Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110results about How to "Achieve flattening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

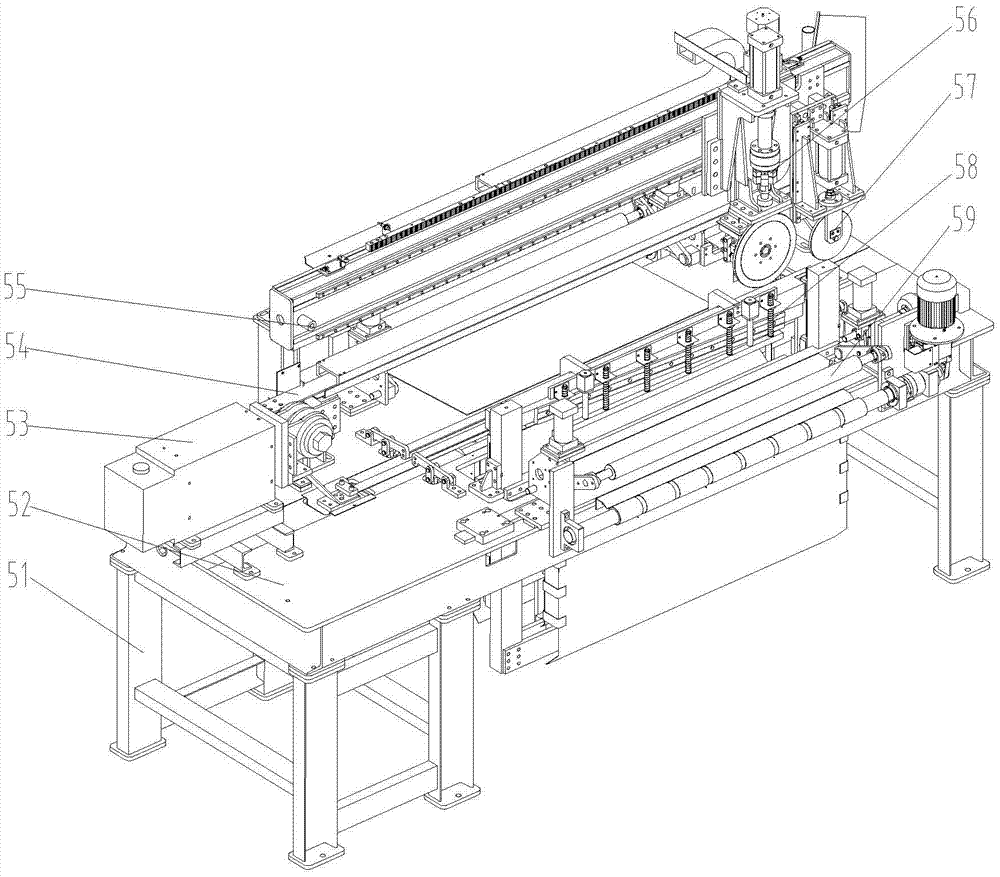

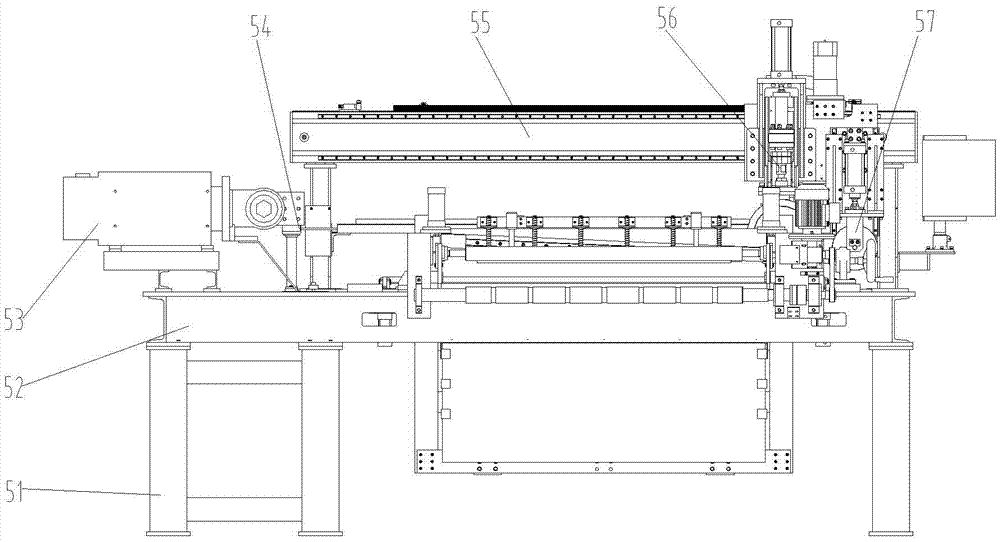

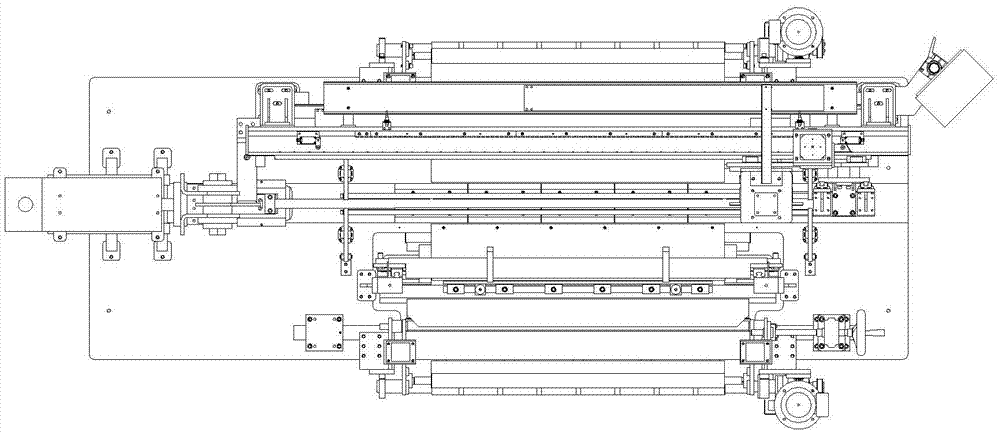

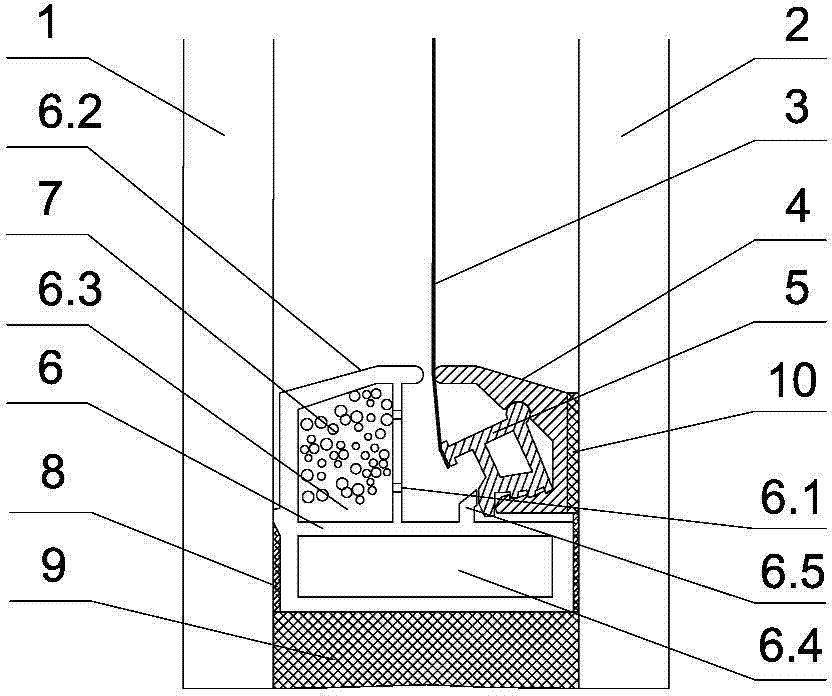

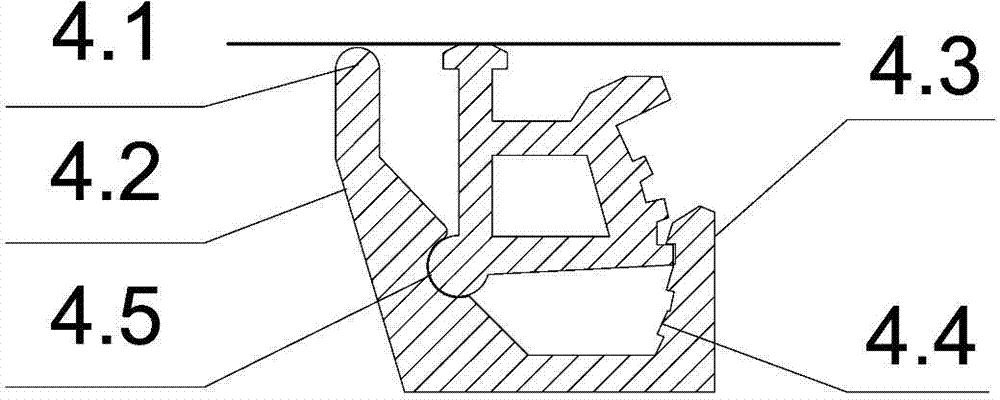

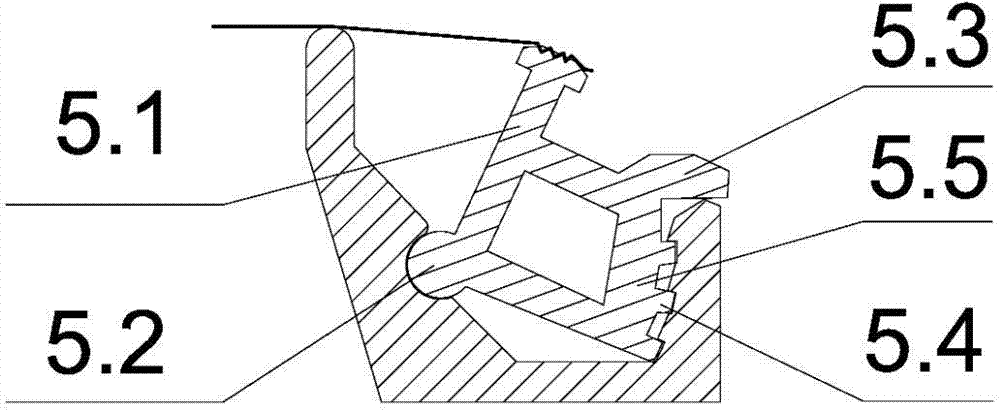

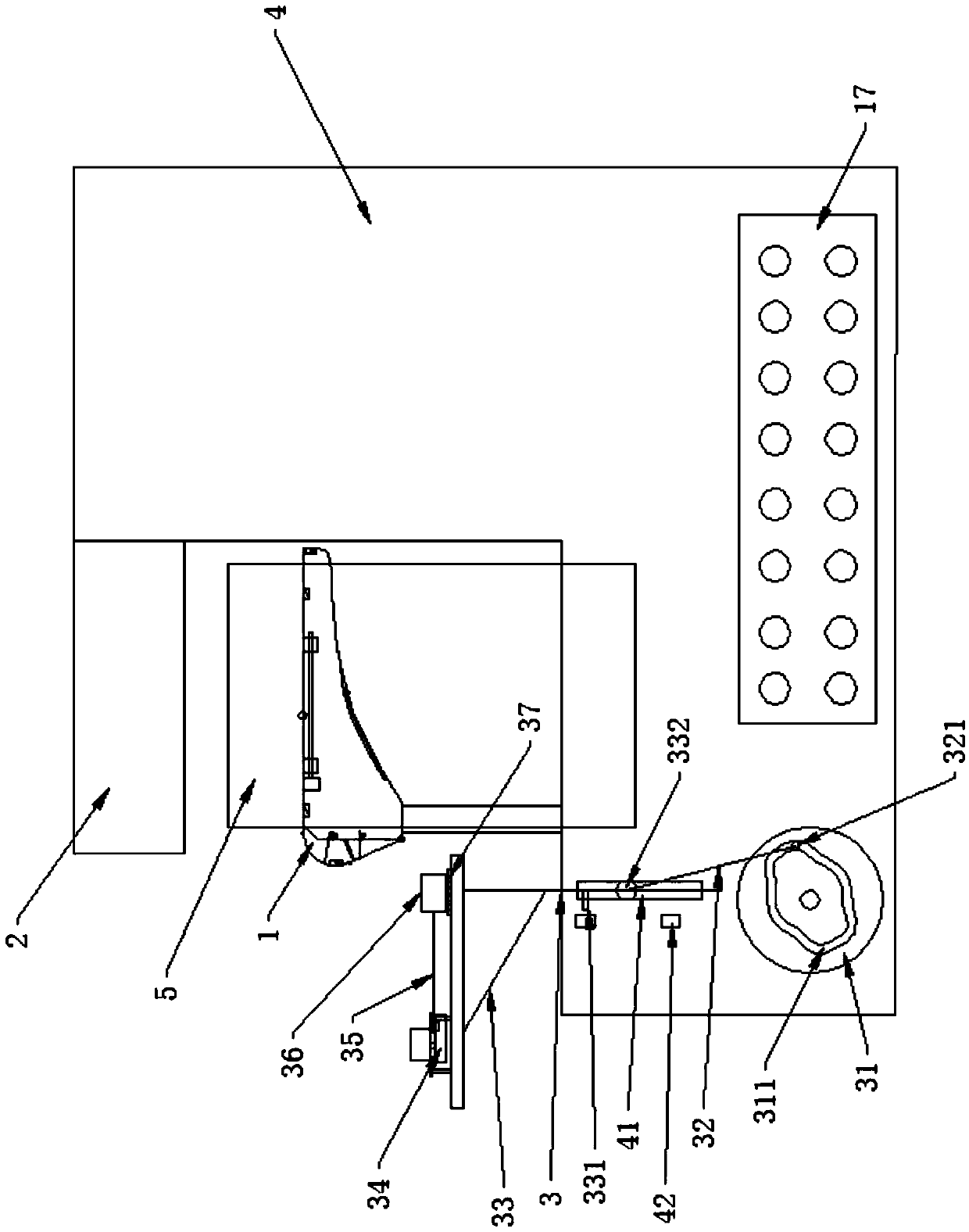

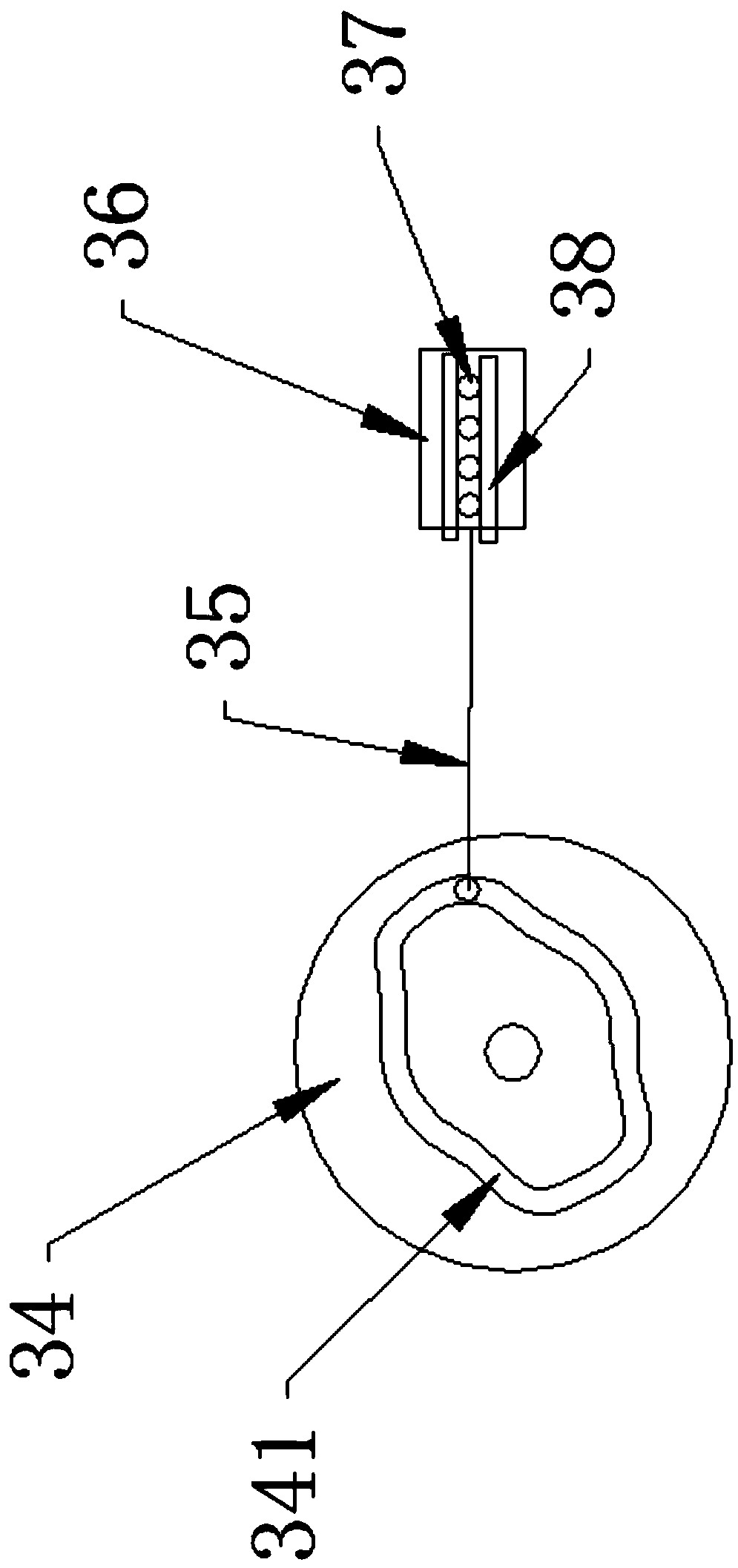

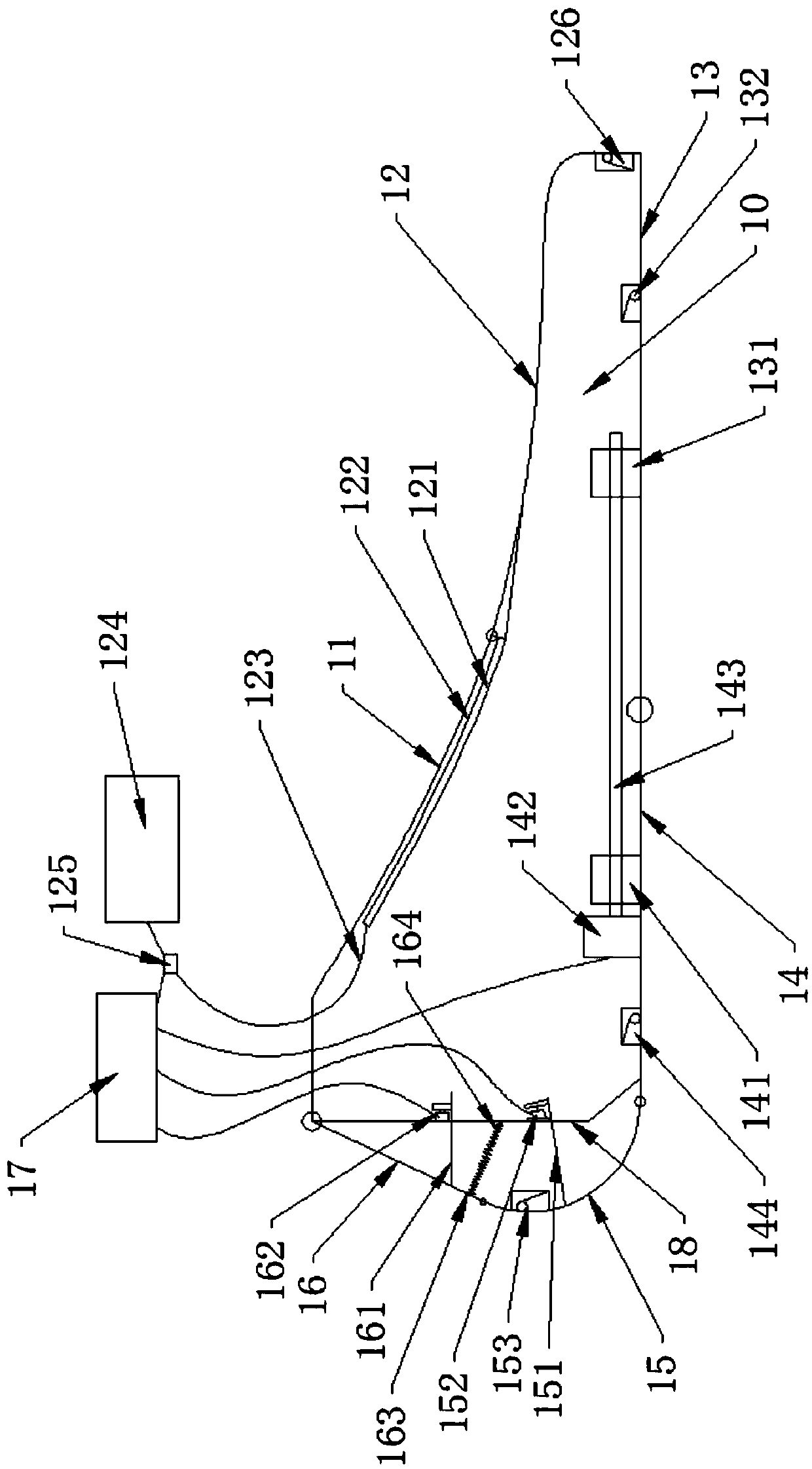

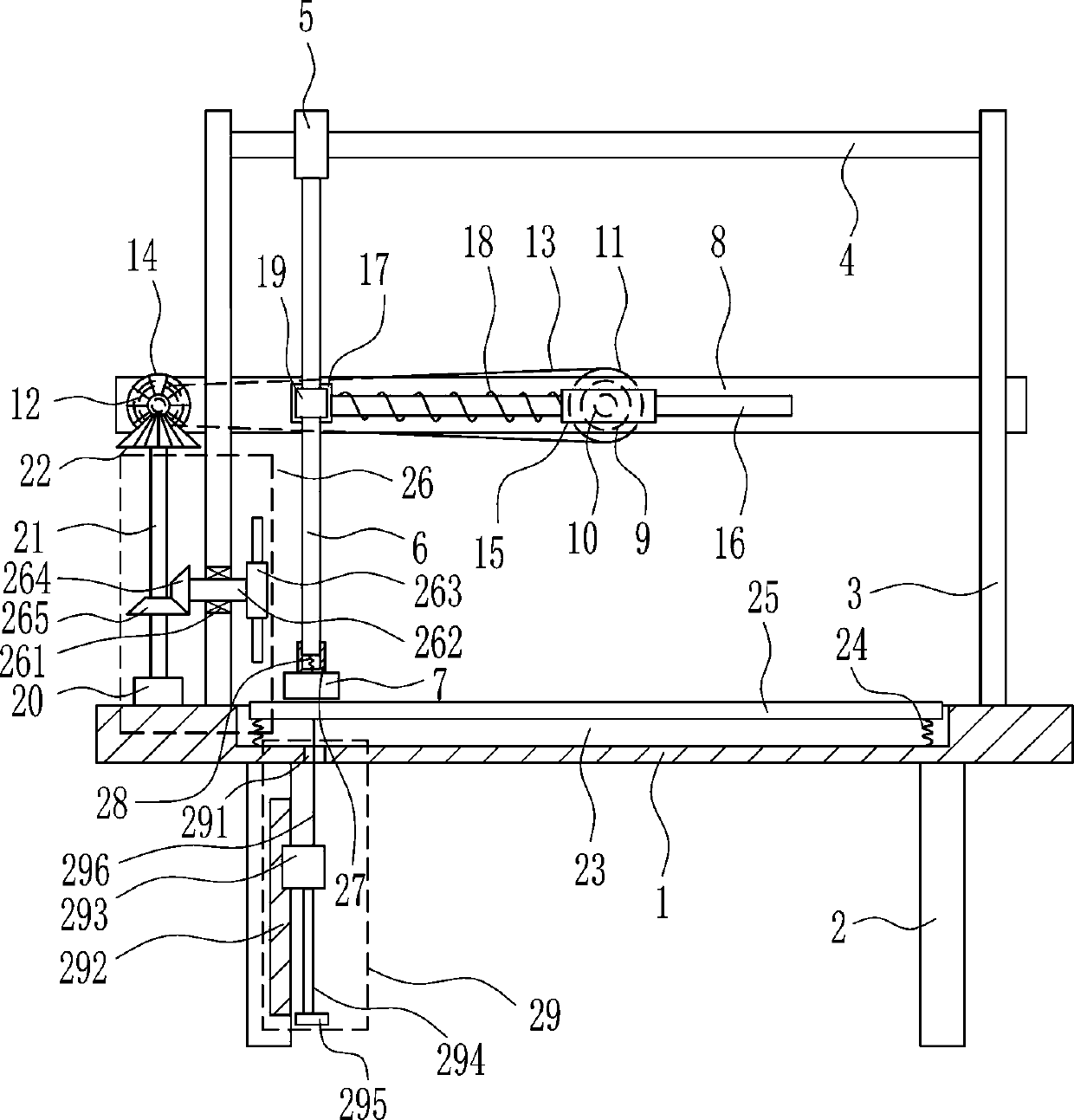

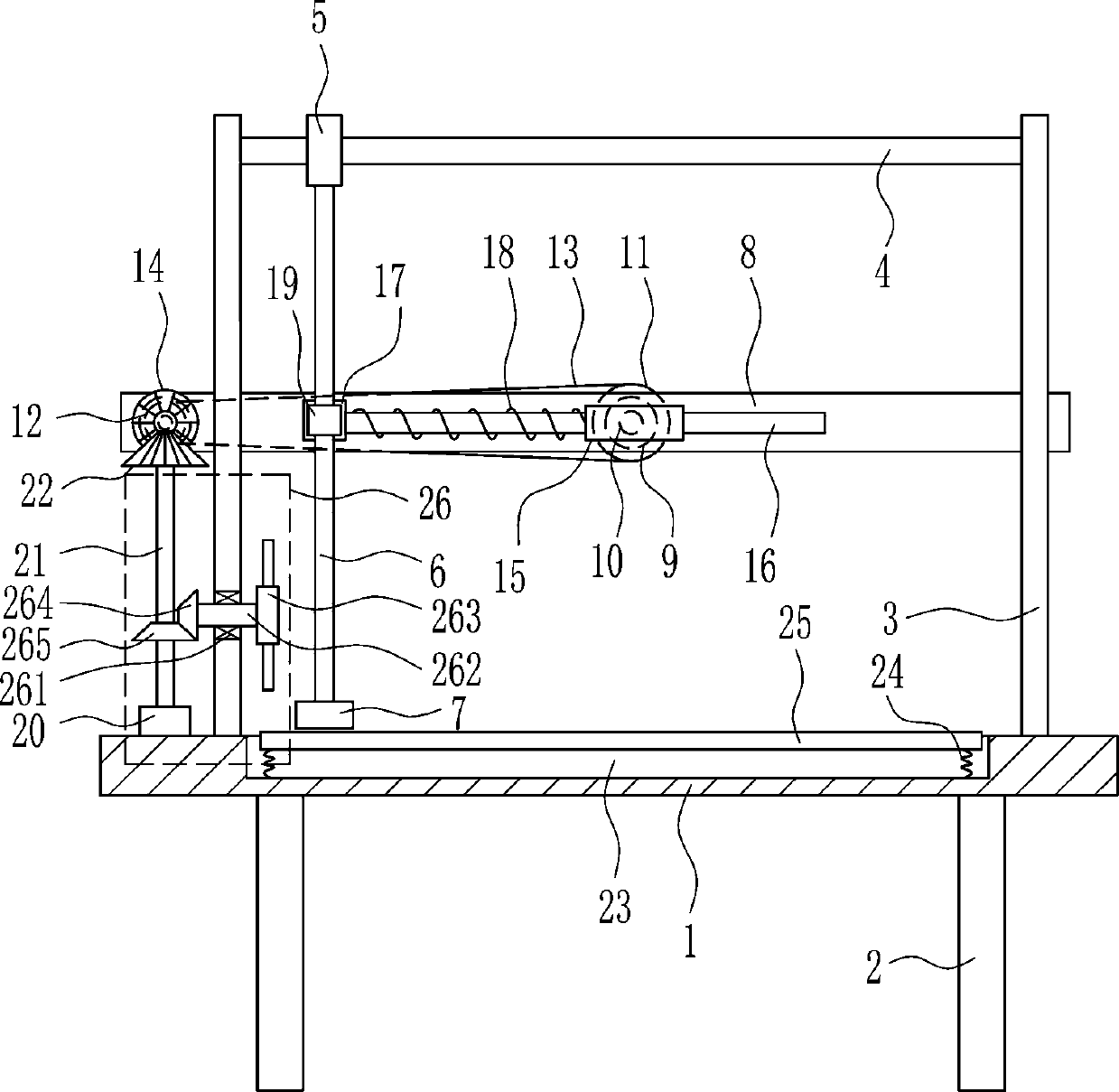

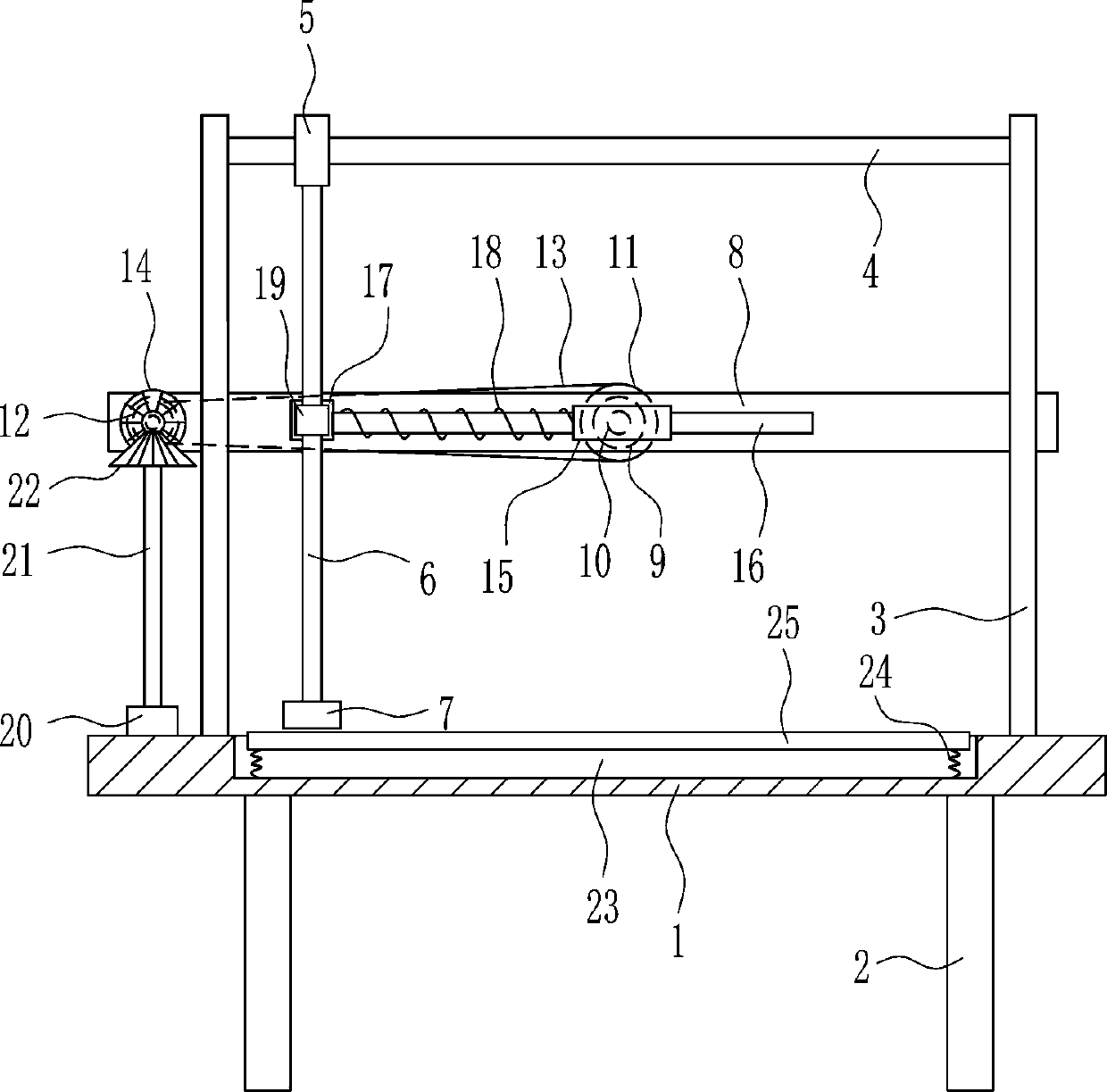

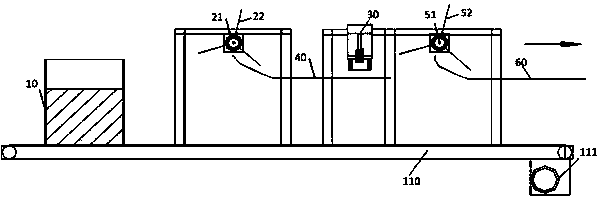

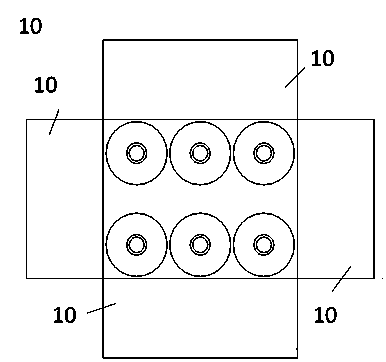

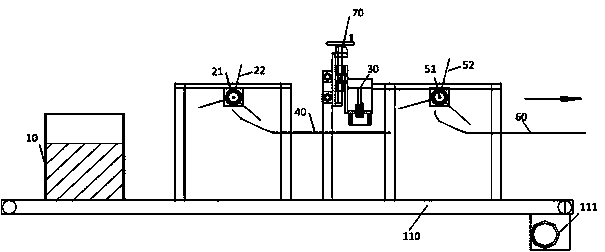

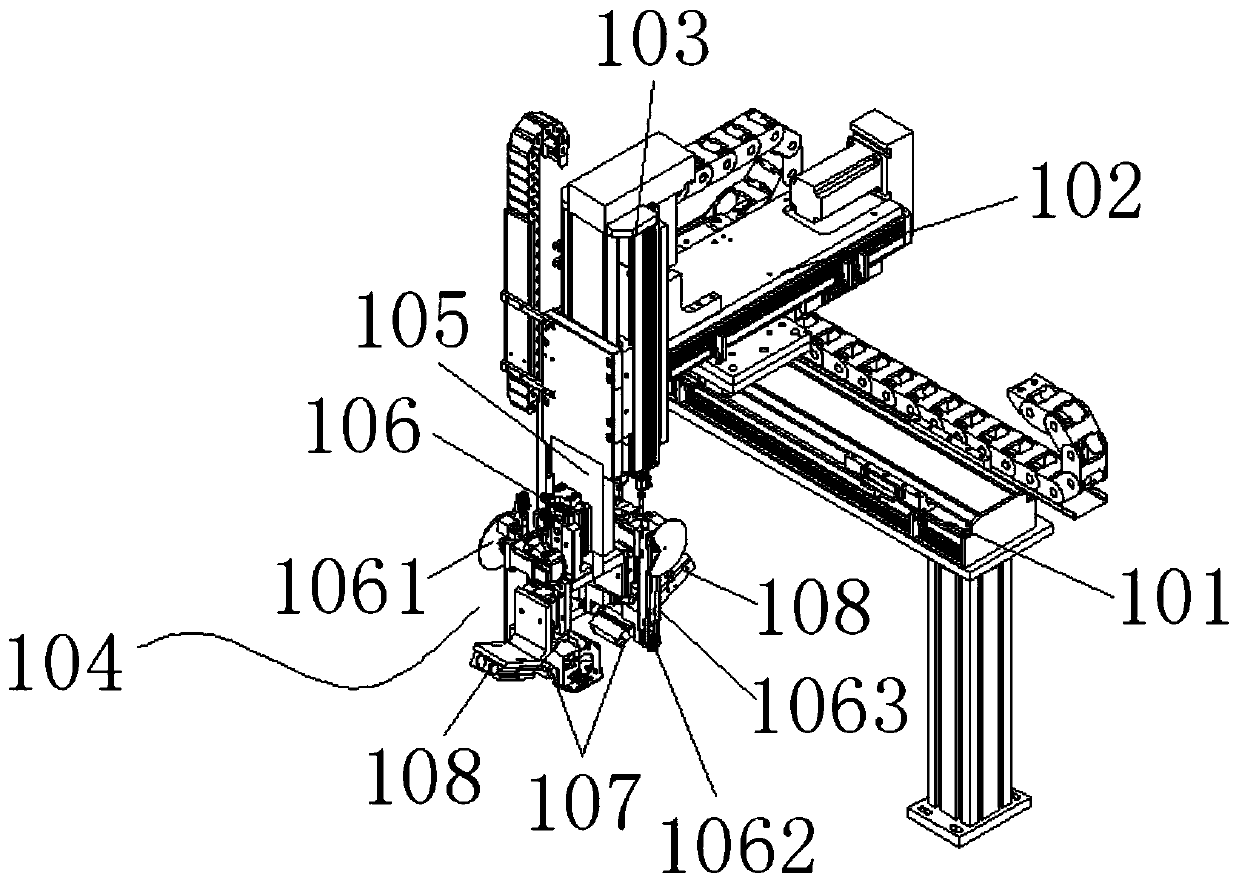

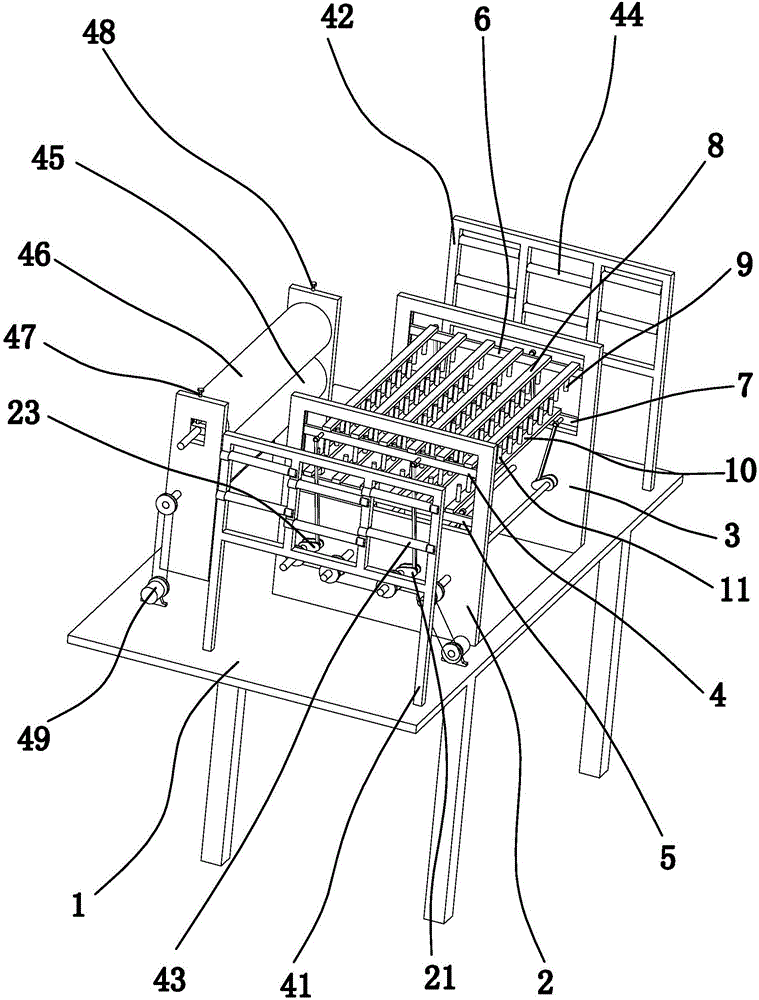

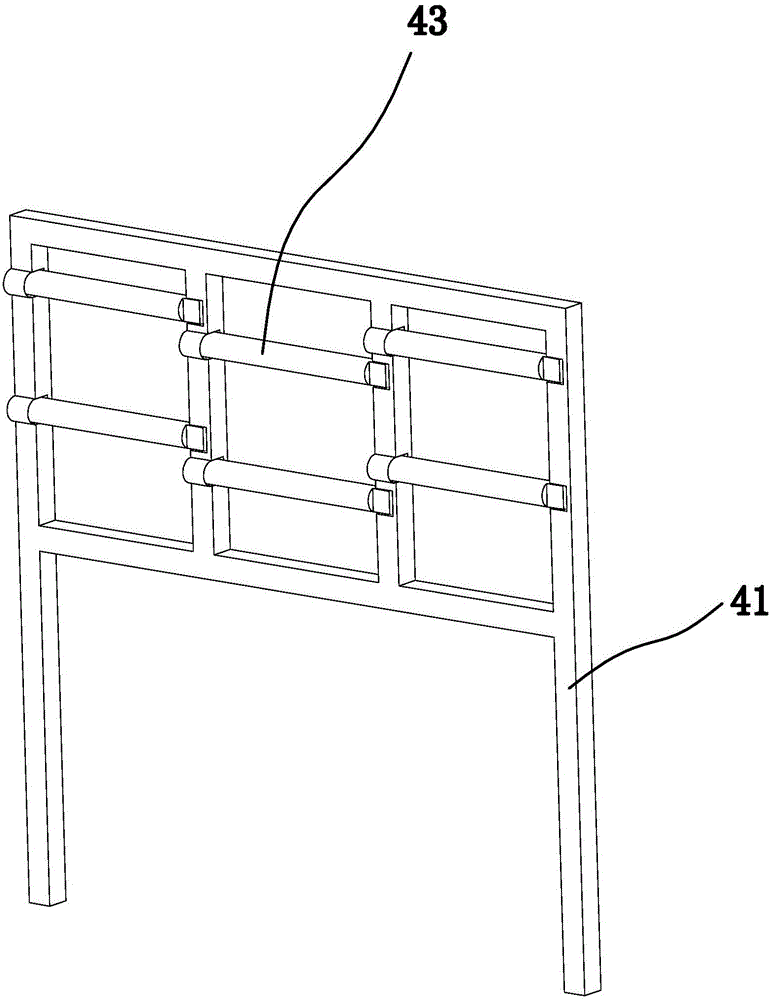

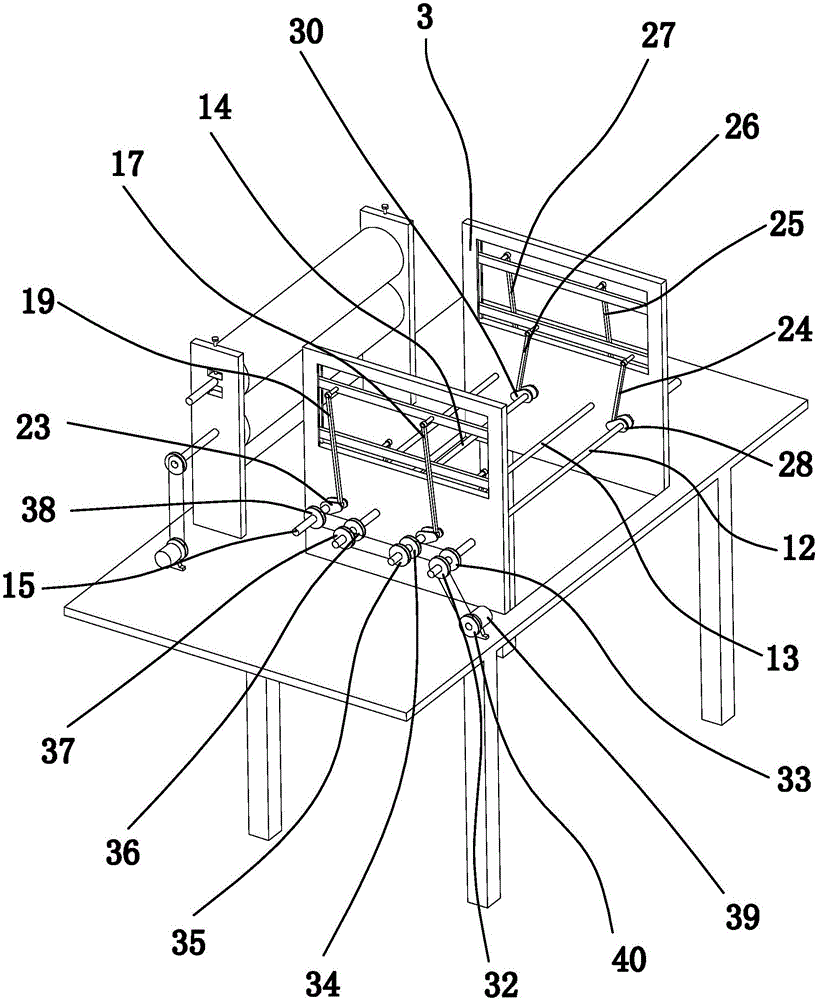

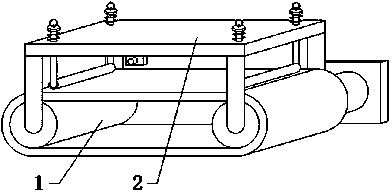

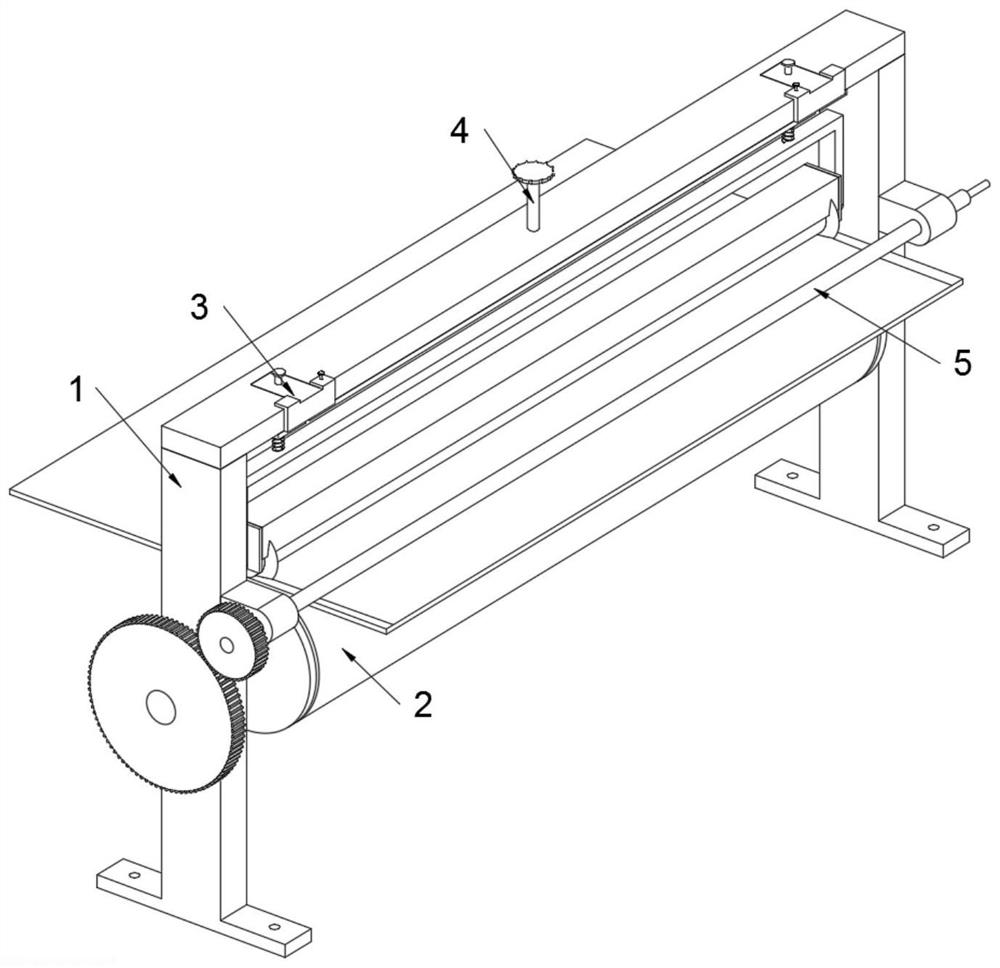

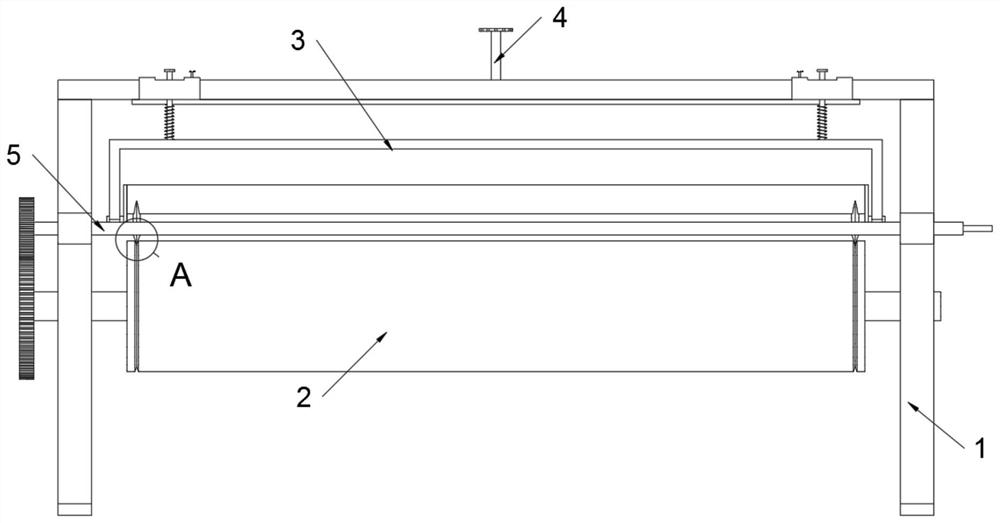

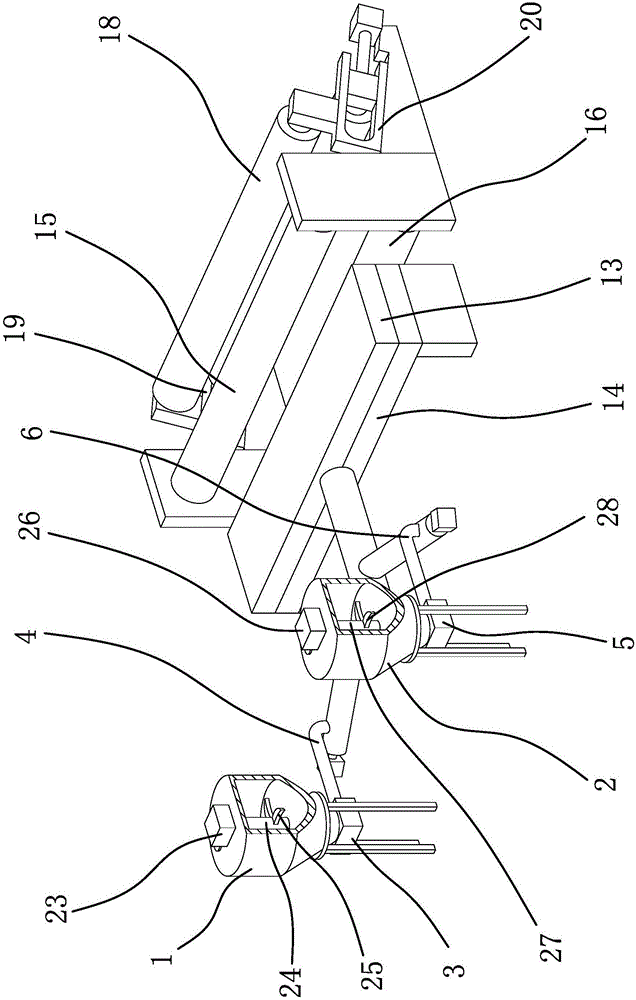

