Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce the amount of cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

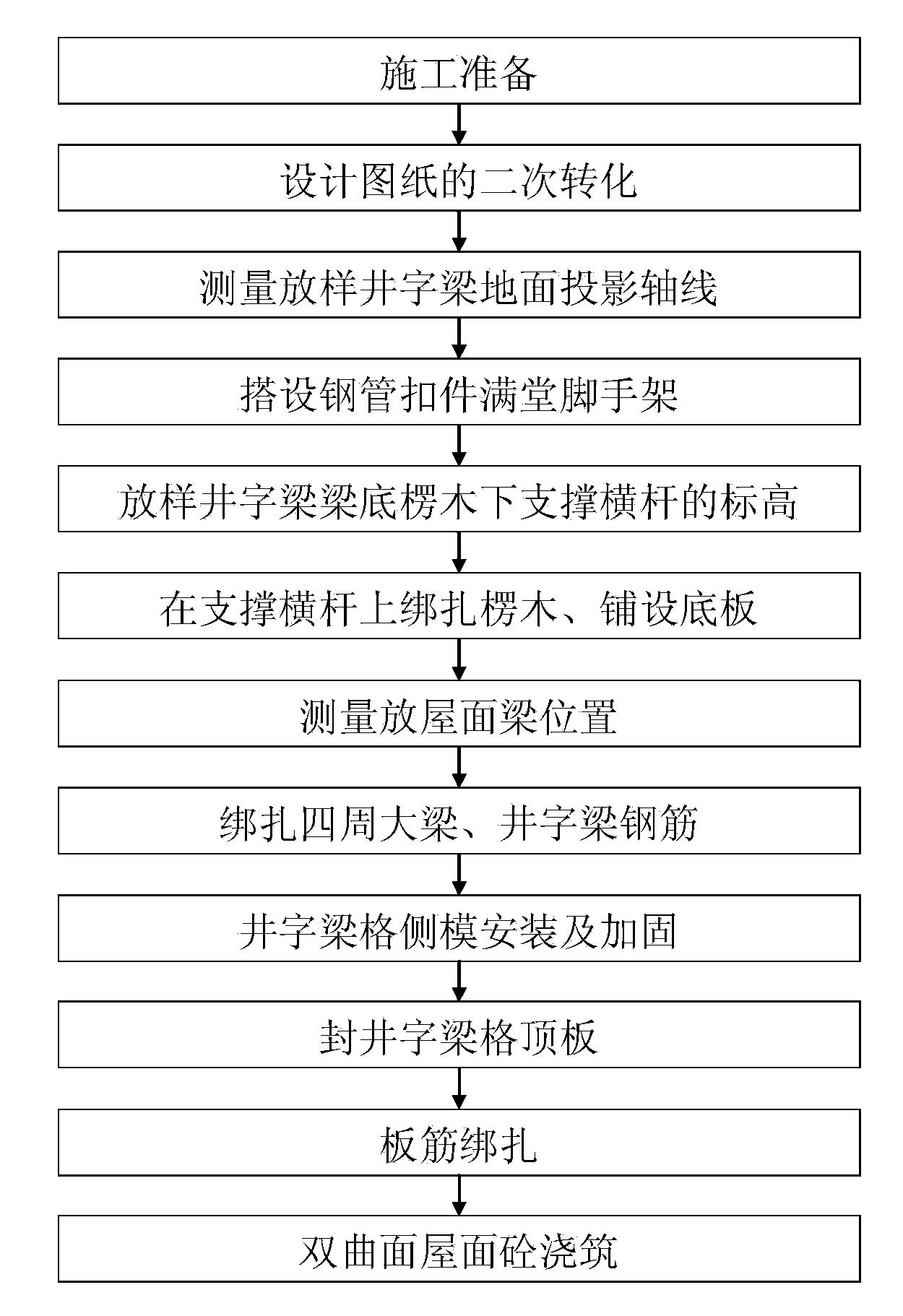

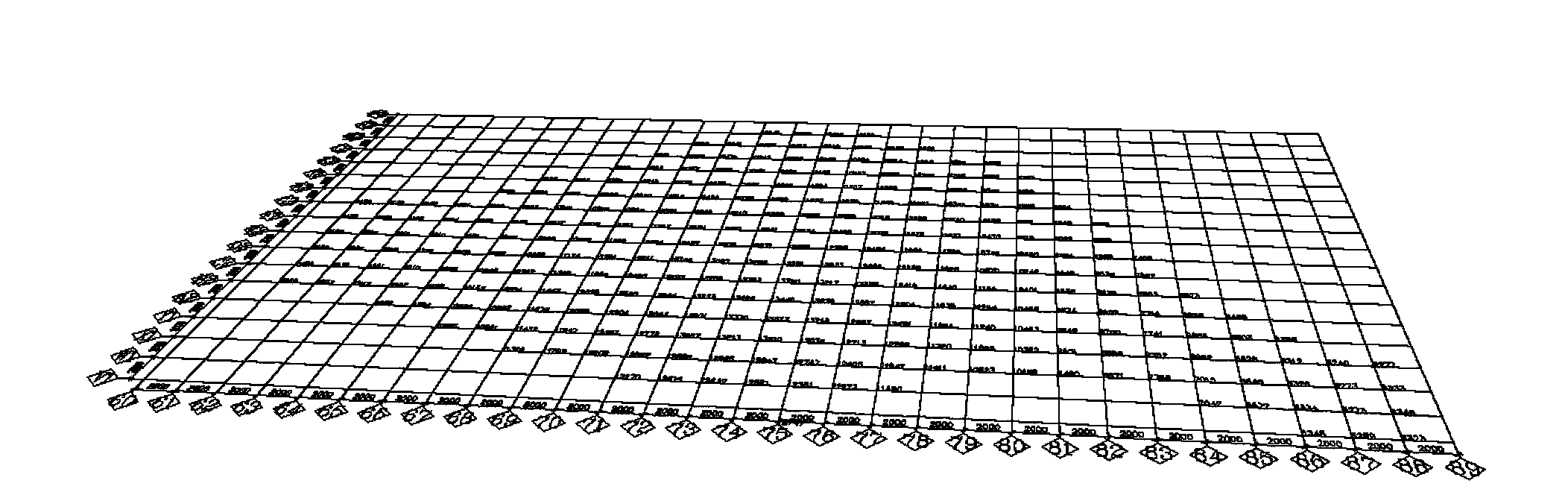

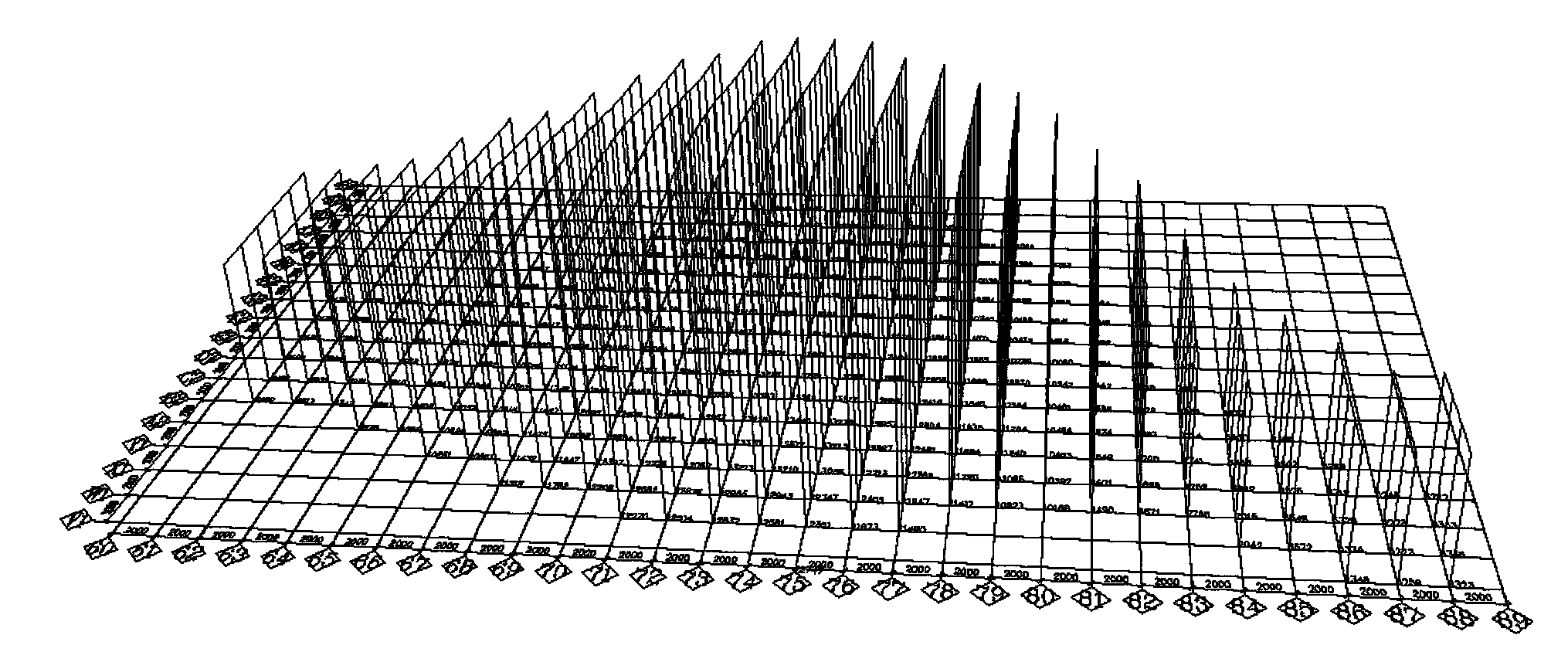

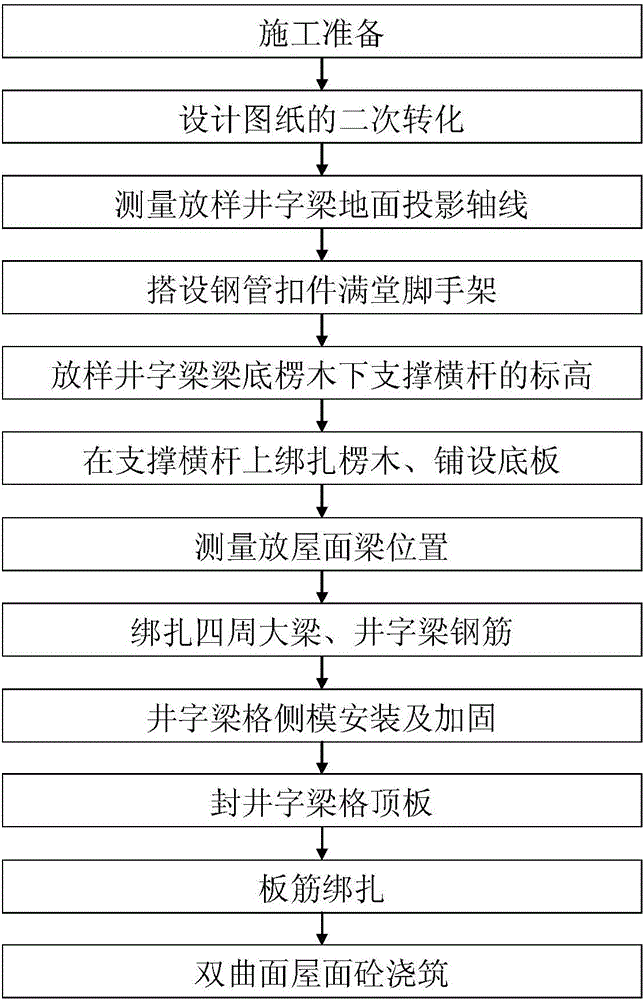

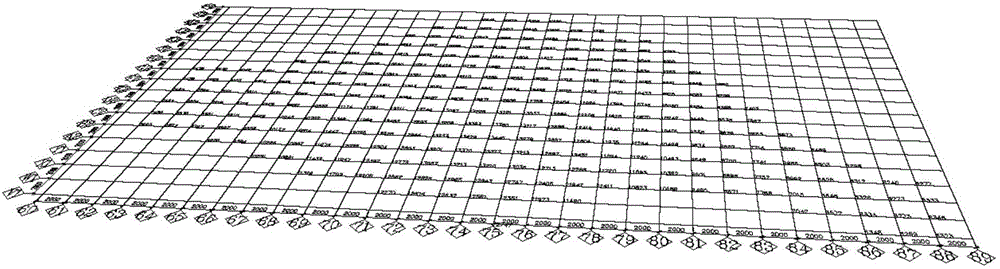

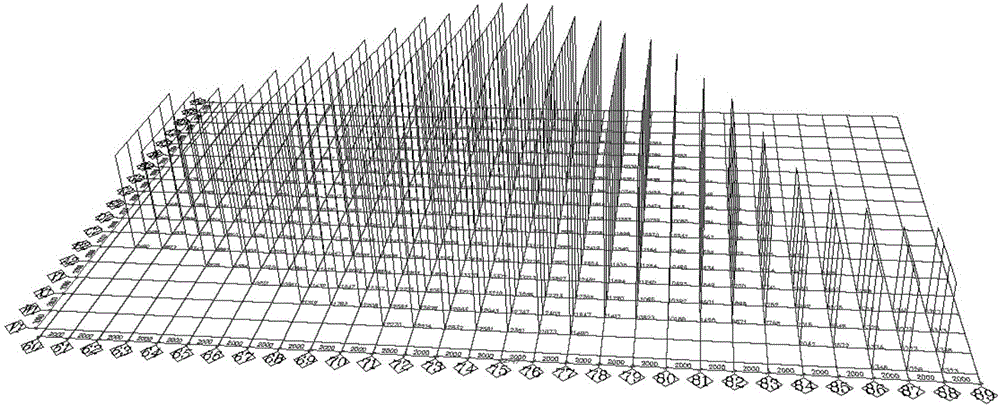

Irregular oblique-crossing web-shaped grillage beam hyperbolic roof structure construction method

ActiveCN103615110AImprove work efficiencyShorten the construction periodBuilding material handlingFalseworkSupporting system

An irregular oblique-crossing web-shaped grillage beam hyperbolic roof structure construction method comprises the steps of construction preparing, secondary conversion of design drawing, lofting grillage beam ground projection axis measuring, steel pipe buckling piece all-round scaffold supporting system erecting, grillage beam bottom wood ridge lower support horizontal rod elevation giving off, wood ridge binding and bottom plate paving on a supporting horizontal rod, given-off roof beam position measuring, bound grillage beam steel rib machining, grillage beam grillage side mould mounting and reinforcing, grillage beam top plate mounting and reinforcing, face plate steel rib binding and hyperbolic roof concrete pouring. Through a space three-dimensional technology, a reasonable supporting system and accurate location of a hyperbolic roof and a grillage beam, the concrete mixing proportion is optimized, the quality and the attractive degree of the hyperbolic roof can be improved, construction difficulty is lowered, and construction efficiency is improved.

