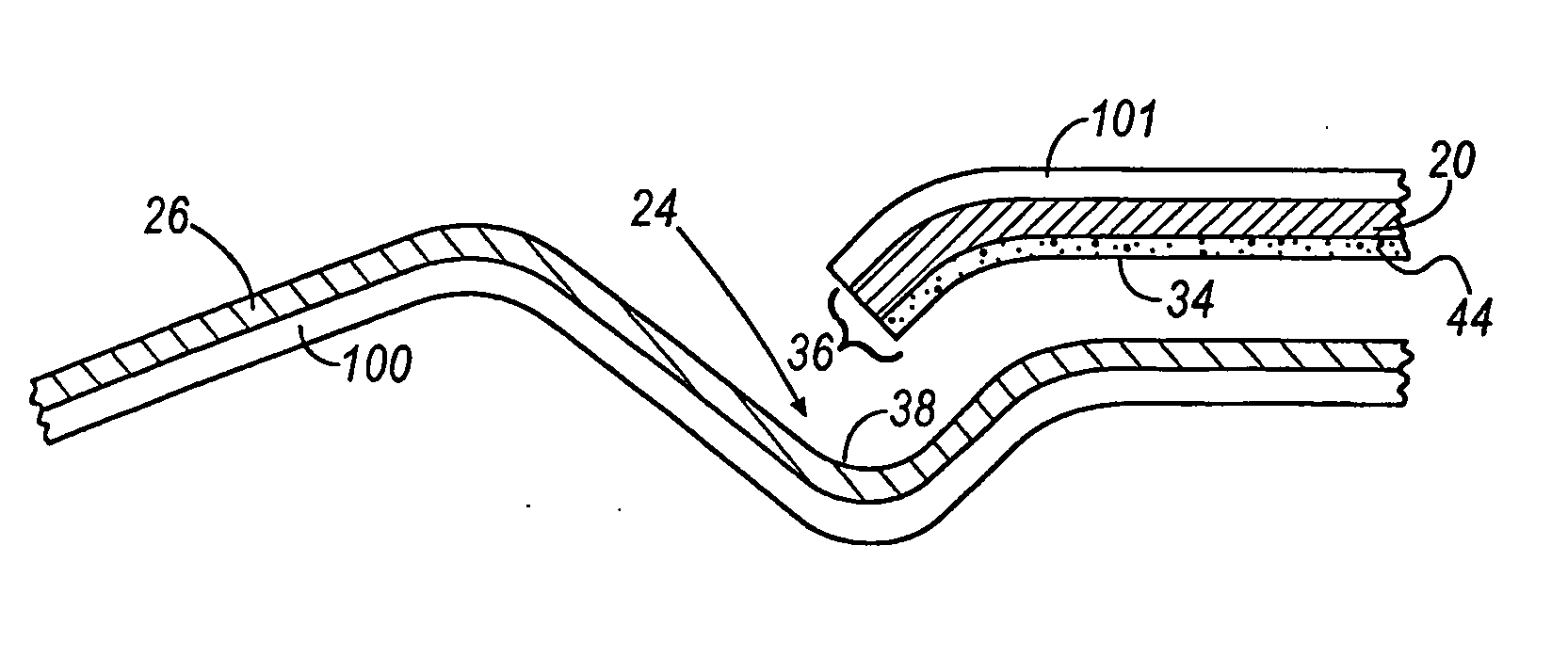

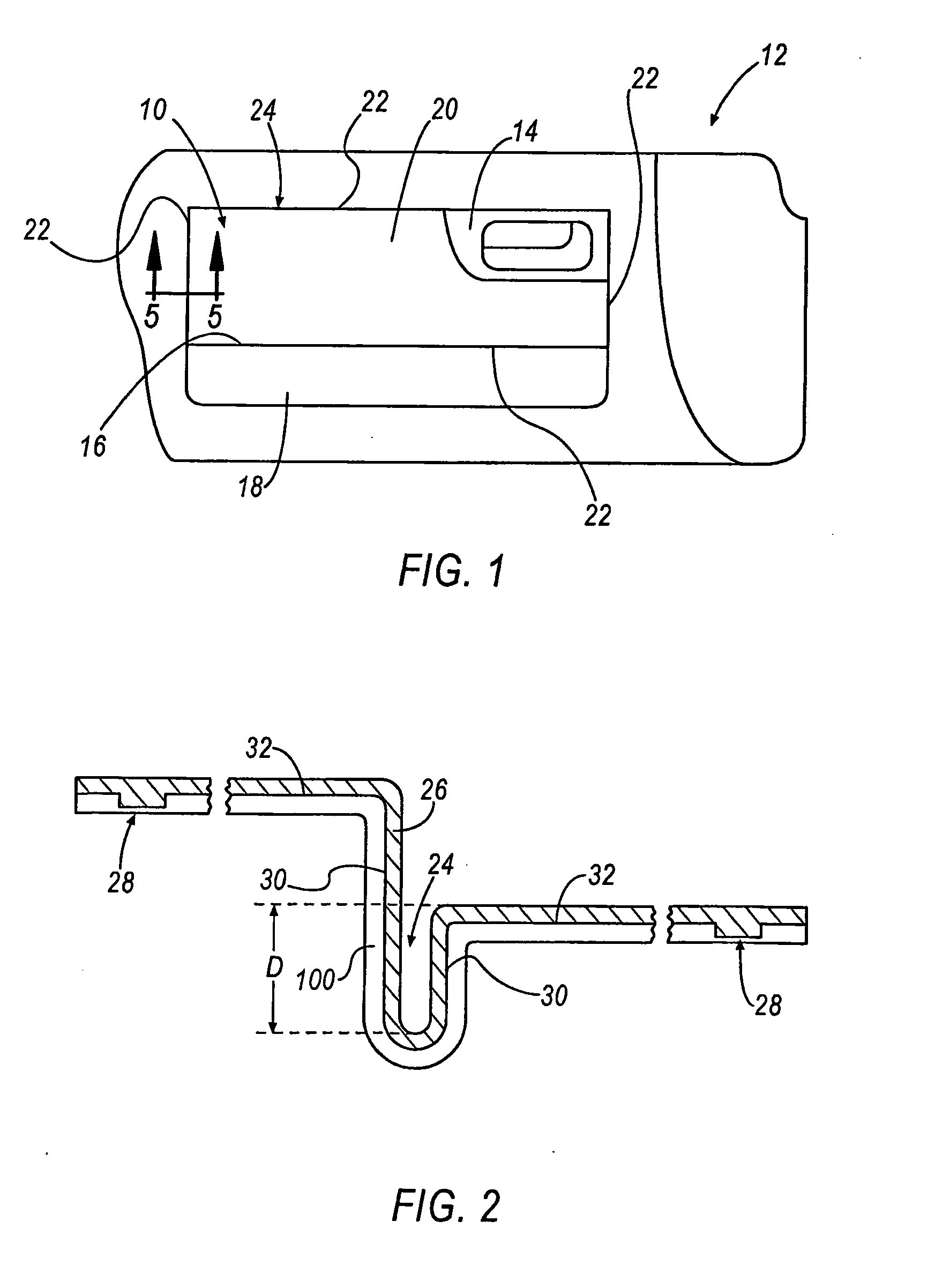

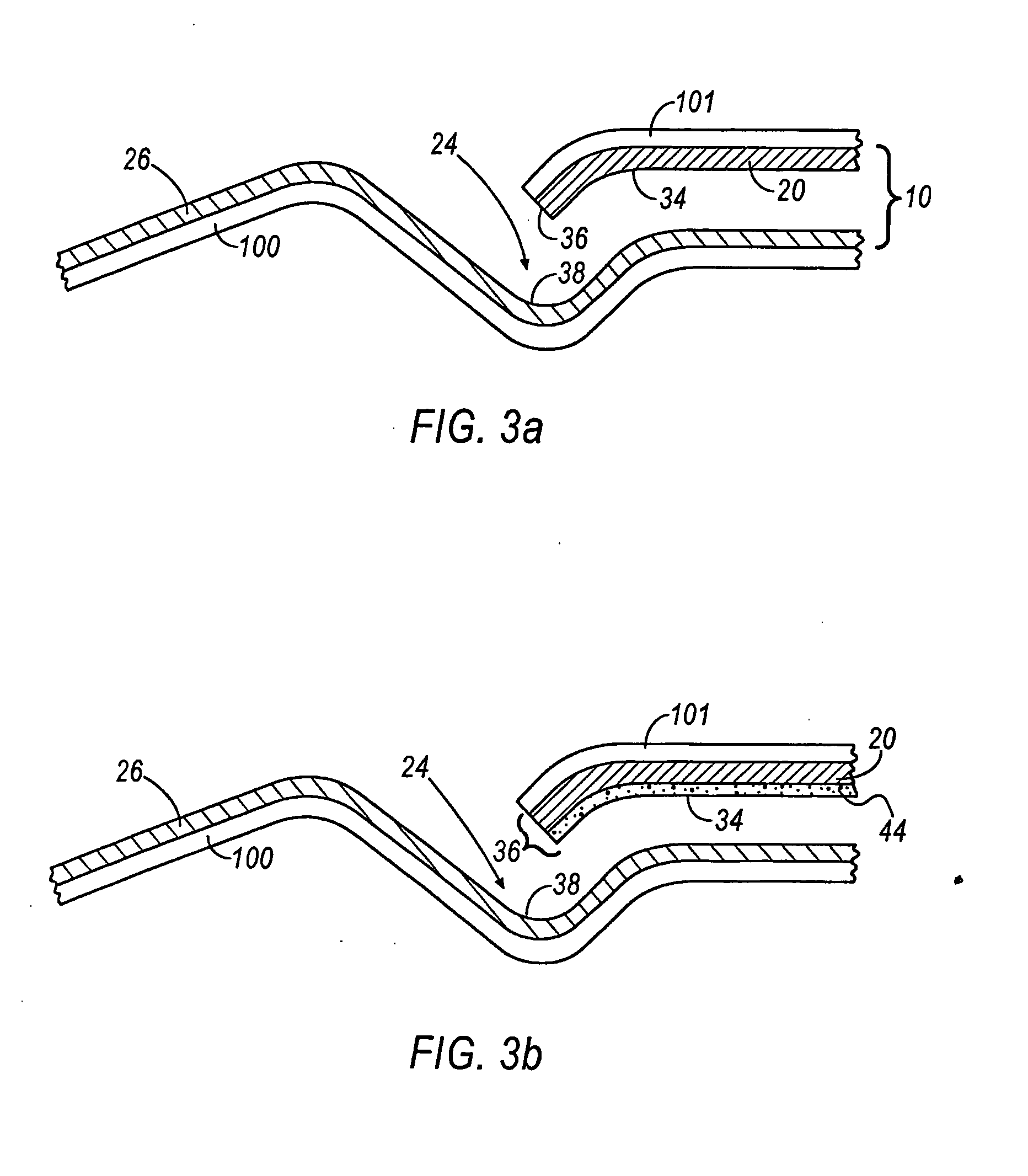

Method of pre-applying a bolster assembly to an interior trim part

InactiveUS20060157881A1Low costReduce the amount of scrapMould separation apparatusMouldsLeading edgeDashboard

A method of pre-applying a bolster assembly to an interior trim part includes the steps of applying a base skin layer to a groove of a first nest, applying a bolster skin layer to a second nest, positioning the first nest in an open position, and inserting a leading edge of a bolster skin layer in the groove of the first nest when the first nest is in the open position until the bolster skin layer engages the base skin layer. The bolster assembly can be attached to the interior trim part by a Foam-In-Place (FIP) or Low-Pressure Molding (LPM) operation. The interior trim part may comprise a dashboard garnish, an instrument panel (IP), a door panel, and the like. A boss locating portion can be integrally formed within the base skin layer and is used for locating the bolster assembly on the interior trim piece during the manufacturing process. Because the bolster assembly is pre-applied to the interior trim part prior to the FIP or LPM operation, the bolster assembly can be positioned at the bottom-most portion of the groove to provide a consistent fit and finish, while reducing scrap material and cost of the interior trim part.