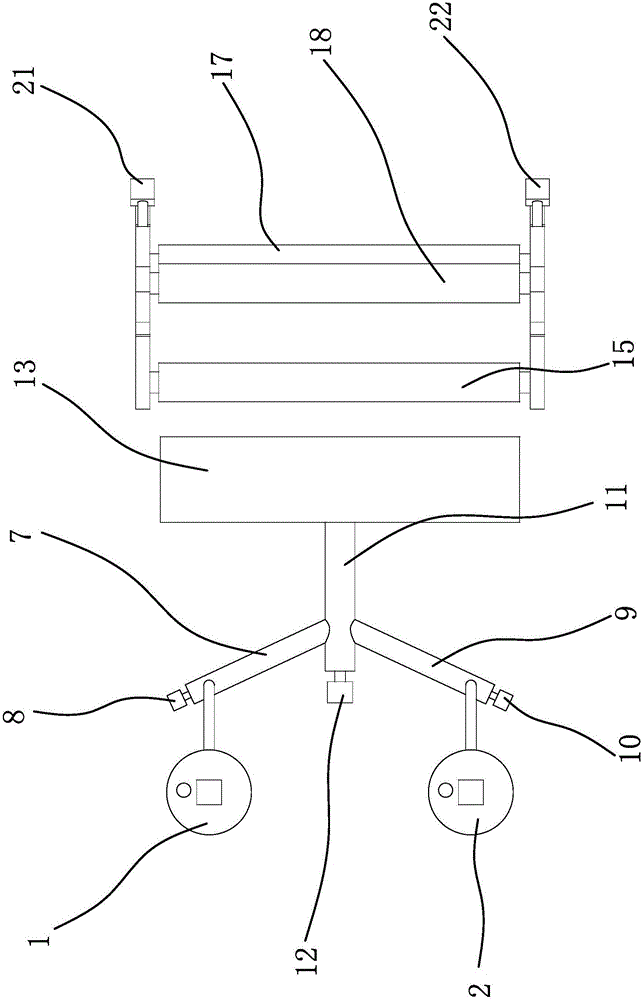

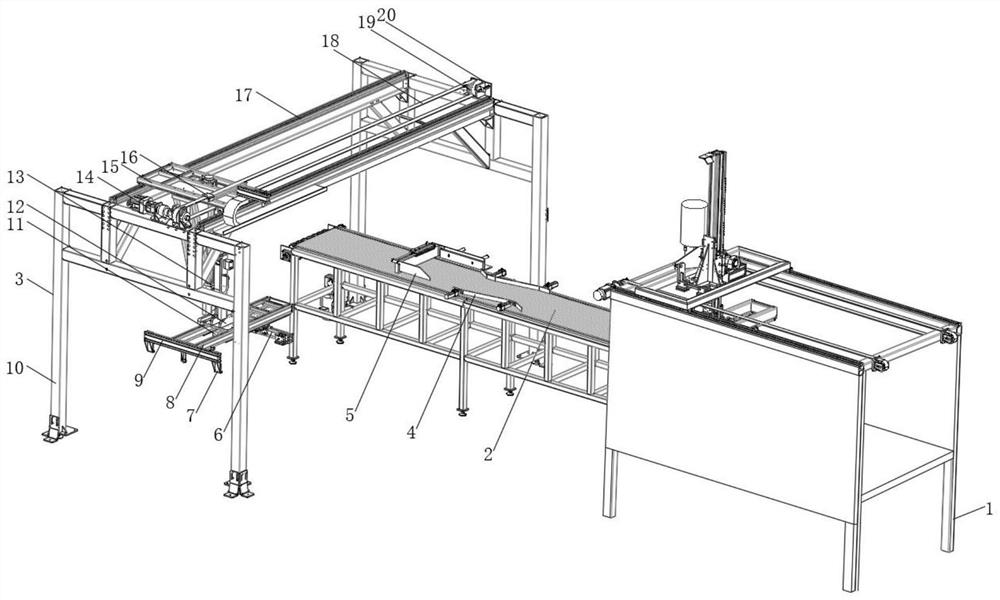

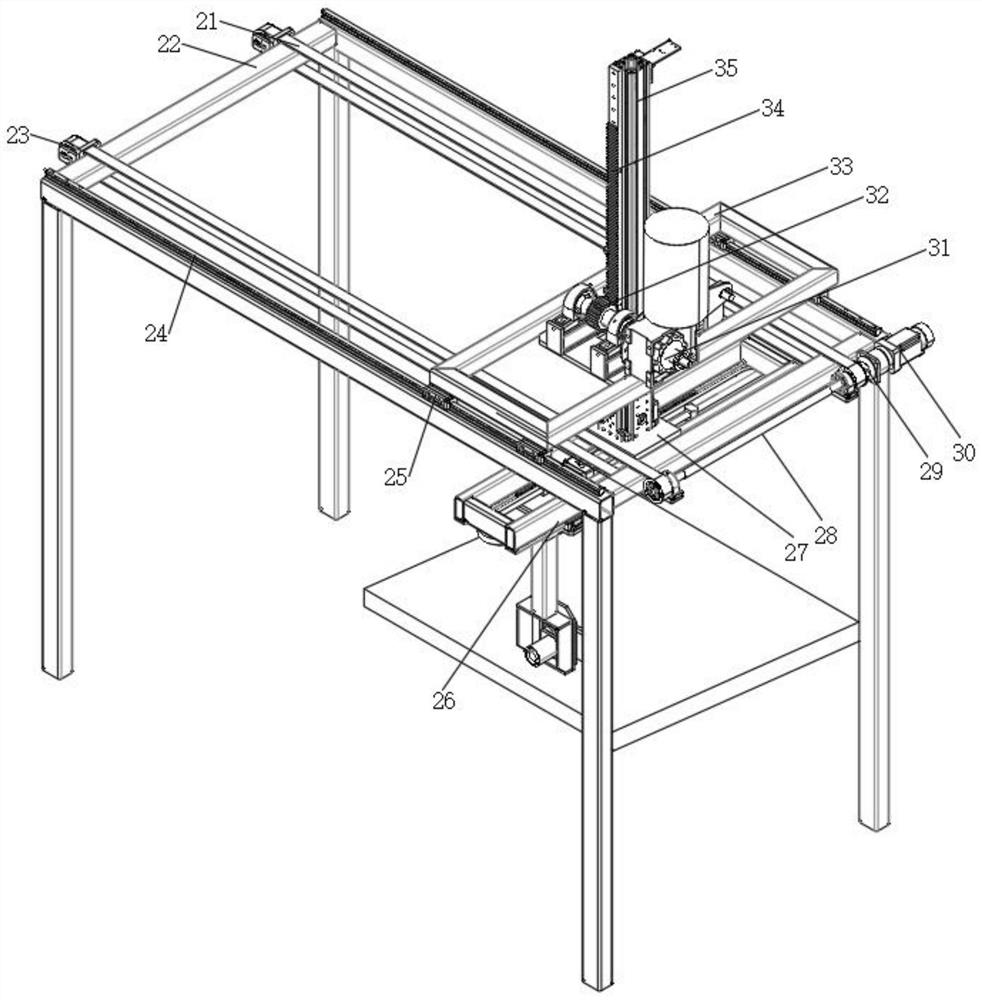

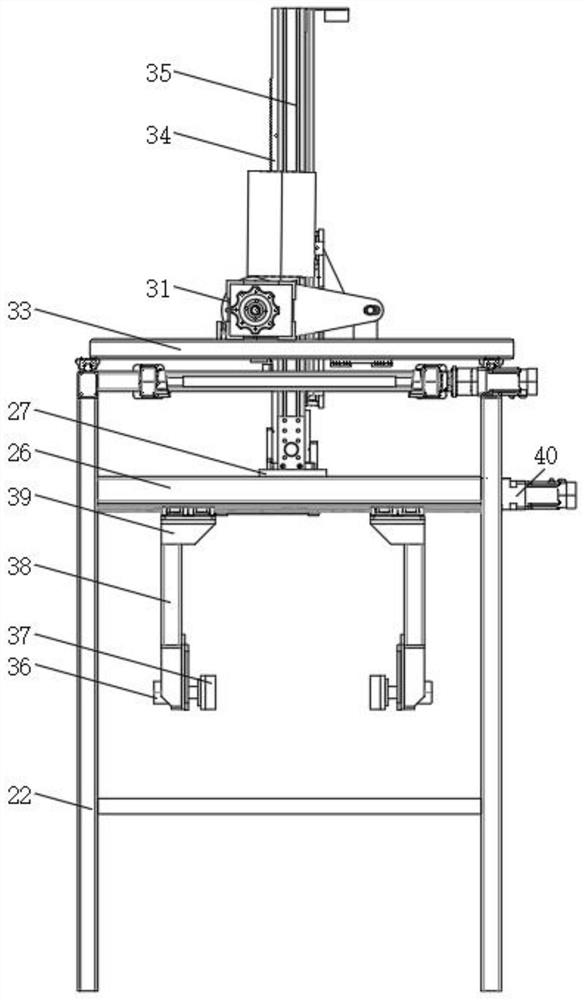

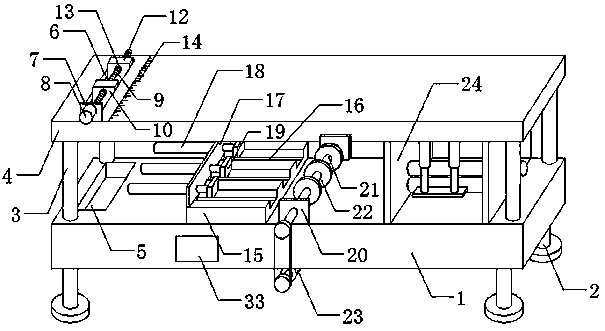

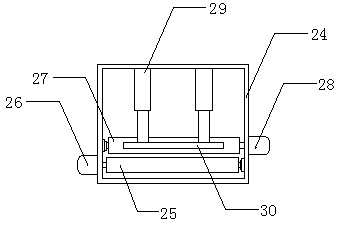

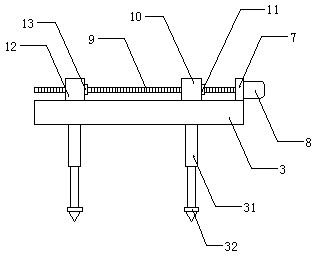

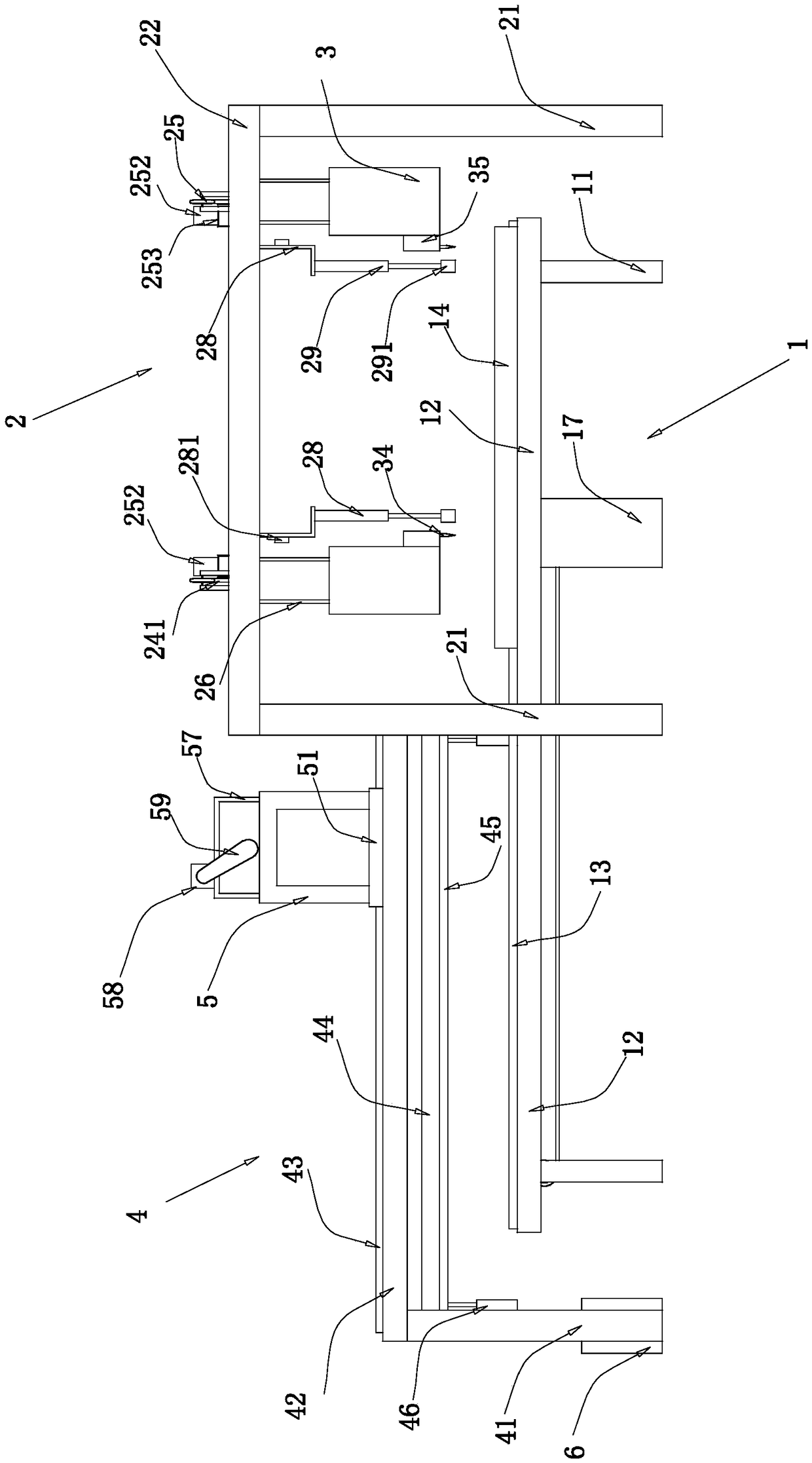

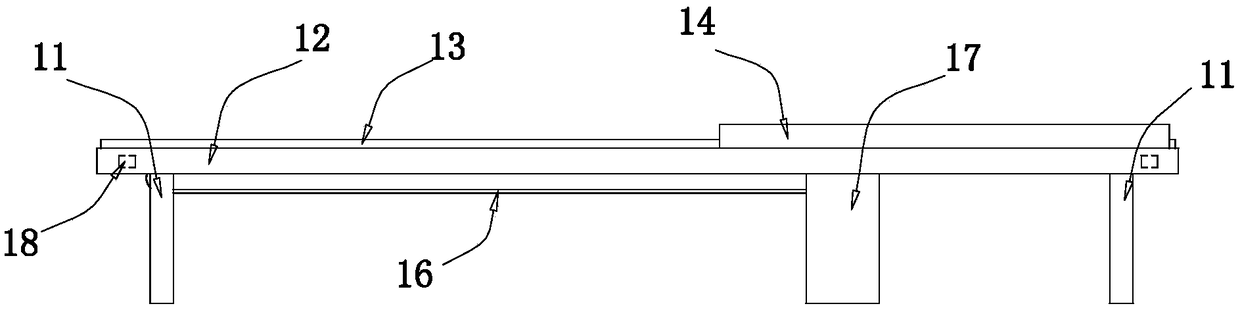

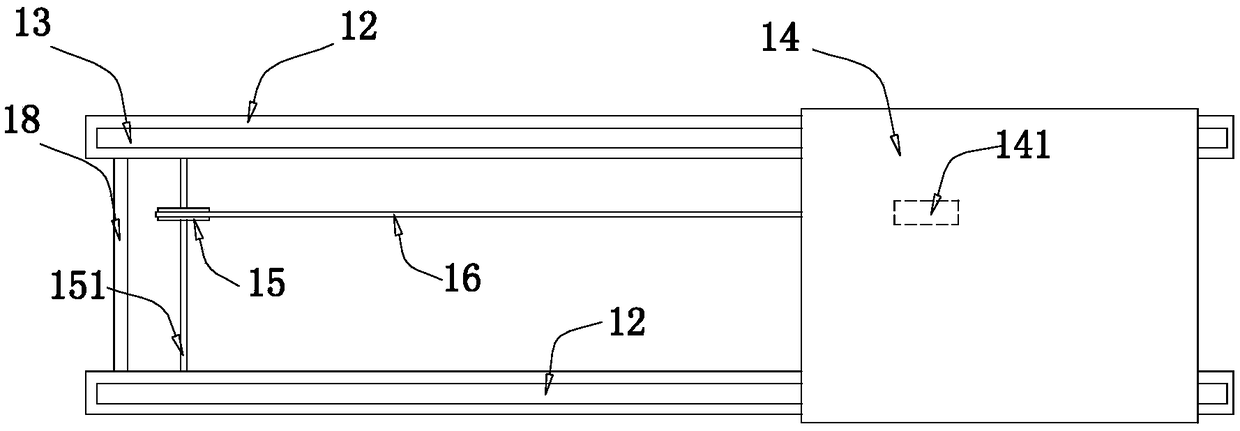

Fully-automatic narrow lap electric-resistance seam-welding machine for thin plates

ActiveCN105436681AReduce processing timeReduce processing efficiencyResistance electrode holdersShearing machinesEngineeringMetal sheet

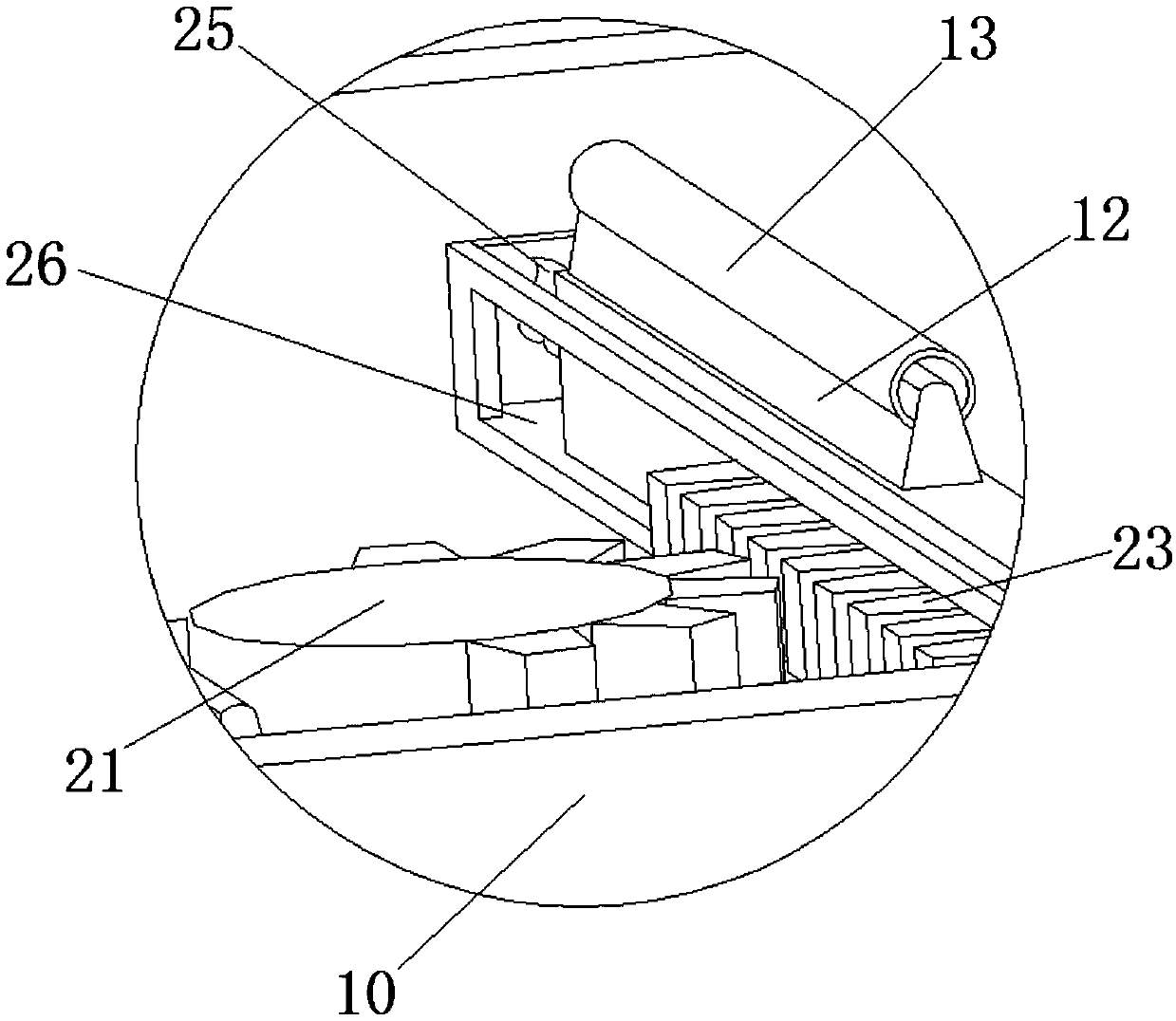

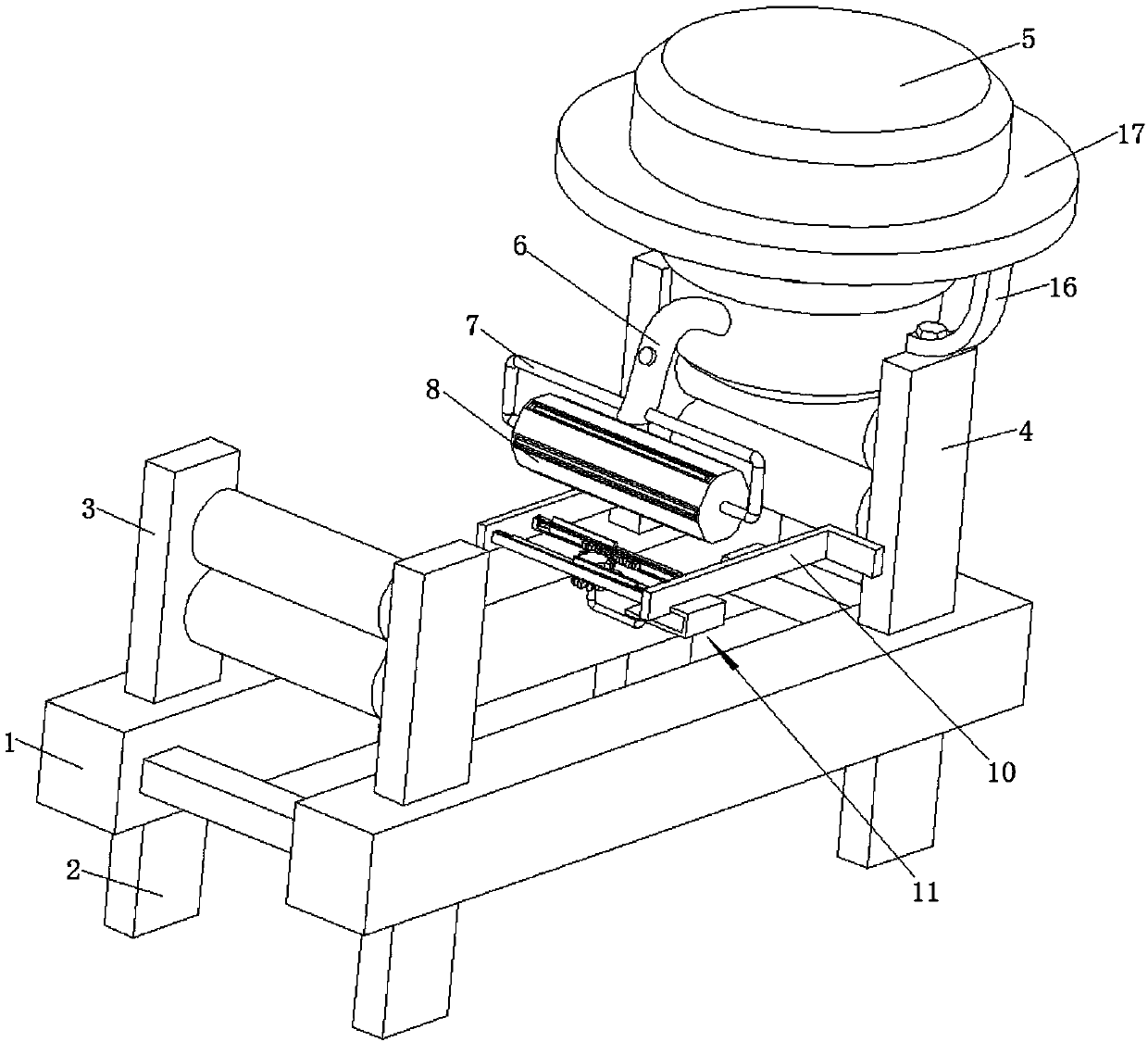

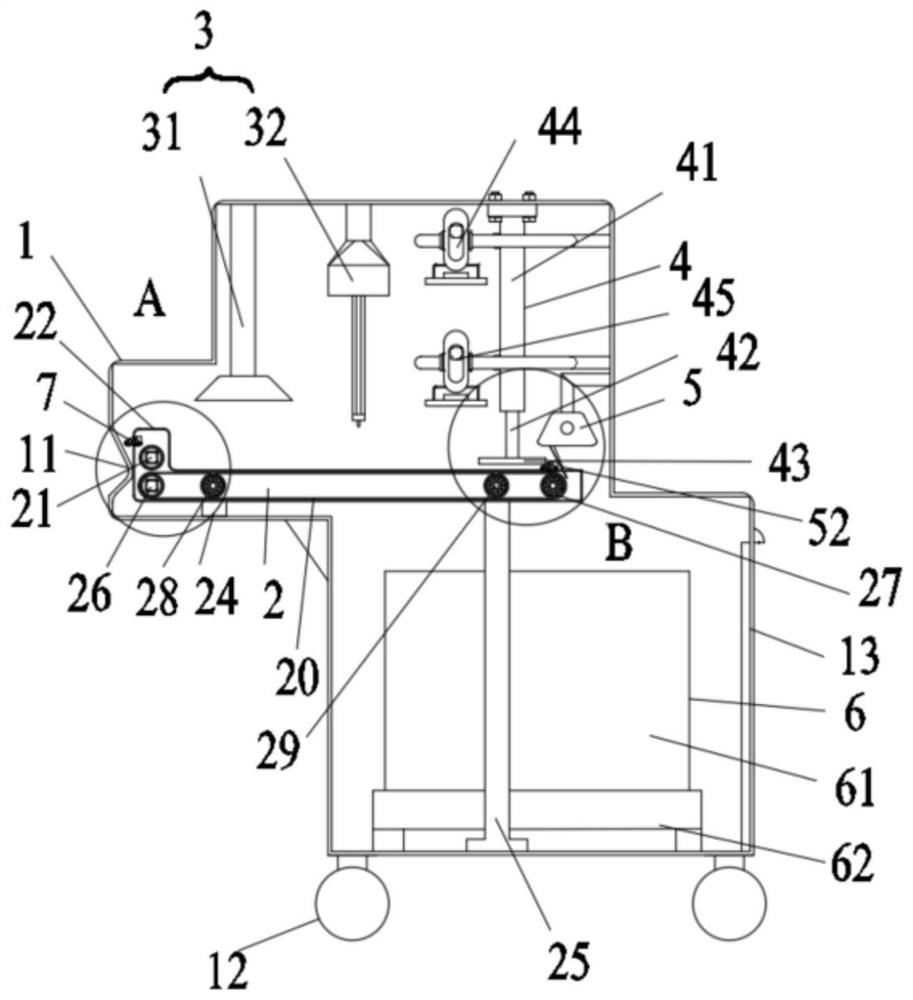

The invention discloses a fully-automatic narrow lap electric-resistance seam-welding machine for thin plates, belongs to a thin plate seam-welding machine in the welding technical field, and aims to provide the fully-automatic narrow lap electric-resistance seam-welding machine, which is high in shearing efficiency and long in service life, for thin plates. According to the technical scheme, the fully-automatic narrow lap electric-resistance seam-welding machine comprises a rack and a workbench, wherein a clamping and delivering device and a single-blade shear are arranged on the rack or the workbench; a beam assembly is connected on the rack; a resistance welding device and a grinding device are connected on the beam assembly; the single-blade shear comprises a framework, wherein an upper shearing sheet, a lower shearing sheet and a shearing air cylinder are connected on the framework; a synchronous slide block is connected on the shearing air cylinder; link mechanisms are connected on the synchronous slide block; the two groups of link mechanisms are symmetrically arranged at left and right sides of the synchronous slide block, the upper shearing sheet and the lower shearing sheet; and the other ends of the link mechanisms are connected to the upper shearing sheet or the lower shearing sheet. The fully-automatic narrow lap electric-resistance seam-welding machine is suitable for shearing and welding metal thin plates in a finish machining continuous line of the metal thin plates.

