Method for detecting defect of doped boron-silicon glass film

A borosilicate glass and borosilicate glass technology, applied in the semiconductor field, can solve the problems of reduced product yield and excessively long inspection cycle, and achieve the advantages of improving product yield, saving time, and reducing the number of scrapped wafers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

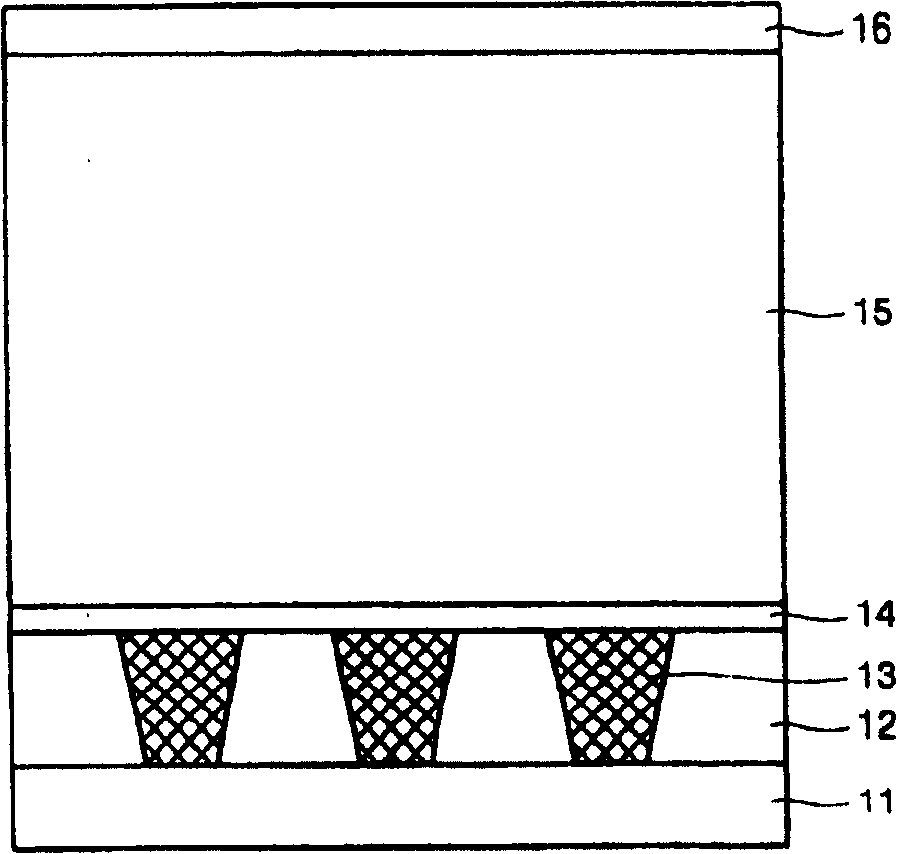

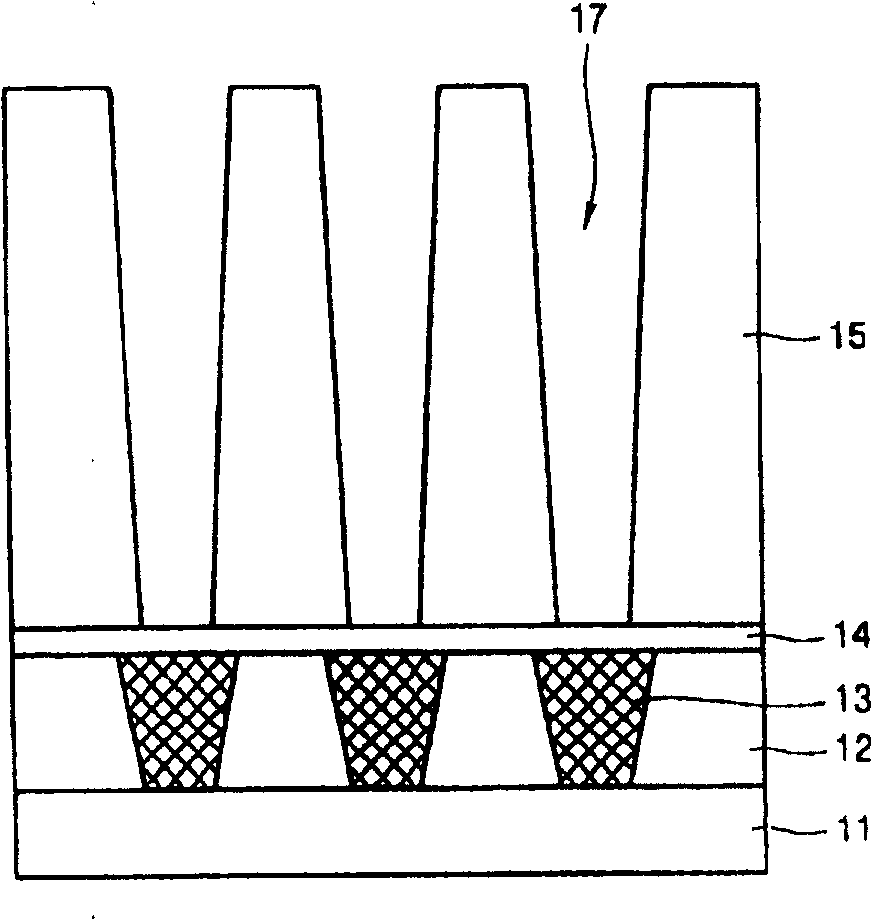

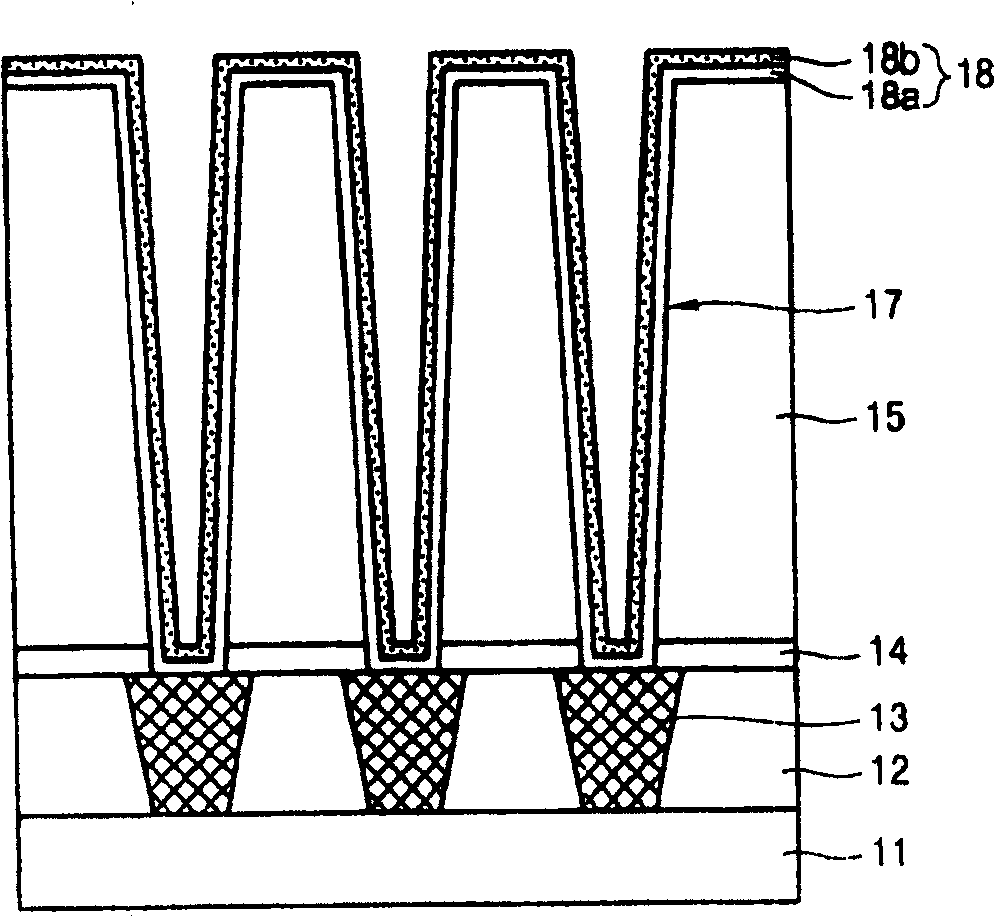

[0028] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] In the manufacturing process of semiconductor devices such as capacitors and diodes, the process of forming a borosilicate glass film on the surface of the wafer is involved. The borosilicate glass mentioned in the present invention refers to boron-containing silicate glass, which can be only boron-doped silicate glass film, or boron-doped phosphorus-silicate glass or doped with boron and other doped glass films. Dopant silicate glass. In the prior art, borosilicate glass films are generally deposited by chemical vapor deposition, especially plasma enhanced chemical vapor deposition.

[0030] Taking the method of plasma chemical vapor deposition in the prior art to deposit only boron-doped silicate glass as an example, generally B 2 h 6 、SiH 4 and N 2 Raw material gases such as O are passed into the reaction chamber of the plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com