Owner:GRUPO ANTOLIN IRAUSA

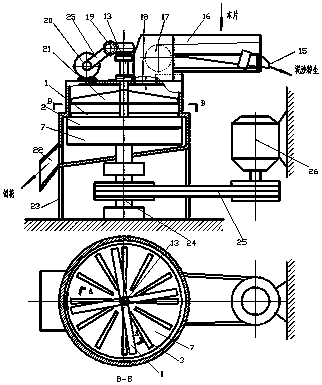

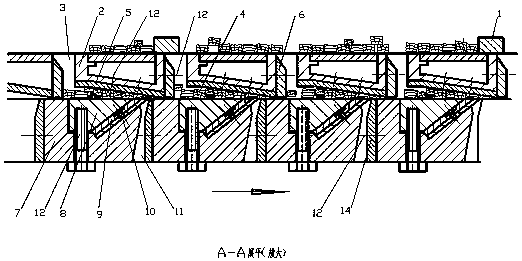

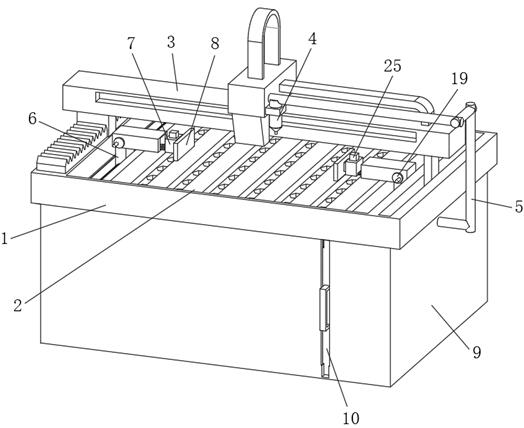

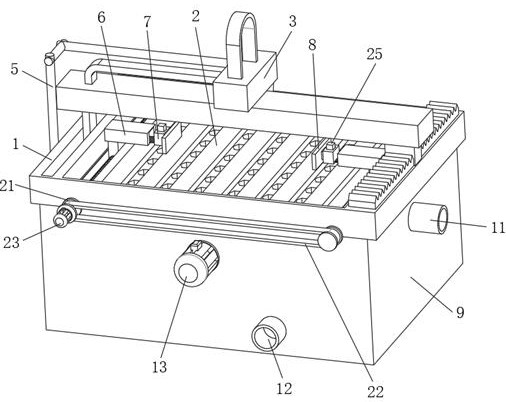

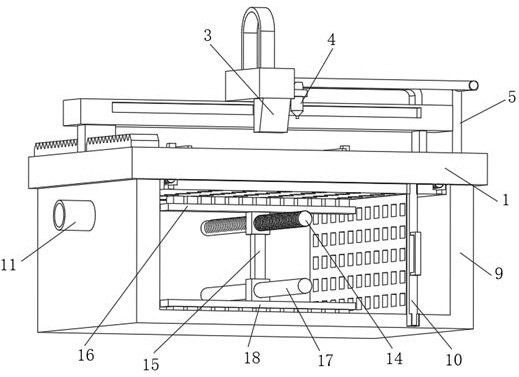

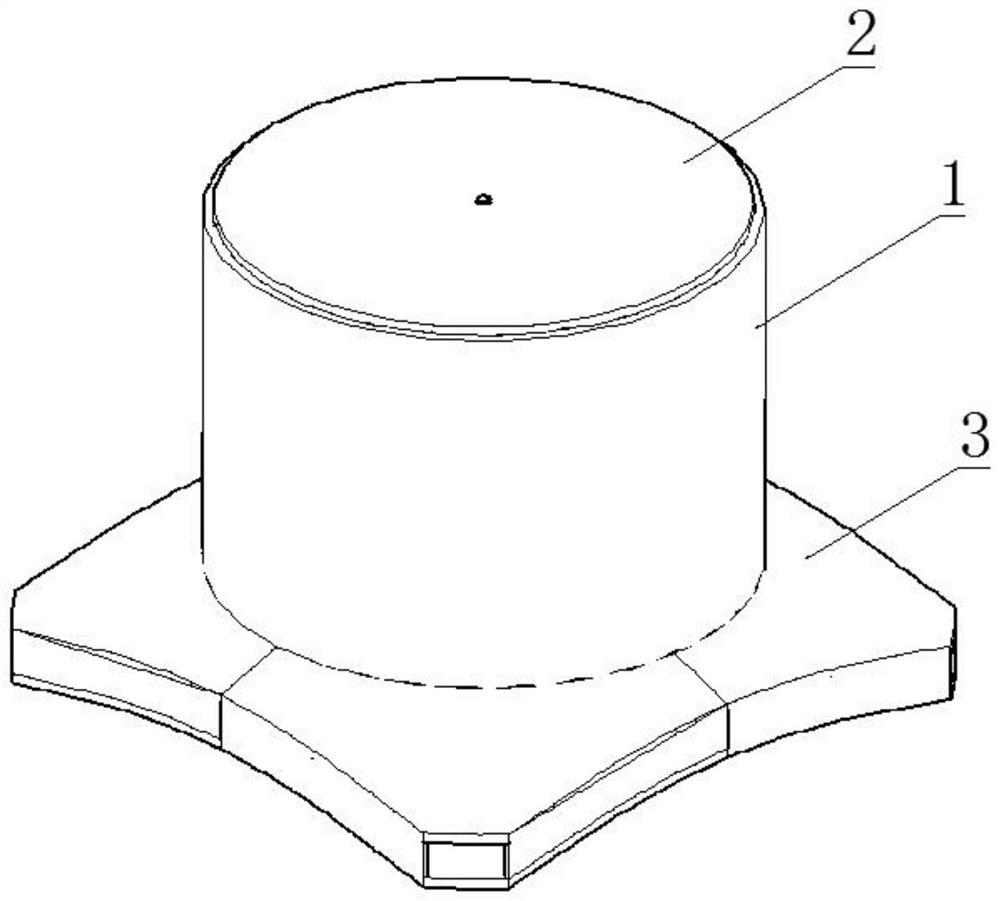

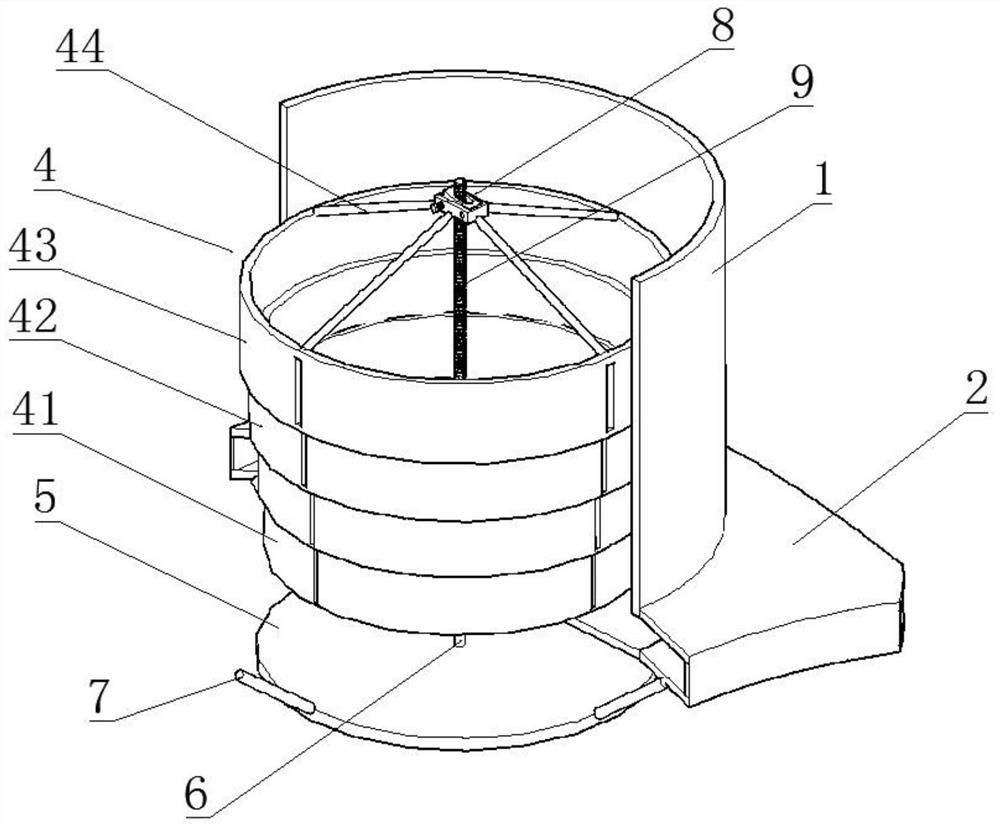

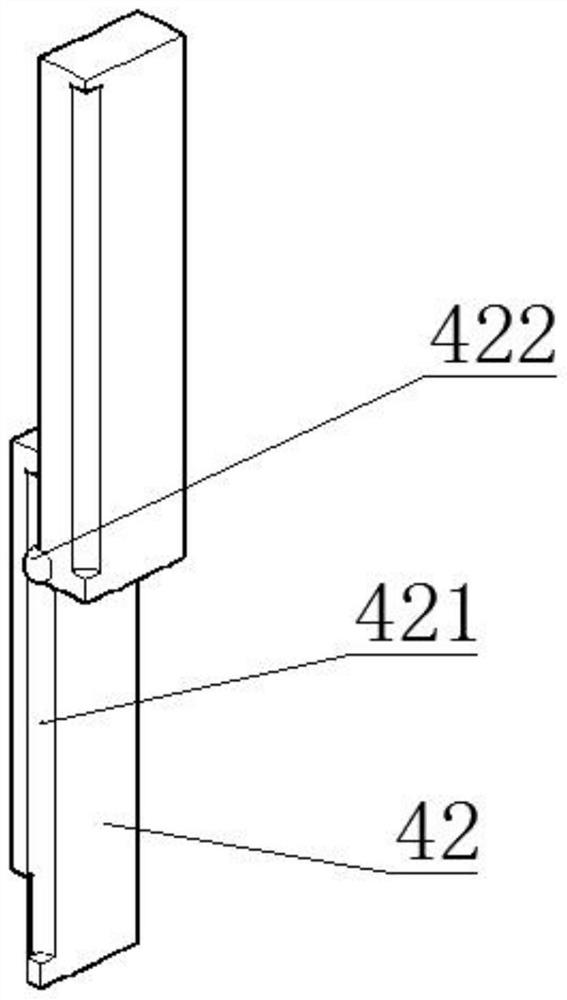

Disc-type wood chip chipper

PendingCN108527585AReduce the amount of scrapLess scrapWood working apparatusWood shavingsEngineering

The invention relates to a disc-type wood chip chipper. The disc-type wood chip chipper comprises a feeding device, a slicing device and a discharging outlet. The feeding device conveys wood chips tobe sliced to the slicing device, and then the wood chips to be sliced are led out through the discharging outlet. The slicing device comprises a horizontally placed feeding disc, and a plurality of slot openings which longitudinally penetrate through are formed in the feeding disc. A discharging rod is arranged above the feeding disc, and a cutter disc is arranged below the feeding disc. The discharging rod is horizontally arranged and moves relative to the feeding disc. The wood chips falling into the feeding disc are scraped down to the slot openings by the discharging rod and drop onto thecutter disc. A plurality of fly cutters are fixed on the cutter disc. The cutter disc and the feeding disc rotate relatively under the action of a driving device. A material guiding slot which is usedfor leading out wood shavings after slicing is formed in the cutter disc, and the material guiding slot communicates with the discharging outlet. The disc-type wood chip chipper realizes transverse slicing of the wood chips, and reduces particle size of the wood shavings.

Owner:NANJING FORESTRY UNIV

A laser photolithography method PCB solder resist pattern transfer and forming process

InactiveCN109041439AReduce production process linksReduce production capacityConductive material chemical/electrolytical removalResistChemical reaction

A laser photolithography PCB solder resist pattern transfer and forming process comprises that following step: 1) surface treatment of the process board: cleaning the surface of the process board to ensure that the surface is coated with ink under the condition of no impurity oxidation; 2) coat photosensitive ink: covering that surface of the whole work plate cop foil by a coating wheel to form anink with uniform thickness; 3) Ink drying: The solvent in the wet ink is evaporated through the uniform temperature of the flintlock furnace to form 18-24UM dry film; 4) laser photoresist pattern: utilizing laser and line pattern data to generate beams with different wavelengths of energy, directly scanning that work plate with photosensitive dry film, and utilizing photochemical molecular bonding principle to solidify and adhere the ink; 5) developing a solder resist pattern: for a solder resist pad pattern by chemical reaction washing of a developing liquid and an ink without molecular bonding; 6) soldering of that solder resist ink: solidifying the ink through a high-temperature oven and a drying path.

Owner:ZHEJIANG LEUCHTEK ELECTRONICS

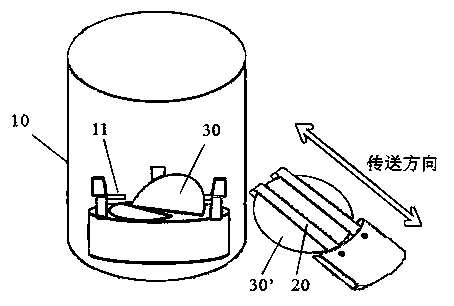

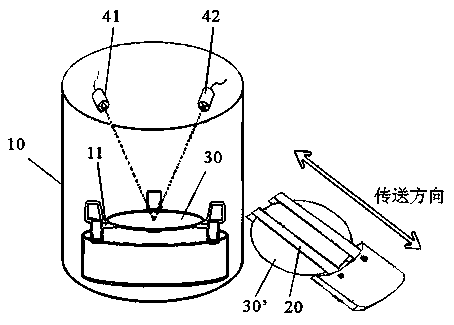

Wafer detection device and method used for ashing machine

InactiveCN103839852AReduce the amount of scrapExtended service lifeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingInfraredEngineering

The invention relates to a wafer detection device and method used for an ashing machine. The method includes: before a vacuum arm is used to transport a wafer which is processed in a reaction chamber, whether the wafer is broken is detected; infrared ray is firstly sent by an emitter to the surface of the wafer and if infrared ray reflected by the wafer can be received by a receiver, it proves that the wafer is not broken and then the vacuum arm is controlled to extend out into the reaction chamber to replace the wafer; and if the receiver cannot receive the infrared ray, it proves that the wafer is broken and then the vacuum arm is stopped from continuing to extend out. The wafer detection device and method are simple and reliable and capable of detecting conveniently the state of the wafer before the wafer is transported so that after the wafer is found to be broken, the vacuum arm can be stopped immediately from extending out into the reaction chamber and thus the number of scrapped wafers is reduced and the vacuum arm and lift pins in the reaction chamber are protected and the service life of the machine is prolonged.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Material mixing device for molding bag shell

The invention relates to a material mixing device for molding a bag shell. The material mixing device a material mixing bin, a swivel nut arranged inside the material mixing bin in the vertical direction, a screw arranged in the swivel nut, a driving mechanism used for driving the screw to rotate and a material adding hopper inserted in from the side portion of the material mixing bin and communicated with the swivel nut, wherein the upper end of the screw is exposed out of the upper end of the swivel nut and is screwed out from the top of the material mixing bin, and a cavity is formed by the inner wall and the top of the material mixing bin and the periphery of the swivel nut; and a material discharging pipe for discharging the materials is arranged on the material mixing bin. According to the material mixing device, multiple materials are stirred and conveyed firstly through the screw and then are further mixed in a freely-scattering manner, so that the materials are evenly mixed sufficiently, the quality of the bag shell is guaranteed, the scrapping number is reduced accordingly, and cost is saved.

Owner:SUZHOU HUAXIANG LUGGAGE MFGR CO LTD

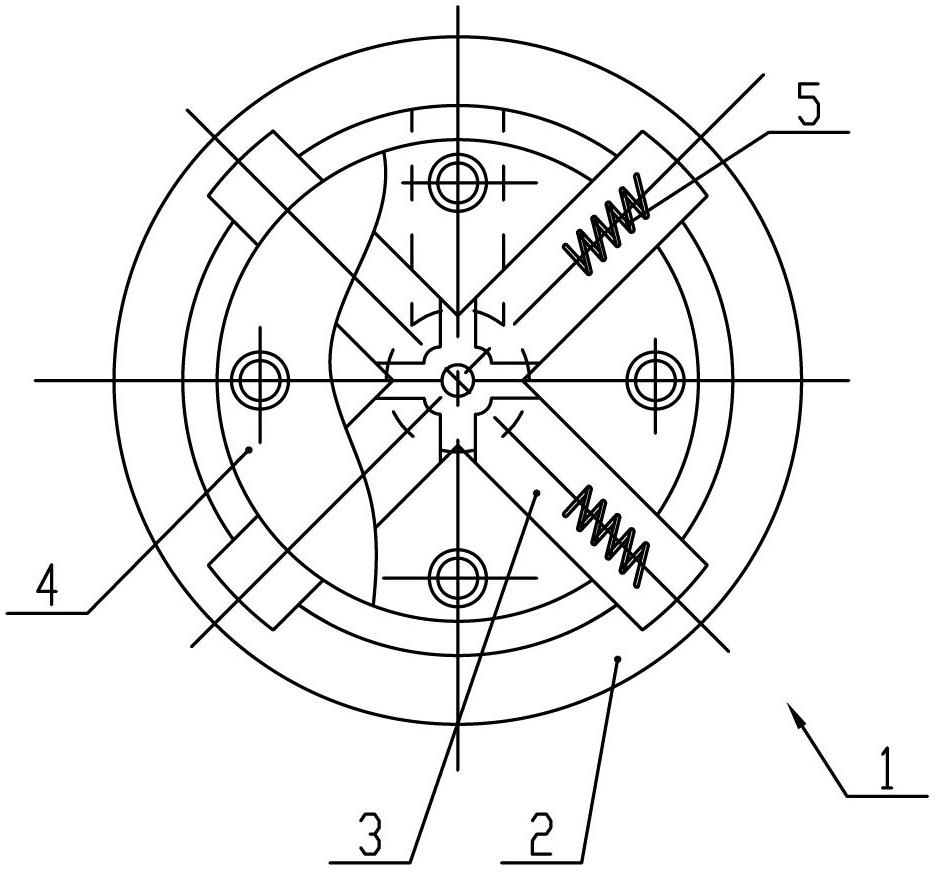

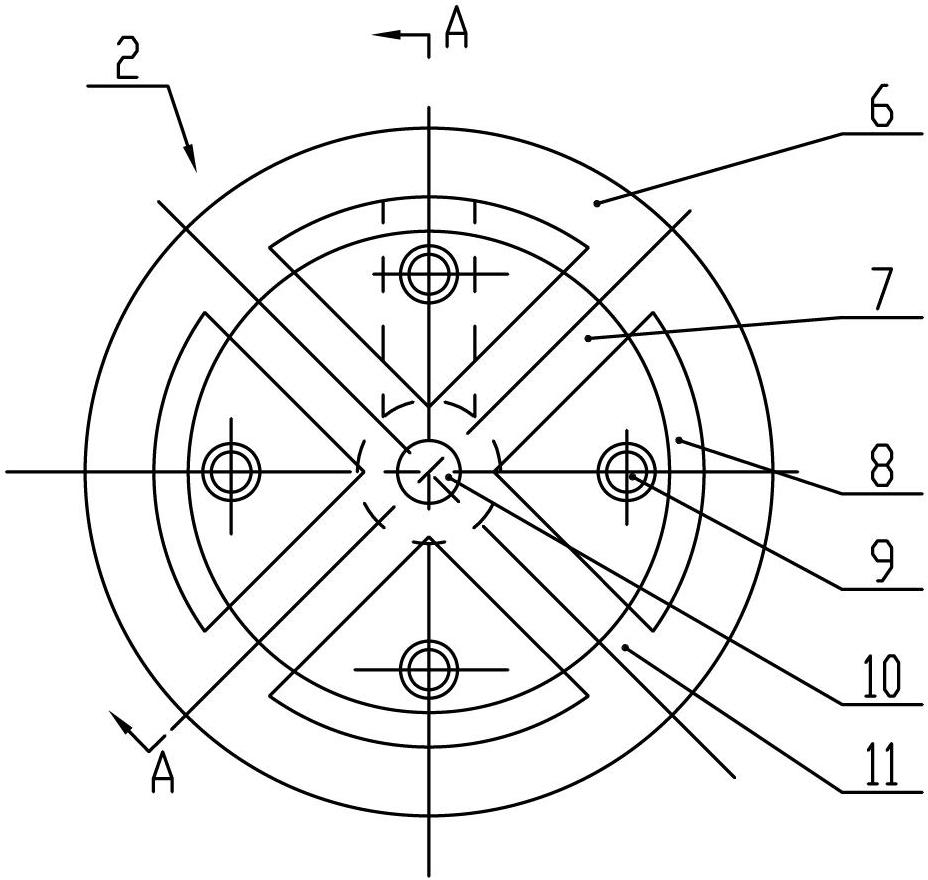

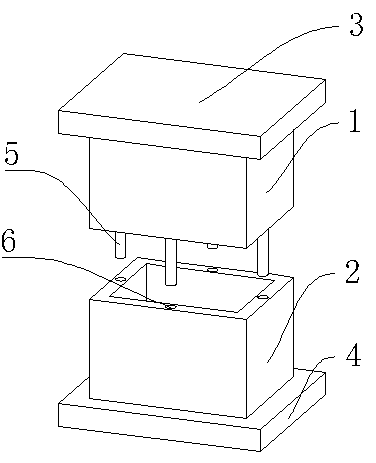

Compound die of automatic nail making machine of peel type rivets

The invention relates to a compound die of an automatic nail making machine of peel type rivets. The compound die comprises a die seat, die cores, a die cover and a spring, wherein one end of a seat body of the die seat is provided with a cross groove, and the other end of the seat body is provided with a positioning groove; the four outer ends of the bottom of the cross groove are respectively provided with a groove; all the grooves are respectively provided with a spring hole; one end of each spring is arranged into the spring hole; four die cores are respectively embedded in the cross groove and can move radially; bosses are arranged on the die cores and abut against the other ends of the springs; the die cover is fixed at the outer end of one end of the die seat provided with the cross groove, and abuts against the die cores. The compound die has the advantages that a main die of the nail making machine can be manufactured into the compound die with four telescopic surfaces of the die cores, and the square shape of the part of a nail head of a nail core can be guaranteed definitely, so that the uniformity of four flaps after riveting is guaranteed, the quality of the peel type rivets is improved, the scrapped quantity is reduced and the cost is saved.

Owner:WUXI ANSHIDA HARDWARE

Welding method for increasing material dimension

InactiveCN108188663AMeet size requirementsReduce the amount of scrapSoldering apparatusSpot weldingMachining

The invention relates to the technical field of non-traditional machining, in particular to a welding method for increasing material dimension. According to the welding method, an alloy sheet, made ofthe same material with a matrix alloy, of the needed dimension is machined in a wire-electrode cutting manner, the surface of the alloy sheet is polished, an oxidation film is removed, the oxidationfilm on the surface, to be welded, of a part is removed, the surface, to be welded, of the part is cleaned and dried, and the alloy sheet is spot welded and fixed to the to-be-welded portion in an resistance pot welding manner; then, after a brazing material is smeared and a flow stopping agent is smeared at the position nearby a weld joint zone, the brazing material and the flow stopping agent are dried, vacuum brazing is conducted, vacuum brazing heating in a vacuum brazing furnace, temperature preservation and cooling are conducted, and finally weld joint detection and machining are conducted on the welded portion so that the dimension of the part can be restored. By the adoption of the welding method for increasing material dimension, the part of a smaller dimension can be restored, the number of scrapped parts is reduced, cost is saved, and the production yield is improved.