Owner:CHENGDU HANYAN TECH

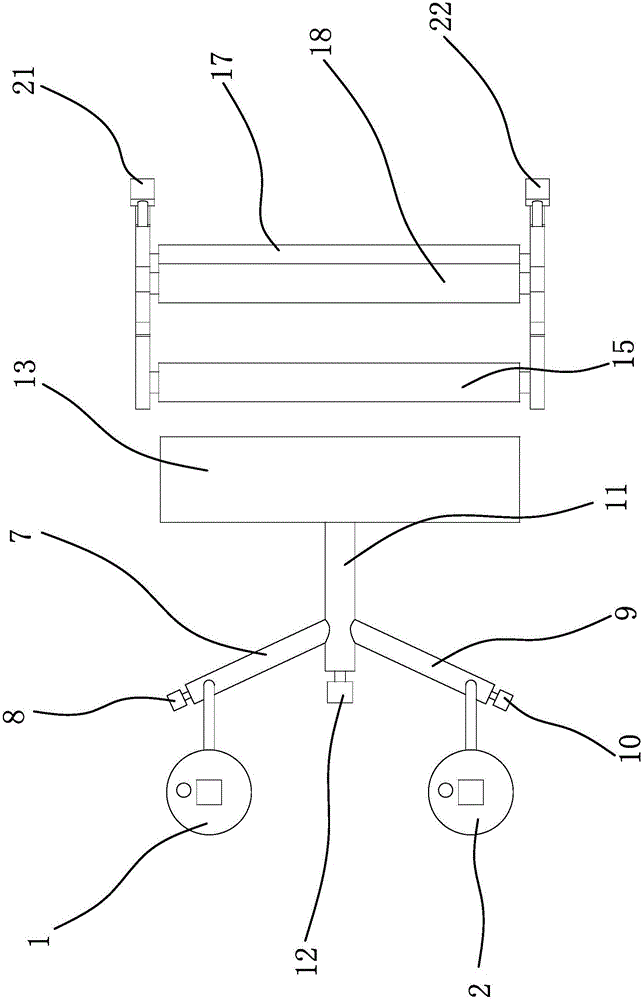

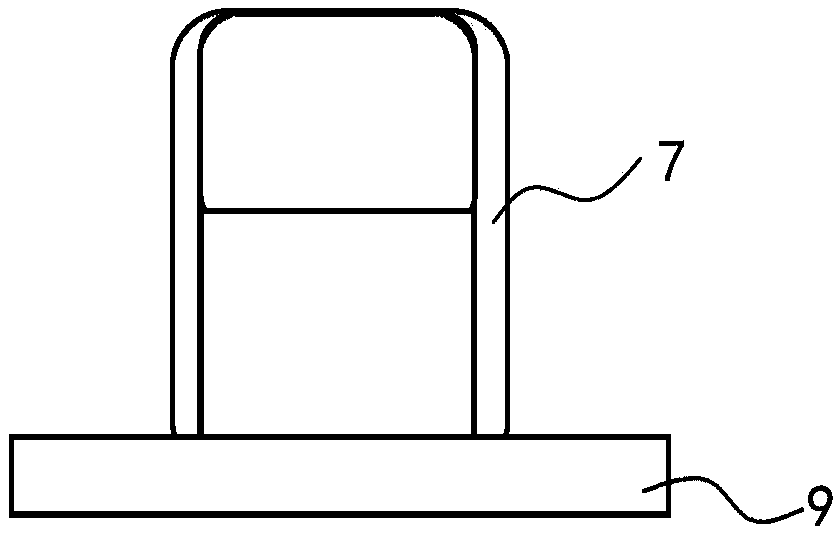

Method for film stretching of internally-suspended film of hollow glass and film stretching frame assembly

ActiveCN103498622AAchieve tautnessAchieve flatteningUnits with parallel planesPolymer scienceThin membrane

The invention discloses a method for film stretching of an internally-suspended film of hollow glass and a film stretching frame assembly. The film stretching frame assembly is composed of a rotary frame and a structure frame which are made of co-extrusion polymer section bars with gradient modulus distribution, the rotary frame rotates around a pivot inside the structure frame, so that protruding chucks distributed on the rotary frame in a spot shape and arranged at intervals are driven, and therefore a thin film can be stretched. The chucks fixing the periphery of the thin film are good in elasticity and low in modulus so that the force enabling the film to be stretched outwards can be generated, the chucks can slightly deform in any direction at 360 degrees along with the change of the stress of the thin film in the process of film stretching and use, and therefore flatness of the thin film can be kept. According to the structure frame with the high modulus, good size stability of the whole film stretching frame assembly can be guaranteed. A dry division bar frame provided with a vertical chamber and a transverse chamber replaces a traditional spaced frame and is matched with an optical film so that a double-sealing structure of the hollow glass can be achieved. According to the method for film stretching of the internally-suspended film of the hollow glass and the film stretching frame assembly, rotation of the film stretching frame assembly controls the tension of the internally-suspended thin film in a matched mode, and therefore the quality and the efficiency of the internally-suspended thin film are reliably guaranteed.

Owner:伟视幕墙(淮安)有限公司

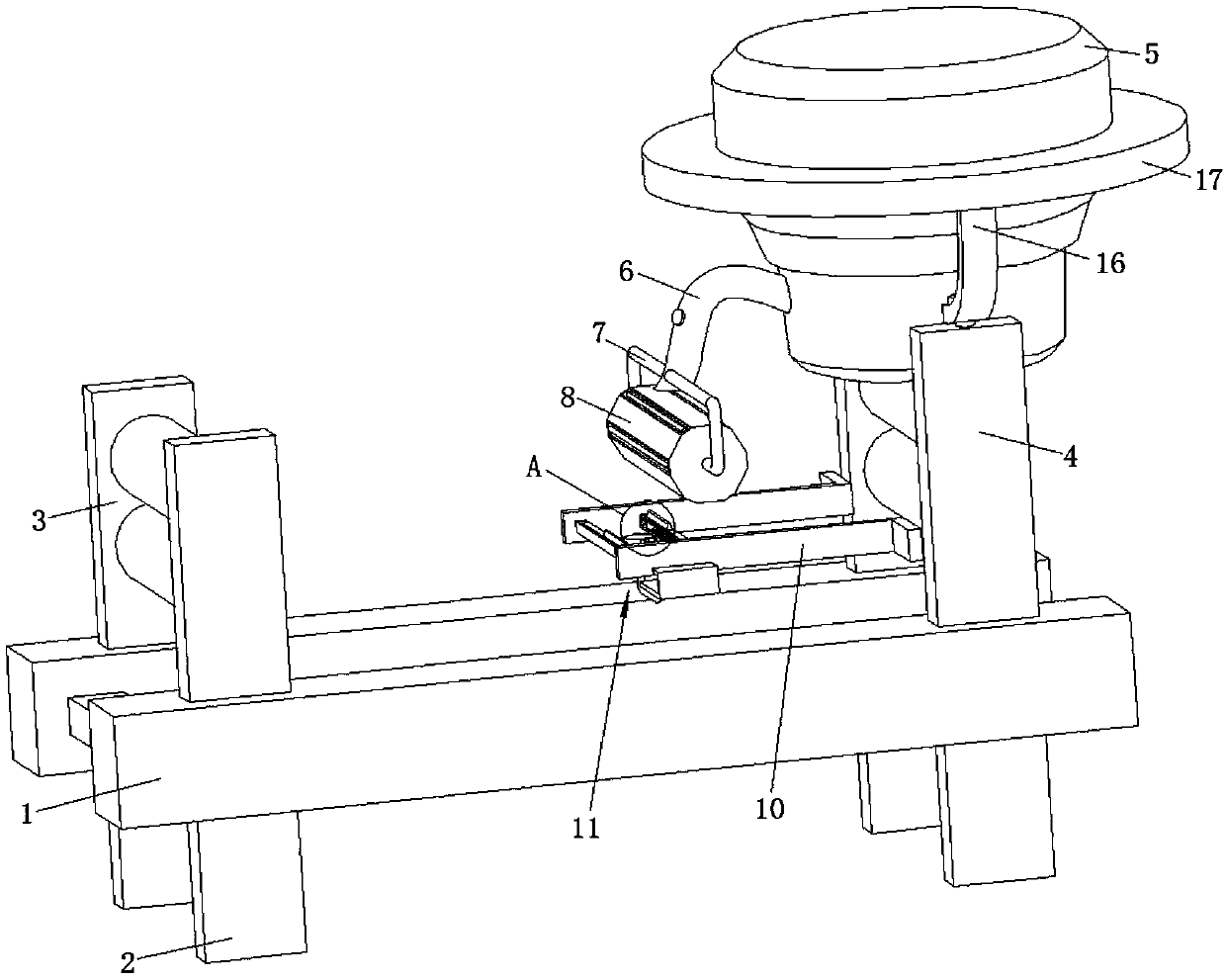

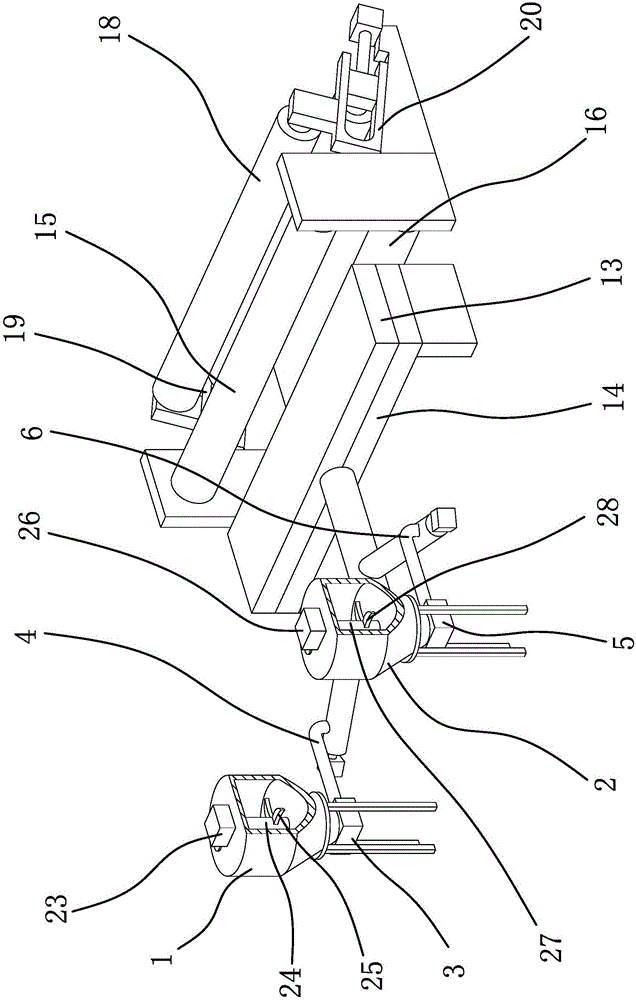

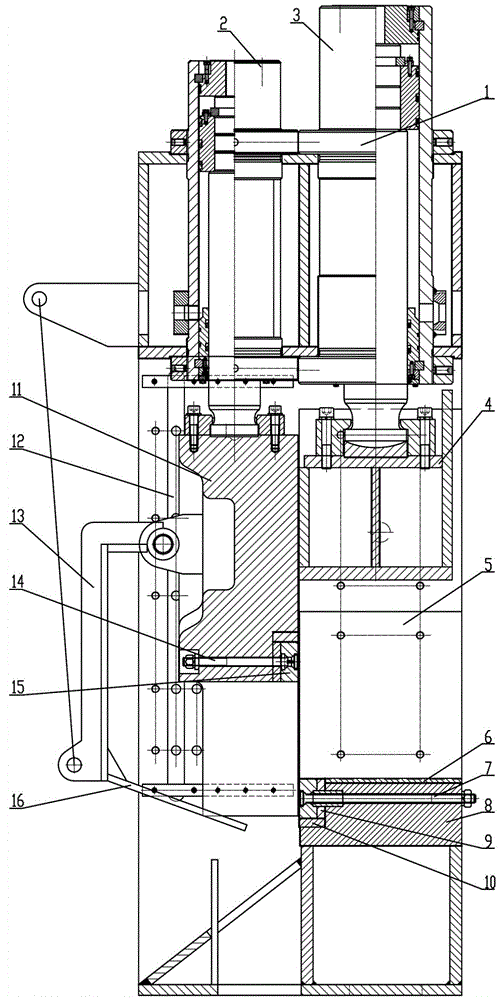

Cam-driven delasting-lasting integrated machine

The invention provides a cam-driven delasting-lasting integrated machine, belonging to the shoemaking equipment field. The integrated machine comprises a fixed frame, wherein an inverted shoe tree isfixedly arranged on the fixed frame, a flat pressing assembly is arranged above the shoe tree, clamping assemblies are arranged on the left and right sides of the shoe tree; and a delasting assembly is arranged at the rear end of the shoe tree and comprises a raising cam, a raising driving rod and a lifting frame, the raising cam is rotatably connected to the fixed frame, a first driving slot is formed in the raising cam and is used for driving the lifting frame to move up and down through the raising driving rod, a translation cam, a translation driving rod and a delasting block are arrangedat the upper end of the lifting frame, the translation cam is horizontally arranged and is rotatably connected with the lifting frame, a second driving slot is formed in the translation cam and is used for driving the block to move leftwards and rightwards through the translation driving rod. The integrated machine is driven by a power supply, so that the operation of the whole structure is relatively stable and reliable, the failure rate is greatly decreased, the energy consumption is reduced, the energy source is saved, and the integrated machine is relatively environment-friendly.

Owner:JIHUA LAB

Foldable coil and greenhouse heat preservation device

PendingCN109315193AAchieve connectionRealize folding and collapsingAgricultural articlesLayered productsGreenhouseSolid structure

The invention provides a foldable coil and greenhouse heat preservation device, which relates to the technical field of a greenhouse built-in heat preservation material. The foldable coil comprises afirst solid structure layer and a multi-bubble structure layer; the multi-bubble structure layer is arranged on the first solid structure layer, the bubble structure zone is formed at the position ofthe bubble structure layer on the first solid structure layer, and a bubble-free folding zone is formed between the adjacent two bubble structure layers, and a bubble-free connection zone is formed atthe two sides of the first solid structure layer; the two adjacent bubble structures can be folded together along the bubble-free folding zone, or flattened along the bubble-free folding zone, multiple groups of foldable coils can be connected through the bubble-free connection zone. The greenhouse insulation device includes the above-described foldable coil. The utility model solves the problemthat the traditional bubble coil is not easy to be folded, and the volume occupies a large space after folding, and the traditional bubble coil is easy to shade and affect the growth of crops when applied in greenhouse.

Owner:宁夏任进礼新连栋温室技术发展有限公司

Household wrinkled clothes flattening device

InactiveCN107794733AWork lessConvenience to workIroning machinesTextiles and paperEngineeringBilateral symmetry

The invention relates to a flattening device, in particular to a household wrinkled clothes flattening device aiming to achieve the technical purposes of flattening wrinkled clothes to make the clothes beautiful and ensuring economy at the same time. To achieve the technical purposes, the household wrinkled clothes flattening device comprises a first mounting plate, supporting plates, supporting rods, a first guide rod, a first guide sleeve, a second guide rod, a pressing block and the like; the supporting plates are arranged at the bottom of the first mounting plate in a bilateral symmetry mode, the supporting rods are arranged at the top of the first mounting plate in a bilateral symmetry mode, and the first guide rod is connected between the upper portions of the inner sides of the supporting rods. The household wrinkled clothes flattening device achieves the effects of flattening wrinkled clothes to make the clothes beautiful and ensuring economy at the same time; a user only needsto press the clothes, and then the pressing block can flatten the clothes automatically, so that the clothes are easily flattened, and convenience is brought to work of the user.

Owner:滁州市嘉固商贸有限公司

Gluing equipment for transparent adhesive tape production

ActiveCN109550639AAvoid adverse effectsImprove fitLiquid surface applicatorsCoatingsAdverse effectEngineering

The invention discloses gluing equipment for transparent adhesive tape production, and belongs to the field of transparent adhesive tape production equipment. The gluing equipment for transparent adhesive tape production comprises a bracket and a gluing box, the top of the bracket is connected with a first roller set and a second roller set, the top of the second roller set is connected with the gluing box, the side wall of the bottom end of the gluing box is connected with a glue conveying tube in a sealed mode, the end, away from the gluing box, of the glue conveying tube is rotatably connected with a gluing pin roller through a U-shaped guiding tube, and a glue discharging hole is formed in the side wall of the gluing pin roller; and the side wall of the second roller set is connected with an intermittent motion mechanism through a supporting rod, the intermittent motion mechanism is connected with a carding rod arranged diagonally, the top of the carding rod is fixedly connected with a carding cover, and the carding cover is specifically a glass cover. According to the gluing equipment for transparent adhesive tape production, the structure is simple, operation is convenient, the adverse effect on adhesive tape gluing and subsequent winding due to existence of wrinkles in the conveying process is avoided, and the carding cover adopts the glass cover to facilitate better fitting of the carding cover and adhesive tape.

Owner:丹阳市维尼光学有限公司

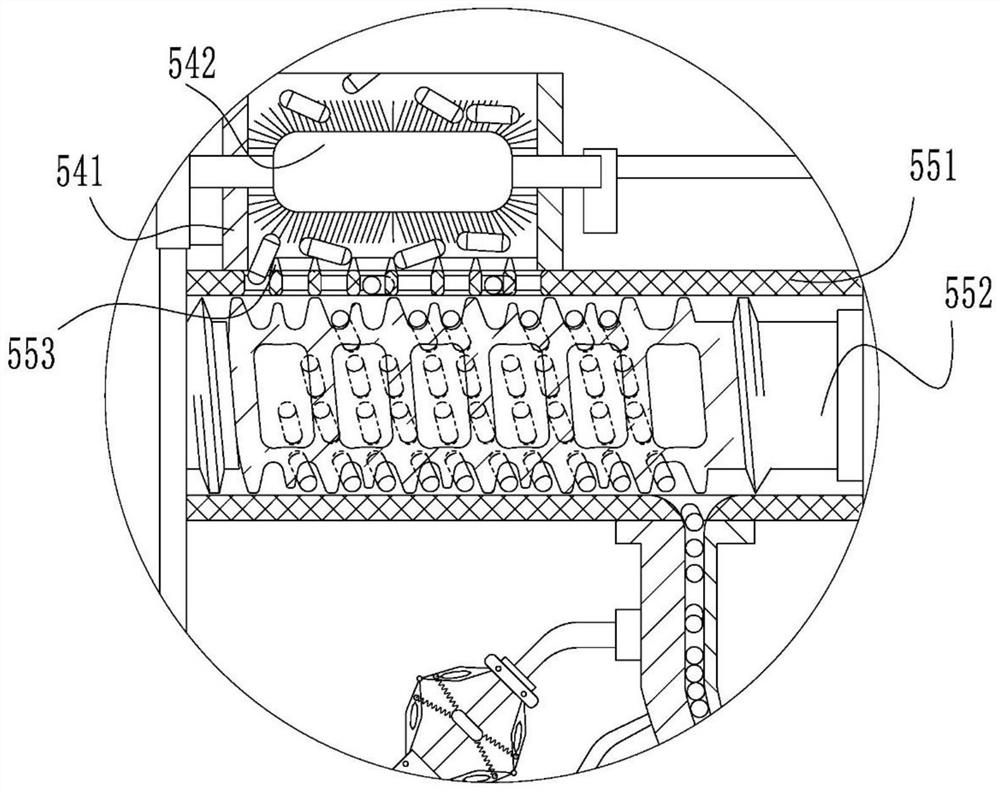

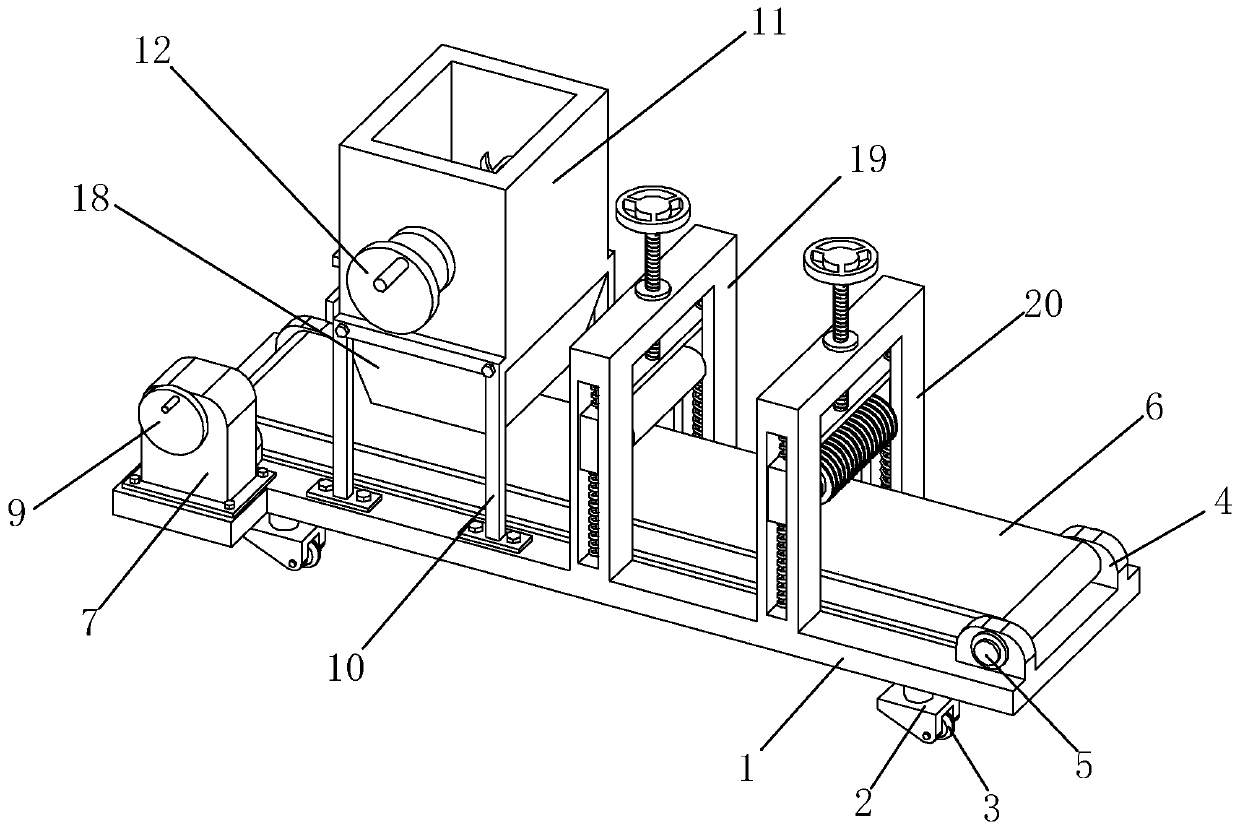

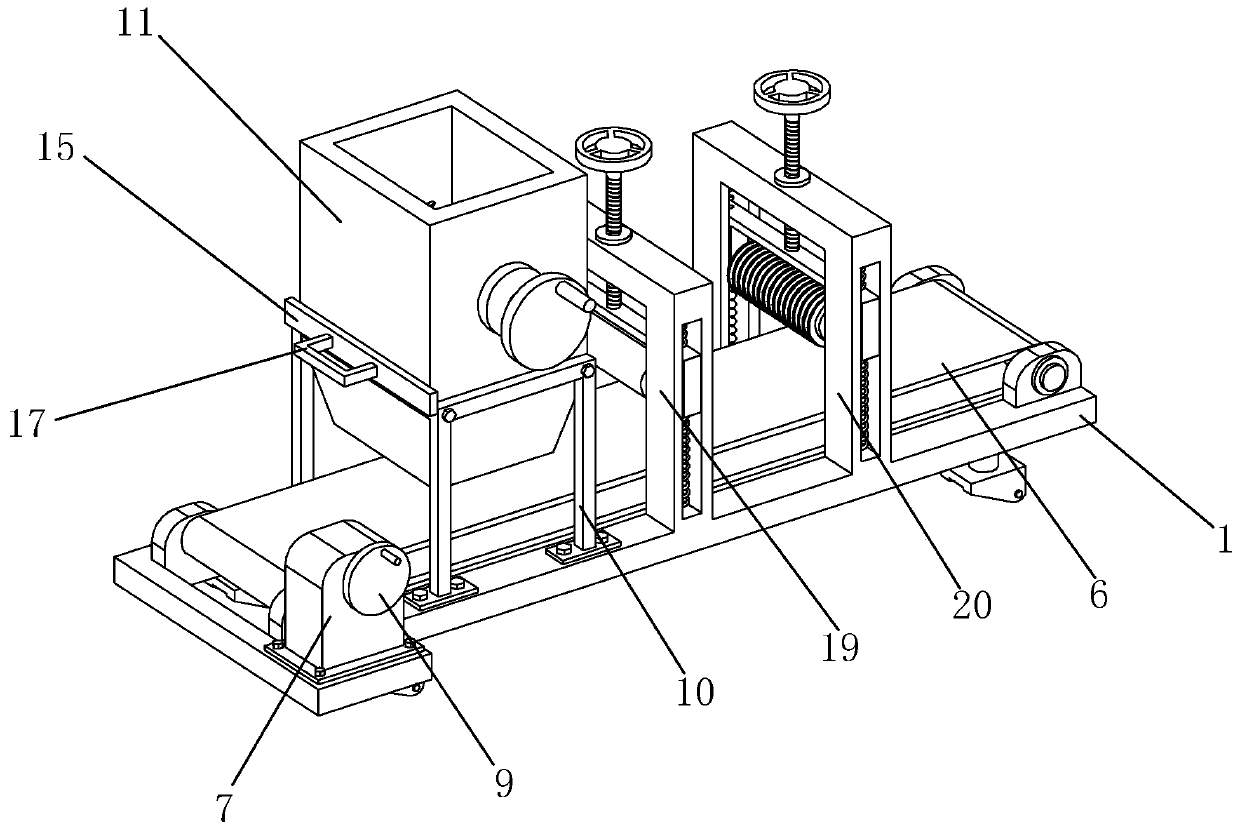

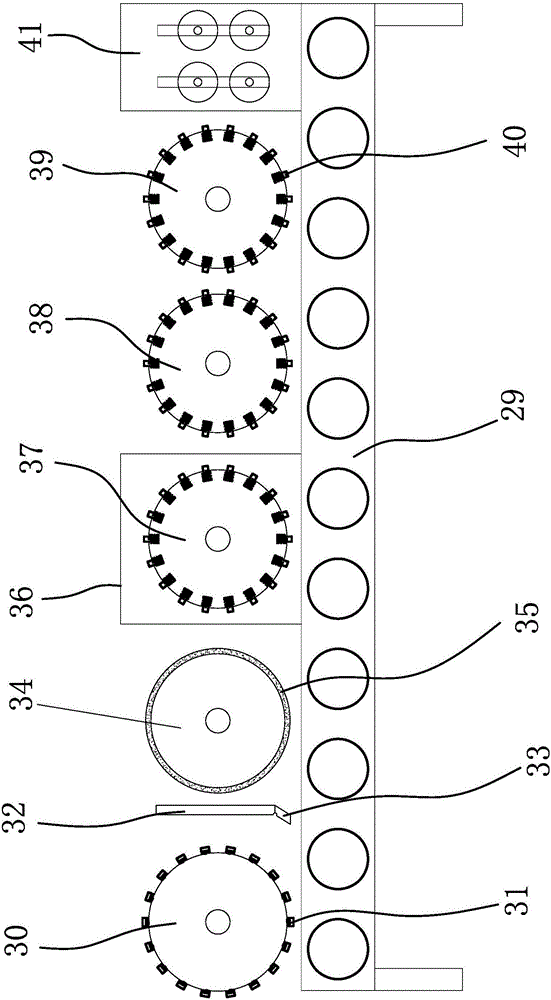

Waste mask recycling and treating device for public places

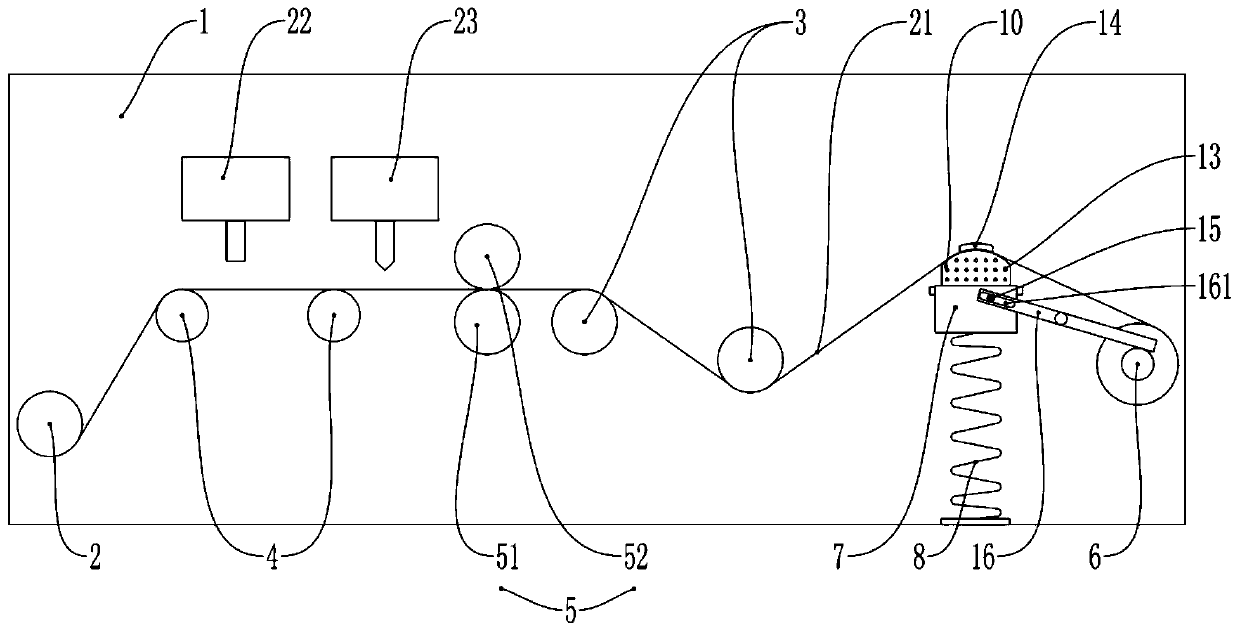

ActiveCN113319102AEmission reductionImprove post-processing effectSolid waste disposalMedical waste disposalMetal stripsPublic place

