Semiconductor chip comb sliver repairing method and device

A semiconductor and chip technology, applied in the field of semiconductor chip sliver repair and device, can solve the problems of sliver processing that does not meet the requirements, cannot meet the production capacity, and is prone to operating errors, etc., and achieves improved repair efficiency, small and compact dimensions, good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

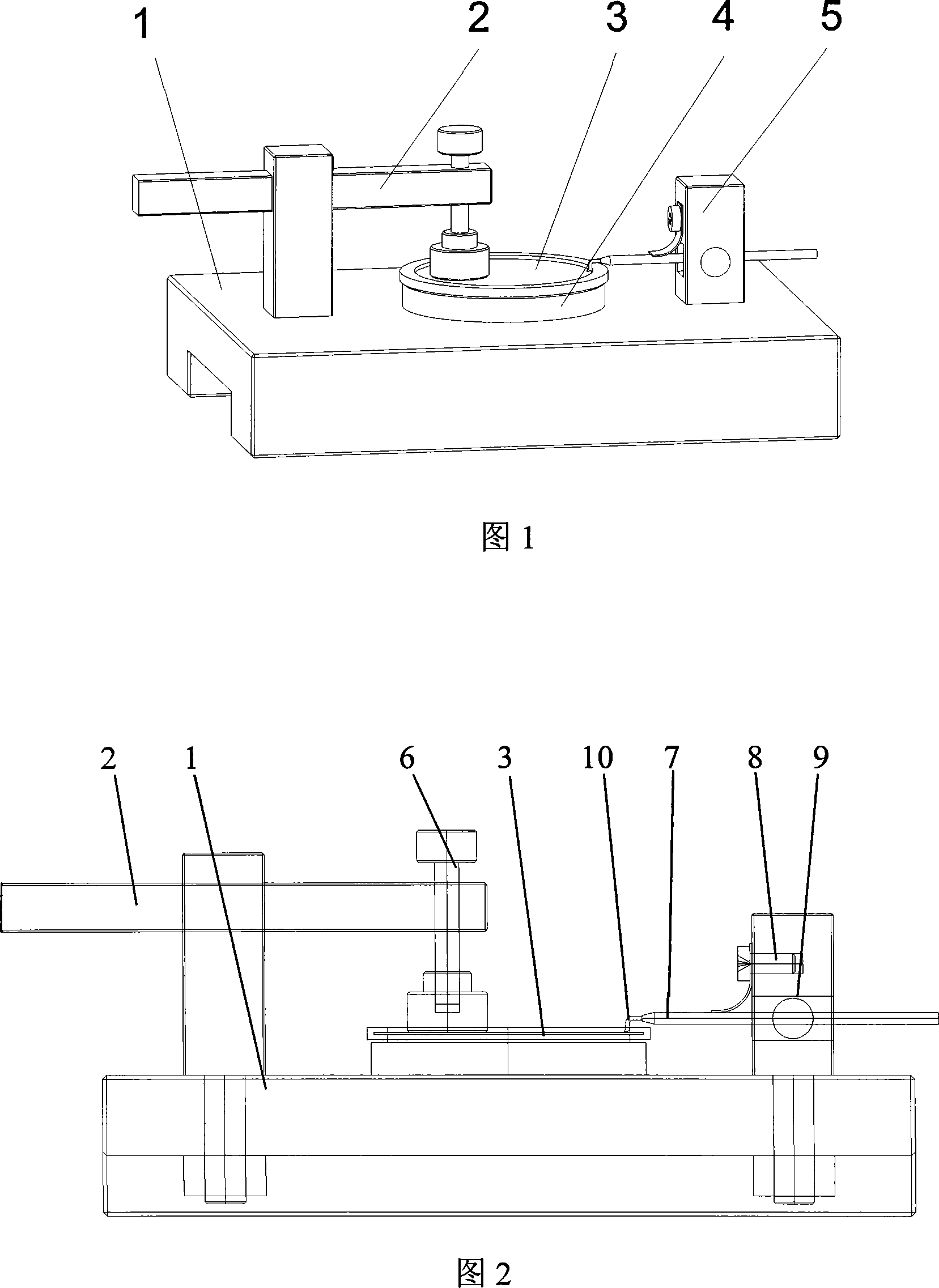

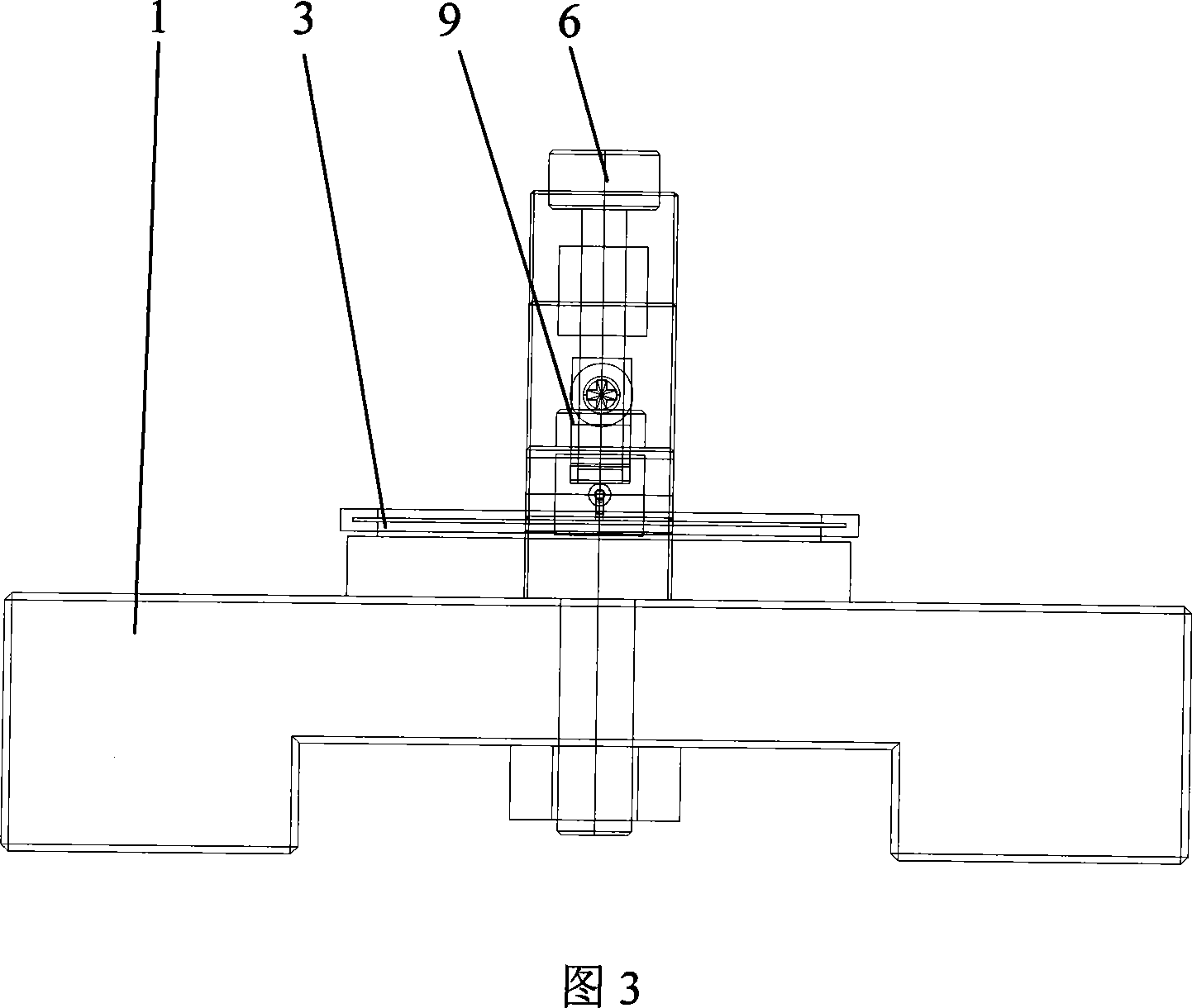

[0015] It can be seen from Fig. 1 that the present invention is a semiconductor device chip sliver repair device, which adopts a set of sliver repair mechanism simulating the manual repair method to repair the problematic sliver. The simulated manual repair method uses a set of sliver repair mechanism arranged on a microscopic workbench to simulate the manual repair method to repair the sliver. The specific repair method can be that a positioning device fixes the semiconductor device chip, and then completes the repair of the chip sliver by a set of picking and combing mechanism simulating manual repair of the chip sliver. Wherein, the combing mechanism for simulating the manual repair of the chip comb is to adjust the knife edge of the repairing comb to the root of the comb to be combed and to align with the length direction of the comb through a micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com