Owner:GUIYANG AVIC POWER PRECISION CASTING

Method for detecting defect of doped boron-silicon glass film

InactiveCN100459088CReduce the amount of scrapImprove yieldSemiconductor/solid-state device testing/measurementBoronSilicon

A method for detecting the defect of glass membrane mixed with borosilicate is provided, whose process is: depositing the glass membrane mixed with borosilicate on the control wafer; forming the polysilicon film on the said glass membrane mixed with borosilicate on the control wafer; detecting the surface of the control wafer. The invention greatly shortens the detecting period of the glass membrane mixed with borosilicate and improves the yield of the wafer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

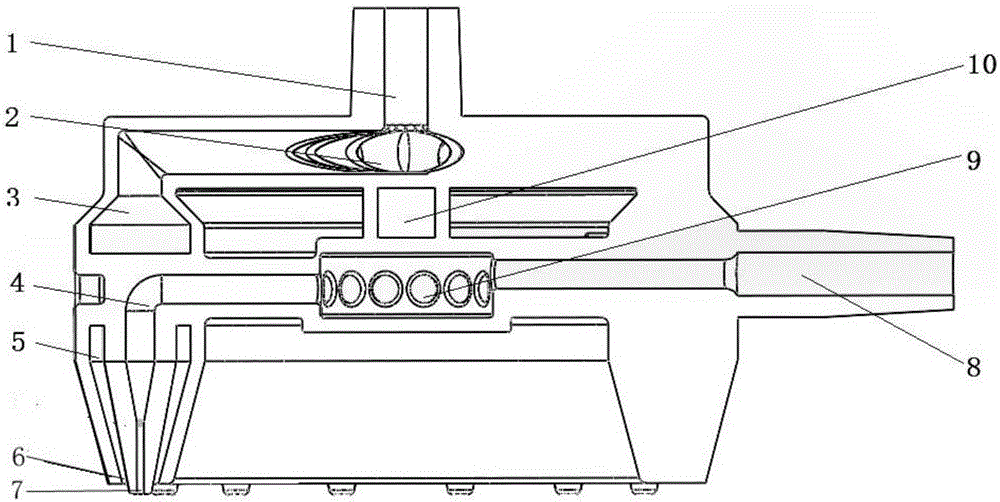

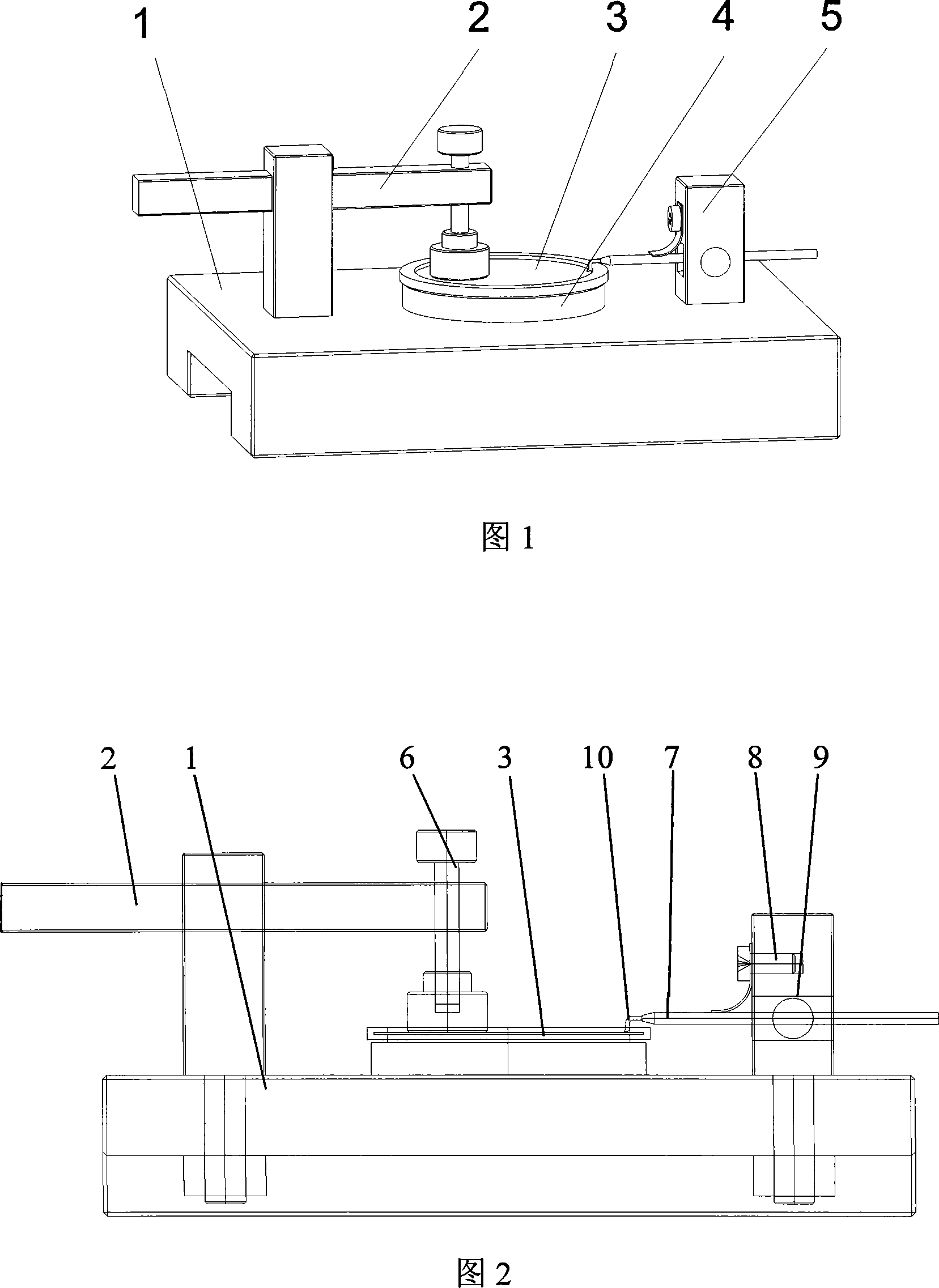

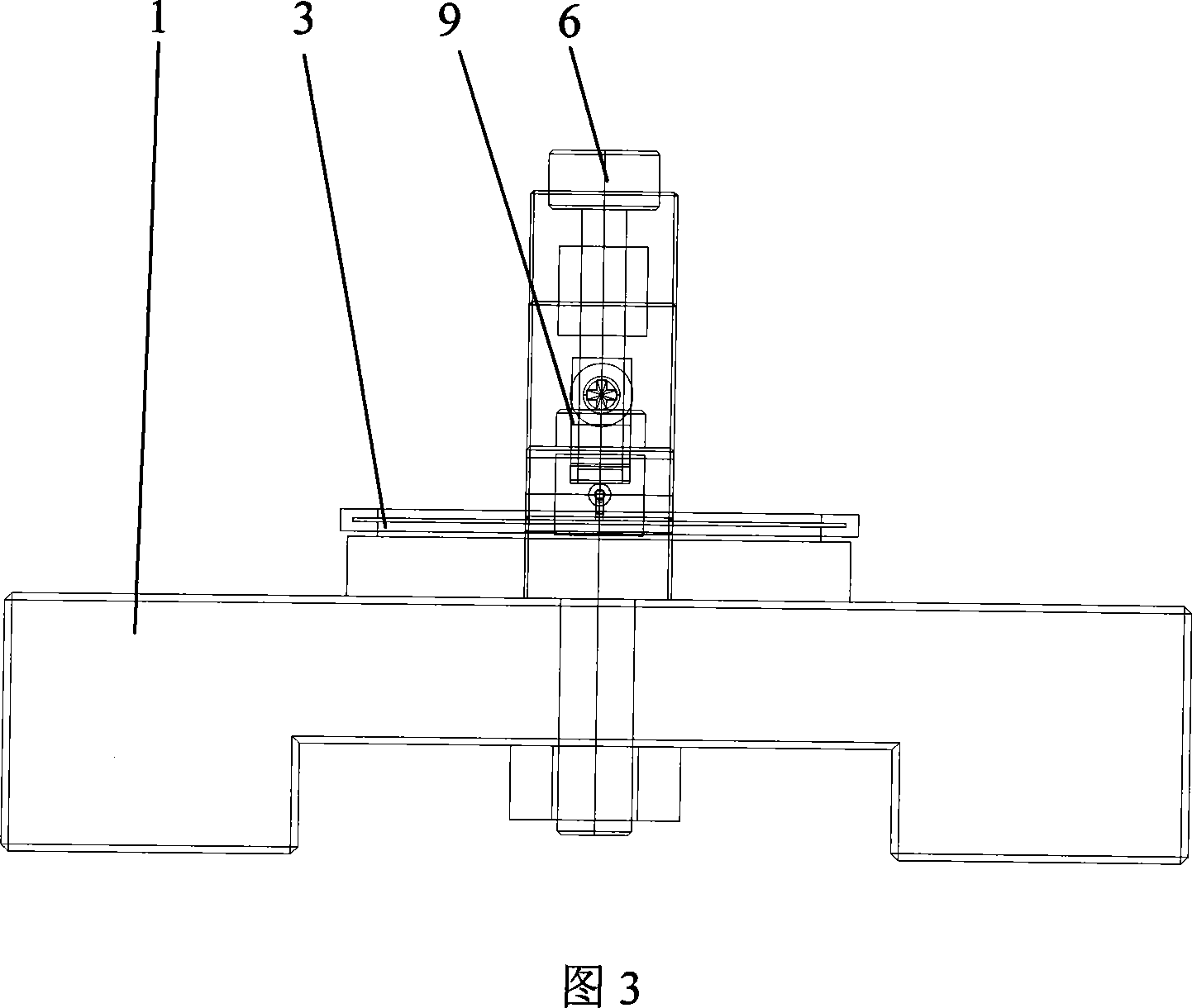

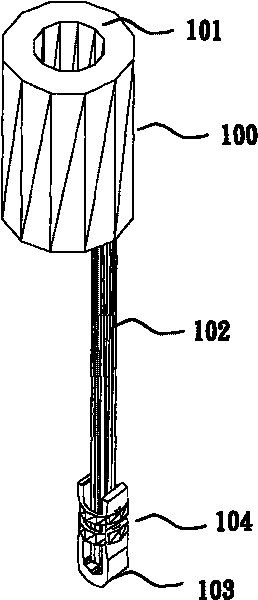

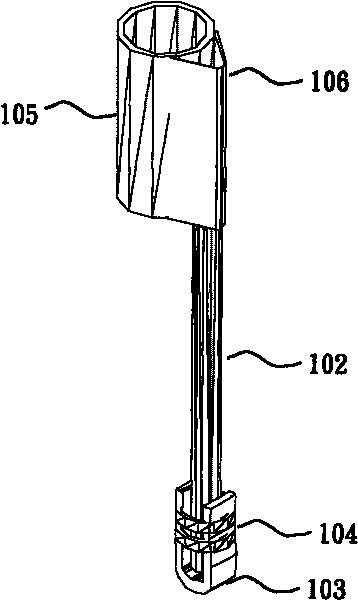

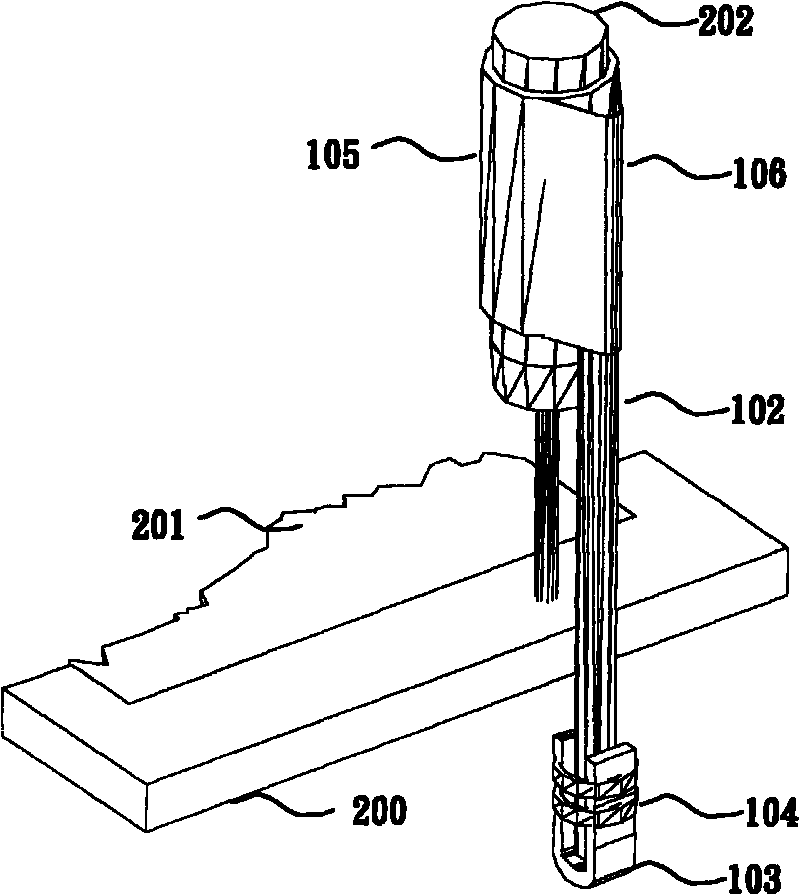

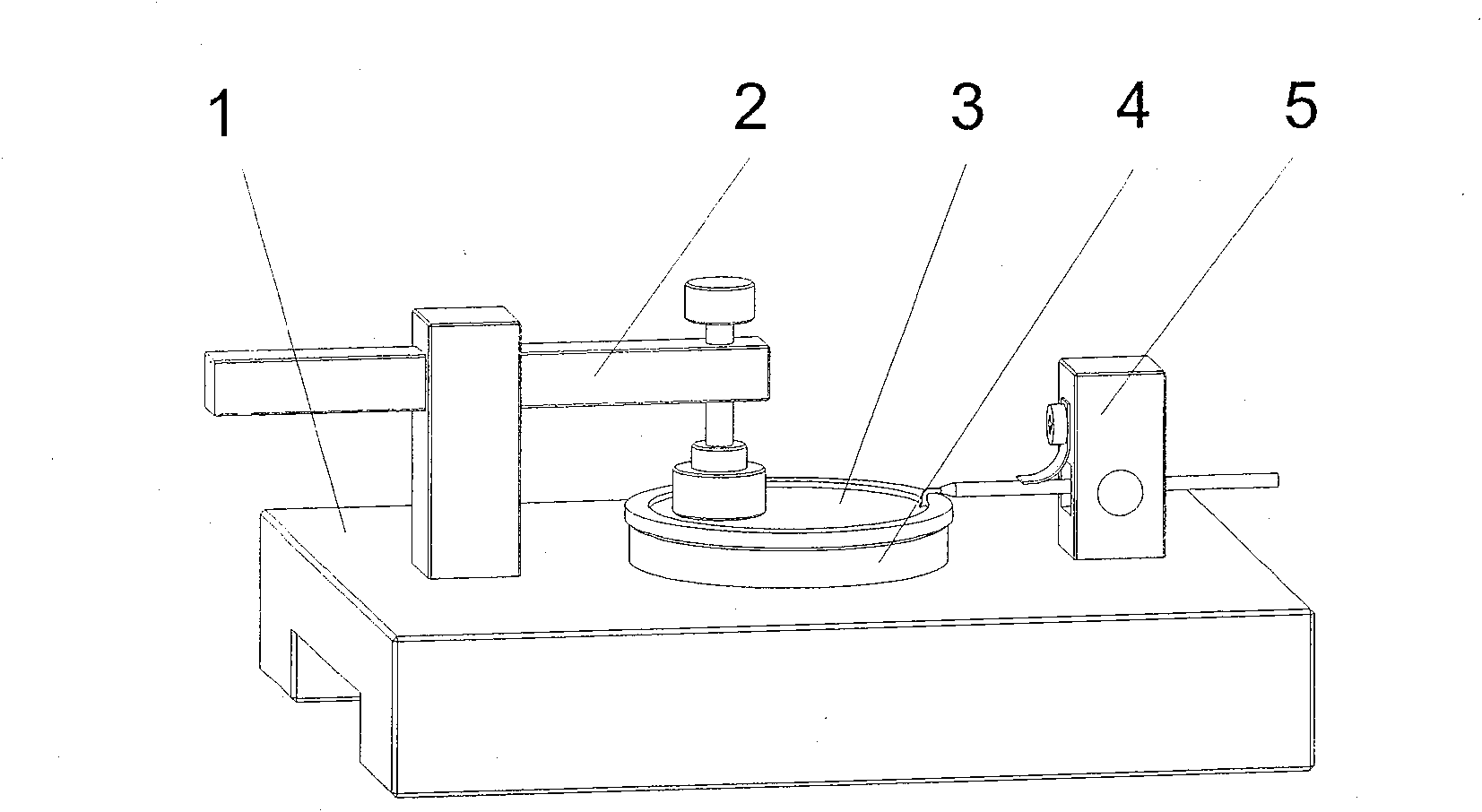

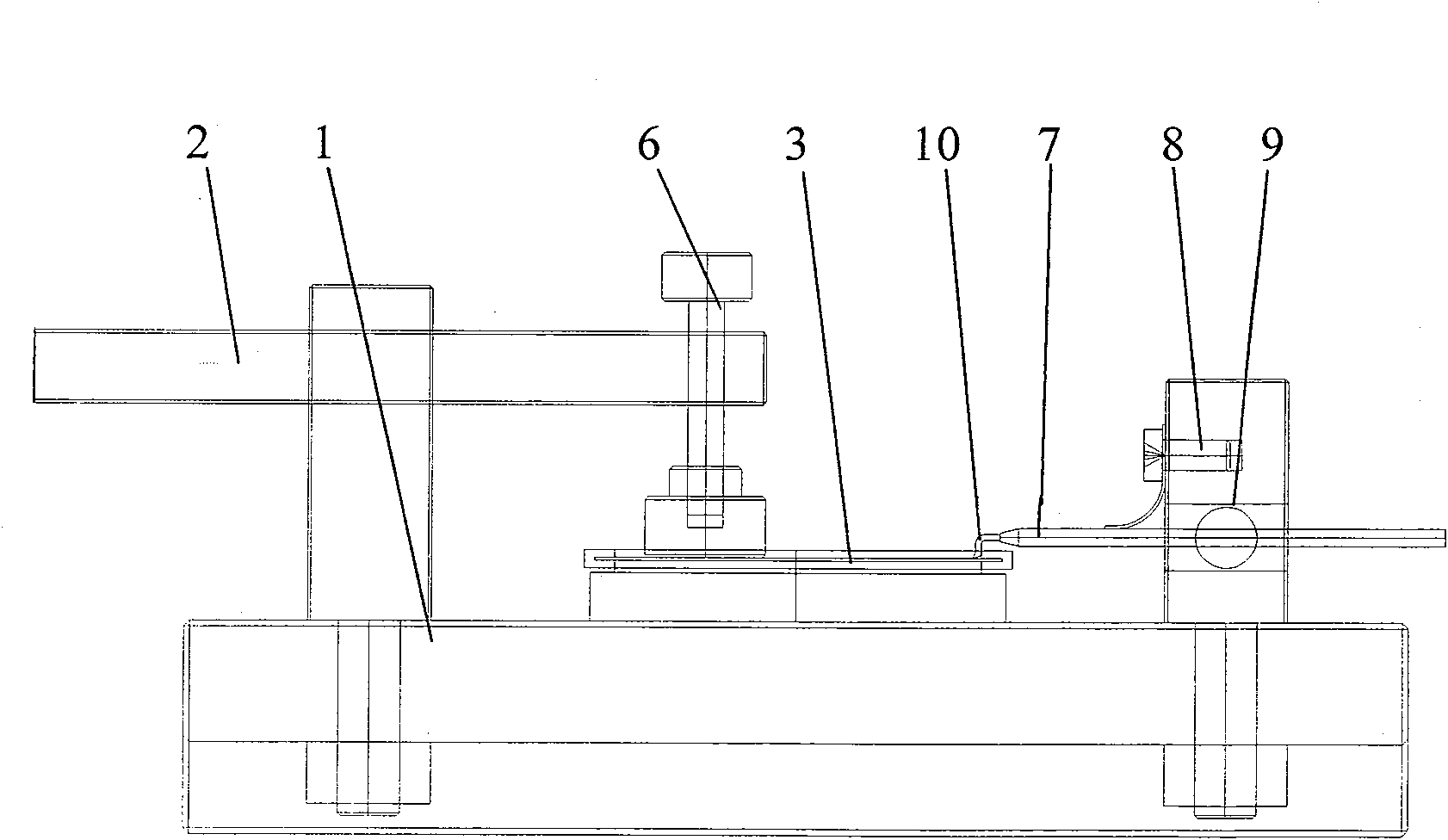

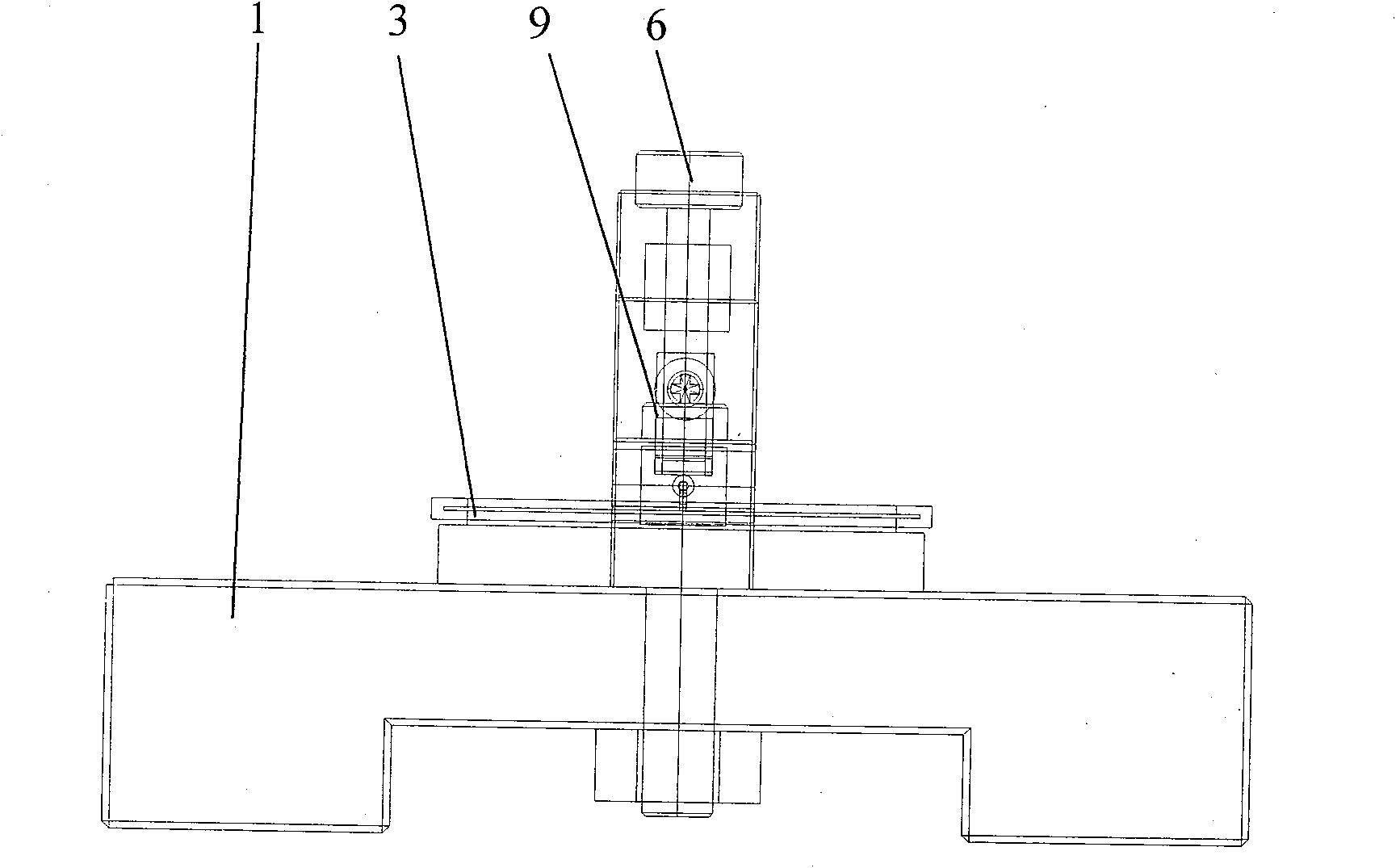

Semiconductor chip comb sliver repairing method and device

ActiveCN101145510AImprove repair efficiencySmall and compact form factorSemiconductor/solid-state device manufacturingEngineeringSemiconductor chip

A combed strip repair method and a device for a semiconductor chip are provided, which repair the abnormal combed strip by using a combed strip repair mechanism simulating the manual repair. The method simulating the manual repair is implemented by fixing a chip for semiconductor devices on a microscopic workbench by using a positioning device assembly, and repairing the chip combed strip by using a combed strip picking mechanism simulating the manual repair of chip combed strips, wherein the combed strip picking mechanism simulating the manual repair