The invention provides a waste mask recycling and treating device for public places. The device comprises a conveying module, a disinfection module, a pressing module, a cutting module and a recycling module. The conveying module is provided with a flattening structure used for flattening and treating recycled waste masks and then conveying the waste masks into the recycling module. The disinfection module is provided with an ultraviolet lamp and a disinfectant sprayer and is used for disinfecting the flattened waste masks. The pressing module reciprocates up and down through the air pressure difference and is used for pressing the disinfected waste masks. The cutting module is provided with cutter bodies in a staggered manner and is used for cutting metal strips of the compressed waste masks. The recycling device can rotate and move, and two barrel cavities are arranged to collect the cut metal strips and the waste masks correspondingly. The device can separate and recycle the metal strips and fabric, and is environmental friendly and good in economical efficiency.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Thin film rolling equipment of food packaging bag

The invention relates to the technical field of packaging bags, in particular to thin film rolling equipment of a food packaging bag. The thin film rolling equipment comprises a machine frame, whereina guide roller, a transmission roller, a traction roller and a winding roller are arranged on the machine frame, an adjusting unit is arranged between the winding roller and the guide roller, the adjusting unit comprises an adjusting seat and a first elastic part, the first elastic part is located below the adjusting seat, one end of the first elastic part is connected with the adjusting seat, the other end of the first elastic part is connected with the machine frame, and the adjusting seat is internally provided with a first a belt line and a second belt line; the rotating central axis of the first belt line and the second belt line is perpendicular to the traction roller, and the transmission directions of the first belt line and the second belt line are opposite. According to the scheme, the tension adjusting and anti-wrinkle processing in the winding process of the packaging bag is achieved through the adjusting unit, and the problems that in the prior art, the packaging bag is deformed, broken and wrinkled in the winding process of the packaging bag are solved.

Owner:重庆富美包装印务有限公司

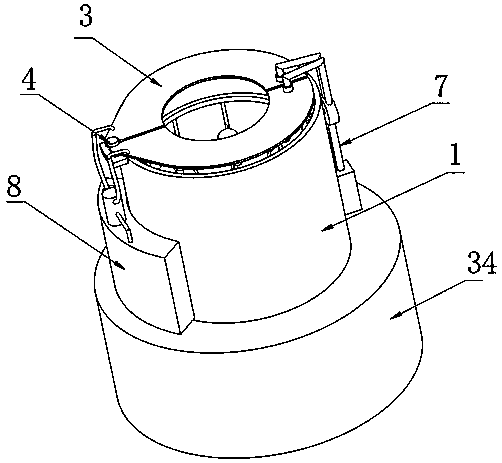

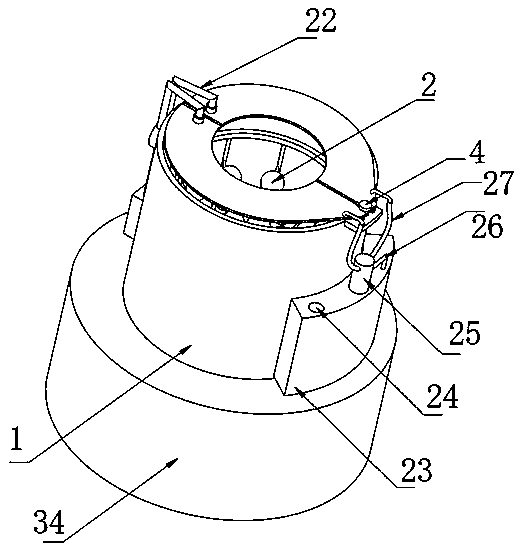

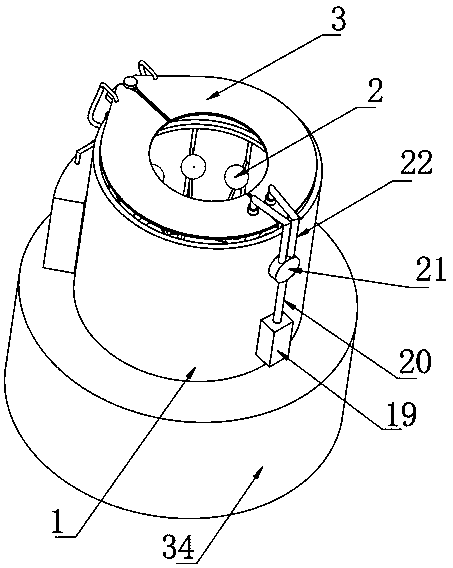

Flowerpot convenient for adjusting soil compactness and soil humidity

InactiveCN111201920ALoose soil achievedAchieve flatteningSelf-acting watering devicesSoil-working equipmentsSoil scienceEngineering

The invention discloses a flowerpot convenient for adjusting soil compactness and soil humidity. The flowerpot comprises a pot body, a soil loosening device capable of loosening soil through gas expansion is installed in the pot body, two sets of rotating plates are installed at the top of the pot body, a driving device is arranged on one side of the rotating plates, the rotating plates are drivento rotate by the driving device, and a soil pressing device for pressing soil through gas expansion is mounted on one side, close to the soil in the pot body, of the rotating plates, so that the flowerpot is capable of conveniently adjusting the soil compactness and the soil humidity. The expandable soil loosening device is arranged in the flowerpot, so that soil loosening in soil is achieved, the soil loosening strength can be effectively controlled through the expanded soil loosening device, excessive soil loosening is avoided, any shaking is avoided, in addition, soil flattening can be achieved through the soil pressing device at the top of the flowerpot, and nutrient loss in the soil is prevented.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

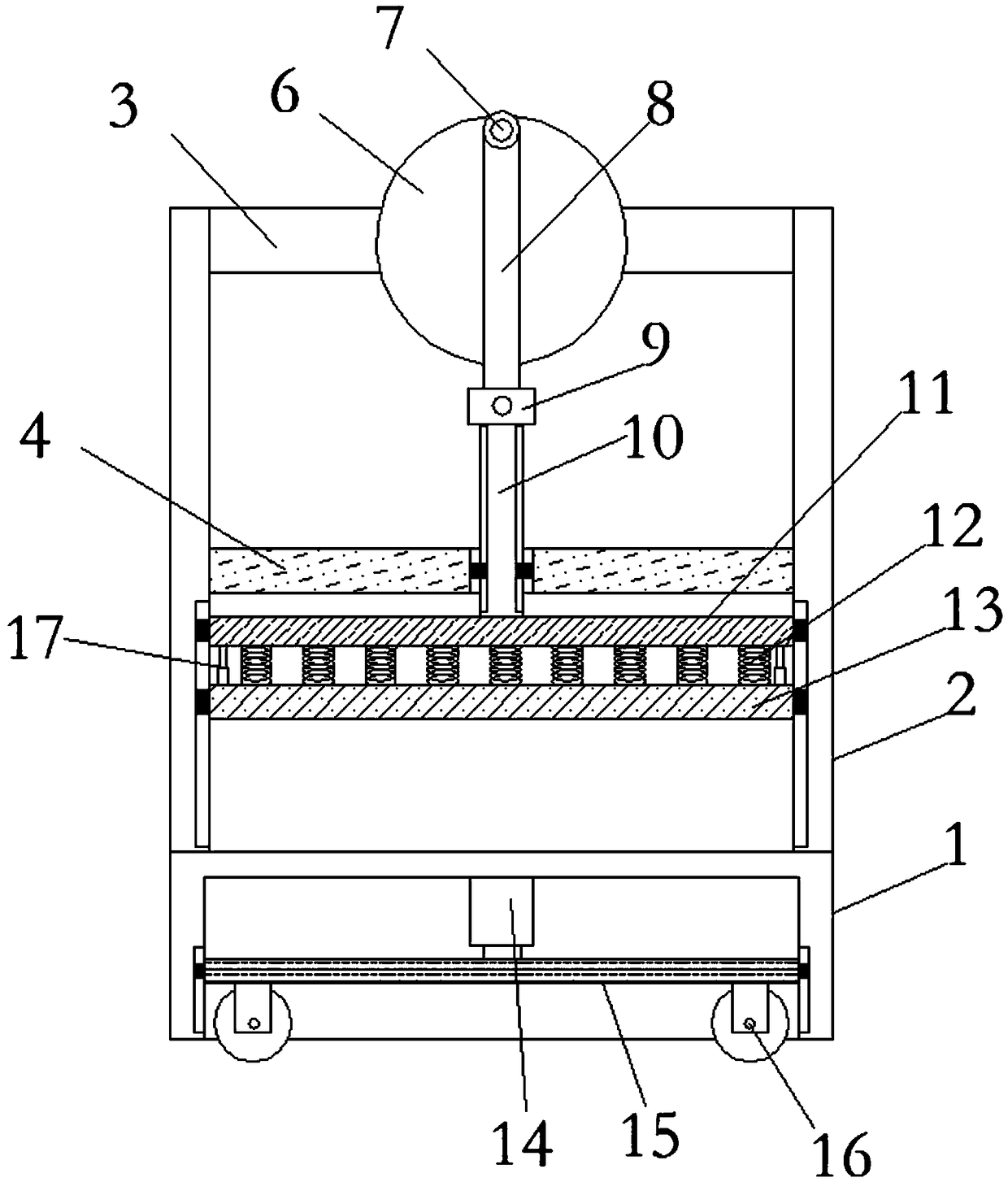

Corrugated case flattening machine

InactiveCN108715053ASimple structureWide applicabilityPaper-makingBox making operationsEngineeringMultiple buffering

The invention discloses a corrugated case flattening machine which comprises a base. Two vertical plates are fixedly connected to the upper end of the base symmetrically. A supporting rod and a supporting plate close to the center of the vertical plates are fixedly connected to the opposite sides of the two vertical plates up and down. A motor is fixedly connected to one side of the supporting rod. An output shaft of the motor is fixedly connected with a rotating disc. The side, away from the motor, of the rotating disc is fixedly connected with an eccentric rod vertically. The rod wall of theeccentric rod is connected with an eccentric rotating rod in a rotating manner through a ball bearing. The end, away from the eccentric rod, of the eccentric rotating rod is connected with a liftingrod in a rotating manner through a U-shaped clamping plate. The lower end of the lifting rod penetrates the lower end of the supporting plate through a through hole formed in the center of the surfaceof the supporting plate and is fixedly connected with a fixing plate. The lower end of the fixing plate is fixedly connected with a pressing plate through multiple buffering springs. The corrugated case flattening machine can flatten a corrugated case fast and conveniently, and is simple in structure, applicable to small-scale production or individual use and convenient to move.

Owner:TIANJIN MAOHAI YONGTAI PAPER PROD

Garment surface ironing equipment

ActiveCN108049052AEasy to operateSimple structureMechanical cleaningPressure cleaningEngineeringConveyor belt

The invention discloses garment surface ironing equipment which comprises an equipment body. A condensation pipe is fixedly mounted on the top of the equipment body, a water inlet pipe is fixedly mounted at an end of the condensation pipe, an atomizer is arranged at an end of the water inlet pipe, a shell is arranged on the outer surface of the bottom of the condensation pipe, an operation panel is fixedly mounted in the center of the outer surface of the front end of the shell, a conveyor belt is arranged at the inner bottom of the shell, and a control electric box is arranged at the bottom of the conveyor belt. The garment surface ironing equipment has the advantages that the garment surface ironing equipment is provided with the atomizer, an electric heating plate and a press fit drum,accordingly, fed clothing or textile products can be humidified, the humidified clothing can rub with the outer surface of the press fit drum, the clothing can be cleaned in flattening procedures, theironing heights can be ultimately conveniently adjusted in comprehensive clothing ironing procedures, and accordingly the garment surface ironing equipment has an excellent use prospect.

Owner:青岛弘诚体育用品有限公司

Slotted type carton data collection tool

ActiveCN104210710ADoes not affect acquisition accuracyRealize simultaneous acquisitionPackaging automatic controlData informationCarton

The invention provides a slotted type carton data collection tool, which is characterized in that a carrier attached with data information is contained in a containing unit, a pair of first swinging covers and a pair of second swinging covers are arranged on the top part of the containing unit, and a control rod of a first motor unit drives the first swinging covers to extend towards the horizontal direction of the outer side of the containing unit; the beginning ends of first pressing rods extend towards the inner inclined upper part of a rod body, and the two first pressing rods respectively press the second swinging covers to extend towards the horizontal direction of the outer side of the containing unit; the beginning ends of second pressing rods extend towards the inclined upper part of the rod body, and the second pressing rods press the first swinging covers to extend towards the horizontal direction of the outer side of the containing unit; a data collector collects the data information on the carrier; a control rod of a second motor unit drives the first swinging covers to extend towards the horizontal direction of the inner side of the containing unit; the beginning ends of third pressing rods extend towards the outer inclined upper part of the rod body, and the two third pressing rods press the first swinging covers and the second swinging covers to extend towards the horizontal direction of the inner side of the containing unit so as to close the containing unit.

Owner:BEIJING JAWA HUICHENG TECH

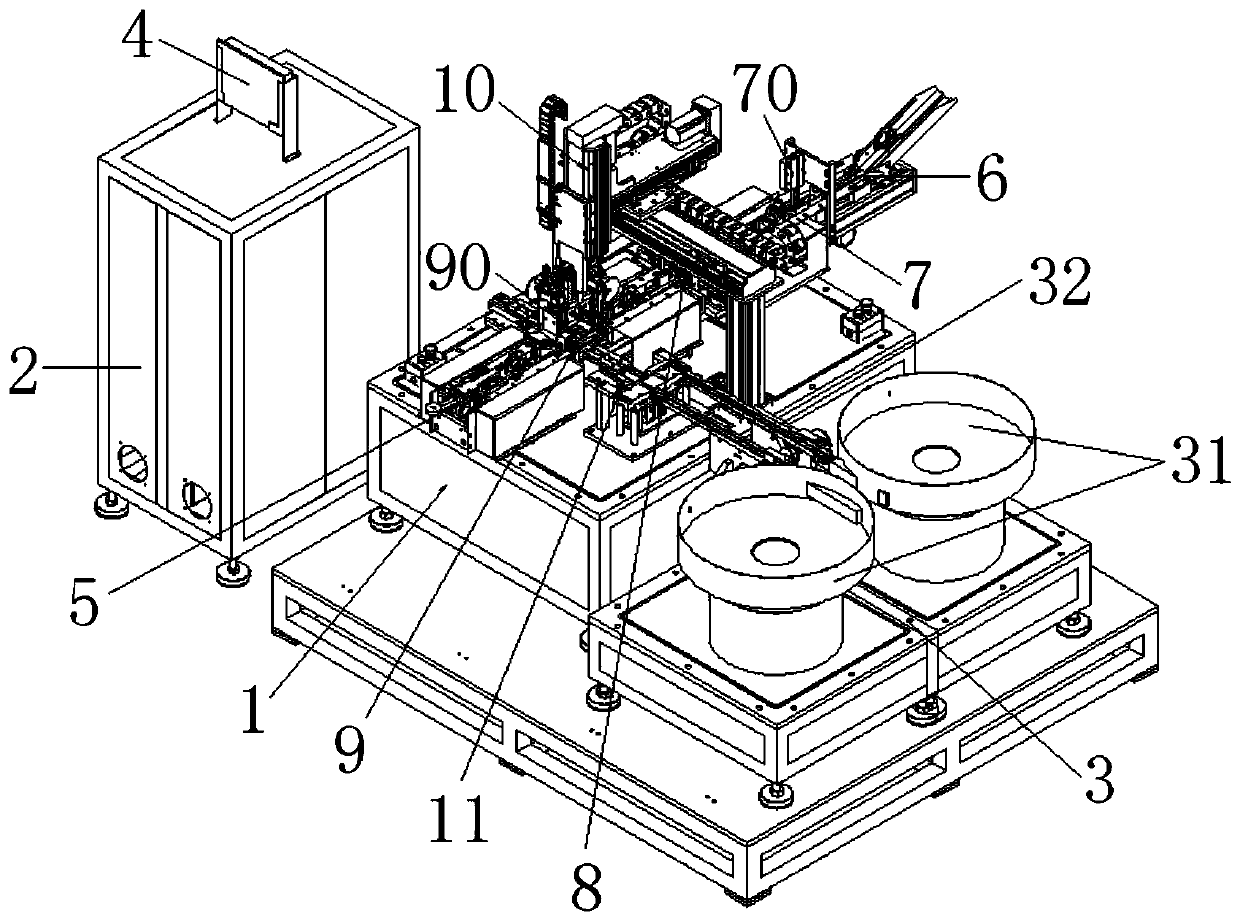

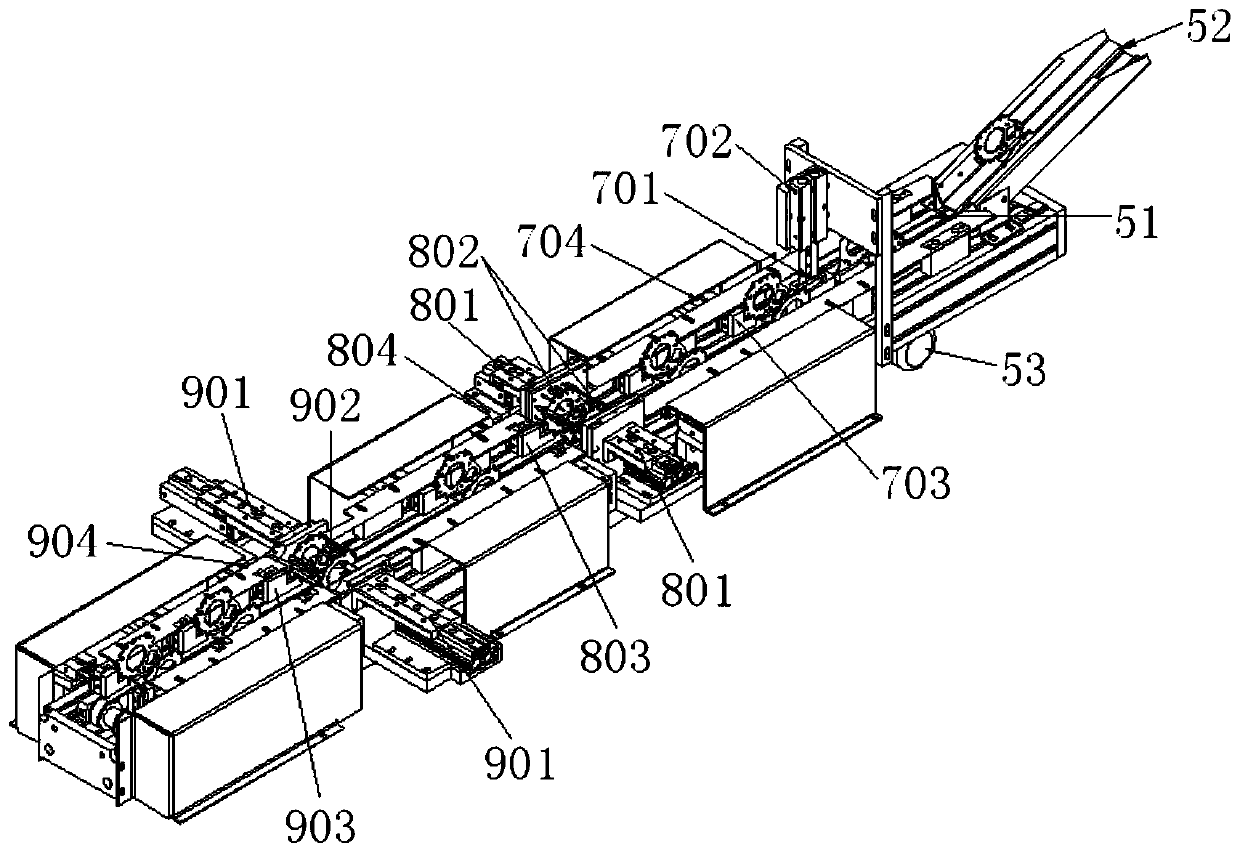

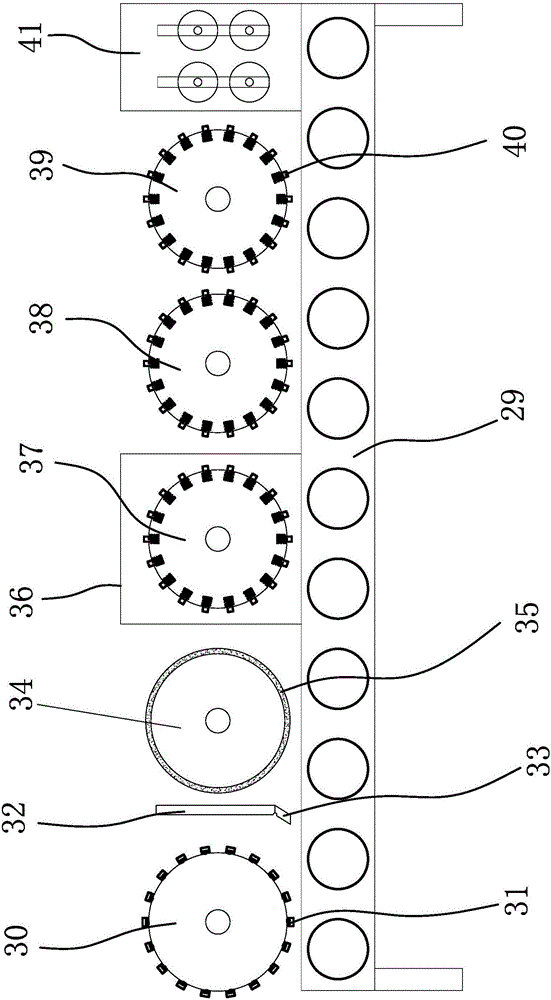

Automatic assembling and riveting machine for automobile safety belt product frame parts

The invention relates to an automatic assembling and riveting machine for automobile safety belt product frame parts. The automatic assembling and riveting machine for the automobile safety belt product framework parts achieves a series of operations of automatic feeding and conveying, frame bottom flattening and shaping process, frame leakage hole position detection, positioning frame, material distributing titanium rake alloy workpiece and synchronously assembling the two titanium rake alloy workpieces together with the frame of a frame and a titanium rake alloy workpiece, the whole detection process and the assembly process do not need manual intervention, automatic detection and automatic assembly are realized, the man-machine separation is realized, the problem that the traditional riveting assembling machine for the automobile safety belt product framework part does not need to participate in loading and unloading due to manual participation is solved, the labor intensity of workers is effectively reduced, the labor cost of enterprises is reduced, the assembly efficiency is high, the productivity can reach 800-900 pcs per hour, and the automatic assembling and riveting machine has the advantages of being high in productivity, high in assembling efficiency, high in assembling precision and convenient to use.

Owner:东莞威仕达汽车零部件有限公司

Production method for polyvinyl chloride sheet flooring

ActiveCN106042150AStir wellGuarantee processing qualityCeramic extrusion diesAuxillary shaping apparatusParaffin waxSurface finishing

The invention provides a production method for a polyvinyl chloride sheet flooring and belongs to the technical field of machinery. The production method for the polyvinyl chloride sheet flooring comprises the following steps that a, surface raw materials are prepared, specifically, 300 kilograms of marble flour and 1-3 kilograms of paraffin are prepared; b, backing raw materials are prepared, specifically, 300 kilograms of marble flour, 100 kilograms of polyvinyl chloride and 1-3 kilograms of paraffin are prepared; c, the polyvinyl chloride sheet flooring is manufactured; and d, the polyvinyl chloride sheet flooring is subjected to surface treatment, specifically, the surface of the polyvinyl chloride sheet flooring is treated through a treatment device, so that the surface of the polyvinyl chloride sheet flooring has better abrasion resistance. The method has the advantage of being capable of efficiently manufacturing the polyvinyl chloride sheet flooring.

Owner:浙江世纪豪门家居科技有限公司

Shearing and recycling device for waste liquid gas storage tank

InactiveCN105127751AImprove work efficiencyReduce labor intensitySolid waste disposalShearing machinesKnife bladesLiquid gas

The invention relates to a shearing and recycling device for a waste liquid gas storage tank. The shearing and recycling device comprises a main machine body. A shearing cylinder and a material pressing cylinder are perpendicularly arranged on the top of the main machine body. A material pressing head is arranged at the bottom of a piston rod of the material pressing cylinder and is used in cooperation with a bottom protection plate for achieving the material pressing work. A shear slide base is fixedly arranged at the bottom of a piston rod of the shearing cylinder and is in slide fit with a guide rail plate. A blade is fastened and arranged at the bottom of the shear slide base through a tool bit bolt and is used in cooperation with a vertical cutter pad for completing the shearing work. By means of the shearing and recycling device, automatic feeding can be conducted on the waste liquid gas storage tank, a tank body can be compressed, the flattened tank body is sheared through the shearing device so that the tank body can be sheared into two parts, and finally waste angle materials obtained after shearing are recycled.