Owner:广西建工第一建筑工程集团有限公司

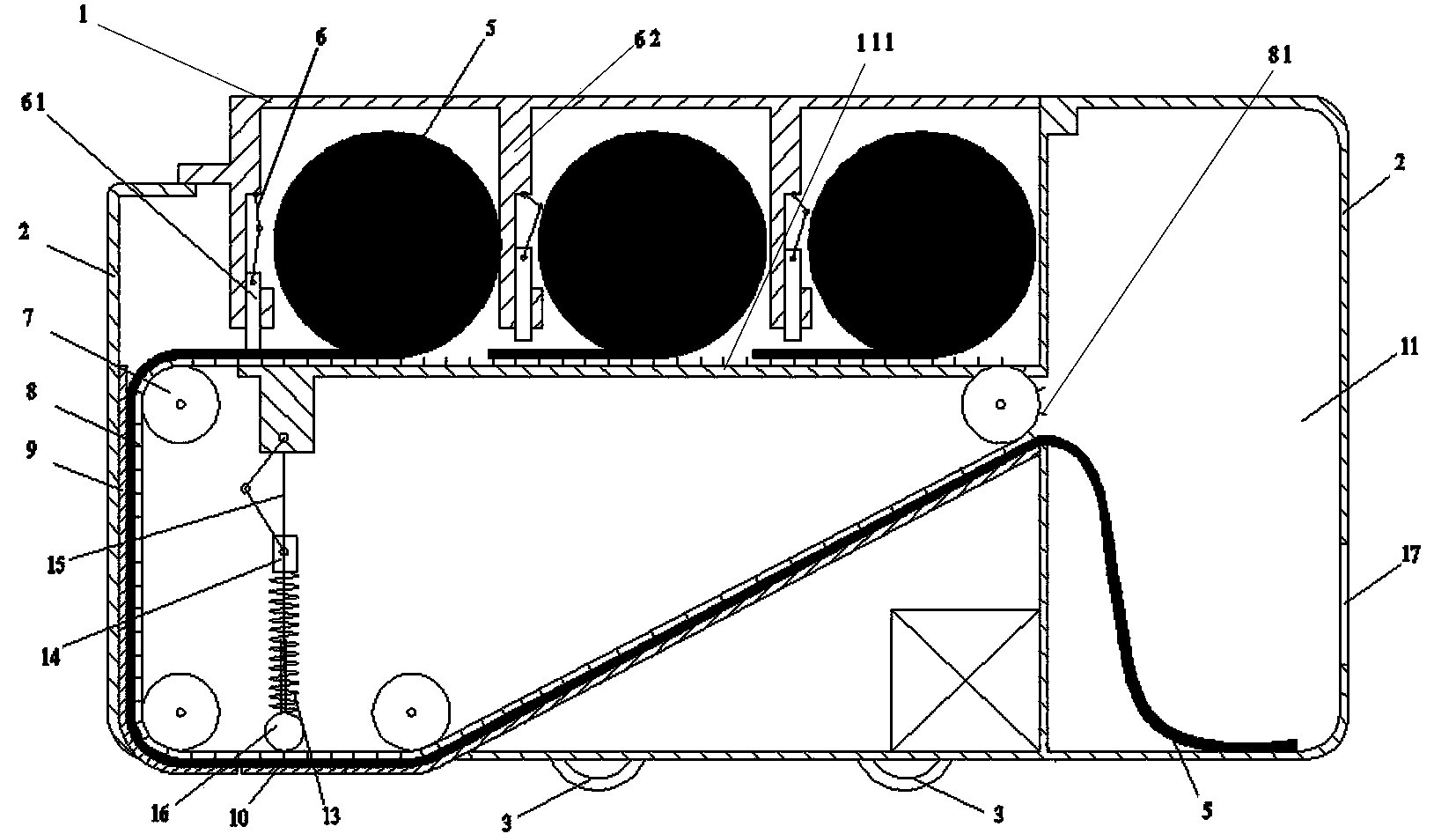

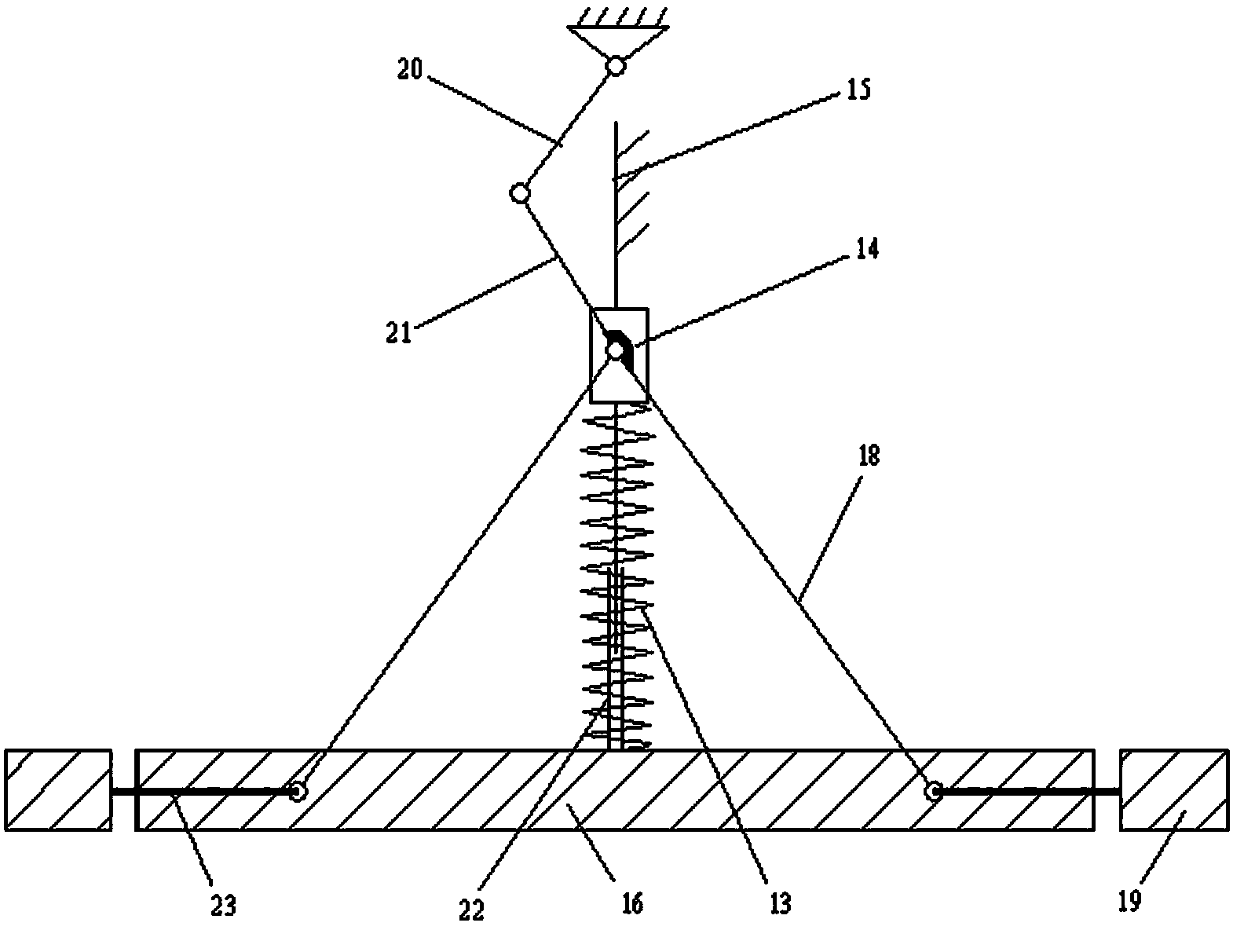