of chip combed strips can regulate the blade of the cutter for repairing combed strips to the root of the combed strip to be repaired and to align to the lengthwise direction of the combed strip by using a microdrive positioning mechanism, preparing for the pick of combined strips; and allow the blade to make linear movement by using a fastening / guide mechanism integrated with the cutter, completing the operation of picking combed strips. The combed strip repair mechanism comprises the chip positioning seat, the cutter, the microdrive positioning mechanism and the fastening / guide mechanism, and the whole mechanism is placed inside the microscopic workbench.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

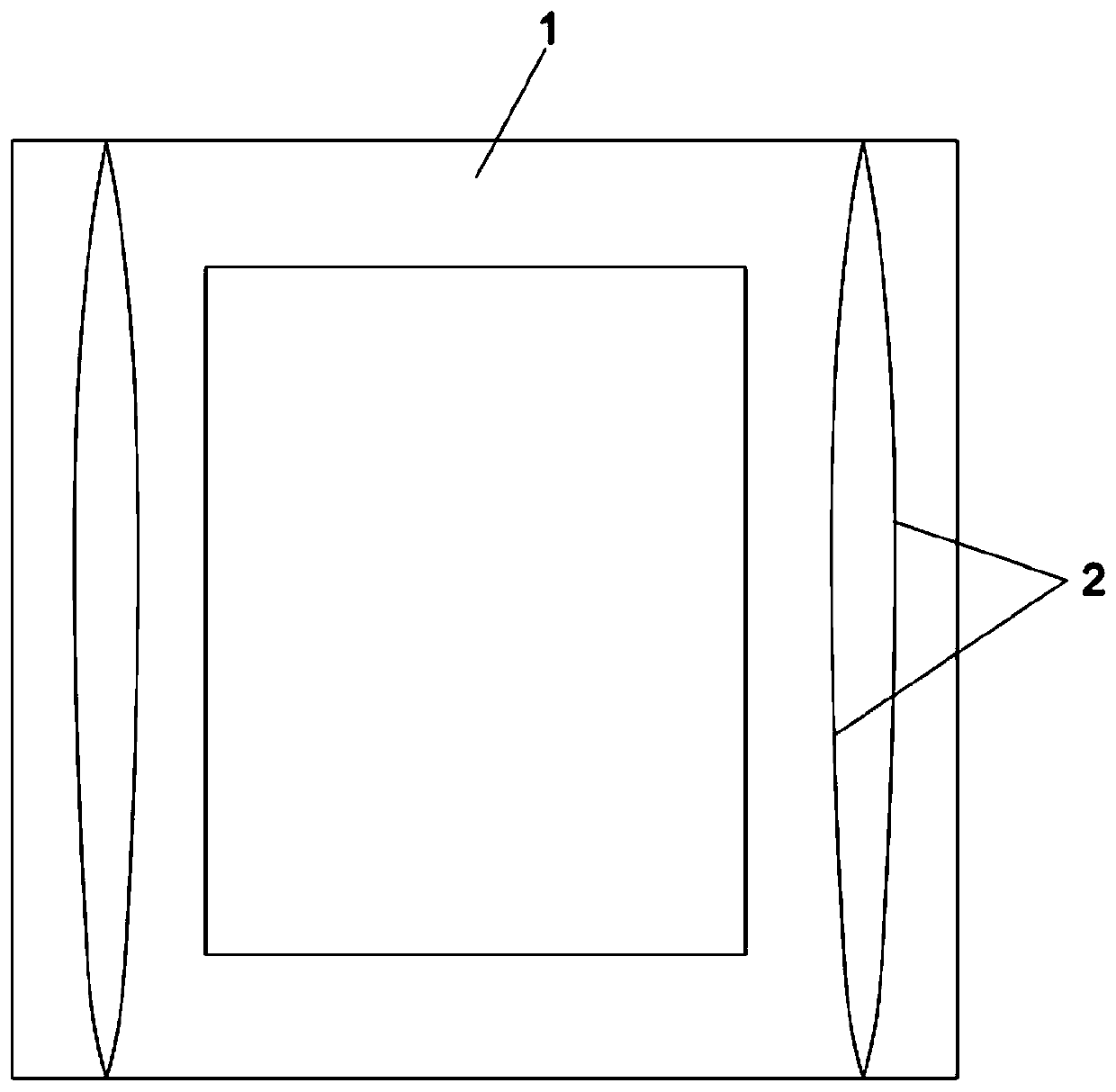

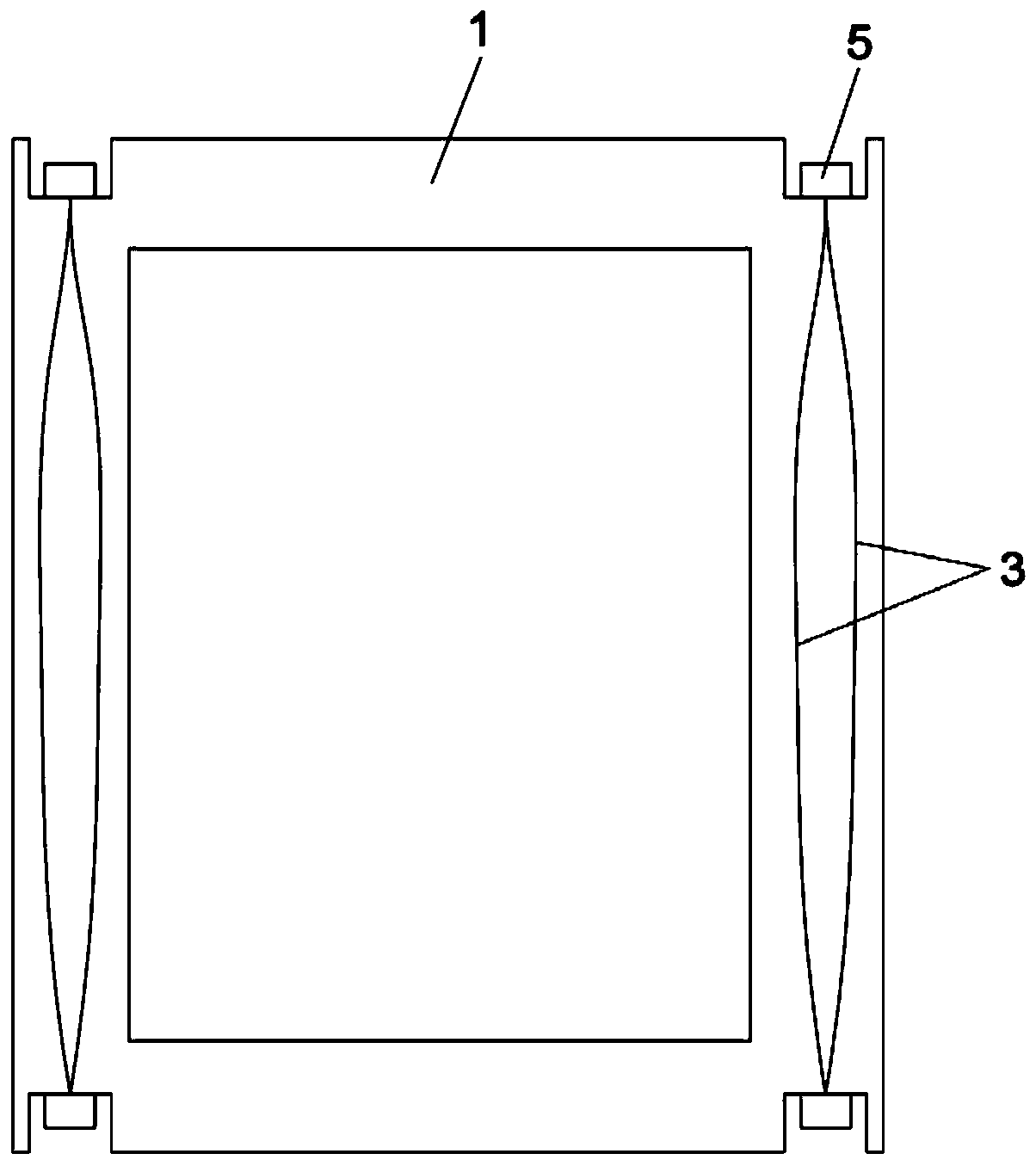

Mask plate frame

InactiveCN110592529AImprove deformationReduce the amount of scrapVacuum evaporation coatingSputtering coatingMultiple frameComputer science

The invention belongs to the technical field of OLED preparing and discloses a mask plate frame. The mask plate frame comprises a frame body. The frame body comprises multiple frames which are sequentially connected end to end. Arc correction structures are arranged on the frames and extend in the length direction of the frames where the correction structures are located. The correction structurescan provide prestress deformation for the frame body so as to correct mask plate deformation, and therefore the deformation phenomenon that inner contraction or outer expansion already happens to mask plates is improved and corrected, the pixel position precision is improved, the mask plate scrap quantity is reduced, and cost is saved; and mask plate deformation can also be adjusted and preventedthrough the correction structures, and the product quality is ensured.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

