Material mixing device for molding bag shell

A material mixing device and shell forming technology, which is applied in the field of luggage forming equipment, can solve the problems of wasting materials, increasing production costs, and scrapping luggage shells, etc., to achieve the effects of ensuring quality, saving costs, and reducing the number of scrapped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

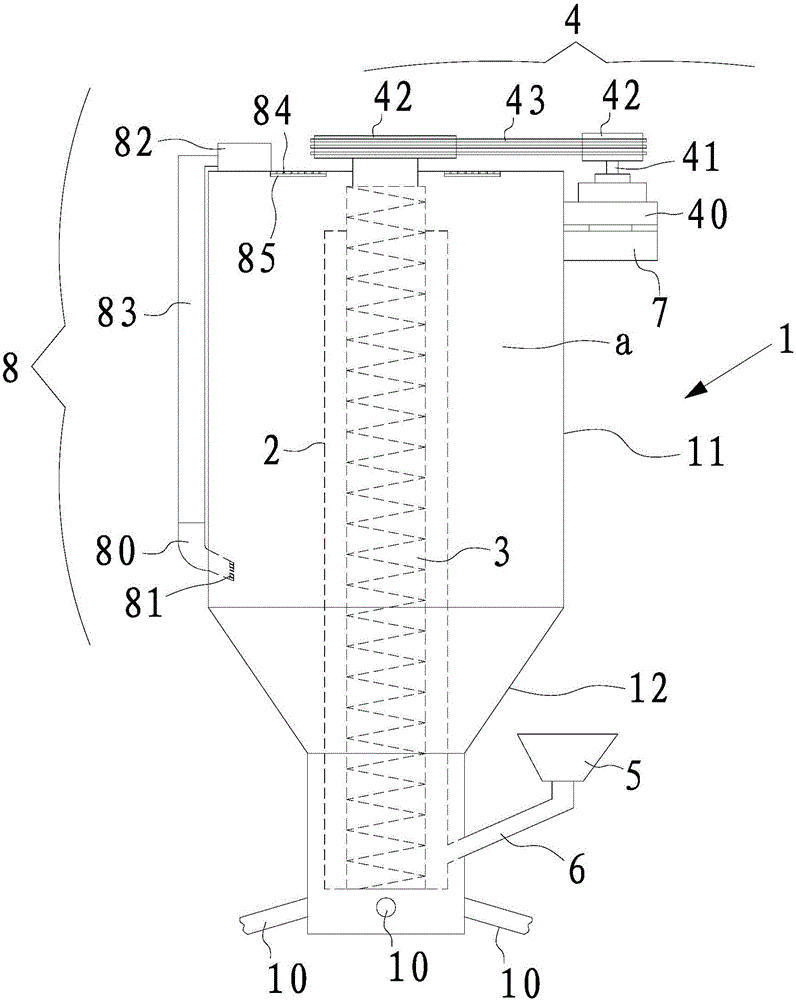

[0021] see figure 1 , the mixing device for case shell molding provided in this embodiment includes a mixing bin 1, a screw sleeve 2 arranged inside the mixing bin 1 along the vertical direction, a screw rod 3 arranged in the screw sleeve 2, The driving mechanism 4 for driving the screw rod 3 to rotate, and the feeding hopper 5 inserted into the side of the self-mixing bin 1 and communicated with the screw sleeve 2, wherein the upper end of the screw rod 3 emerges from the upper end of the screw sleeve 2, and The top of the mixing bin 1 is screwed out, and the inner wall and top of the mixing bin 1 and the outer periphery of the screw sleeve 2 form a cavity a, and the mixing bin 1 is provided with a discharge pipe 10 for discharging materials.

[0022] In this example, the mixing bin 1 includes a straight cylinder part 11 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com