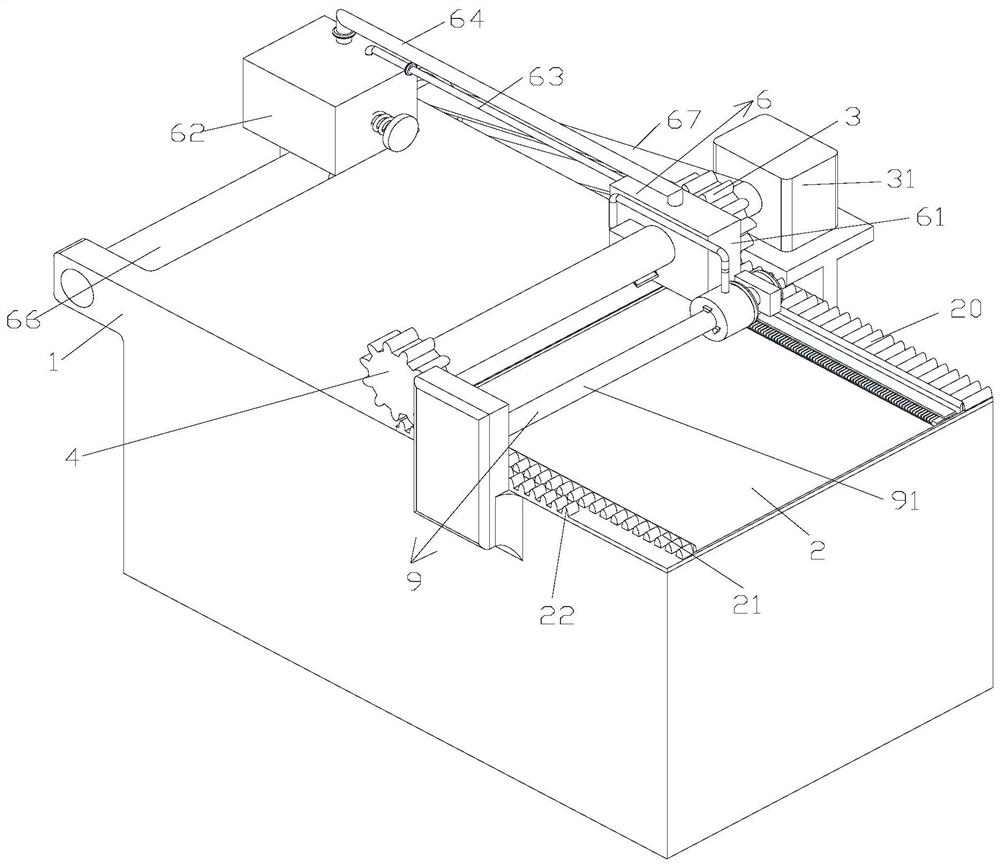

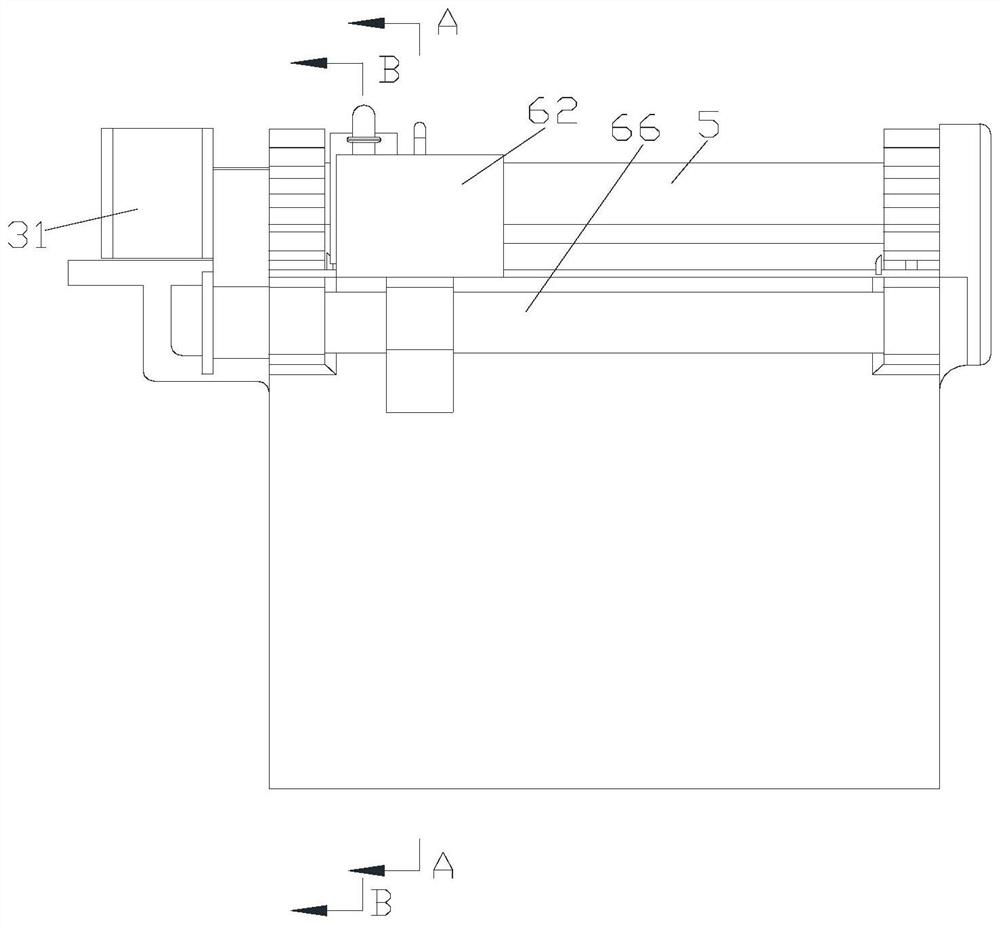