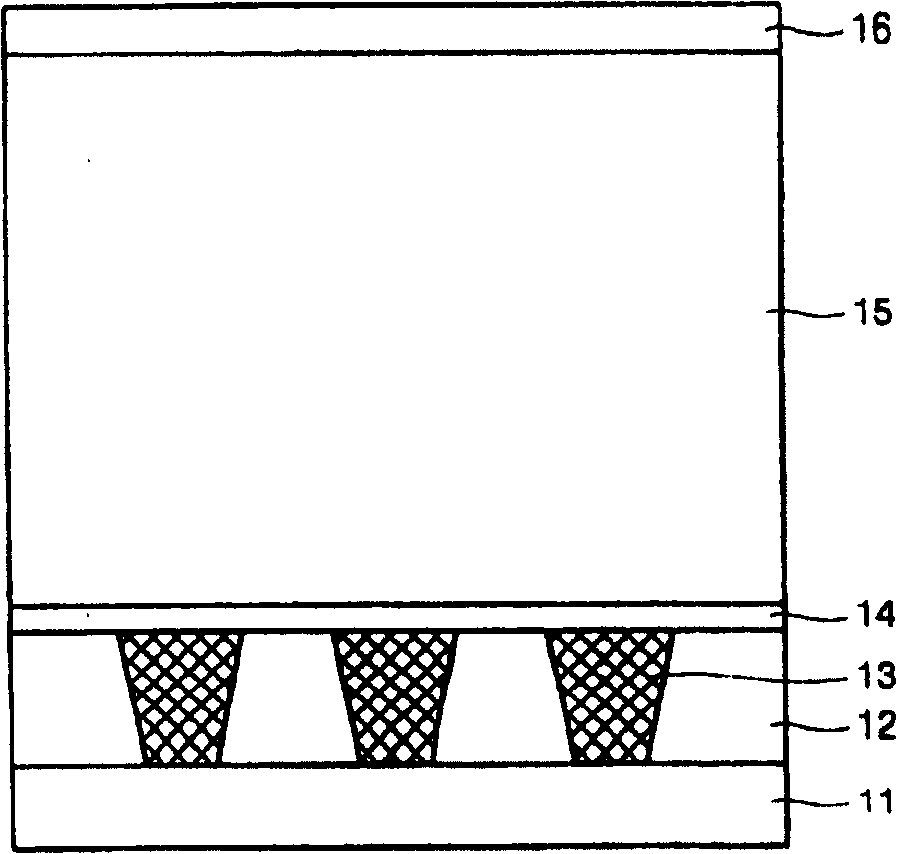

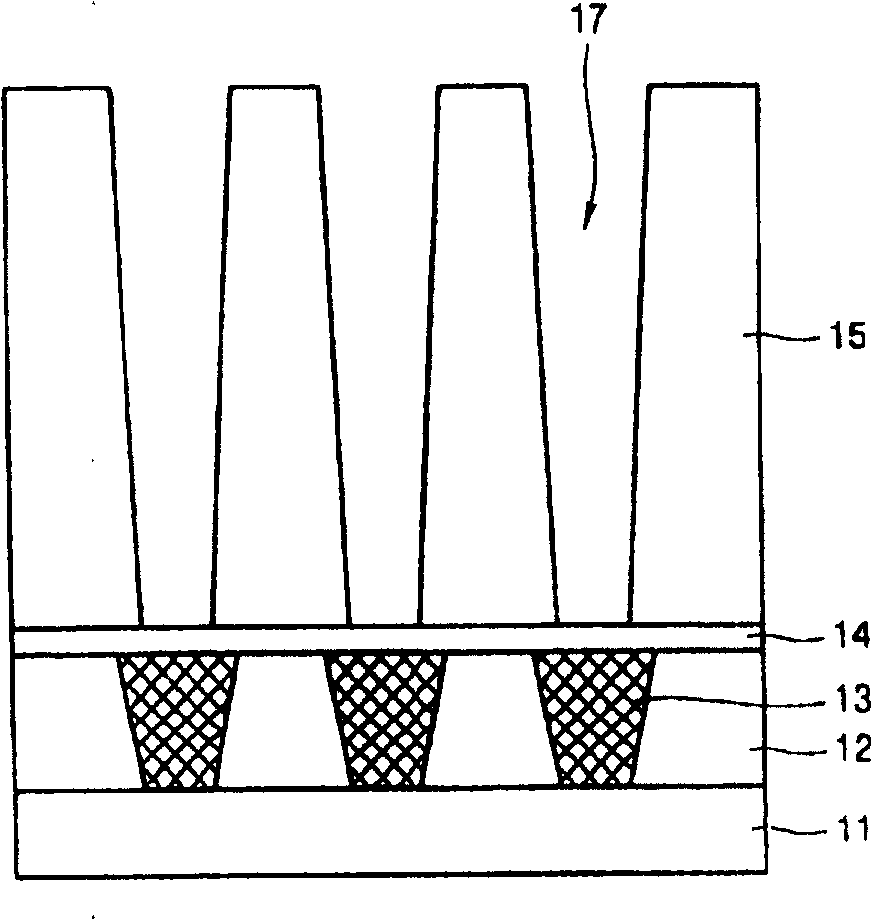

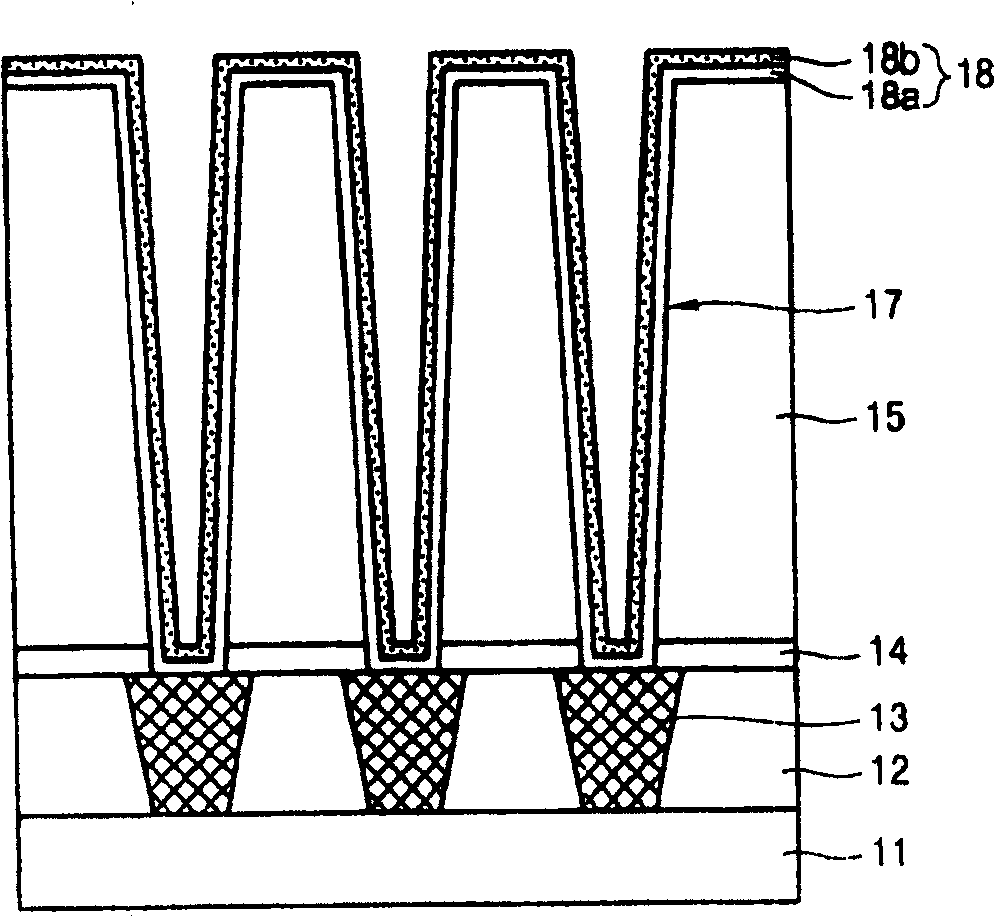

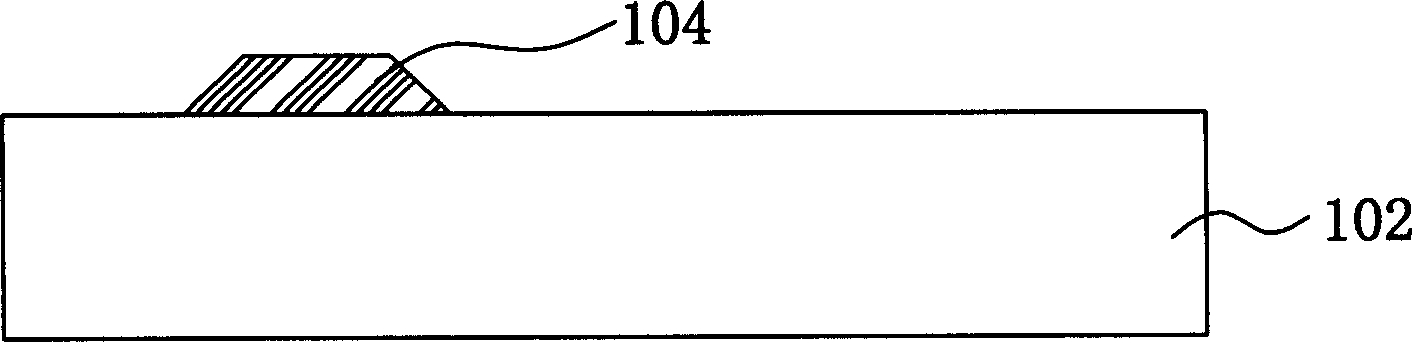

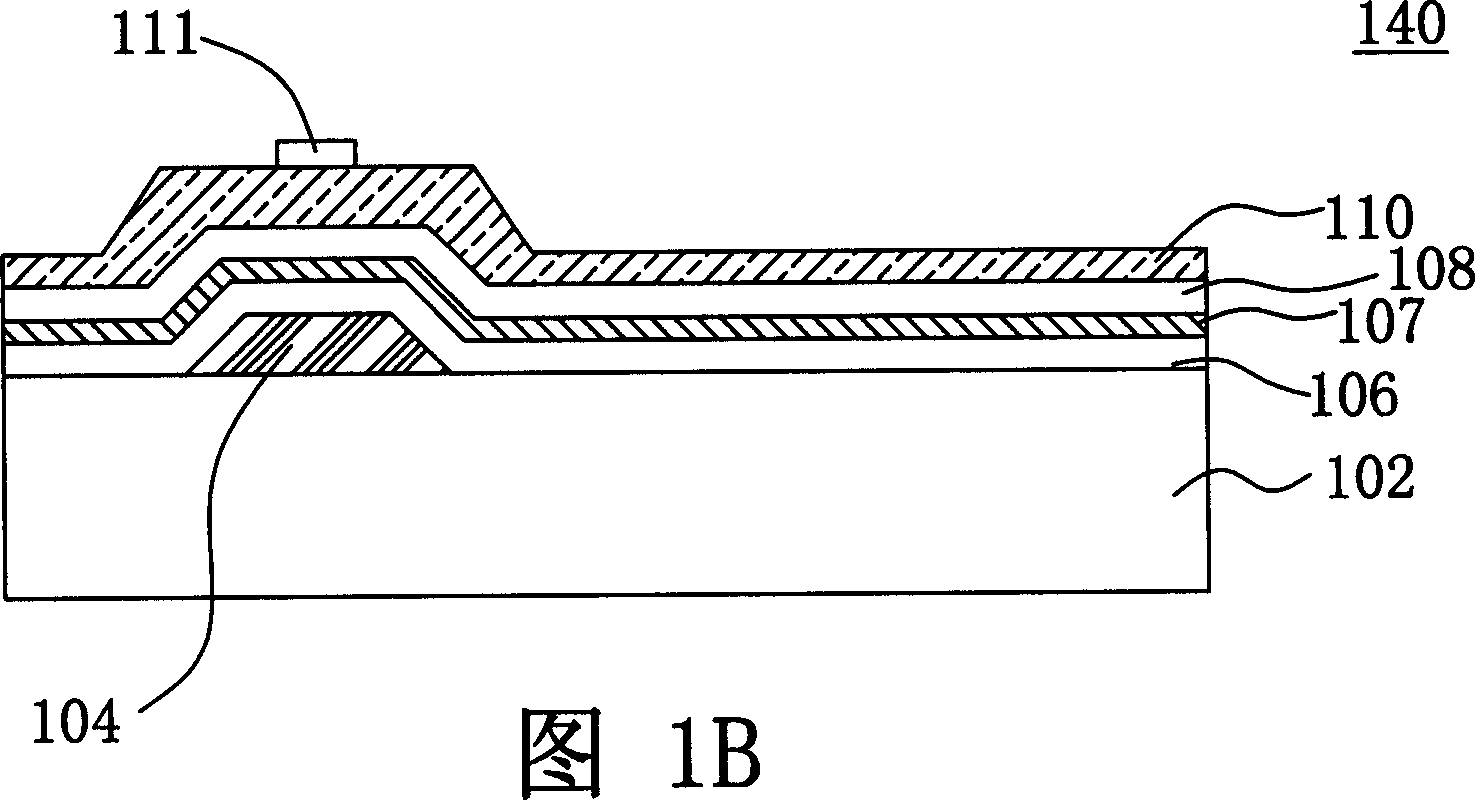

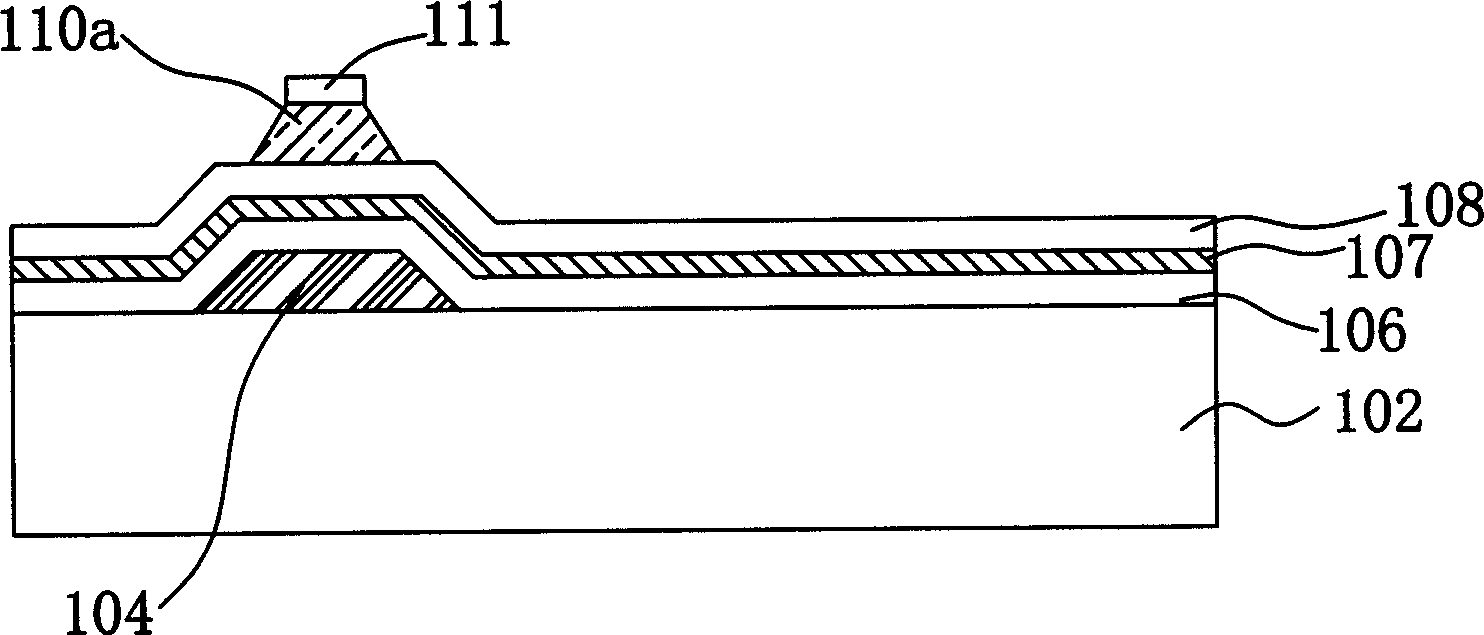

Method for remaking etching suspension layer

InactiveCN1581425AReduce the amount of scrapImprove the qualified rate of finished productsSemiconductor/solid-state device manufacturingNon-linear opticsEtchingHydrogen

In the invention, semiconductor structure includes an amorphous silicon layer, an incomplete etching stopped layer, and first patterned photoresist layer. The incomplete etching stopped layer is formed on the amorphous silicon layer. The first patterned photoresist layer is formed on the incomplete etching stopped layer. The procedure for remaking etching stopped layer includes following steps: removing first patterned photoresist layer, incomplete etching stopped layer; cleansing surface of the amorphous silicon layer by using N+ precleaning method; processing serface of the amorphous silicon layer through hydrogen gas-plasma, and forming a silicon nitride layer on the amorphous silicon layer by using method of chemical vapor deposition; forming second patterned photoresist layer on the said silicon nitride layer, and removing exposed partial silicon nitride layer through etching.

