Storage and distribution device capable of uniformly discharging tea leaves

A material distributing device and a uniform technology, which is applied in the field of storage and distributing devices for evenly discharging tea leaves, can solve the problems of affecting appearance and easy occurrence of broken materials, and achieve the effects of easy recovery, convenient operation, and avoiding mutual separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

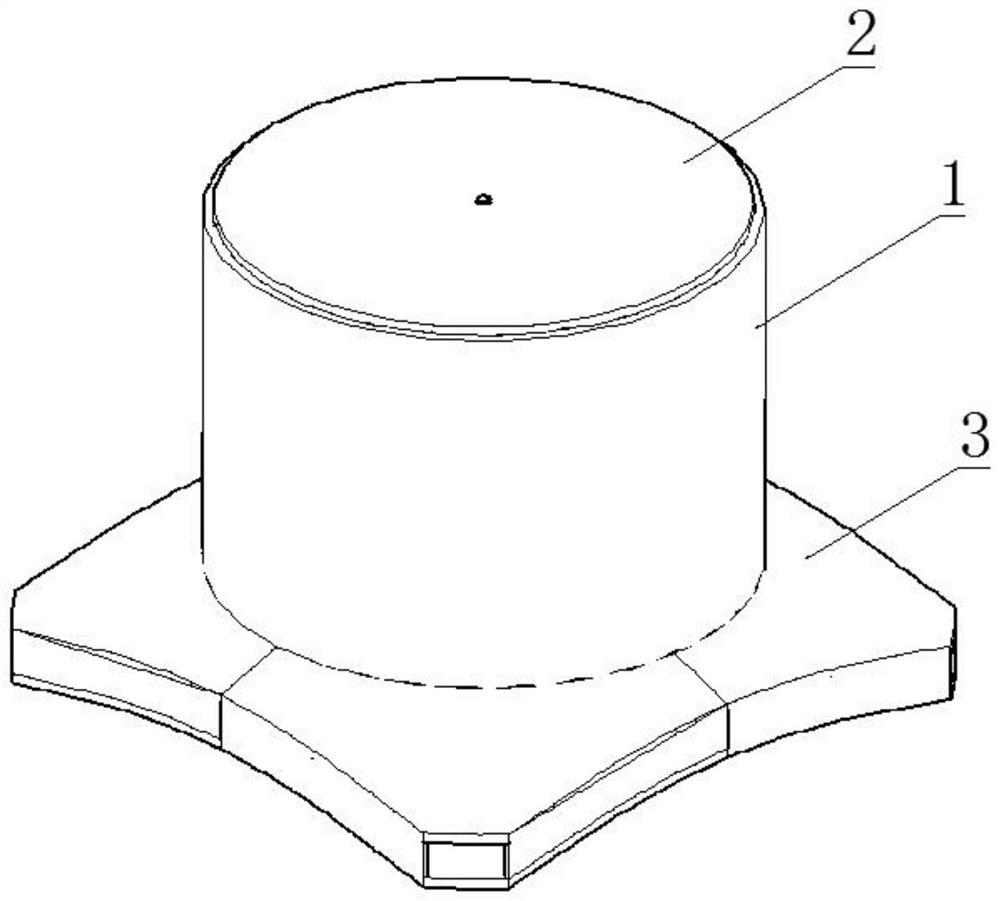

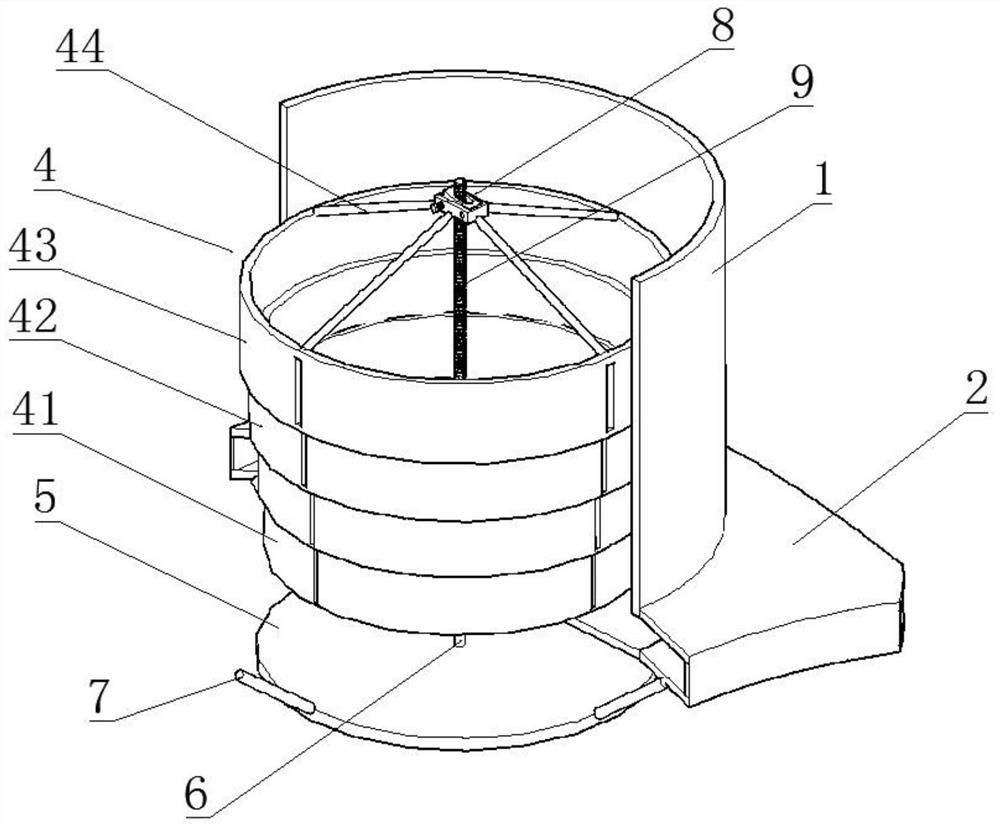

[0026] Such as Figure 1-4 As shown, a material storage and distributing device for evenly feeding tea leaves includes a sleeve 1, the top of which is open, and the bottom end of the sleeve 1 is coaxially connected to the shaft 6 which is fixedly connected to the base 5, and is located in the sleeve. 1 is provided with a bottom plate that is rotatably connected with the shaft rod 6. The bottom plate is radially fixed and axially slidably connected with the bottom ring 41. The outer side of the bottom ring 41 is sleeved with the connecting ring 42, and the top end of the connecting ring 42 is sleeved with the top ring 43. Through multiple The storage tube 4 is formed by the connection of two rings. When storing tea leaves, the adjacent rings are pulled apart to form a cylindrical cavity. The tea leaves can be stored in the cavity, and the sleeve is sleeved on the outside of the storage tube 4. 1. When distributing materials, the top ring 43 in the storage tank 4 slides downward...

Embodiment 2

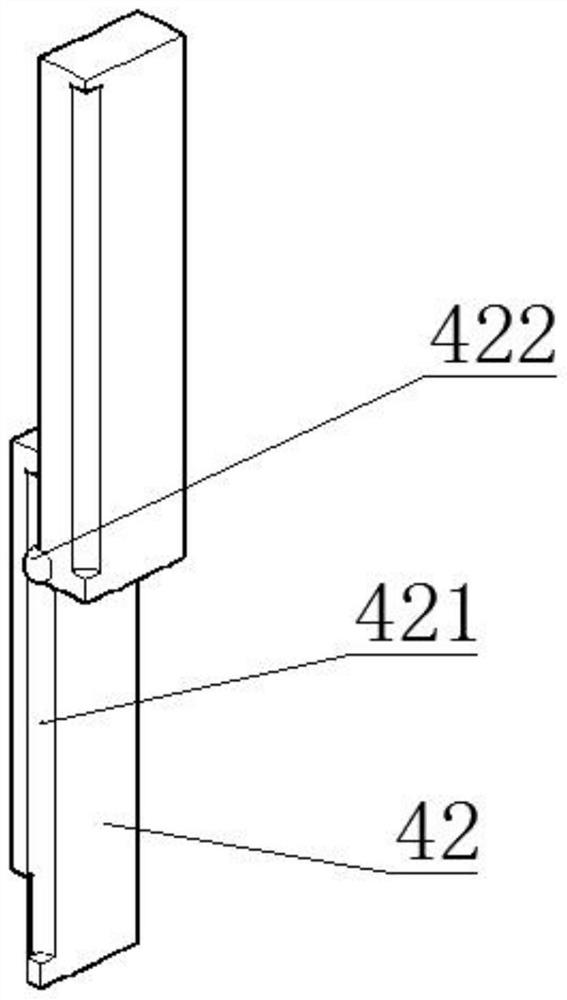