Owner:YICHANG CITY RUIYANG MACHINERY MFG

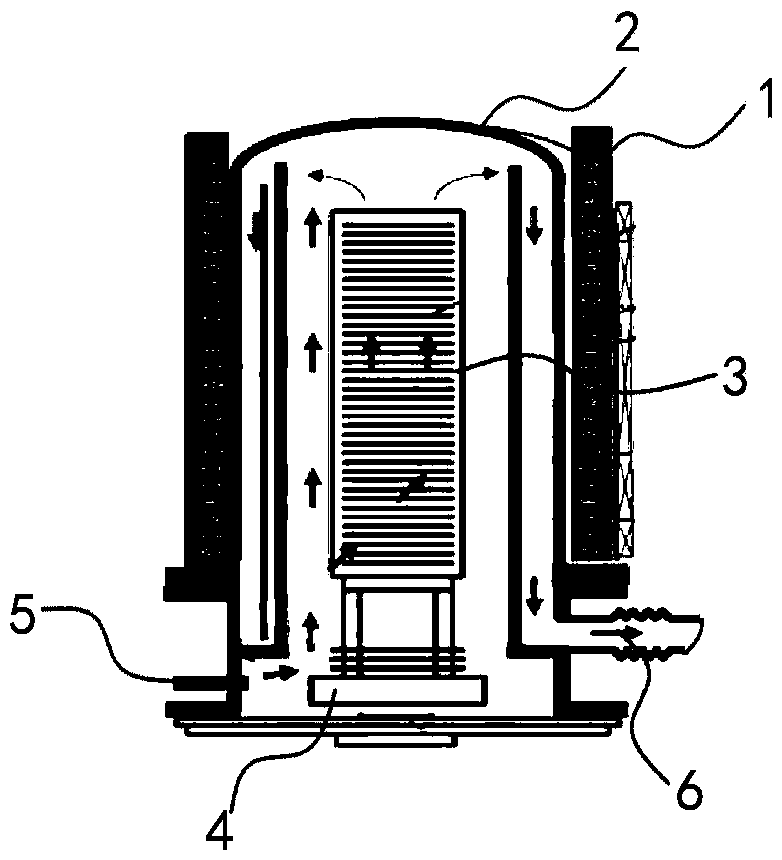

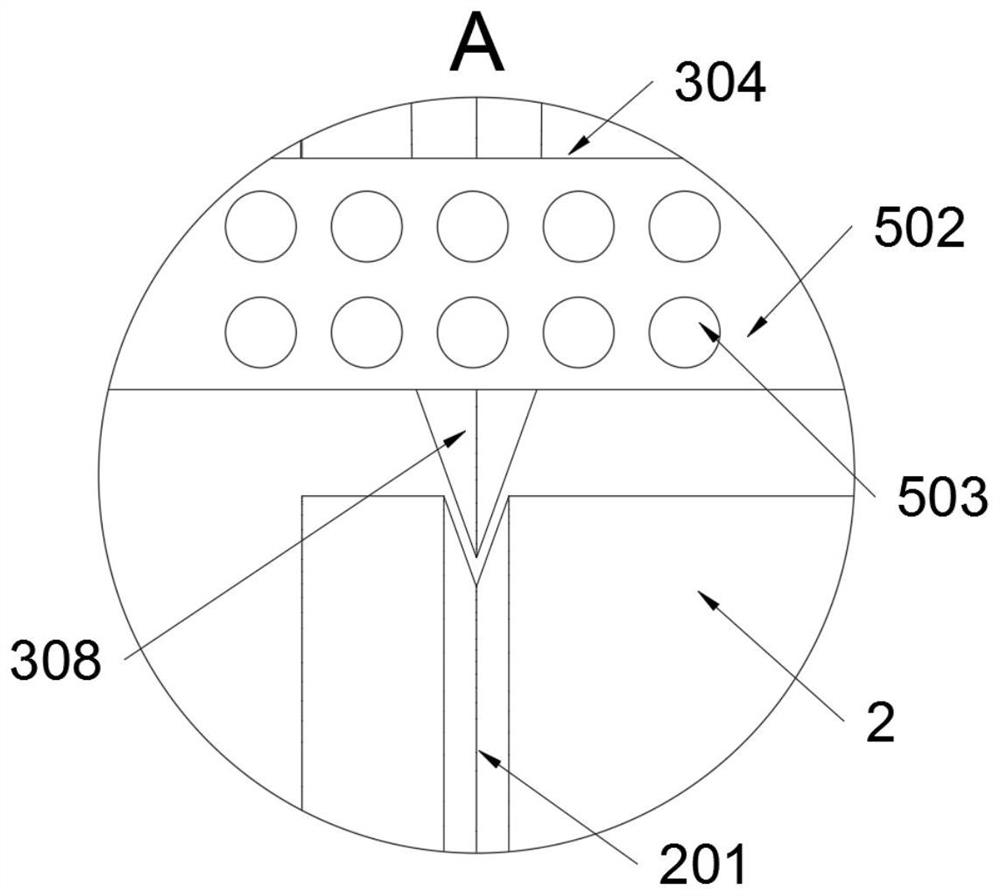

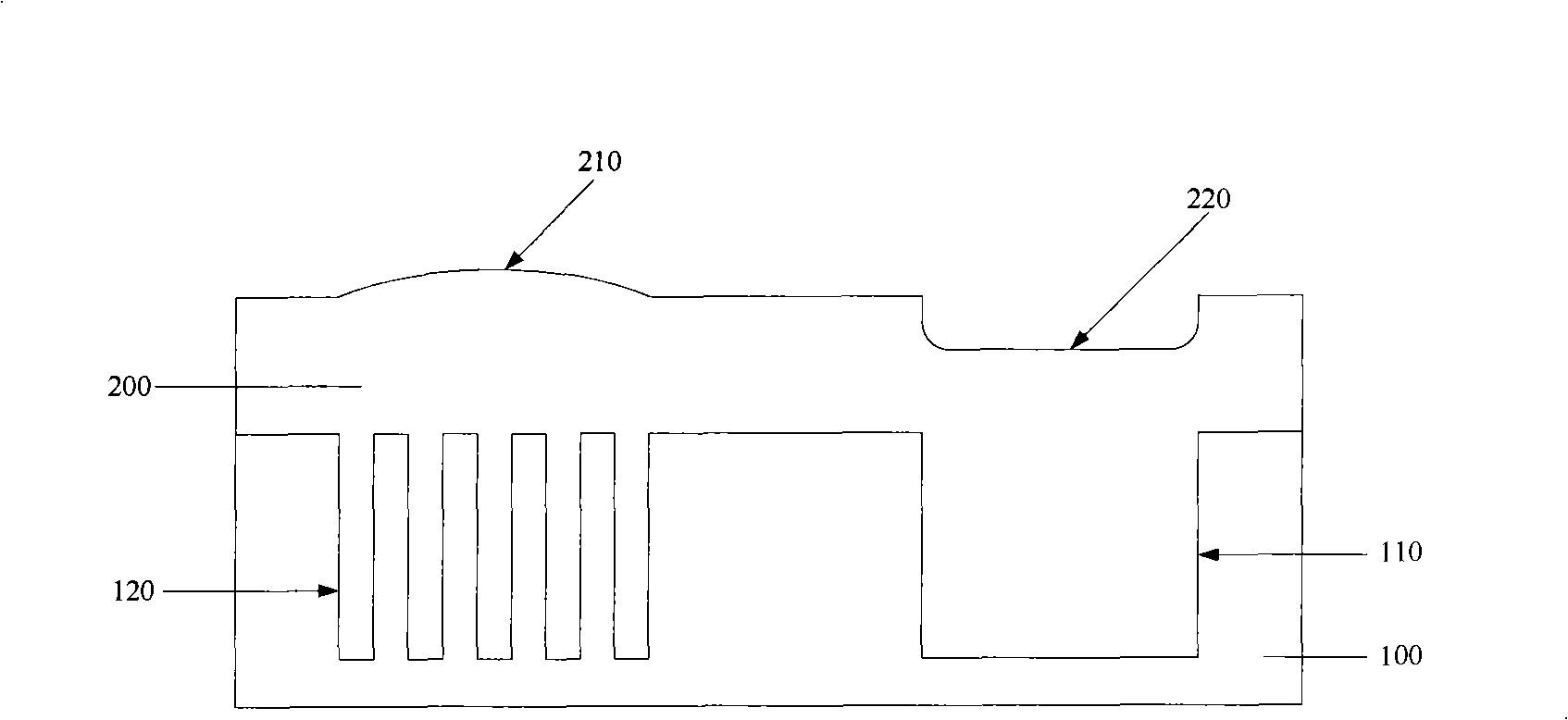

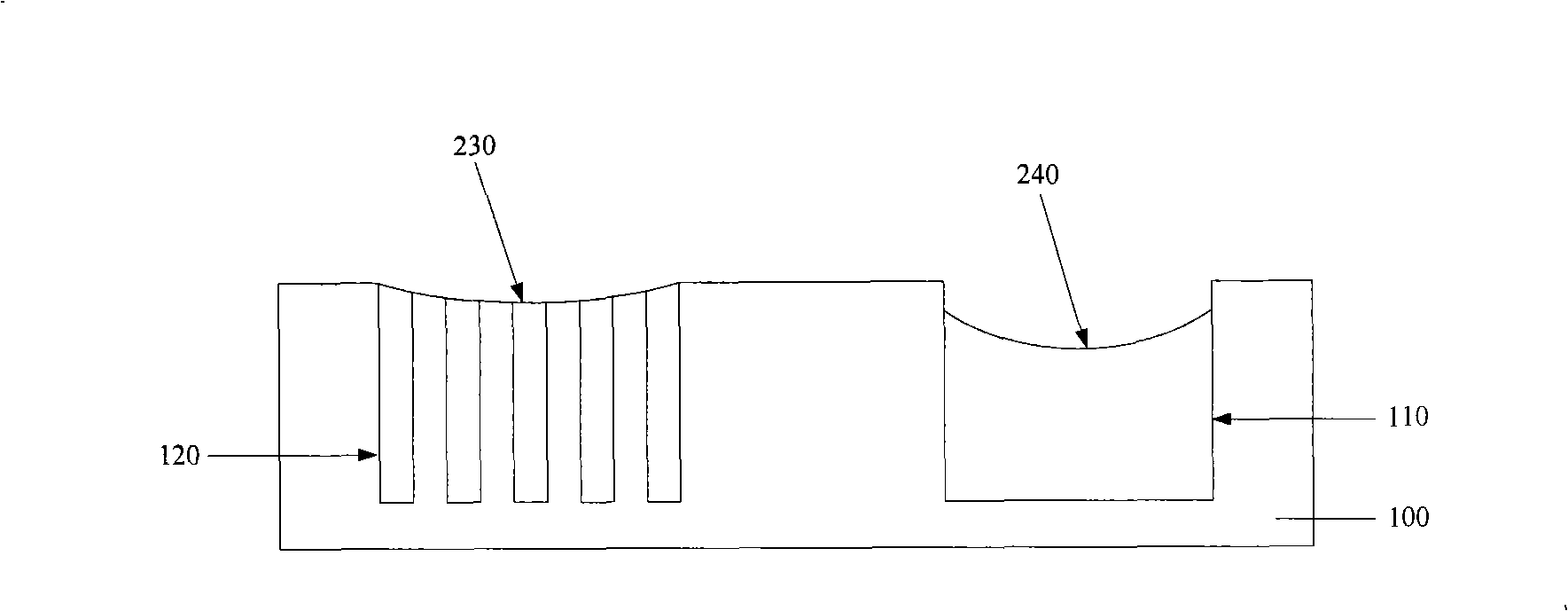

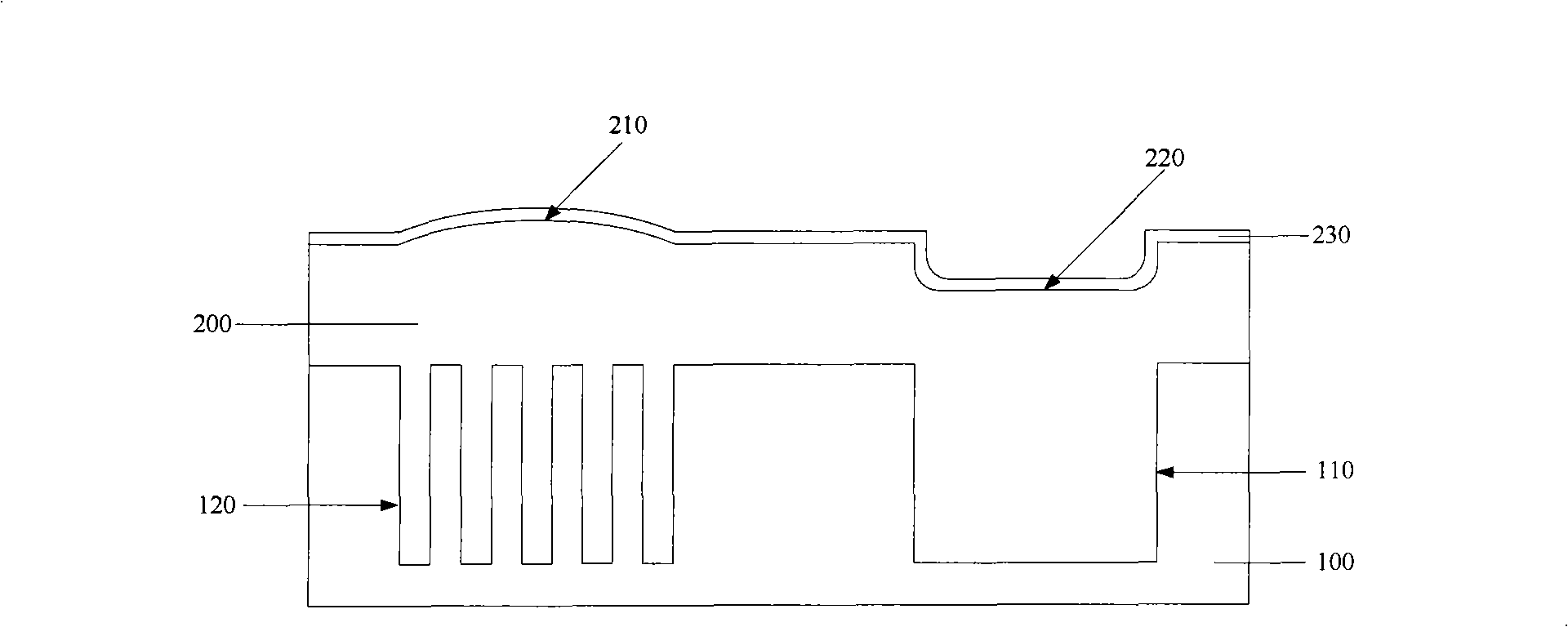

Sedimentation furnace tube

PendingCN110894598AIncrease deposition rateConsistent thicknessChemical vapor deposition coatingWaferMaterials science

The invention provides a sedimentation furnace tube which comprises a reaction cavity, a heater, a cassette, a base and an auxiliary heating part. One end of the reaction cavity is closed, and the other end of the reaction cavity is provided with an opening. The heater is arranged on the periphery of the reaction cavity. The cassette is located in the reaction cavity and used for bearing multiplebatches of wafers. The base supports the cassette and can drive the cassette to move into the reaction cavity and close the opening or drive the cassette to move out of the reaction cavity. The auxiliary heating part is arranged at one end of the reaction cavity and located above the cassette, and the auxiliary heating part heats the middles of the wafers on the top of the cassette when the heaterperforms heating.

Owner:CHANGXIN MEMORY TECH INC

Positioning printing window curtain fabric with pencil drawing style and manufacturing method thereof

InactiveCN106283337AHigh weft weightNo textureCurtain accessoriesDyeing processDigital printingPolyester

The invention provides a positioning printing window curtain fabric with pencil drawing style and a manufacturing method thereof. The positioning printing window curtain fabric with pencil drawing style comprises a base cloth, wherein the base cloth is provided with at least one layer of fabric, and is formed by weaving warp yarns and weft yarns; each warp yarn is a 8.35tex interlaced yarn, and each weft yarn is a 33.4tex luster polyester drawn textured yarn; the arrangement ratio of weft yarns with different colors is 1 to 1; the base cloth is provided with a to-be-printed area and a printing-free area; the to-be-printed area adopts a five-satin weave, and the printing-free area adopts a honeycomb weave; a printing layer is attached to the to-be-printed area. The positioning print window curtain fabric has the advantages that by adopting weaving and printing integral technique, the digital jacquard weave technique and the precise positioning digital printing technique are organically combined, and the jacquard weave luster and obvious texture are realized by the precise mounting of printing patterns.

Owner:ZHEJIANG HEXIN TEXTILE

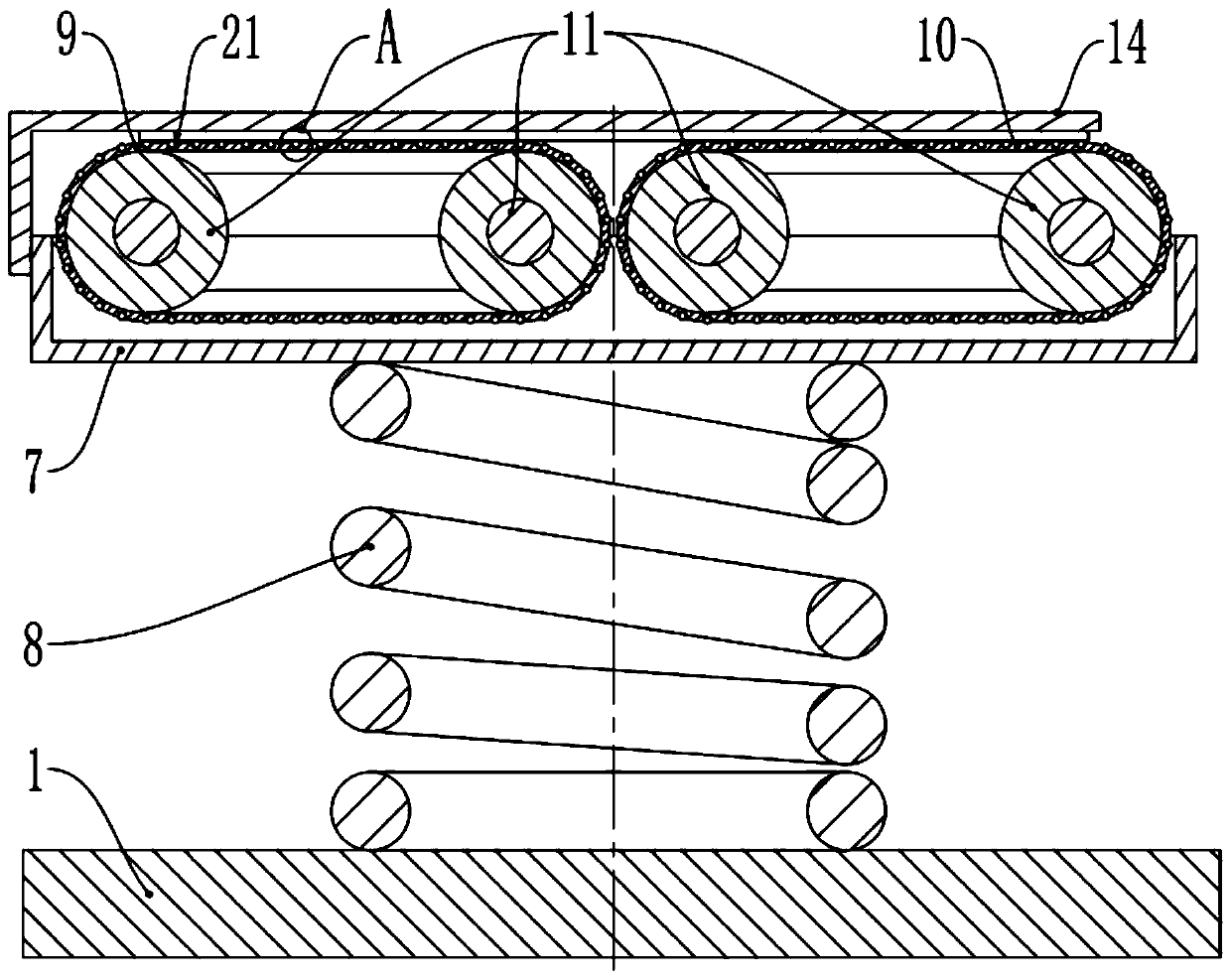

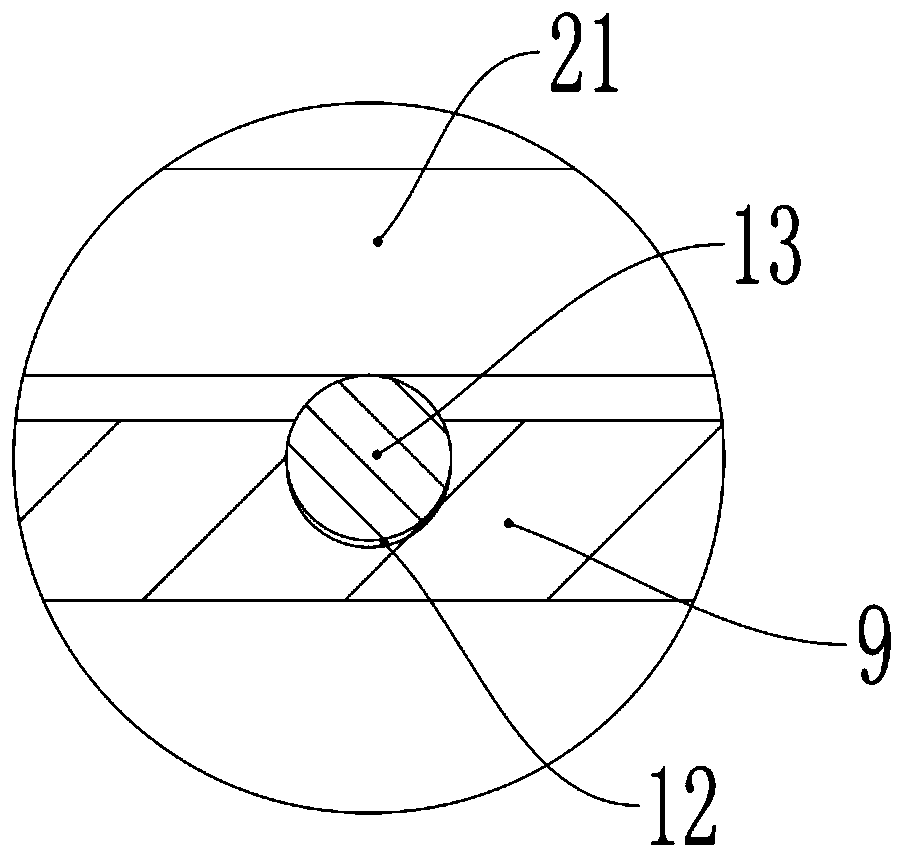

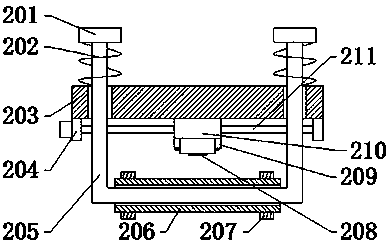

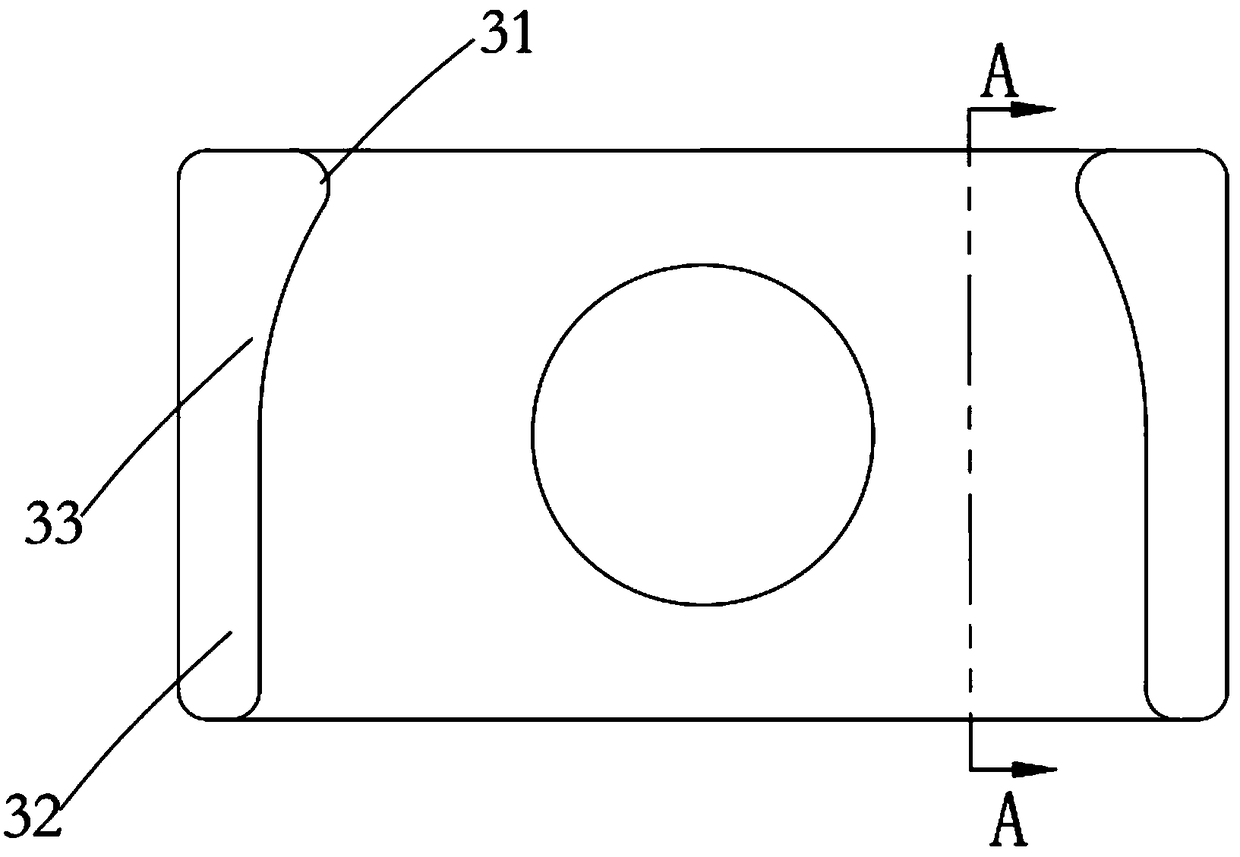

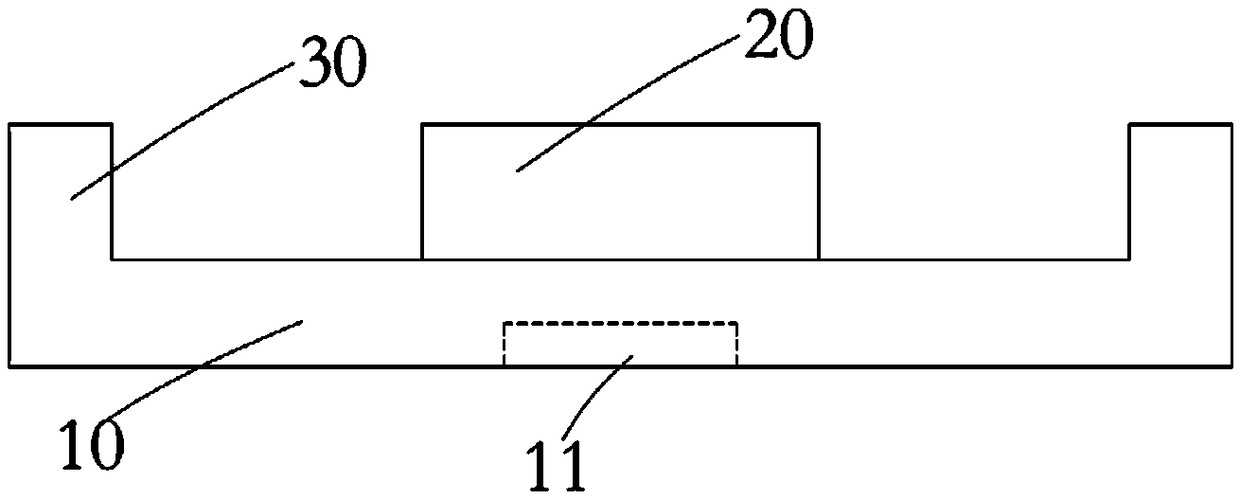

Thin film positioning device for thin film positioning measurement

InactiveCN109051939AAchieve flatteningRealize limitLighting applicationsMechanical apparatusThin membraneEngineering