Owner:AU OPTRONICS CORP

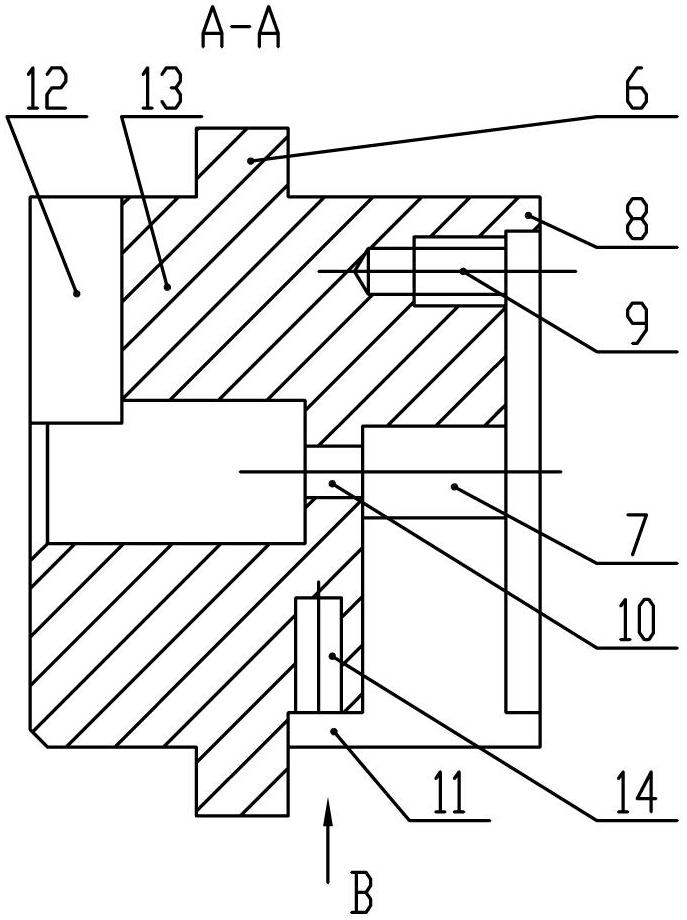

Die with inserting mechanism

InactiveCN103212640ASimple structurePrecise positioningShaping toolsEngineeringMechanical engineering

Owner:昆山众信精密模具标准件有限公司

Polarizing film locking unit on front frame of liquid crystal display

InactiveCN101710213AAvoid jitterReduce the amount of scrapNon-linear opticsLiquid-crystal displayOperating point

The invention provides a polarizing film locking unit on a front frame of a liquid crystal display, which is applicable to preventing the locking device from damaging the polarizing film of a liquid crystal display panel module while assembling the liquid crystal display panel module by using the locking device. The locking device unit comprises an integral member of a sleeve and an insulating rod and an elastic terminal, wherein the integral member of the sleeve and the insulating rod is sleeved on the locking device through the sleeve; the elastic terminal is arranged at the tail end of the insulating rod. When the locking device unit is arranged on the locking device, the tail end of the insulating rod exceeds one end of the locking device which is used for locking screws. In the locking unit of the invention, when the liquid crystal display panel module is assembled, the locking device vibrates or obliquely slips, and the tail end of the insulating rod in the locking device unit arranged on the locking device exceeds one end for locking the screws of the locking device,, which can provide the function of horizontally limiting, and has supporting action to rapidly adjust the position of the locking device to ensure that the top end of the locking device returns to an accurate operating point. Thus, the top end is prevented from scratching the polarizing film.

Owner:AU OPTRONICS CORP

Arc common-edge type laser cutting device and cutting process thereof

PendingCN113878242ARealize the clamping effectImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesStraightedgeWire cutting

The invention discloses an arc common-edge type laser cutting device and a cutting process thereof. The arc common-edge type laser cutting device comprises a laser cutting device body, a workbench is fixedly installed in the laser cutting device body, a cutting tool bit is movably installed on the upper end face of the laser cutting device body, and a spraying head is fixedly installed on one side of the cutting tool bit. And one end of the spray head is fixedly connected with a water guide pipe. According to the arc common-edge type laser cutting device and the cutting process thereof, through cooperation of a clamping plate, a gear, a straight ruler strip and a movable device, horizontal movement of the straight ruler strip is driven through circumferential rotation of the gear, movement of the clamping plate towards a cutting piece is achieved, the clamping effect of the clamping plate on the cutting piece is achieved, the problem that the position of the cutting piece moves when one side is cut in a collinear mode is effectively solved, and the stability of the cutting piece is enhanced through clamping of the cutting piece.

Owner:云切智能制造(苏州)有限公司

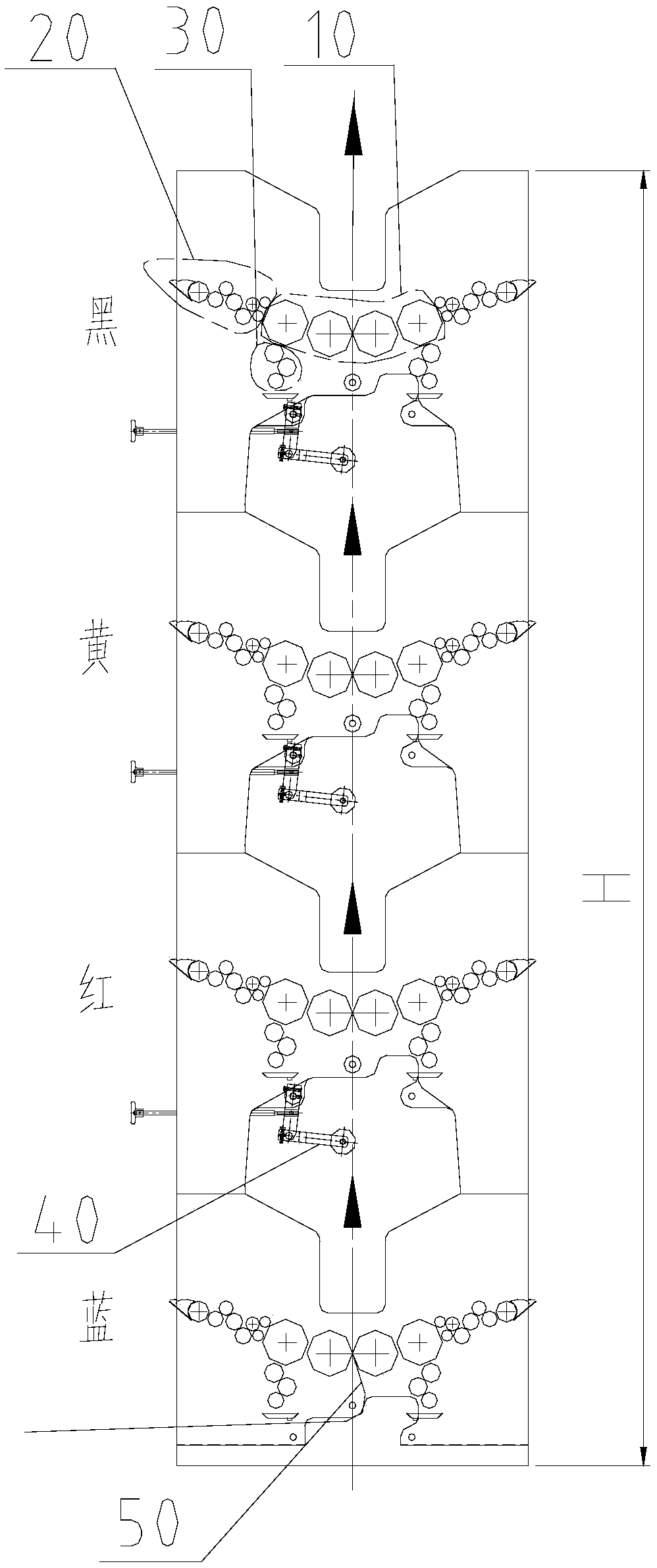

Compact newspaper printing machine

InactiveCN109572159AReduce the layout distanceThe value of the expansion is reducedRotary pressesPrinting press partsPulp and paper industryNational standard

The invention discloses a compact newspaper printing machine. The compact newspaper printing machine comprises four color cell units mounted between an operation side wall board and an engine side wall board of a printing machine body from bottom to top, wherein each of the four color cell units comprises a set of a printing cylinder group, two ink supply systems and water supply systems; the printing cylinder group is located at the middle part; the ink supply systems are located on the left side and the right side of the printing cylinder group in a one-to-one correspondence manner; the water supply systems are located on the lower left side and the lower right side of the printing cylinder group in a one-to-one correspondence manner; and the arranging distance between every two adjacentcolor cell units is 0.5-0.7 m, so that the total height of the printing machine body is not greater than 2.8 m. According to the compact newspaper printing machine disclosed by the invention, the expanding numerical value of a paper belt is reduced by half, and meets the a national standard of 0.1mm, the printing quality is improved, and the waste newspaper capacity during printing can be obviously reduced.

Owner:GOSS GRAPHIC PRINTING SYST CHINA

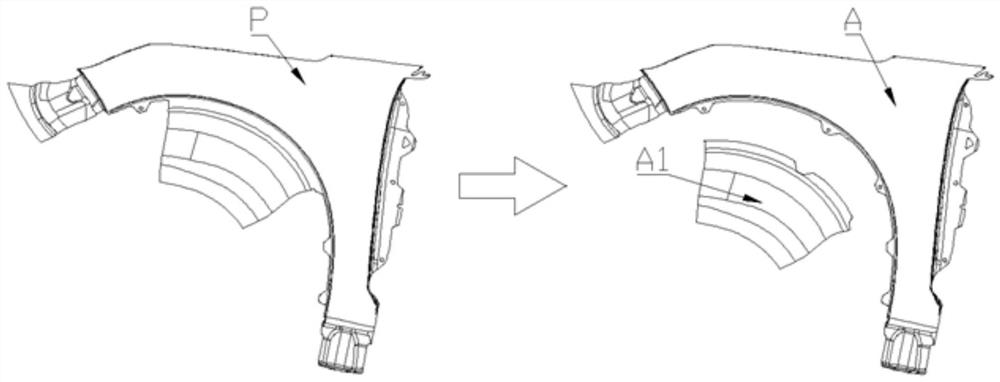

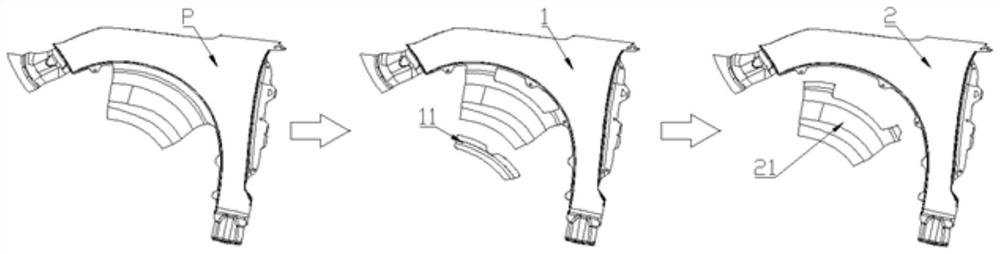

Die process structure facilitating discharging of fender wheel opening waste and using method

PendingCN112792215ASolve the problem of discharging parts with partial processReduce the amount of scrapPerforating toolsStripping-off devicesFenderPunching

The invention discloses a die process structure facilitating discharging of fender wheel opening waste and a using method. The die process structure comprises a punching female die, a punching male die, an OP30 cut-off tool, an OP30 punching and flanging insert and an OP30 waste sliding way. The punching female die is fixed on an OP20 lower die holder through a bolt, the punching male die is fixed on an OP20 upper die holder through a bolt, the OP30 cut-off tool is fixed on an OP30 lower die holder through a bolt, the OP30 punching and flanging insert is fixed on an OP30 upper die holder through a bolt, the OP30 waste sliding way is fixed to the OP30 lower die holder through the bolt, and a position of the OP30 waste sliding way is in lap joint with the back of the OP30 cut-off tool, and is used for bearing OP30 waste. By renovating an OP20 wheel opening part die process structure, under the condition that the number of original dies is not increased, a waste material separation process completed in an original process is divided into two processes to be completed, the problem that the waste is discharged upwards to cause deviation of a process part is solved with an extremely low cost, the production efficiency is improved, potential safety hazards are eliminated, and the production cost is reduced.

Owner:CHINA FIRST AUTOMOBILE

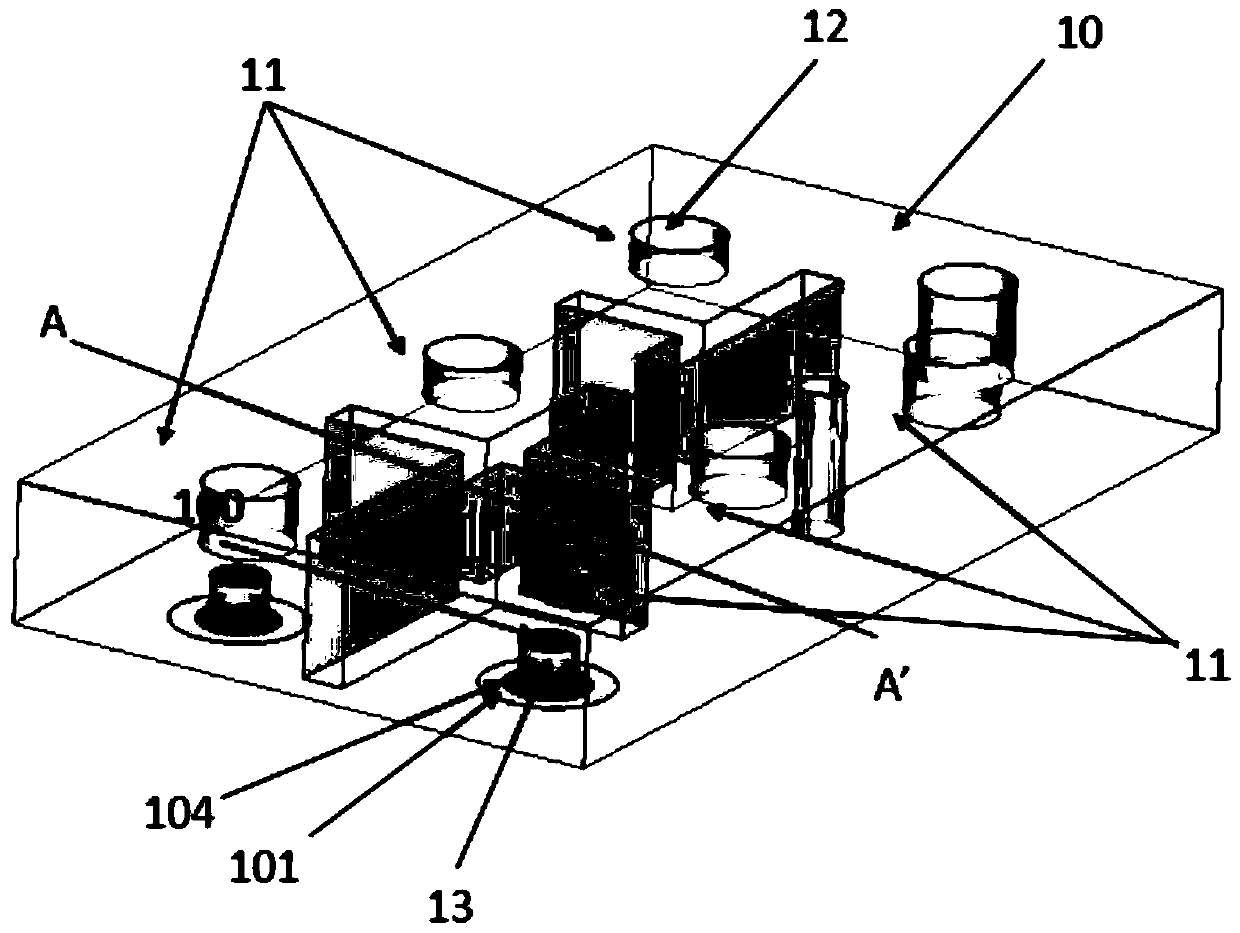

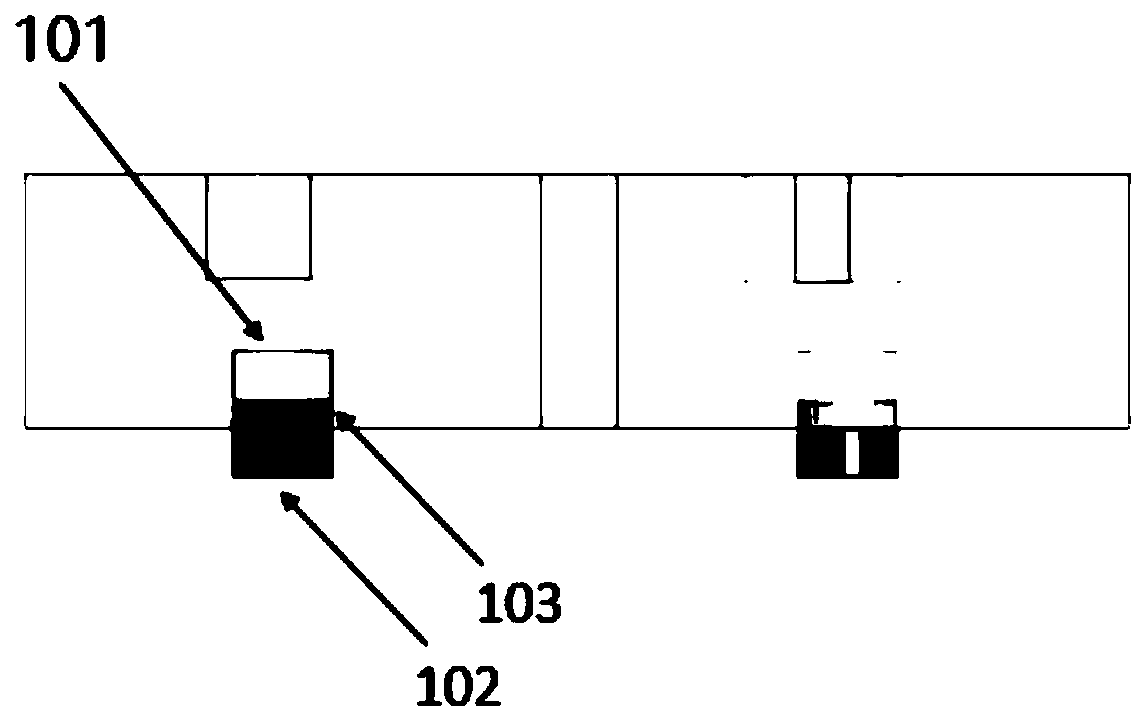

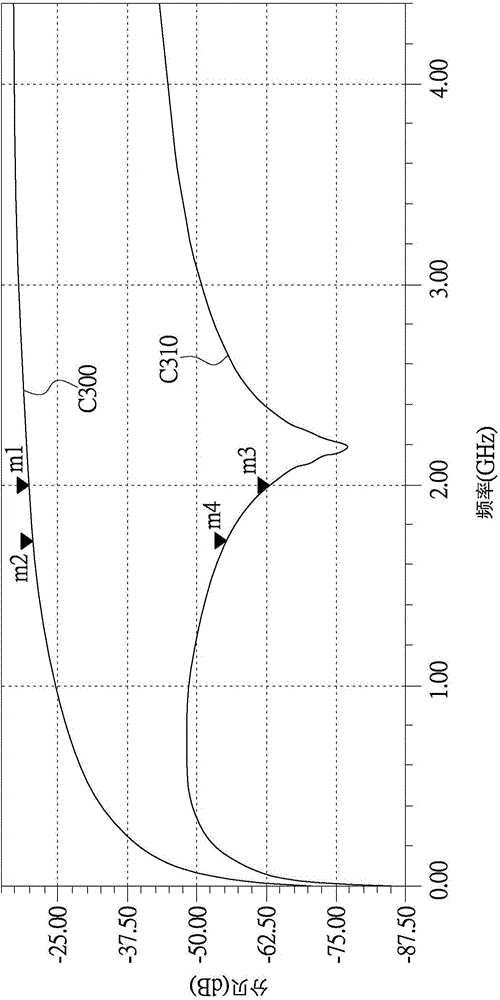

Dielectric waveguide filter with adjustable port coupling strength

PendingCN111293385AAdjustable strengthStrong and flexible adjustmentWaveguide type devicesEngineeringMaterials science

The invention provides a dielectric waveguide filter with adjustable port coupling strength. The dielectric waveguide filter comprises at least one resonance unit, at least one port blind hole and atleast one port inner core, wherein the port blind hole is formed in the surface of the dielectric waveguide filter, and the port blind hole is provided with at least one non-electroplating area; and the port inner core is arranged in the port blind hole, and the coupling strength of the port is adjusted by adjusting the area of the non-electroplating area and the length of the port inner core extending into the port blind hole. According to the invention, the port coupling strength of the dielectric waveguide filter can be flexibly adjusted only by processing the port blind hole through a conventional electroplating process; the method has the advantages of being simple in implementation mode and easy to operate; the number of scrapped materials is reduced; and the production cost is reduced.