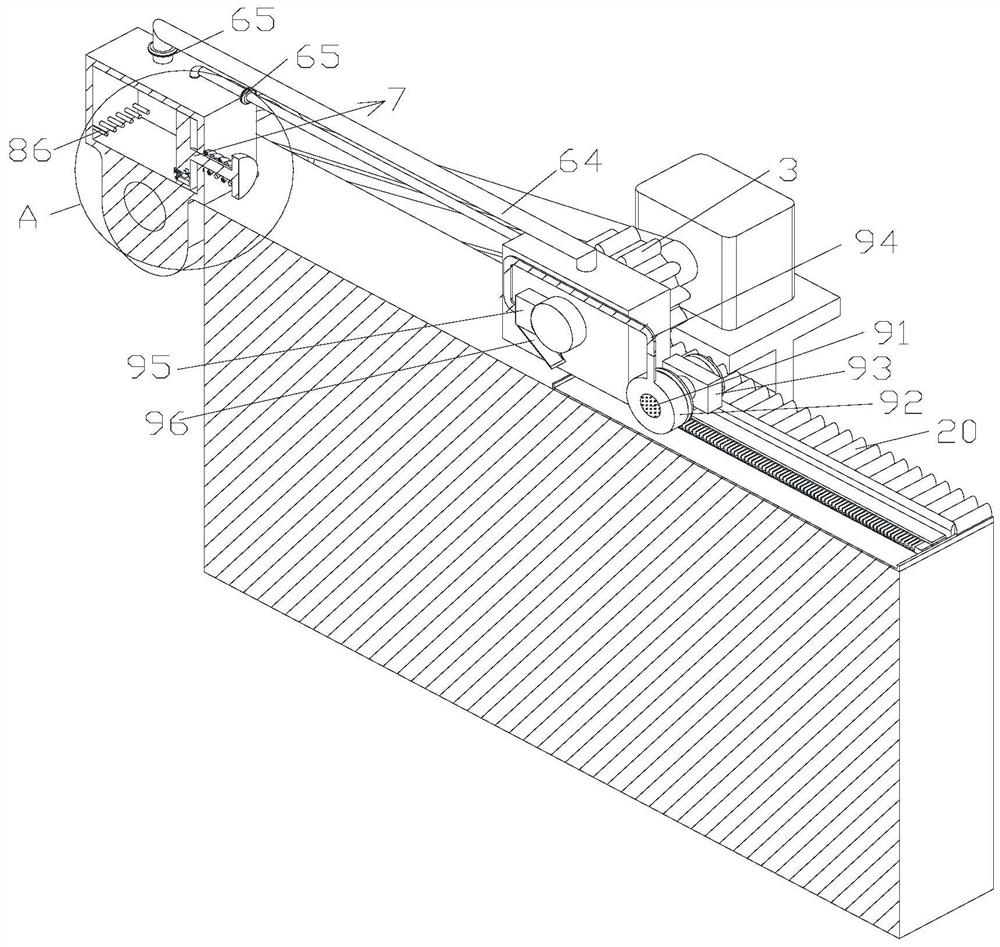

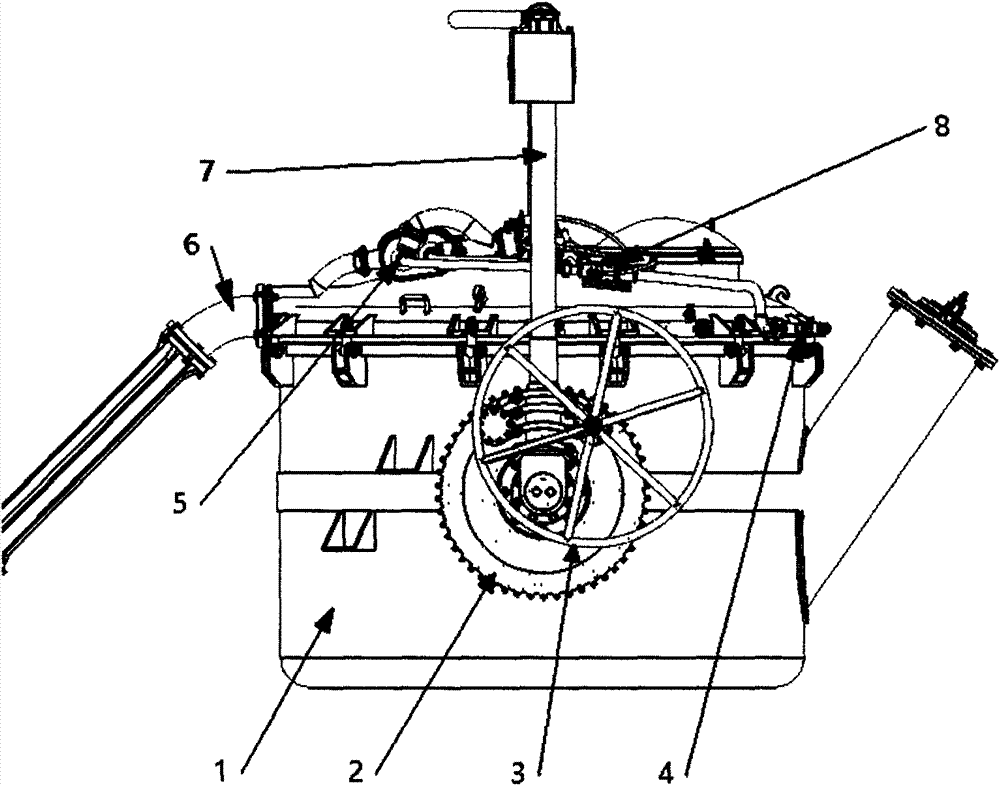

