Compound die of automatic nail making machine of peel type rivets

An automatic and composite mold technology, applied to rivets, connecting components, etc., can solve problems such as easy wear of nail molds, difficulty in quality control, and large amount of scrapped nail cores, so as to save costs, reduce the number of scrapped, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

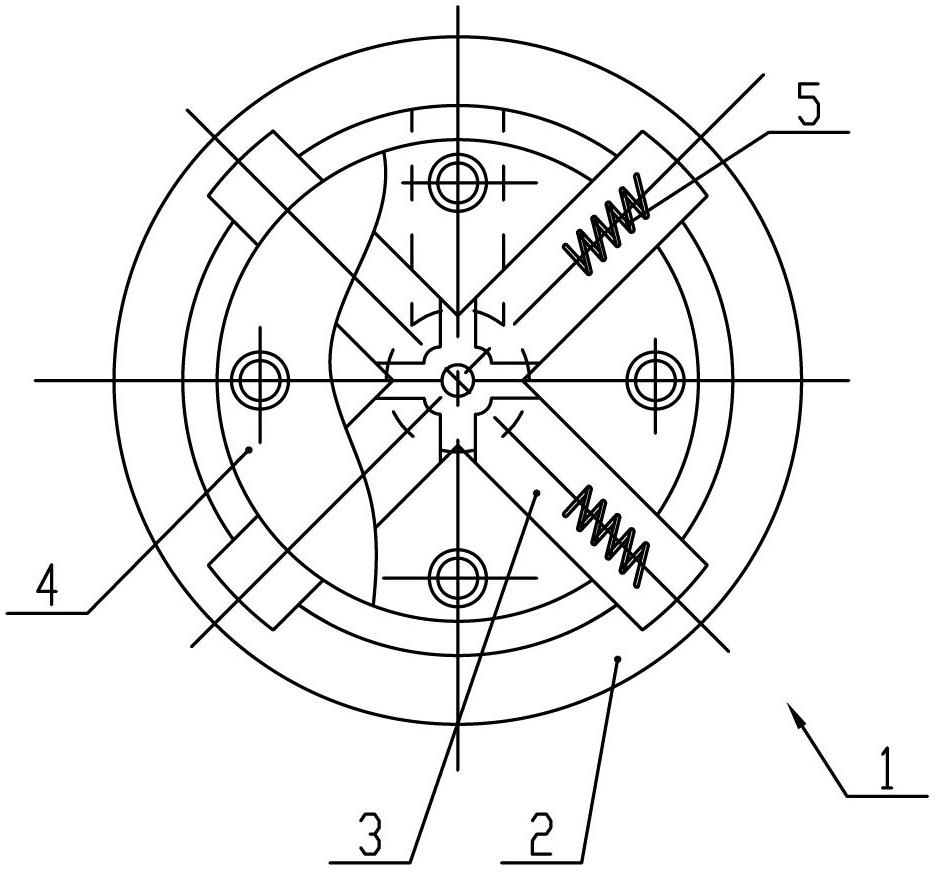

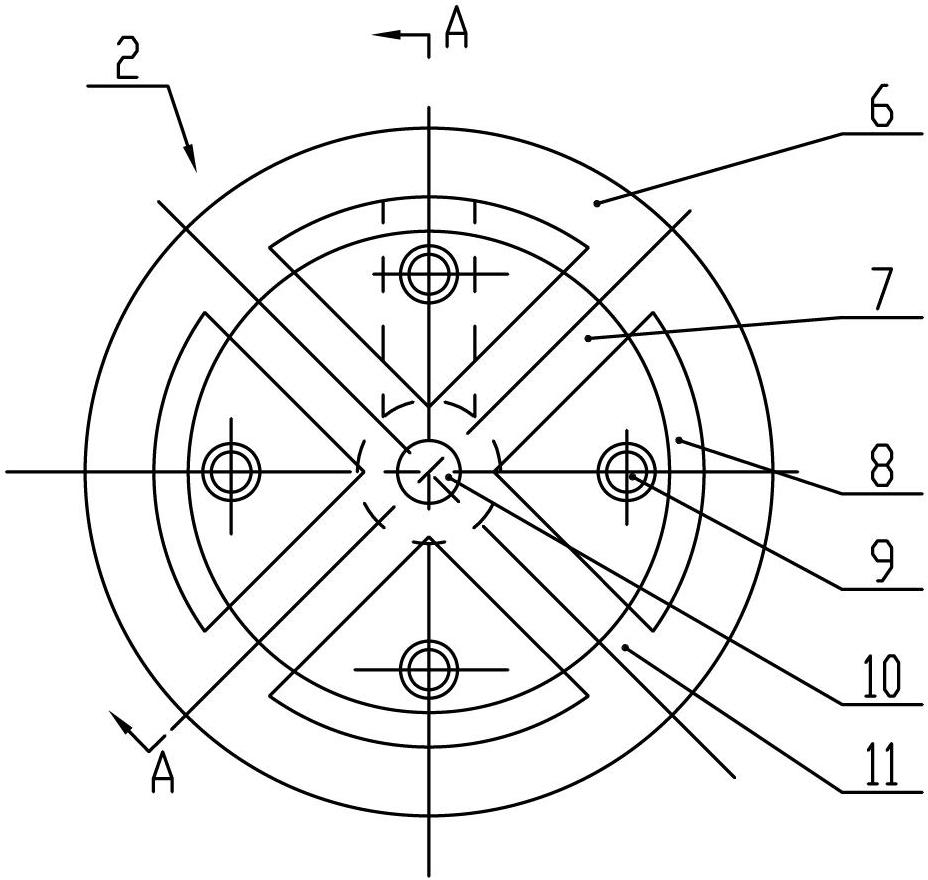

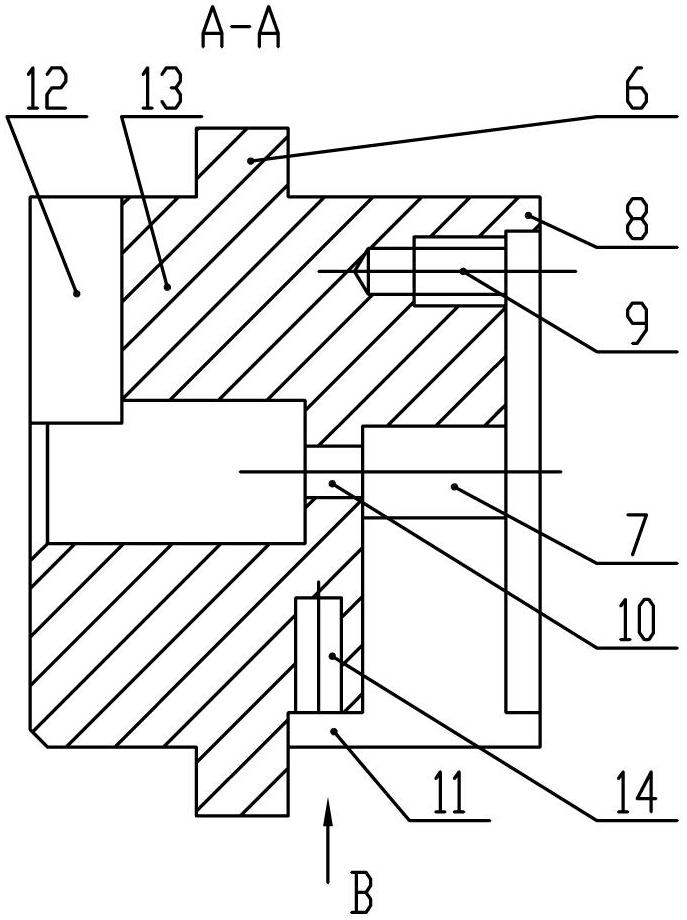

[0016] Figure 1~Figure 7 Including composite mold 1, mold base 2, mold core 3, mold cover 4, spring 5, flange 6, cross groove 7, rib 8, threaded hole 9, center hole 10, groove 11, positioning groove 12, Seat body 13, spring hole 14, boss 15, core body 16, chamfer 17, bolt hole 18, perforation 19, etc.

[0017] Such as figure 1 As shown, the present invention is a compound mold 1 of a pull flower type rivet automatic nail making machine, comprising a mold base 2, a mold core 3, a mold cover 4 and a spring 5. There are four cores 3, and four corresponding springs 5.

[0018] Such as figure 2 , image 3 As shown, the main body of the mold base 2 is a cylindrical base body 13, which has a central hole 10 through which the feeding steel wire passes. One end of the seat body 13 is provided with a longitudinal cross groove 7 , the outer end of the end is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com