Wafer detection device and method used for ashing machine

A detection method and detection device technology, which are used in measurement devices, optical testing flaws/defects, semiconductor/solid-state device testing/measurement, etc., to achieve the effect of reducing the number of scraps and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

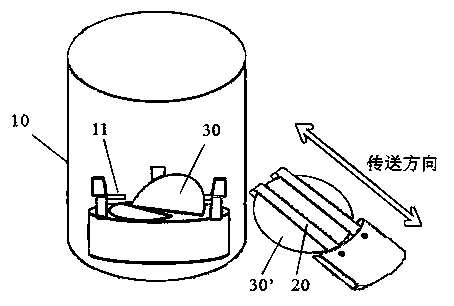

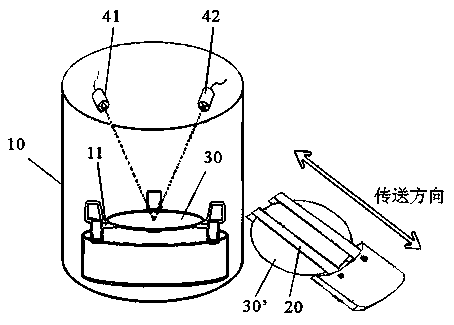

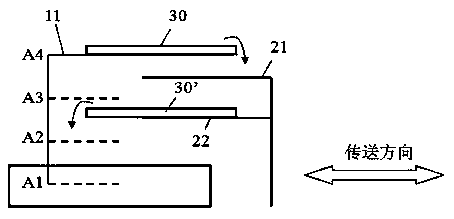

[0020] Such as figure 2 As shown, the wafer detection device used in the ashing machine according to the present invention is used to detect the state of the wafer 30 before transferring the processed wafer 30 in the reaction chamber 10 .

[0021] The wafer detection device includes an infrared transmitter 41 and a corresponding receiver 42, which are respectively arranged on the top in the reaction chamber 10 and above the wafer 30; then, if the infrared rays produced by the transmitter 41, If the normal reflection from the surface of the wafer 30 reaches the receiver 42 , it means that the wafer 30 is complete, and the vacuum arm 20 can be controlled to extend into the reaction chamber 10 to pick up the wafer 30 .

[0022] If the wafer 30 in the reaction chamber 10 is damaged, it may be that the emitted infrared rays cannot reach the surface of the wafer 30, or the angle at which the infrared rays are reflected by the wafer 30 may change, so that the infrared rays cannot no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com