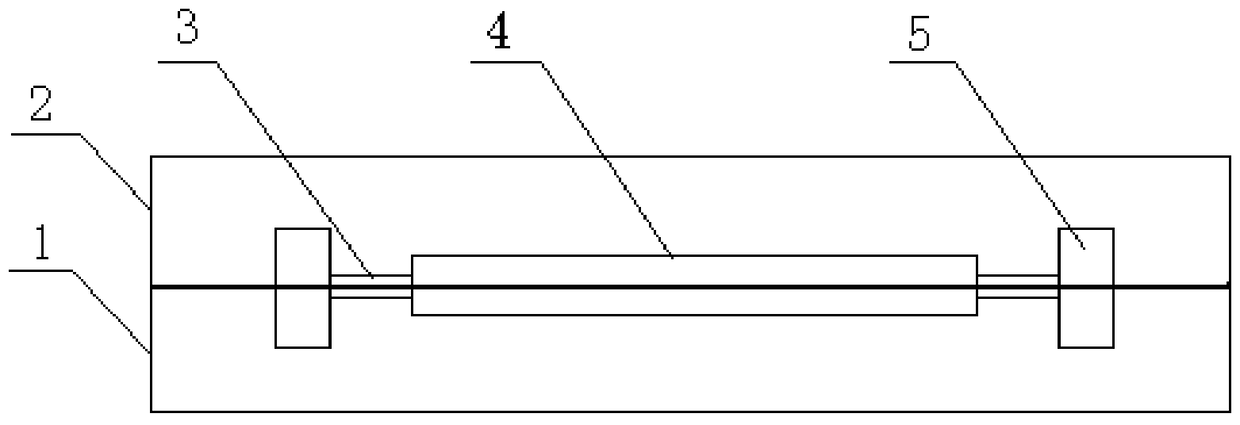

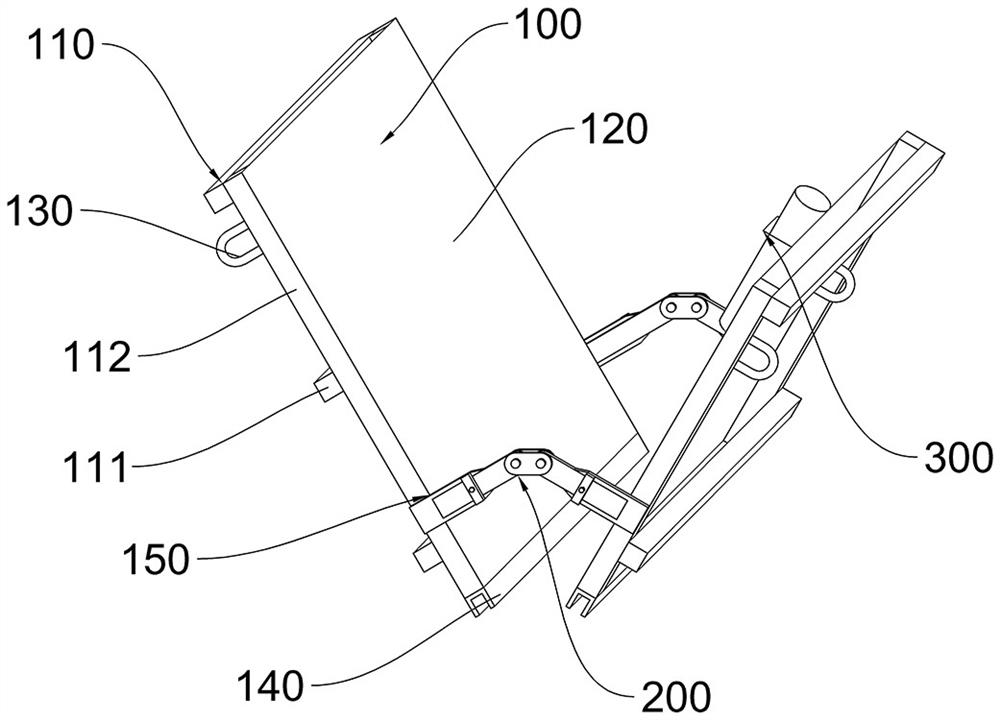