[0029] Such as Figure 1-4 As shown, the screw rod is fixedly connected to the top of the shaft rod 6, the screw rod is threadedly connected with the nut 8, and the screw thread is connected with the top ring 43 through the connection frame 81, the connecting rod 44, so that the top ring 43 is connected with the pole 7, and the top ring 43 is opposite When the screw mandrel rotates, the top ring 43 can be slid downward, and the inner side of the top ring 43 is fixedly connected with the stop block 422, and the stop block 422 slides in the stop slot 421 on the outside of the connection ring 42, so that the top ring 43 and the connection ring 42 It is radially fixed, and during the relative rotation of the nut 8 and the screw rod, the storage cylinder 4 rotates, and at the same time, the ejector rod slides down, so that the tea leaves generate centrifugal force and fall to the bottom of the sleeve 1; One end of the waist-shaped groove 831 in the middle of the inclined threaded p...

Embodiment 3

[0031] Such as Figure 1-4 As shown, the bottom of the sleeve 1 is connected to the screw distribution ring 3, and the distribution ring 3 is fixedly connected to the base 5 through the support rod 7. During the rotation of the sleeve 1, the tea leaves falling in the sleeve 1 enter into the In the distributing ring 3, the bottom side of the distributing ring 3 is inclined, so that the tea leaves can slide down along the distributing ring 3 and be discharged into the dispensing container from the distributing port, so as to realize uniform and efficient discharge, avoid material blocking and reduce The pulverization of tea leaves caused by mechanical intervention produces a large amount of debris, and the sleeve 1 can also be set to the same structure as the storage barrel 4, and the sleeve 1 can be set to be connected in sequence with multi-layer connecting rings 42, which can be used according to the amount of tea storage. Determine the height of the storage barrel 4 to avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com