Owner:MOBILE ANTENNA TECH SHENZHEN +5

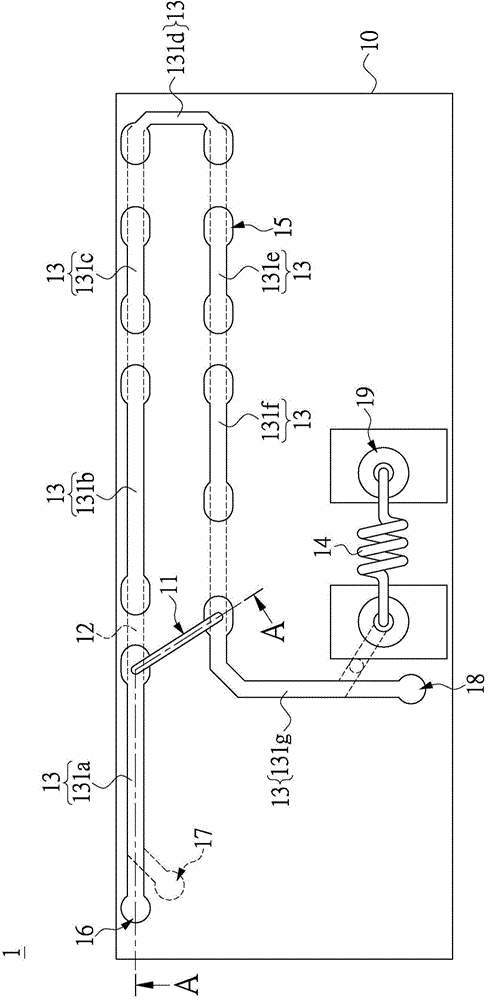

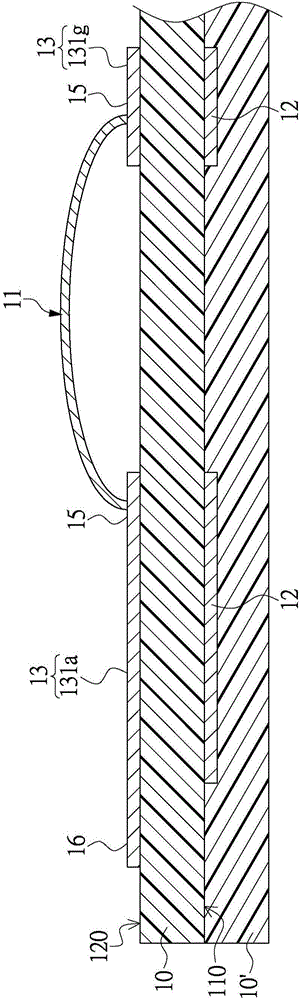

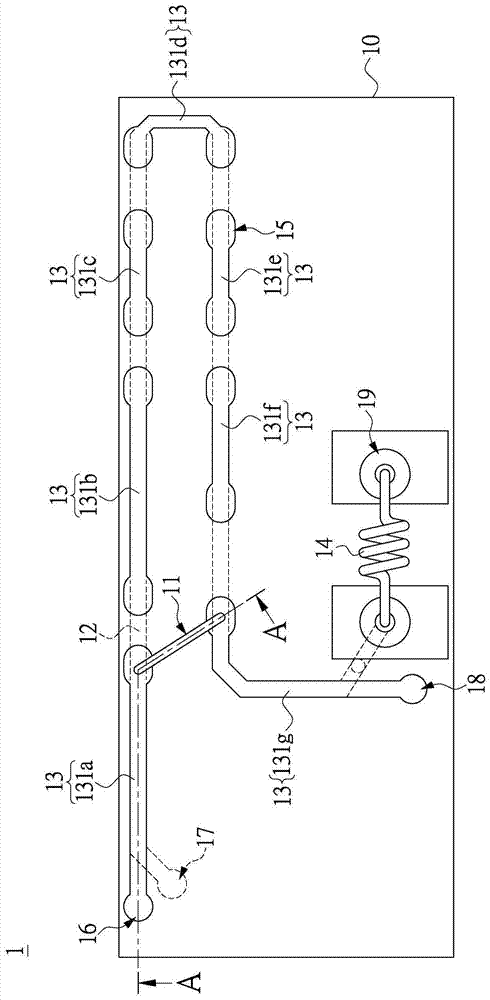

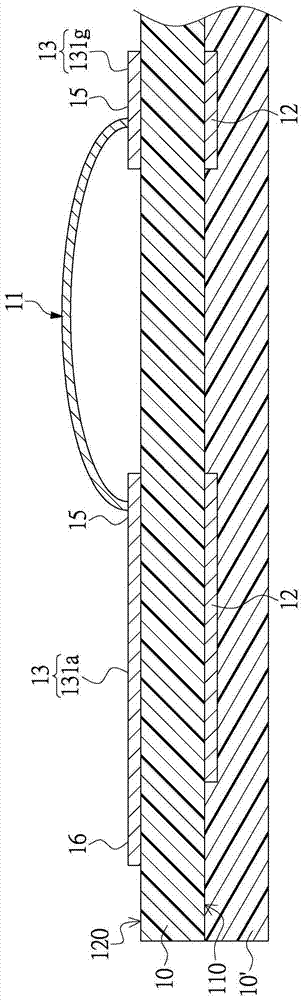

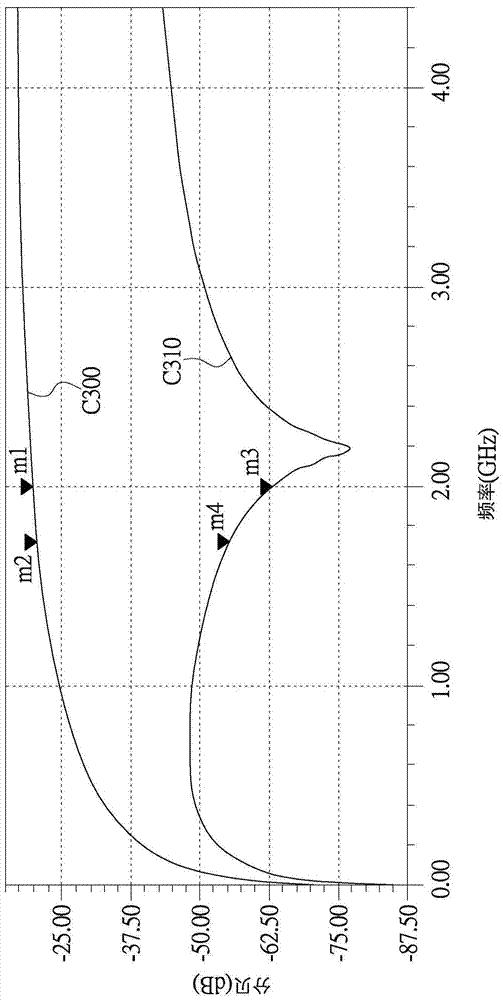

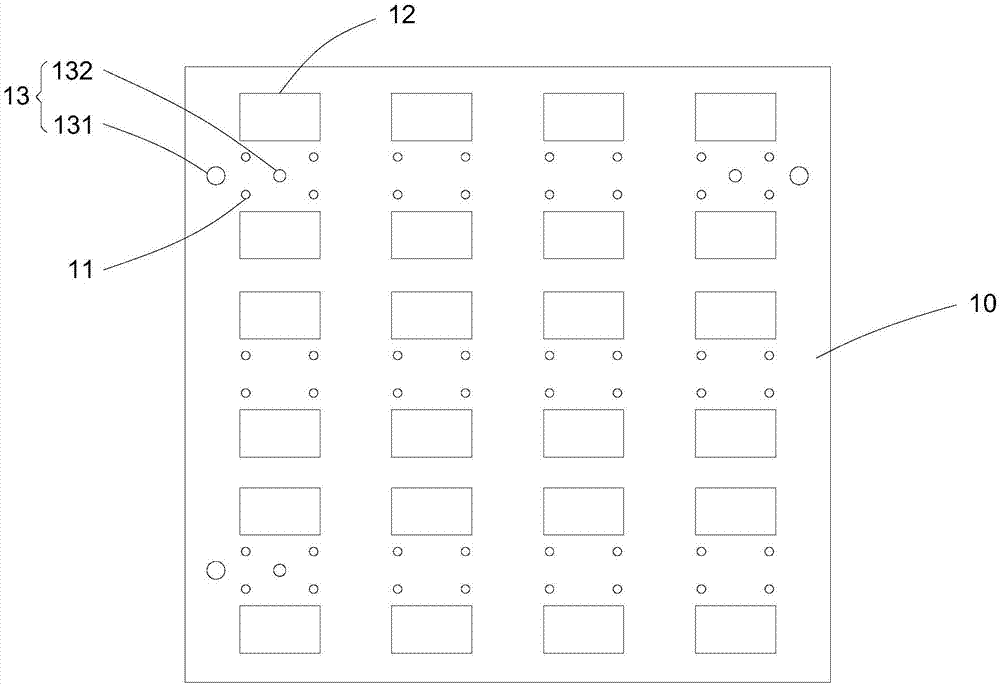

Adjustable RF coupler and manufacturing method thereof

ActiveCN104868219AAdjust the amount of couplingChange overlap lengthCoupling devicesEngineeringLine segment

The invention provides an adjustable RF coupler and a manufacturing method thereof. The adjustable RF coupler comprises an insulating layer, a first transmission line and a second transmission line, wherein the second transmission line and the first transmission line are arranged correspondingly; the insulating layer is configured between the first transmission line and the second transmission line; the second transmission line comprises a plurality of line segments which are separated from one another and distributed along the extending path of the first transmission line; and at least one lead wire is used for electrically connecting at least two of the line segments, so that the at least two line segments are electrically conducted through the at least one lead wire. According to the adjustable RF coupler and the manufacturing method thereof, the number of scrapped adjustable RF coupler can be reduced.

Owner:ADVANCED SEMICON ENG INC

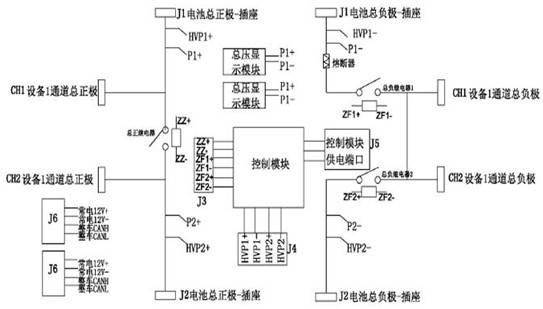

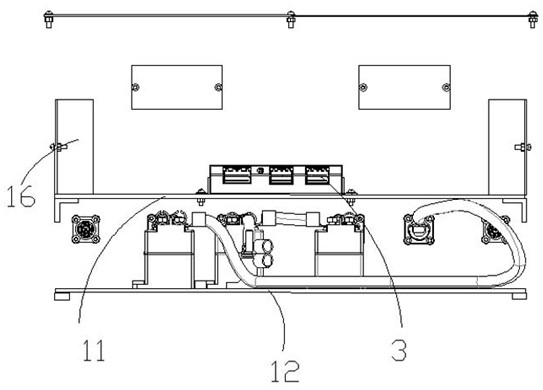

A power battery test control device

ActiveCN110515010BReduce the amount of scrapFirmly connectedElectrical testingPower batteryHemt circuits

The present invention provides a power battery test control device, which includes a housing, a controller disposed in the housing, a socket disposed on the housing, and a power supply for power supply, the first battery positive plug interface and the second battery positive A positive relay is provided between the plug ports, a first negative relay is provided between the negative plug port of the first battery and the negative plug port of the first device, and a second relay is provided between the negative plug port of the second battery and the negative plug port of the second device. Negative relay, the controller is provided with a voltage acquisition circuit for collecting the open circuit voltage U1 of the first battery and the open circuit voltage U2 of the second battery, and a logic operation unit is also provided on the controller, and the controller passes through the process according to the collected information of U1 and U2 The logical operation unit controls the opening / closing of the positive relay, the first negative relay and the second negative relay after calculation.

Owner:LINKDATA NEW ENERGY CO LTD

Adjustable radio frequency coupler and method of making the same

ActiveCN104868219BAdjust the amount of couplingChange overlap lengthCoupling devicesCouplingEngineering

The invention provides an adjustable radio frequency coupler and a manufacturing method thereof. The adjustable radio frequency coupler includes an insulating layer, a first transmission line and a second transmission line. The second transmission line is arranged corresponding to the first transmission line, and the insulating layer is arranged between the first transmission line and the second transmission line. The second transmission line includes a plurality of line segments separated from each other and arranged along the extension path of the first transmission line, wherein at least one wire is used to electrically connect at least two line segments, so that the at least two line segments are electrically conductive via at least one wire Pass. The invention can reduce the number of scrapped adjustable radio frequency couplers.

Owner:ADVANCED SEMICON ENG INC

PCB tolerance plate structure and processing method thereof

ActiveCN107580408AGuaranteed performanceAccurate locationPrinted circuit detailsPrinted circuit manufactureImage transferEngineering

The invention provides a PCB tolerance plate structure and a processing method thereof. The structure comprises a PCB substrate, the PCB substrate is provided with n positioning holes and n PCB line units, the PCB substrate is provided with a reference measuring hole and an anti-weld counterpoint column, and the thickness of the anti-weld counterpoint column is larger than or equal to that of thePCB line units; etching is conducted according to the position of the positioning hole, whether the PCB line units and the anti-weld counterpoint column are qualified or not is judged according to thereference measuring hole, according to the position of the anti-weld counterpoint column, the exposed anti-weld ink is solidified, image transfer is achieved, and a PCB tolerance plate is obtained. Accordingly, whether the PCB line units formed through etching meet the requirements or not can be detected in time, the rate of certified products of etching is guaranteed, when the anti-weld ink is printed, image transfer can be achieved accurately according to the anti-weld counterpoint structure, the positions of all structures of the finished PCB tolerance plate product are accurate, the PCB line unit performance obtained through quantity production is guaranteed, the number of scrap is reduced, and the cost is reduced.