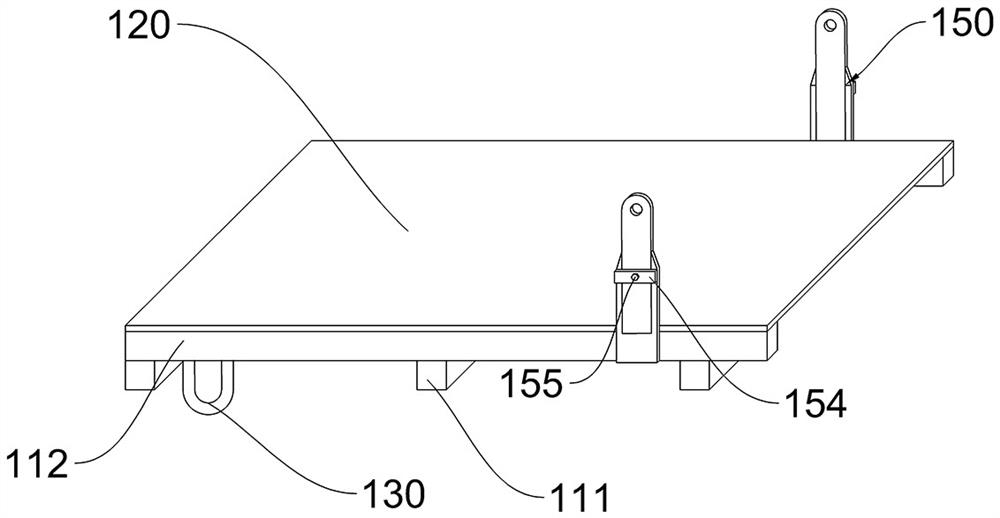

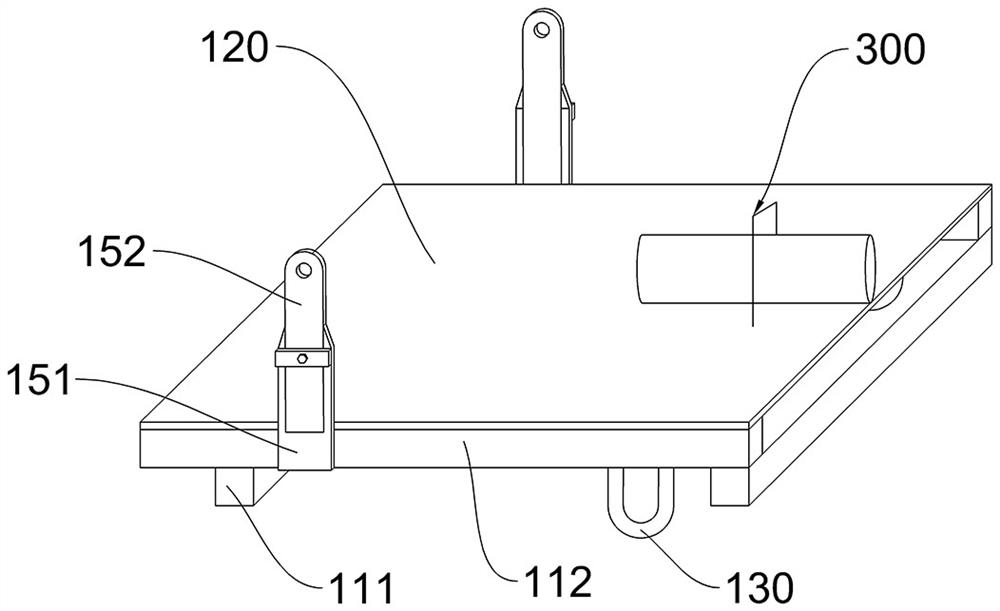

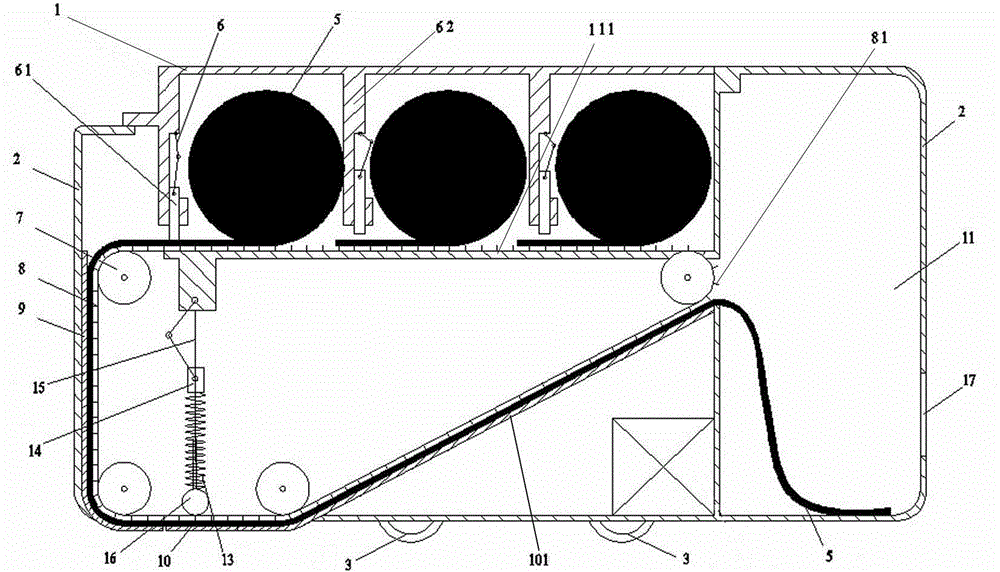