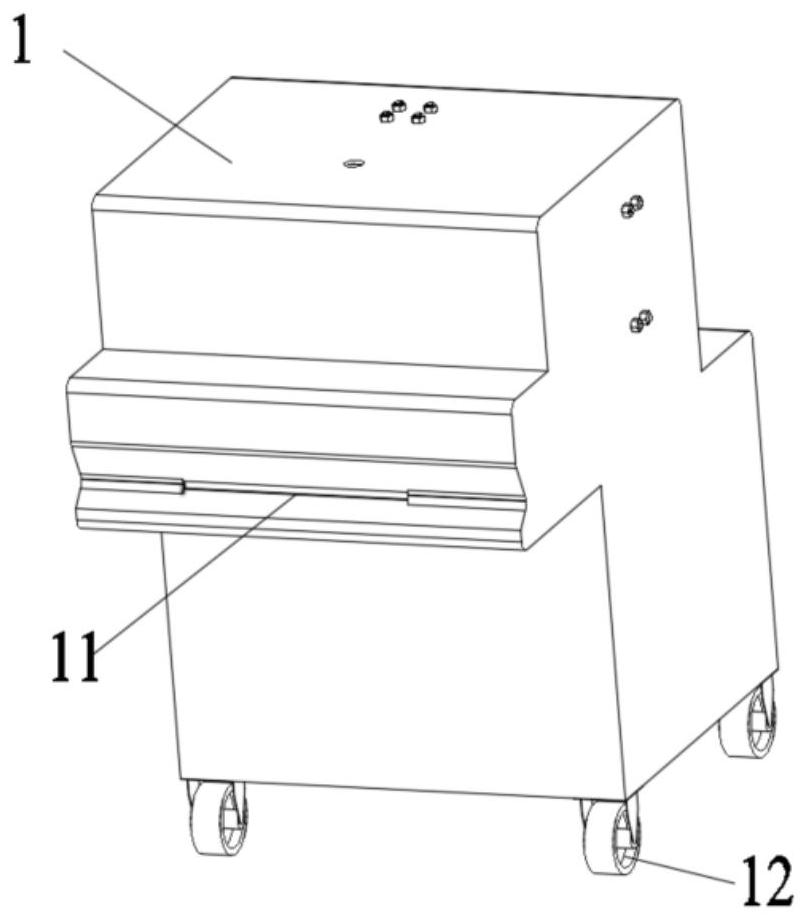

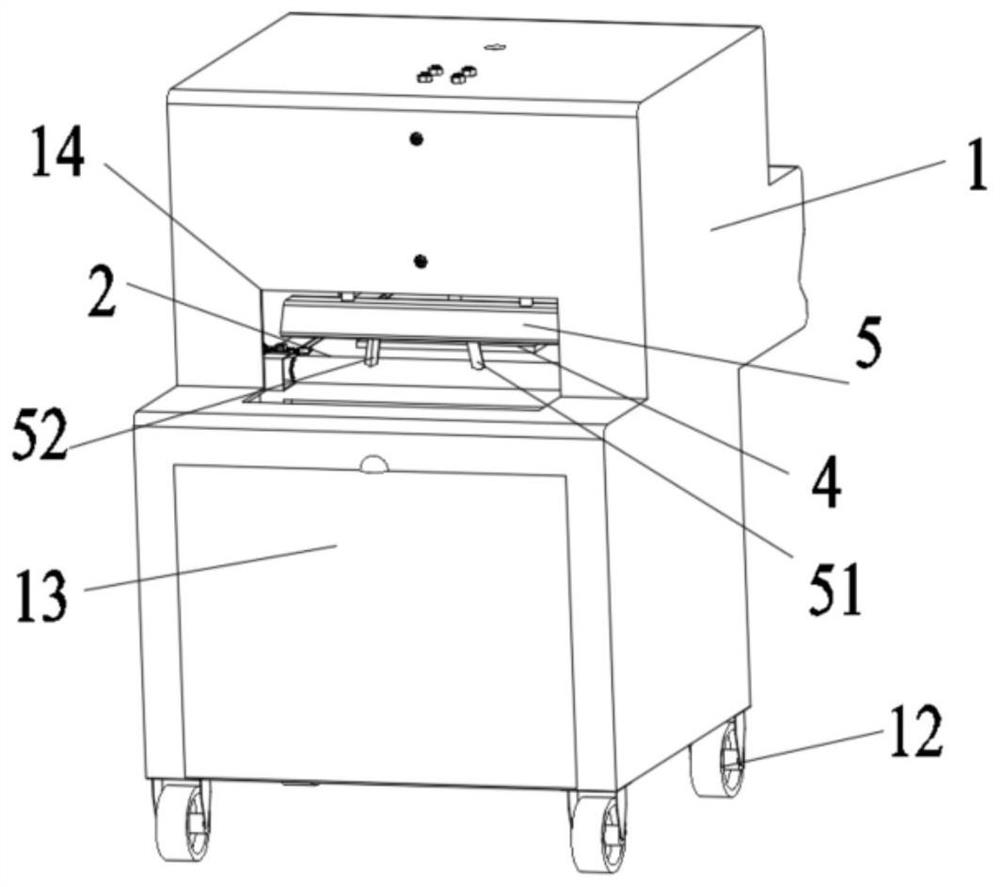

The invention provides a thin film positioning device for thin film positioning measurement. The thin film positioning device comprises pressing plates, springs, a cover plate, lug plates, a U-shapedsupporting frame, a pressing wheel, an industrial camera, an illuminating lamp, a slide block and a screw rod; the springs are connected to the upper side surface of the cover plate; the pressing plates are connected to the upper end surfaces of the springs and fixed to the upper end surface of the U-shaped supporting frame; the U-shaped supporting frame is slidably connected to the cover plate, and the pressing wheel is installed on the U-shaped supporting frame through a bearing in a sleeving mode; the lug plates are fixed to the front edge and the rear edge of the lower end surface of the cover plate and connected to the front side and the rear side of the screw rod correspondingly; the slide block is installed on the screw rod; and the industrial camera and the illuminating lamp are fixed to the lower side of the slide block. Through the design, the measurement accuracy degree is increased, the thin film positioning device is convenient to use and operate, the positioning and flattening functions are achieved, and the measurement accuracy degree is increased.

Owner:SUZHOU HONGSUN ELECTROMECHANICAL TECH CO LTD

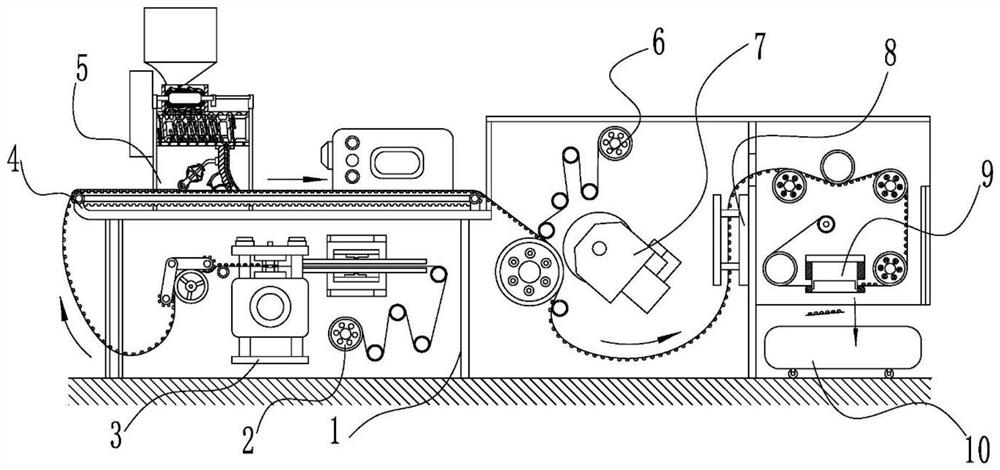

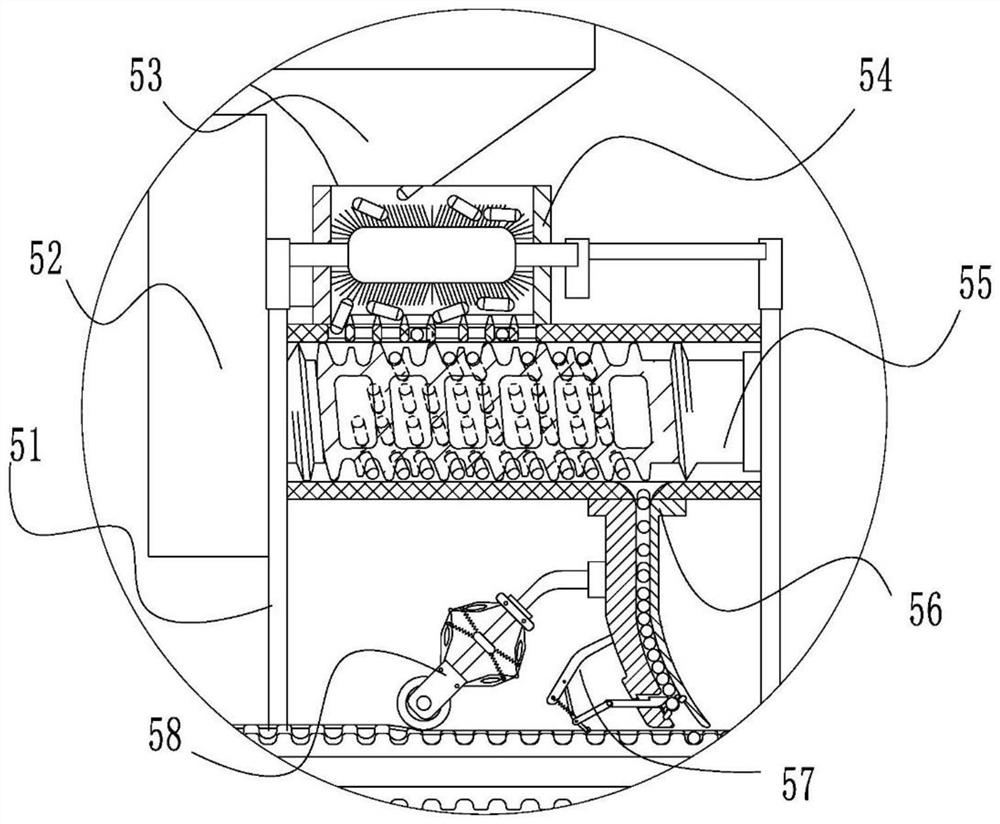

Full-automatic aluminum plastic packaging equipment for pharmacy

InactiveCN114132567AAdjustable interference storageAchieve regulationWrappingPackaging automatic controlEngineeringPlastic packaging

The invention discloses full-automatic aluminum plastic packaging equipment for pharmacy, and relates to the field of packaging. The PVC conveying part is arranged in the rack in a relatively rotating manner; the preheating forming device is fixed in the rack and is positioned above the PVC conveying piece; the belt wheel set is arranged on the upper surface of the rack in a relatively rotating mode, and grooves are evenly formed in the surface of the belt wheel set; the feeding assembly is fixed to the upper surface of the rack and located over the input end of the belt wheel set. The aluminum foil conveying piece is arranged in the rack in a relatively rotating mode and located on the side close to the output end of the belt wheel set; the heat sealing device is arranged in the rack in a relatively rotating mode and located below the aluminum foil conveying assembly; the printing device is fixed to the inner wall of the rack and located on the side, away from the belt wheel set, of the heat sealing device. And the blanking device is fixed in the rack and located on the side, away from the heat sealing device, of the printing device, and a trolley is arranged below the blanking device.

Owner:李永前

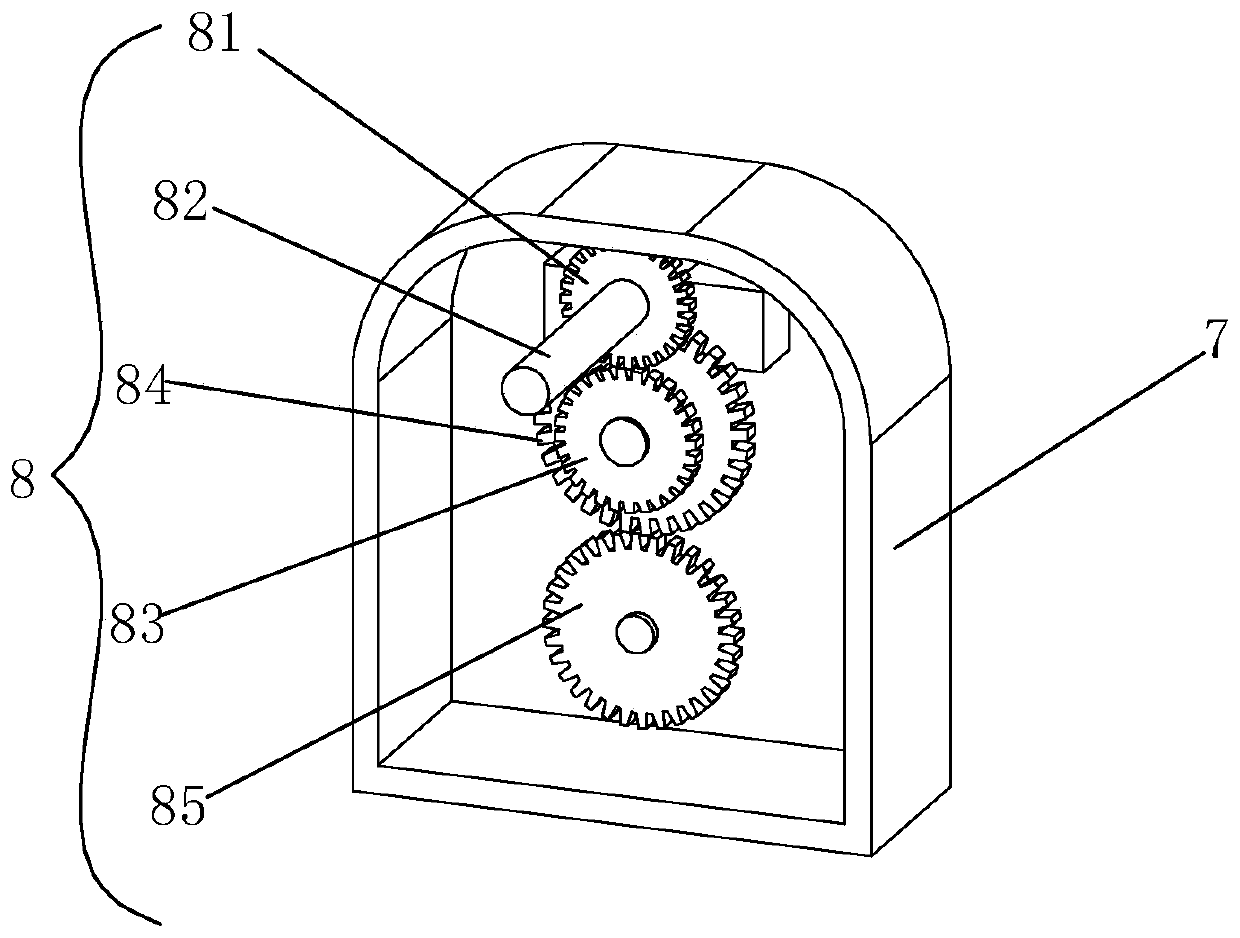

Low-cost sculpture clay manual pugging equipment for sculpture creation

InactiveCN110126071ASimple and fast operationImprove plasticityFeeding arrangmentsClay processing apparatusEngineeringConveyor belt

The invention relates to the technical field of sculpture clay equipment, in particular to low-cost sculpture clay manual pugging equipment for sculpture creation. The equipment comprises a bottom plate, sliding wheel seats are arranged at the four corners of the bottom of the bottom plate, the sliding wheel seats are connected with sliding wheels through pin rolls, bearing seats are arranged at the two ends of the top of the bottom plate, rollers are clamped on the bearing seats, the two rollers are rotationally connected with the bearing seats correspondingly, a conveyor belt is arranged between the two rollers, a driving box is arranged at one end of the top of the bottom plate, the driving box is internally provided with a transmission mechanism, a feeding box is arranged above the conveyor belt, a support frame is fixedly arranged on the outer side of the feeding box, the bottom end of the support frame is fixedly connected to the bottom plate, a discharge hopper is fixedly arranged at the bottom of the feeding box, a clay pressing mechanism is arranged on one side of the feeding box, and a clay cutting mechanism is arranged on the side, away from the feeding box, of the claypressing mechanism. According to the equipment, stirring, flattening and slicing of clay are realized by manual operation, operation is simple, and the manufacturing cost is low.

Owner:温州志通雕塑艺术有限公司

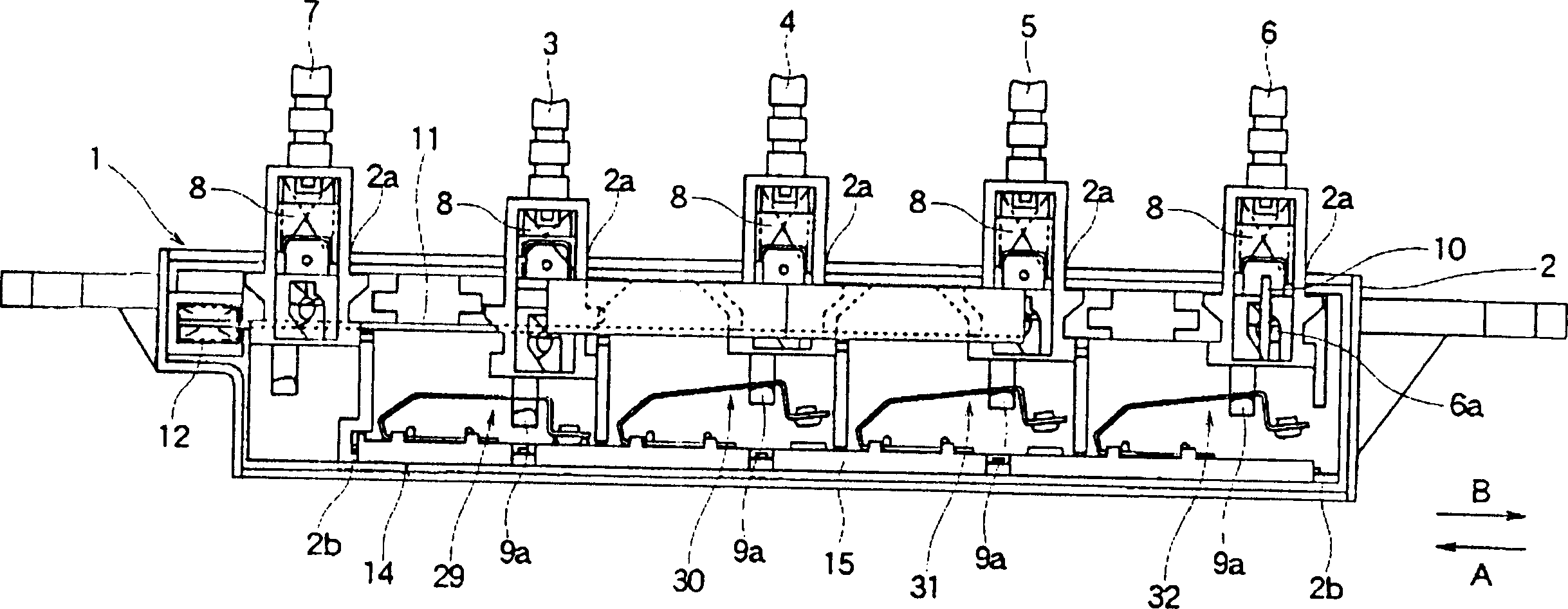

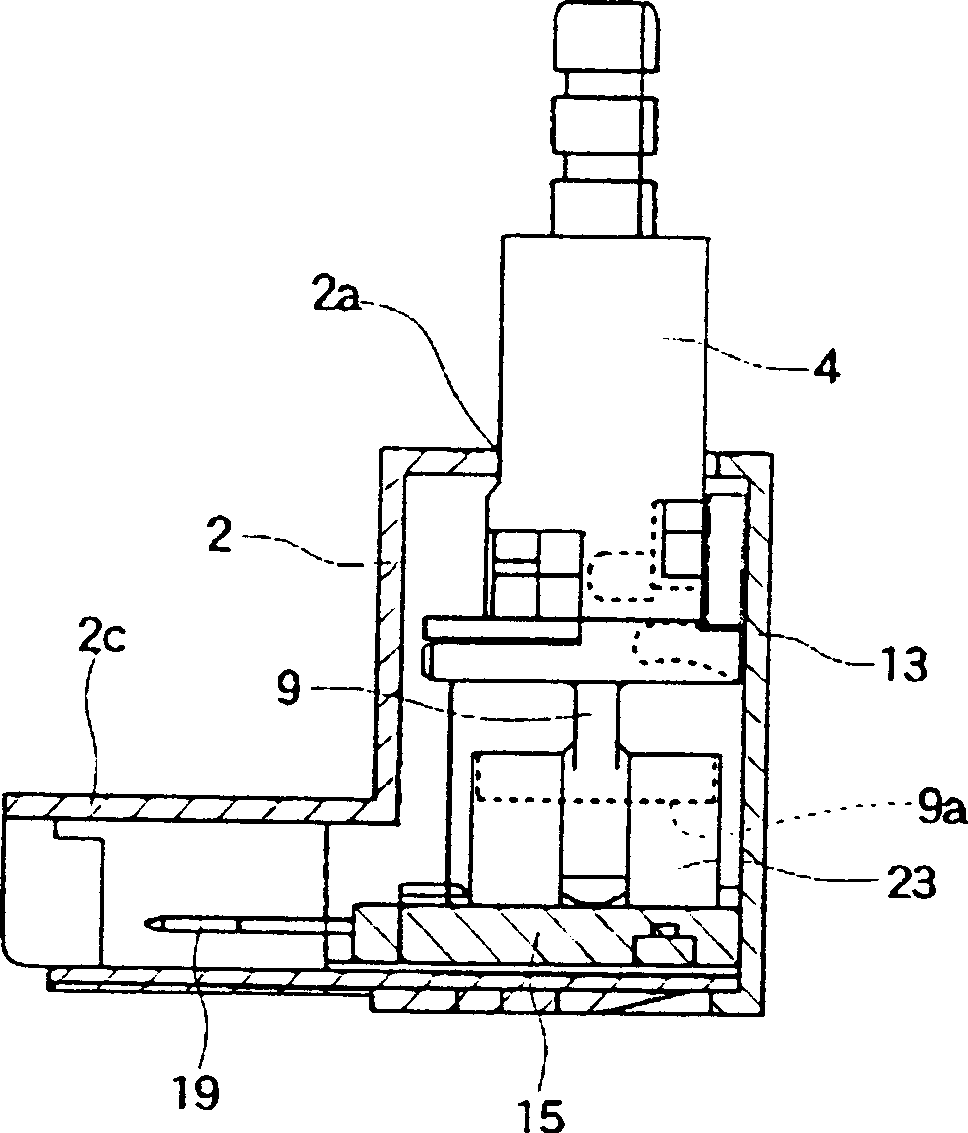

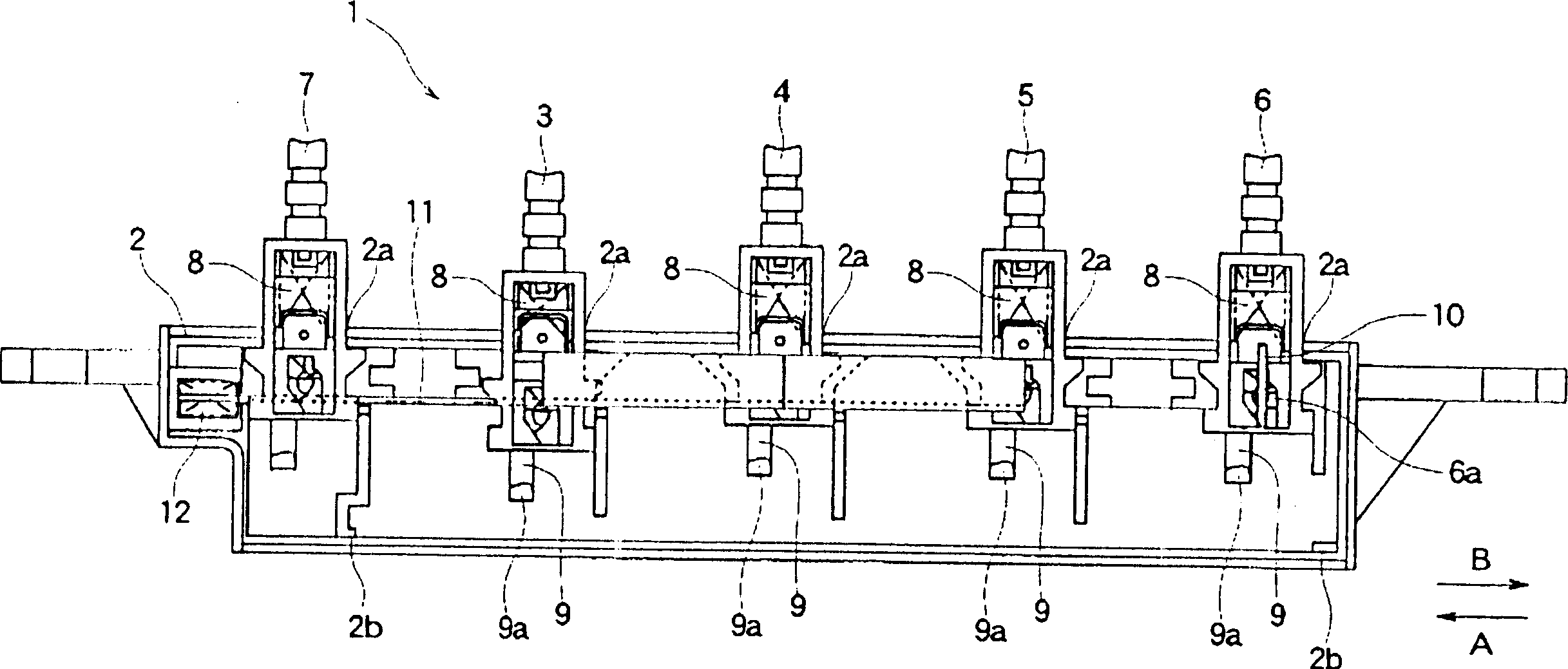

Multigang switchgear

Owner:ALPS ALPINE CO LTD

Low temperature rising magnetic core

PendingCN109087772AUniform densityReduce thicknessTransformers/inductances detailsCores/yokesEngineeringMiddle column

A low temperature rising magnetic core is disclosed, and comprises an integrally formed bottom plate, Center and side columns, The bottom plate is of rectangular structure, the middle column protrudesfrom the center of the top surface of the bottom plate, two side columns protrude from two ends of the top surface of the bottom plate respectively, one end of the side columns protrudes inwardly andprotrudes protruding parts, the bottom plate is concentric with the middle column, and a forming groove is concentric with the forming groove and is concentric with the bottom surface of the middle column. A forming groove is arranged at the bottom of the low-temperature-rising magnetic core, which is convenient to separately exert pressure on the center pillar during blank making, so that the overall density of the blank body is constant and deformation caused by density non-uniformity in the sintering process is avoided, and at the same time, the side pillar itself is designed as an asymmetrical symmetrical structure, so that the low-temperature-rising magnetic core has good heat dissipation performance.

