Connecting line production equipment and method for LCD device

A technology of liquid crystal display devices and production equipment, which is applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of polarizer foreign matter, panel scratches, low production efficiency, etc., and achieve the effect of reducing the number of scrapped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

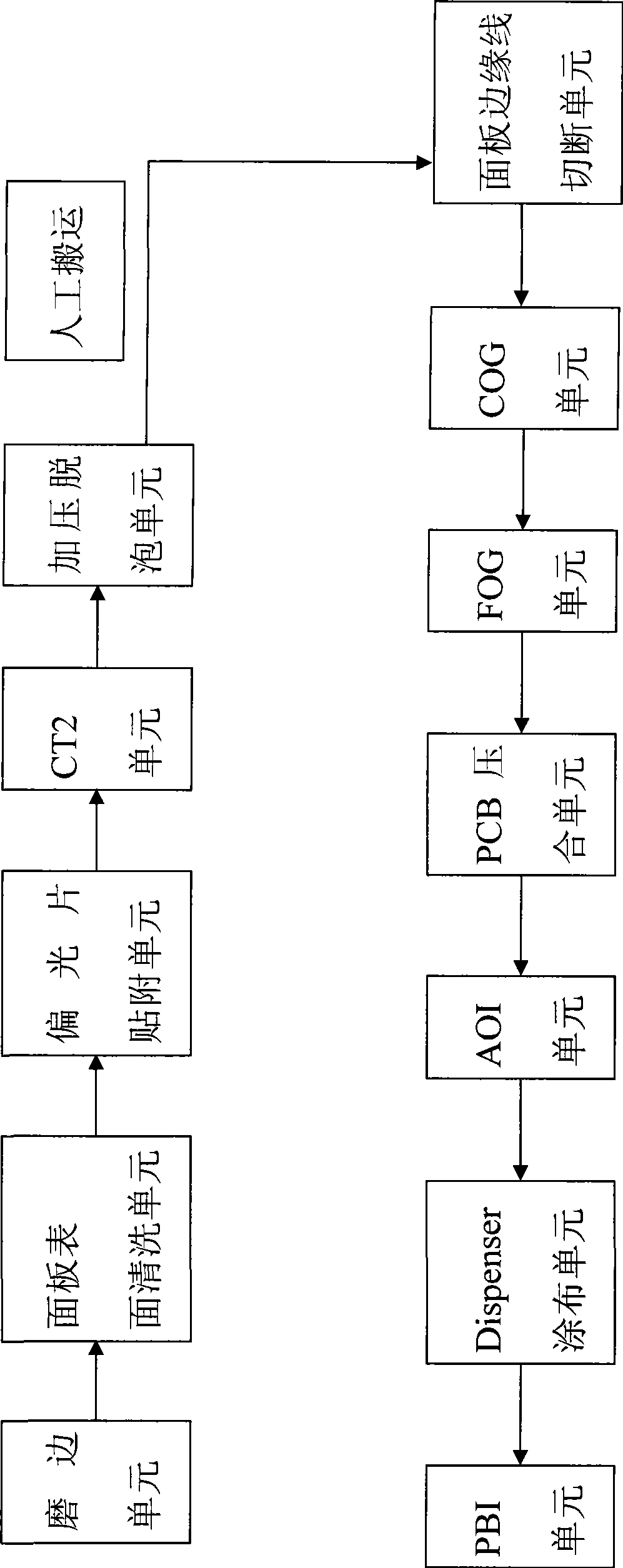

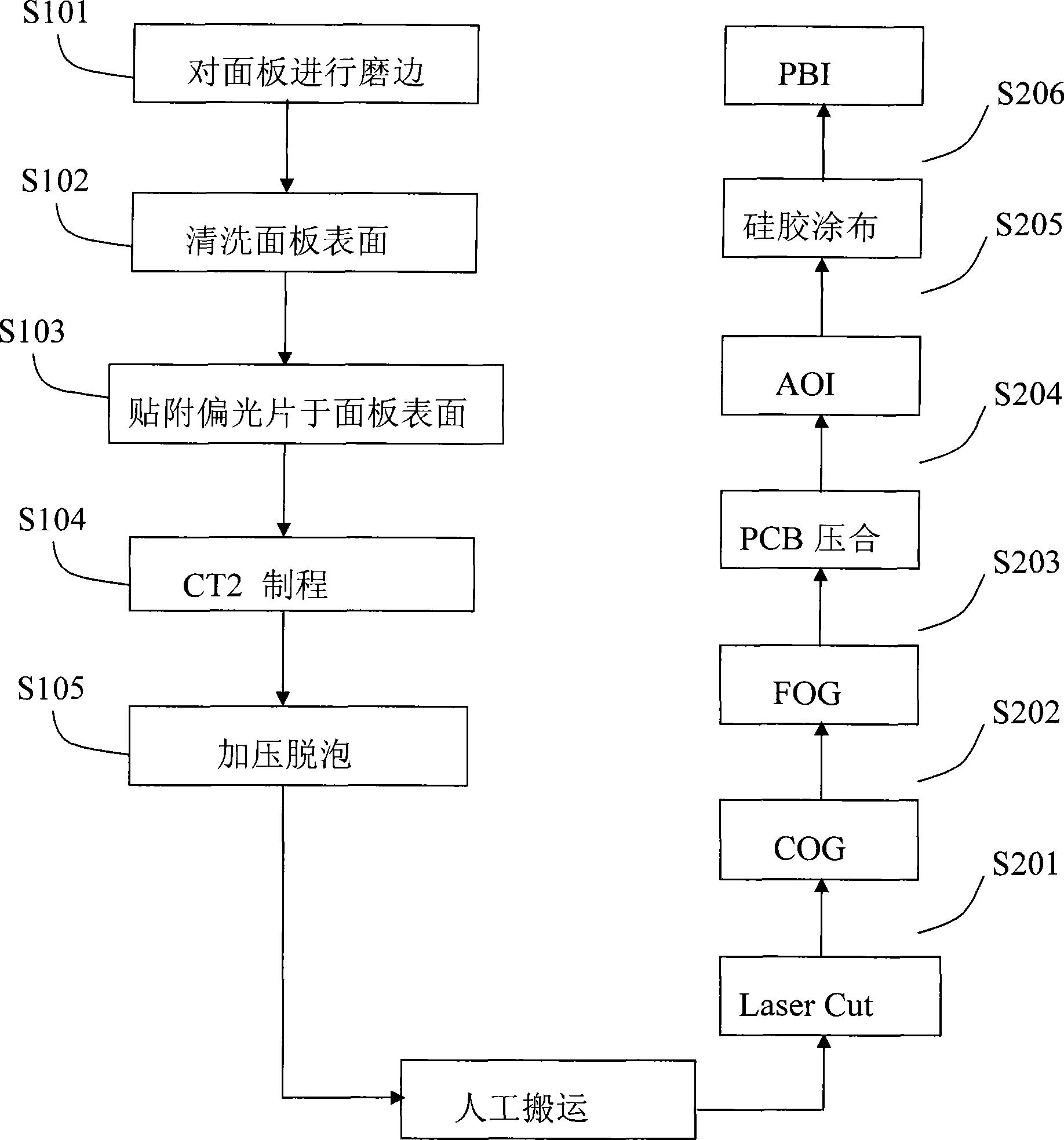

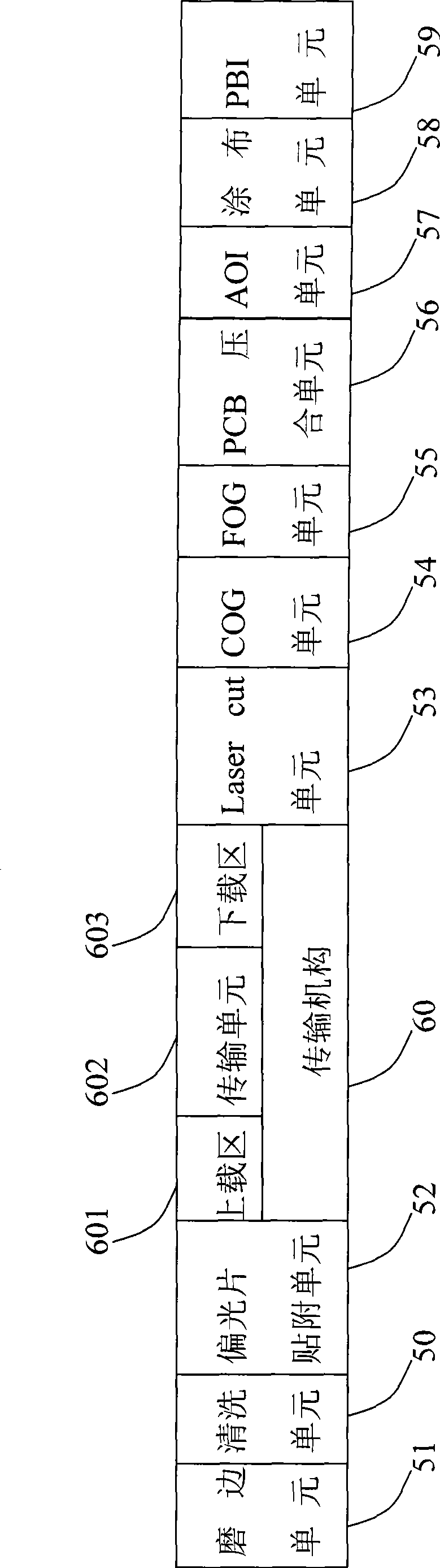

[0019] Some assembly steps of the liquid crystal display device in the present invention are similar to those in the prior art. see image 3 , image 3 It is a block diagram of the in-line production equipment of the liquid crystal display device according to the present invention. The on-line production equipment of the liquid crystal display device of the present invention includes: an assembly process production line, a module process line and a transmission mechanism 60 . Among them, the assembly process production line and the module process production line are all connected production lines. The assembly process production line is used to bond the array substrate and the color filter substrate, and add liquid crystal between the two substrates to form a liquid crystal panel; when the liquid crystal is sealed in the panel, the liquid crystal panel assembly process is basically completed, and the subsequent The assembly process is the processing of the panel. In the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com