Owner:DIGITAL PRINTED CIRCUIT BOARD CO LTD

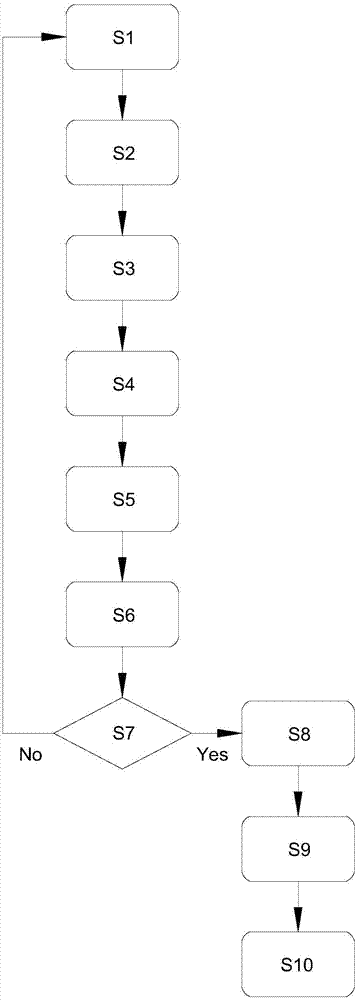

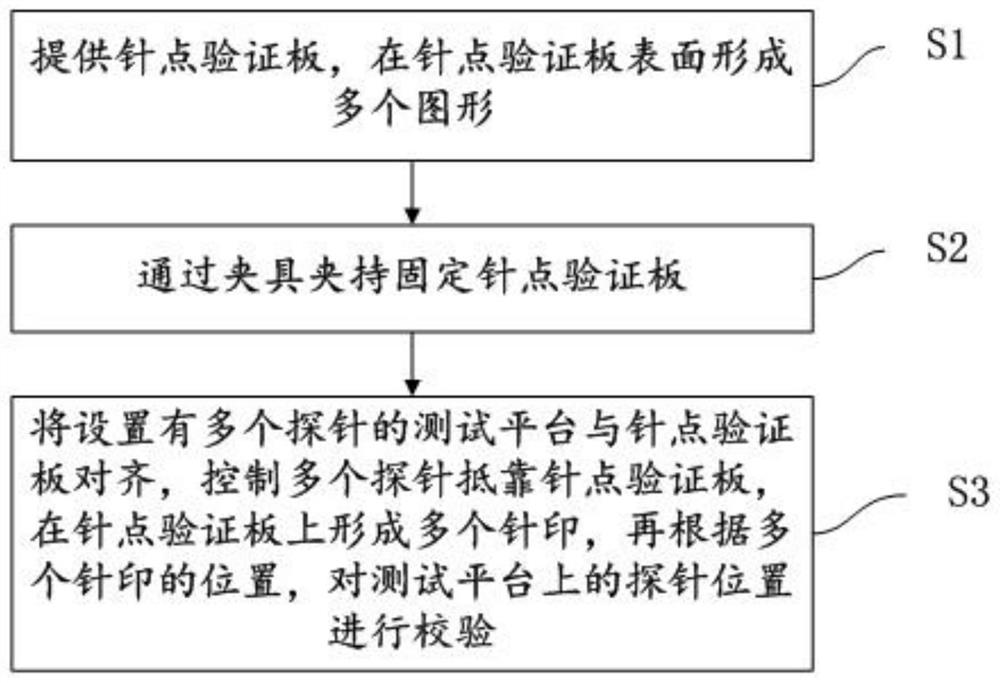

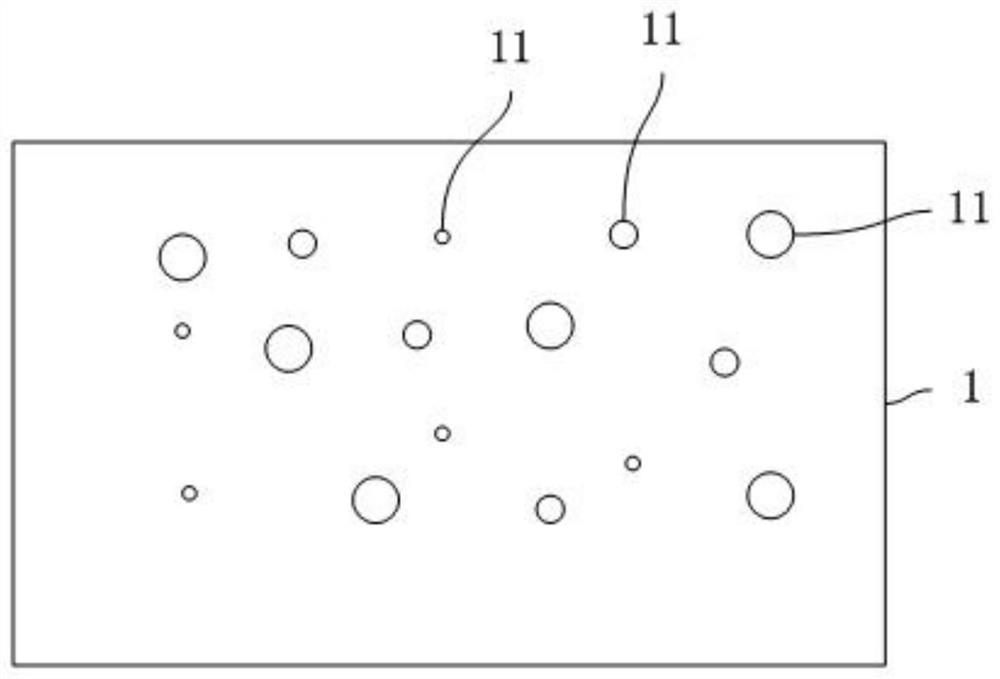

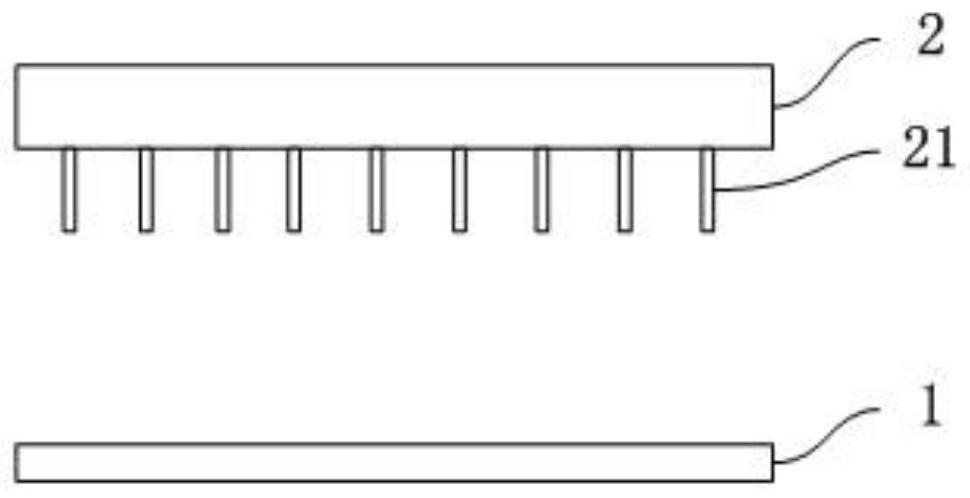

Verification method and system for ICT test platform

The invention discloses a verification method and system for an ICT test platform. The method comprises the following steps: providing a needle point verification plate, and forming a plurality of patterns on the surface of the needle point verification plate, wherein the shapes, sizes and positions of the plurality of patterns are respectively corresponding to the shapes, sizes and positions of a plurality of bonding pads on the PCB; clamping and fixing the needle point verification plate through a clamp; and aligning a test platform provided with a plurality of probes with the probe point verification plate, controlling the plurality of probes to abut against the probe point verification plate, forming a plurality of probe prints on the probe point verification plate, and verifying the positions of the probes on the test platform according to the positions of the plurality of probe prints, wherein the plurality of graphs comprise a plurality of categories of graphs, and different categories of graphs are different in size and color. According to the invention, the position of the probe on the ICI test platform can be verified, and the PCB is prevented from being scratched to cause the waste of the PCB.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Semiconductor chip comb sliver repairing method and device

ActiveCN100557768CImprove repair efficiencyReduce the amount of scrapSemiconductor/solid-state device manufacturingLinear motionSemiconductor chip

The semiconductor chip sliver repair method and device repair the problematic sliver through a set of sliver repair mechanism simulating the manual repair method. The simulated manual repair method is to fix the semiconductor device chip on the microscopic workbench through a set of positioning devices, and then complete the repair of the chip sliver by a set of picking and combing mechanism that simulates manual repairing of the chip sliver. Wherein, the combing mechanism for simulating manual chip repairing is to adjust the knife edge of the repairing sliver to the root of the sliver to be slivered and to align with the length direction of the sliver through a micro-motion positioning mechanism, so as to prepare for slitting ; Then the bolt guide mechanism installed together with the cutter makes the knife edge produce the required linear motion to complete the action of removing the sliver. The sliver repair mechanism is composed of a chip positioning seat, a cutter, a micro-motion positioning mechanism and a fastening guide mechanism, and the whole structure is placed in the "microscopic workbench".

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

Storage and distribution device capable of uniformly discharging tea leaves

PendingCN113335615AReduce the amount of scrapChange heightSolid materialAgricultural engineeringStructural engineering

The invention discloses a storage and distribution device capable of uniformly discharging tea leaves, and relates to the field of tea leaf storage. The storage and distribution device comprises a storage barrel. The storage barrel comprises a bottom plate, the side face of the bottom plate is slidably connected with a bottom ring, the bottom ring is connected with a top ring through connecting rings which are sequentially connected in a sleeved manner, and the bottom ring and the top ring are connected through a supporting mechanism. The outer side of the storage barrel is sleeved with sleeves at intervals, the sleeves are rotatably connected with a shaft rod which is coaxially and rotatably connected with the middle of the bottom plate, and the sleeves are in transmission connection with the supporting mechanism. The shaft rod is fixedly connected with a support, a base is fixedly connected with distribution rings which surround the outer sides of the sleeves and are communicated with the interiors of the sleeves, and the bottom plate is fixedly connected with the sleeves. According to the storage and distribution device, tea leaves in the storage barrel can be discharged in the mode that the storage barrel stretches out and draws back, the discharged tea leaves are discharged through the distribution rings connected to the bottoms of the sleeves, and the tea leaf crushing quantity can be reduced in the mode that the tea leaves slide down from the top of the storage barrel.

Owner:SHUCHENG SHUCHA JIUYILIU TEA PLANTATION

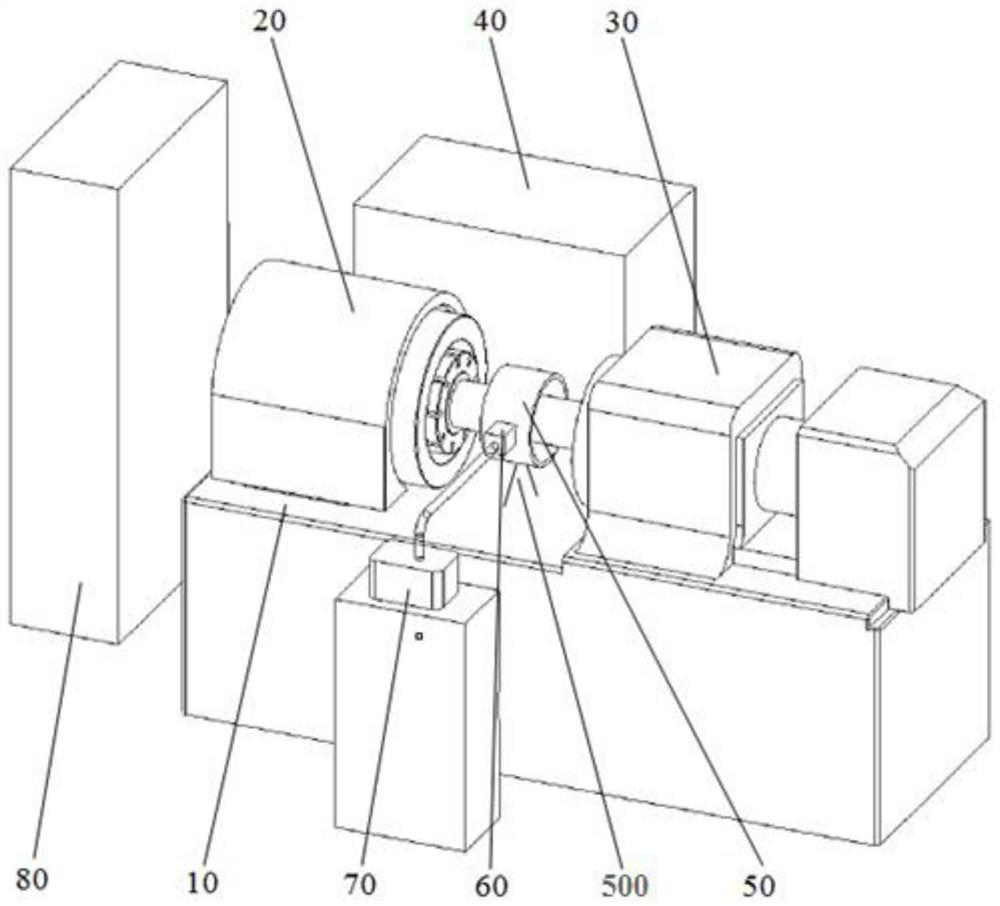

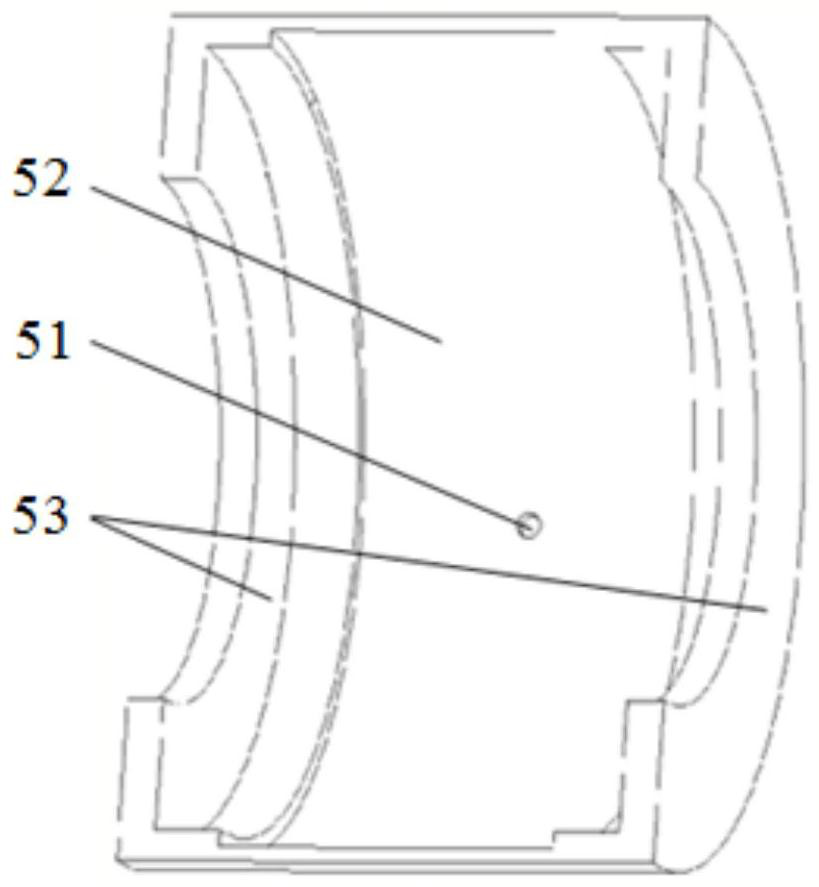

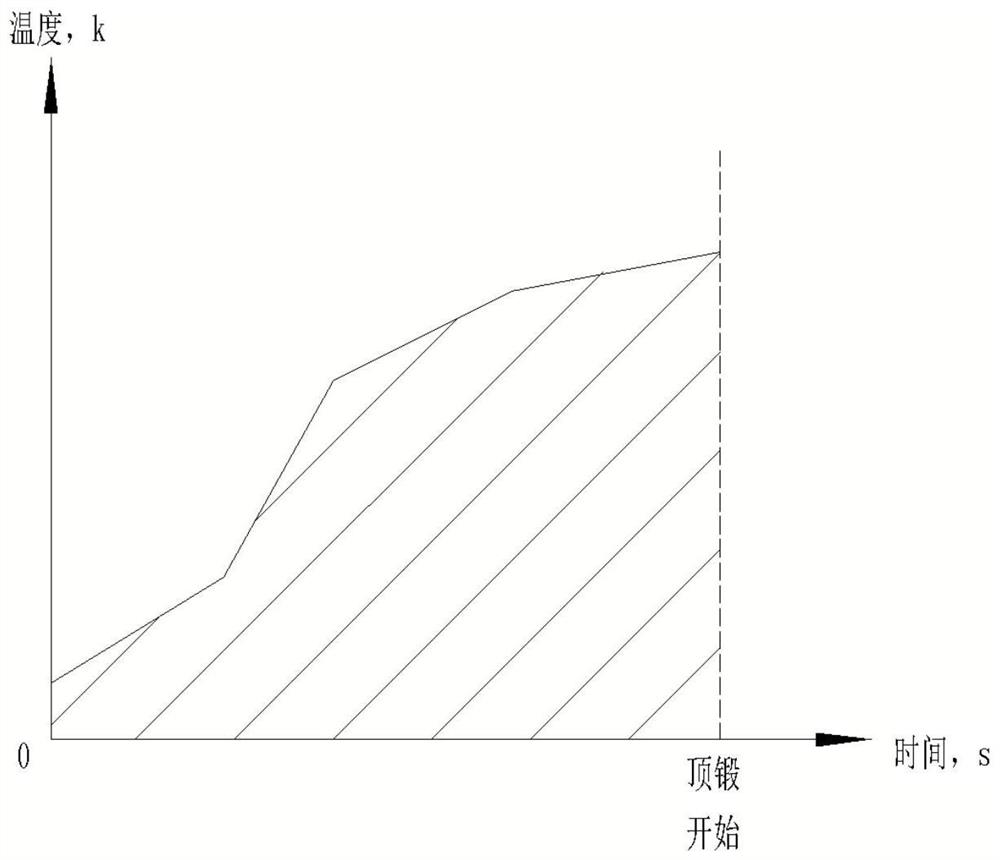

Friction welding control and quality evaluation method based on weld temperature and spatter detection

ActiveCN113857648BEasy to assembleQuick releaseNon-electric welding apparatusFriction weldingThermodynamics

The invention provides a friction welding control and quality evaluation method based on weld seam temperature and spatter detection, including a, equipment installation; b, starting the friction welding process; c, welding process quality control; d, post-weld quality evaluation. Among them, the post-weld quality evaluation compares the spatter weight, spatter size and temperature curve, and evaluates the welding quality based on the weight, spatter size and temperature curve. The method adopts a welding machine platform (10), a welding machine rotating end (20), a welding machine moving end (30), an oil pressure station (40), a spatter detection device (50), an infrared thermal imager (60), an industrial The friction welding control system of the computer (70) and the welding machine control system (80). The method evaluates the welding quality during and after welding and can control the welding process, has comprehensive evaluation information and high accuracy, effectively saves welding time, improves production efficiency, and reduces production costs.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com