Owner:江苏佰迪凯磁性材料有限公司

Cloth processing device for textile cloth printing and dyeing

ActiveCN112095327AAchieve flatteningRealize windingMechanical cleaningPressure cleaningDyeingEngineering

The invention provides a cloth processing device for textile cloth printing and dyeing, relates to the technical field of textile processing, and solves the problems that edge cutting of cloth and winding and collection of leftovers cannot be realized under single driving equipment through structural improvement; the flattening and fluff removing of the cloth cannot be automatically realized in the conveying process; and annular suction of fluff and dust cannot be automatically realized in the cloth conveying process, and organic combination between dust collection and leftover winding cannotbe achieved. The cloth processing device for textile cloth printing and dyeing comprises a frame body, a conveying roller is rotationally connected to the frame body, and a gear A is mounted on a rotating shaft of the conveying roller; and a dust collection structure further comprises a gear B, the gear B is installed on a dust collection pipe and meshes with the gear A, and therefore cut cloth strips can be sucked to the dust collection pipe under the suction effect of dust collection holes, and when the conveying roller drives the dust collection pipe to rotate, the cloth strips can be wound.

Owner:绍兴金祥惠纺织印染有限公司

Production line for PVC sheet

The invention provides a production line for a PVC sheet and belongs to the mechanical technical field. The production line for the PVC sheet comprises a rack. A bottom material burdening cylinder and a face material burdening cylinder are fixed to the rack. A first outlet is formed in the lower end of the bottom material burdening cylinder. A second inlet is formed in the upper end of the face material burdening cylinder. The first outlet is connected with a first extrusion device through a first conveying structure. The second outlet is connected with a second extrusion device through a second conveying structure. A third extrusion device is arranged on the rack and is provided with a third inlet and a third extrusion opening. The third extrusion opening is connected with a die structure. The die structure comprises an upper die and a lower die, a channel is arranged between the upper die and the lower die, and the channel is provided with a conveying-out device capable of conveying manufactured PVC sheets out. The production line has the beneficial effect that the PVC sheets can be manufactured more efficiently.

Owner:浙江世纪豪门家居科技有限公司

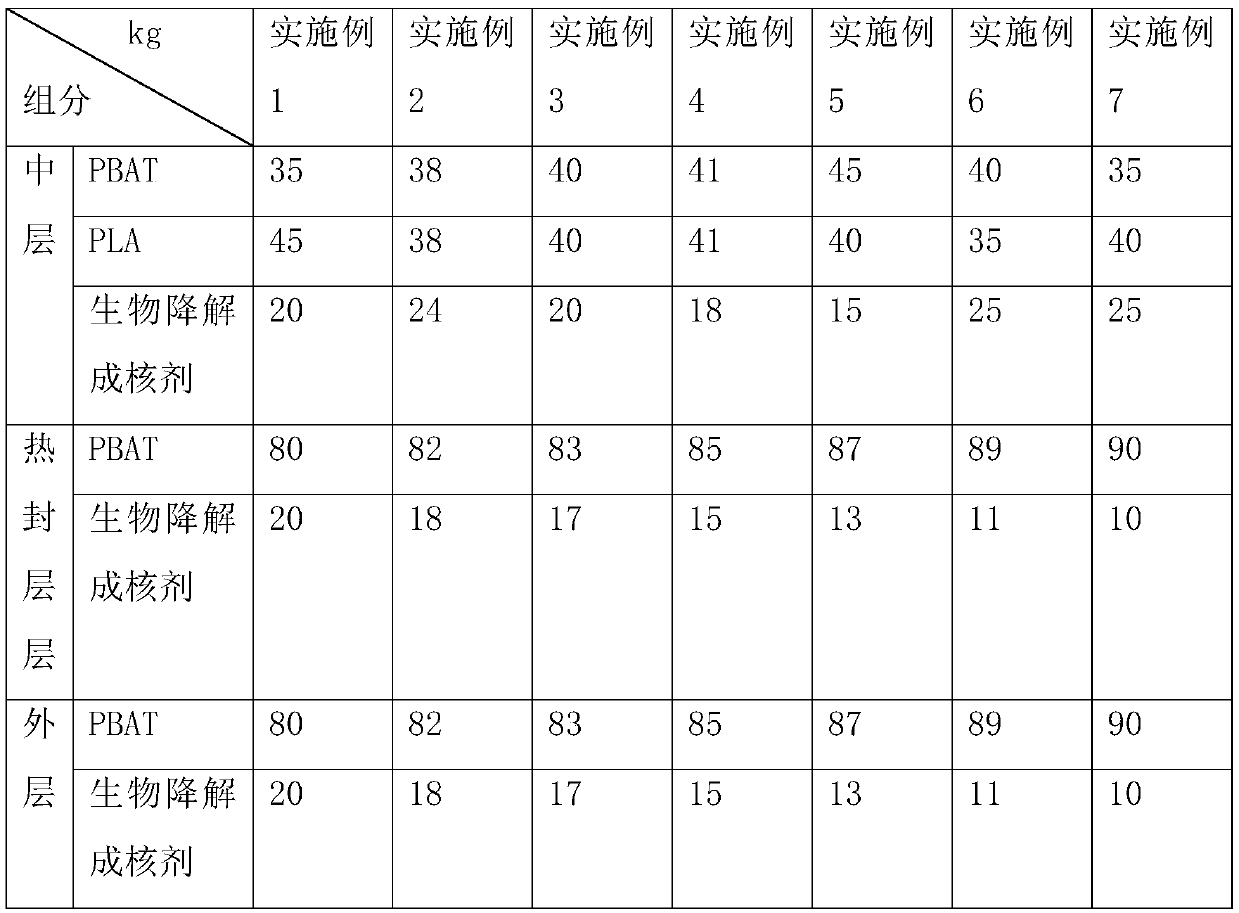

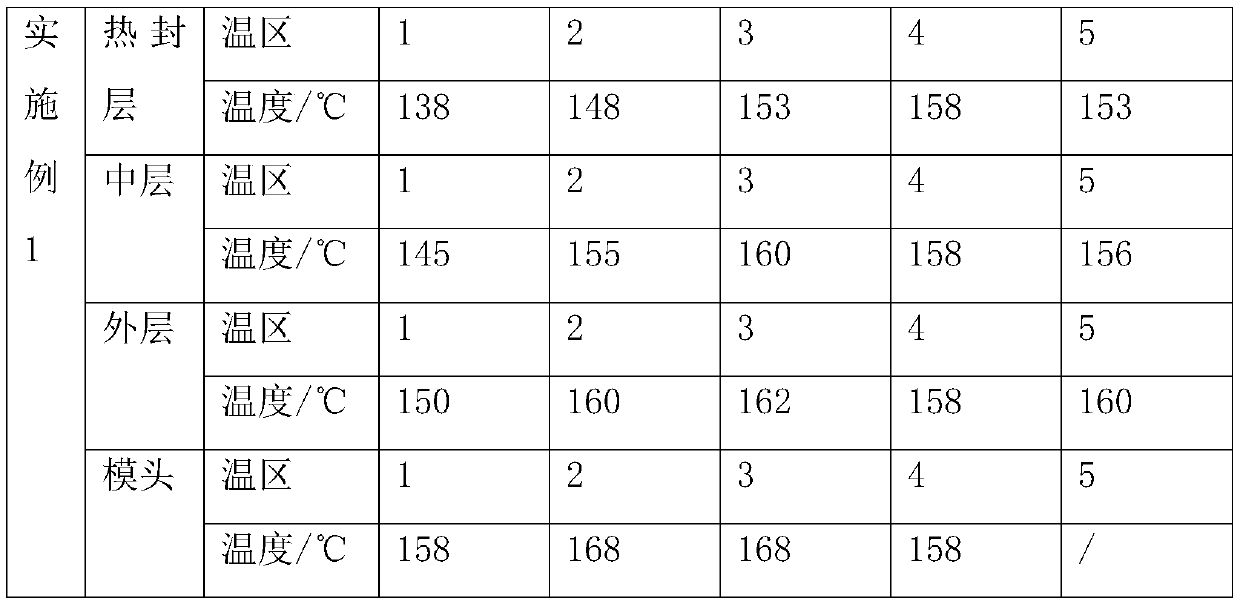

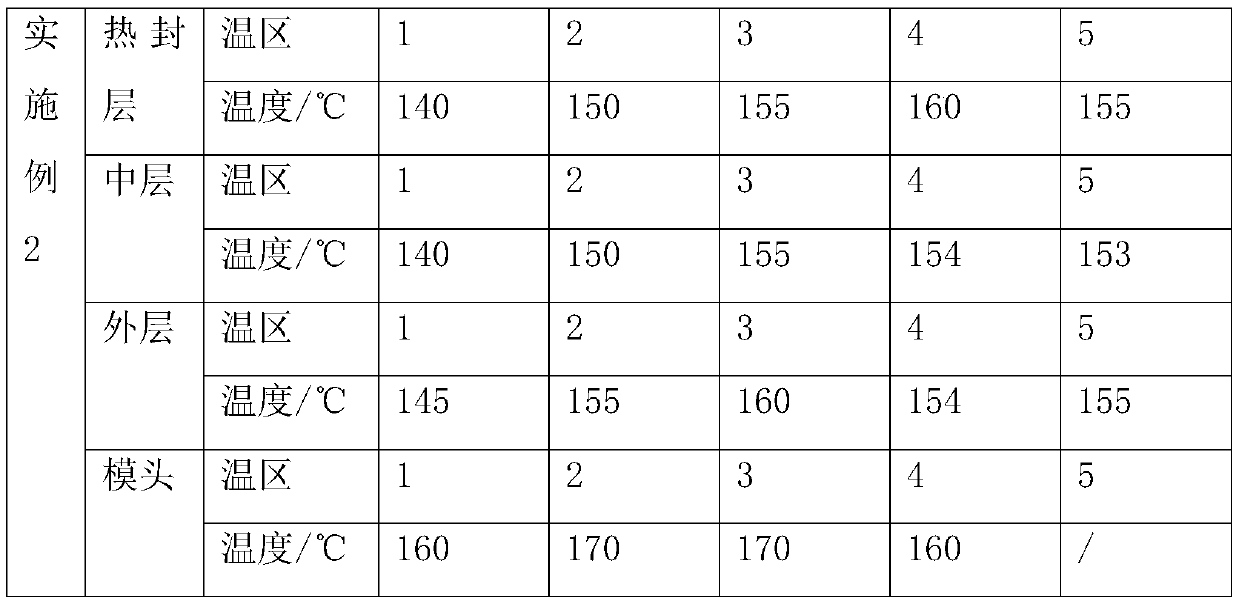

Degradable heat sealing film for compounding and preparation method thereof

InactiveCN111055564AAvoid gelatinizationAchieve secondary stretchSynthetic resin layered productsFlat articlesPolymer sciencePolymer chemistry

The invention discloses a degradable heat sealing film for compounding and a preparation method thereof. The degradable heat sealing film comprises a heat sealing layer, a middle layer and an outer layer, which are connected in sequence. The middle layer comprises the following components in parts by weight: 35 to 45 parts of PBAT, 35 to 45 parts of PLA, and 15 to 25 parts of a biodegradable nucleating agent; the heat sealing layer comprises the following components in parts by weight: 80 to 90 parts of PBAT and 10 to 20 parts of a biodegradable nucleating agent; and the outer layer comprisesthe following components in parts by weight: 80-90 parts of PBAT and 10-20 parts of a biodegradable nucleating agent. The degradable heat sealing film has the advantages that the crystallization rateof an extruded material is high, the melt strength is high, the film is not easy to break under traction, the film is easy to form, the heat sealing property is good, the printing effect is good, thehardness is moderate, certain softness and certain stiffness can be considered, and the degradable heat sealing film can be compounded with a printed film to be used as a heat-sealing layer and can beindependently made into bags.

Owner:青岛东海包装产业有限公司

Conveying device capable of facilitating discharging and used for garment processing

InactiveCN112830300AThere will be no large distance offsetEasy to operateClothes making applicancesWebs handlingGear wheelEngineering

The invention discloses a conveying device capable of facilitating discharging and used for garment processing. The conveying device comprises a feeding structure, and a roller type conveyor is arranged in an inner cavity of the feeding structure. According to the conveying device capable of facilitating discharging and used for garment processing, through cooperative use of material guiding structures, a frame body, threaded holes, a sleeve frame, bolts and gear frames, when materials move on the roller type conveyor, the materials firstly pass through the position between the two material guiding structures, and guiding plates on the two material guiding structures can limit the positions of the materials, so that the materials are just located in the center of the conveying end of the roller type conveyor, deviation after mechanical feeding can be guided and repaired, and the situation that the positions of the materials are not right is avoided; meanwhile, the sleeve frame and the frame body are fixed through the bolts, the distance between the two gear frames is adjusted through arrangement of the multiple threaded holes, and then the material guiding structures can be suitable for guiding and limiting the materials with different sizes.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Copper surface chemical mechanical polishing/planarization method

InactiveCN101295644AAchieve flatteningAchieve planarizationSemiconductor/solid-state device manufacturingCopperMedia layer

Owner:SEMICON MFG INT (SHANGHAI) CORP

Reed shaping machine and using method thereof

InactiveCN108818799AAchieve shapingReduce labor intensityWood compressionCane mechanical workingDrive shaftEngineering

The invention discloses a reed shaping machine and a using method thereof. The reed shaping machine comprises a workbench. The bottom end of the workbench is fixedly provided with four support legs. One end of the top of the workbench is provided with a placing groove. The top end of the workbench is fixedly connected with the bottom end of a top plate through the four support rods. The top end ofthe top plate is provided with a groove. The interior of the groove is provided with a cutting mechanism. The middle of the top end of the workbench is provided with a support base. The top end of the support base is provided with a plurality of reed rod placing grooves. One end of the support base is provided with a material pushing mechanism. The reed shaping machine and the using method thereof are capable of, through a transmission shaft of an installed step motor, driving a screw rod to be rotated, thereby driving a first moving block and a second moving block to be slid in the groove, through an installed scale line, conveniently and accurately adjusting a position between two cutting knives, and conveniently cutting two heads of the reed.

Owner:东营职业学院

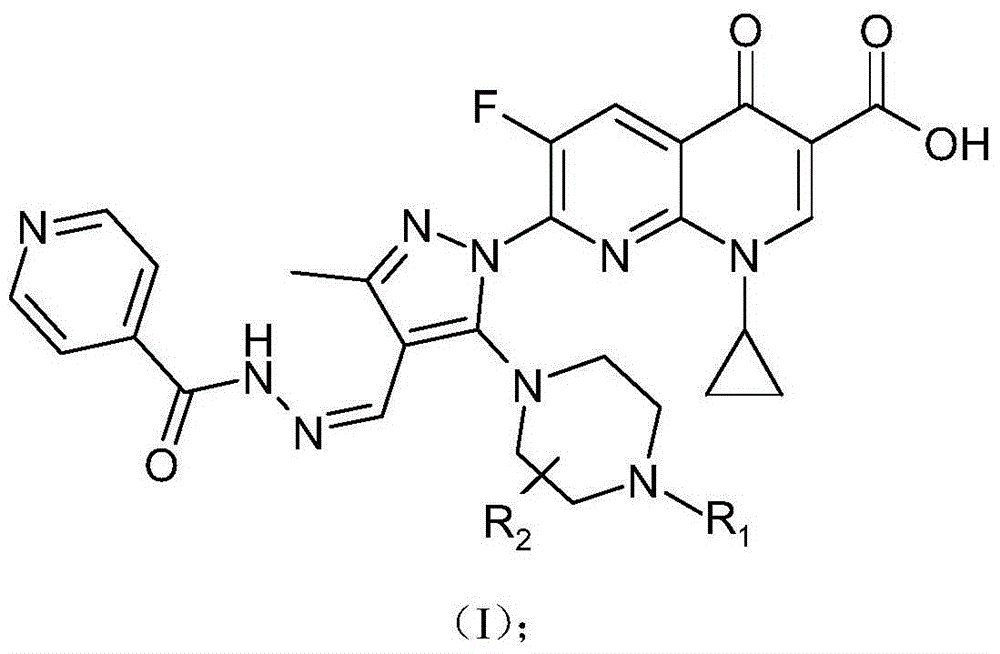

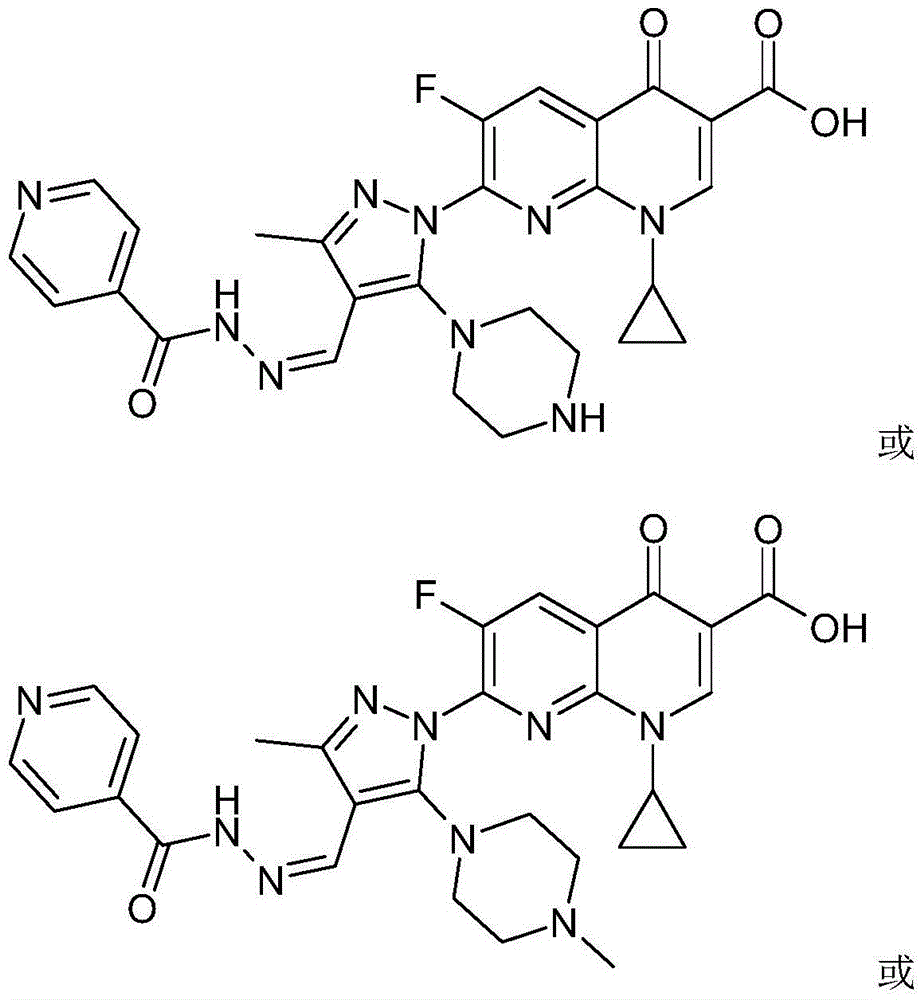

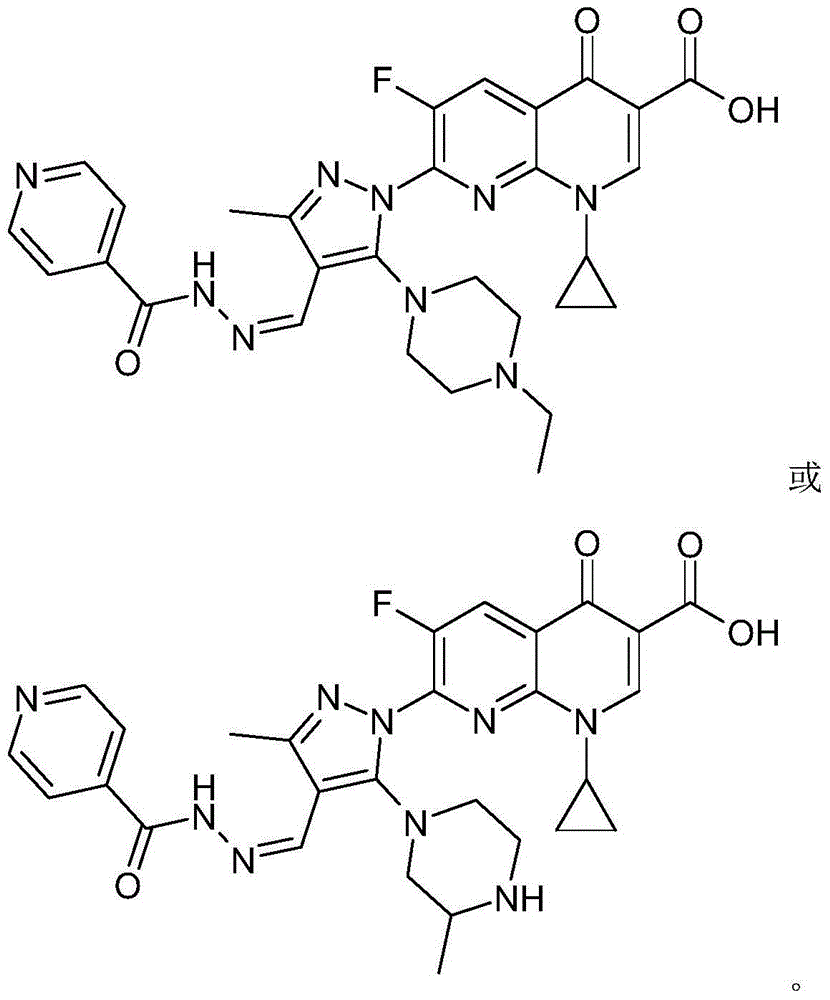

Derivative of 7-(piperazine substituted pyrazole aldehyde isoniazid hydrazone) fluoronaphthyridinone carboxylic acid as well as preparation method and application of derivative

InactiveCN104557919AAchieve flatteningStrong complementarityAntibacterial agentsOrganic active ingredientsSide effectIsoniazid

The invention discloses a derivative of 7-(piperazine substituted pyrazole aldehyde isoniazid hydrazone) fluoronaphthyridinone carboxylic acid as well as a preparation method and an application of the derivative. The derivative of the 7-(piperazine substituted pyrazole aldehyde isoniazid hydrazone) fluoronaphthyridinone carboxylic acid is a compound having a structural general formula (I), wherein R1 is H, methyl or ethyl; R2 is H or methyl. According to the derivative of the 7-(piperazine substituted pyrazole aldehyde isoniazid hydrazone) fluoronaphthyridinone carboxylic acid, fluoroquinolone, isoniazid and pyrazole aldehyde hydrazine are effectively combined to form a compound having a new structure, the joint of pharmacophores and the mutual complementation of structures are realized and the overlapping and cooperation of the activity are achieved; the antituberculous activity is added, the toxic and side effects of fluoroquinolone and isoniazid on normal cells are reduced, and meanwhile, the probability of drug resistance of mycobacterium tuberculosis to the drug is also reduced; as a result, the derivative can be used as an antituberculous active substance to develop antituberculous drug having a brand new structure.

Owner:HENAN UNIVERSITY

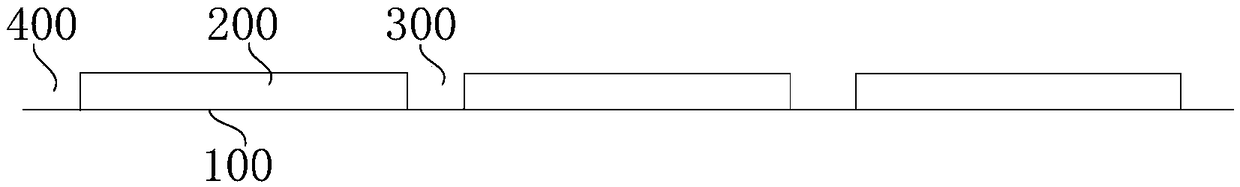

Cutter used for manufacturing drum rack plate

PendingCN108818754AAchieve flatteningAvoid partial warpingFeeding devicesCircular sawsEngineeringWood plank

The invention discloses a cutter used for manufacturing a drum rack plate, and the cutter is used for manufacturing drum rack plates of various drums. The cutter comprises a conveying mechanism, a trimming mechanism, a first planishing mechanism, a second planishing mechanism and a cutting mechanism; the conveying mechanism comprises a first rack, a conveying table arranged on the first rack and adriving unit which drives the conveying table to move leftwards and rightwards; the first planishing mechanism comprises a first pressing rod and a compaction air cylinder which drives the first pressing rod; the trimming mechanism comprises a second rack, a first sliding block arranged on the second rack, a first feeding unit which drives the first sliding block and a cutting unit which is fixedly connected with the first sliding block; the cutting mechanism comprises a third rack, a walking rack arranged on the third rack, a second feeding unit which drives the walking rack to move back andforth, a cutting unit which is fixedly connected with the second sliding block and a third feeding unit which drives the walking rack to move leftwards and rightwards; and the second planishing mechanism comprises a square frame which is located in a plane and a lifting air cylinder which drives the square frame. By adopting the cutter, wood plates can be cut conveniently.

Owner:临清市森源博乐器配件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com