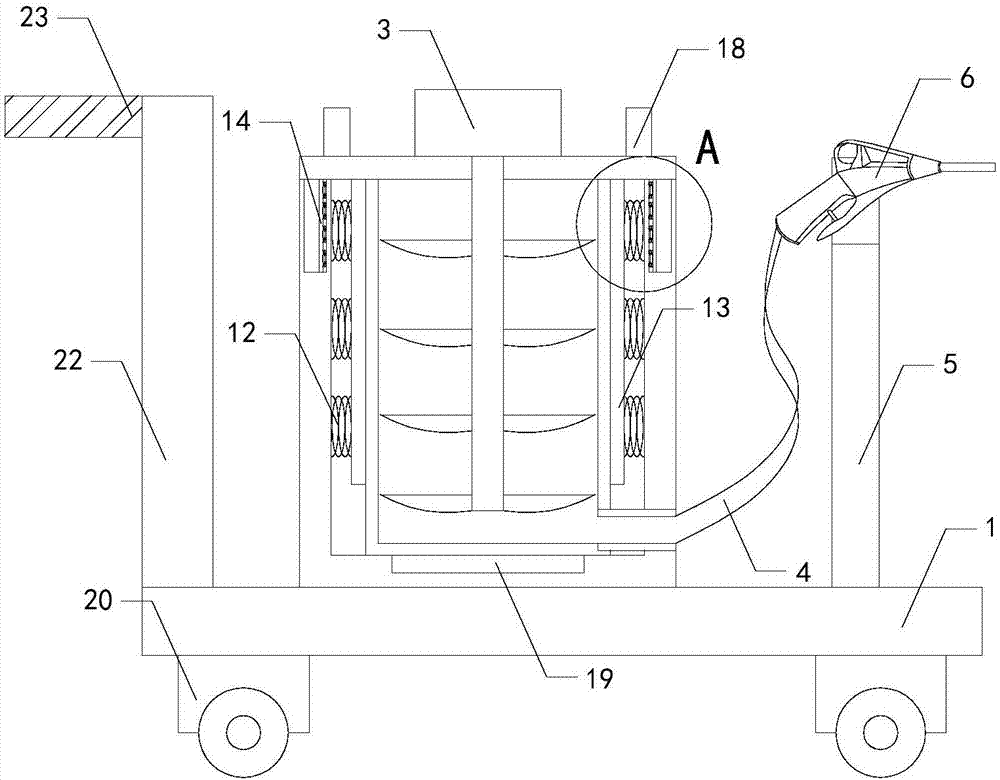

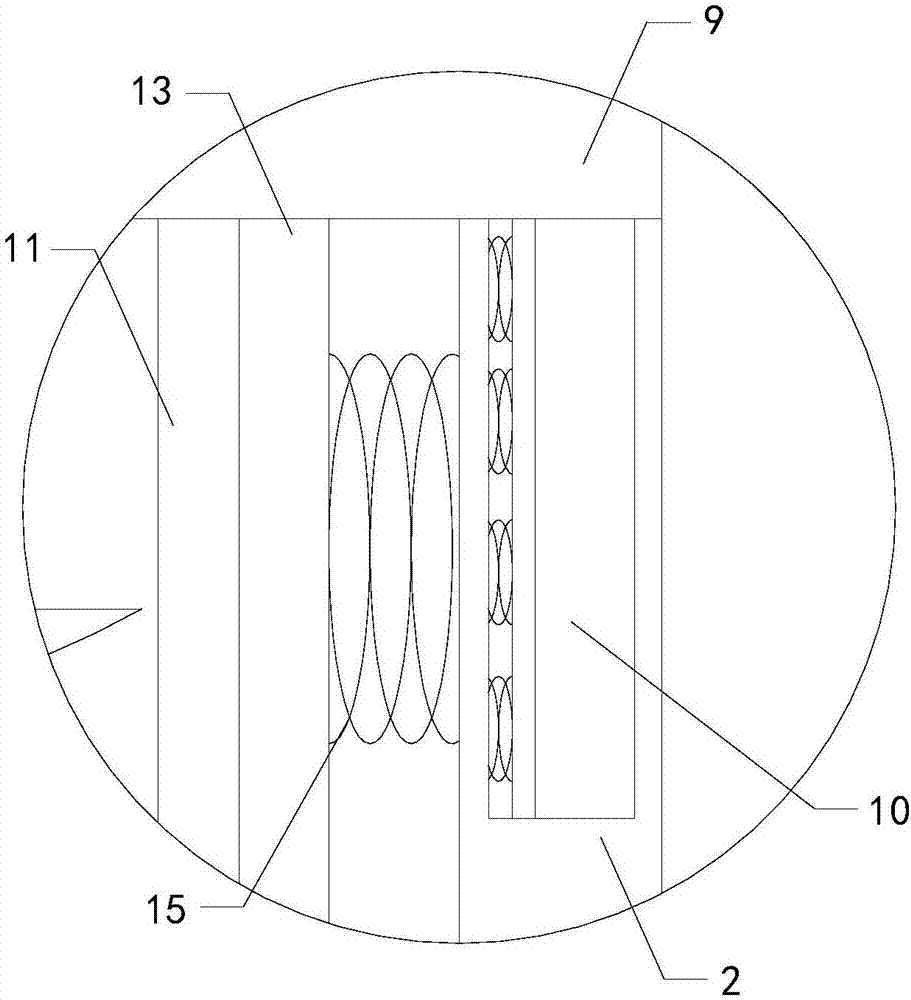

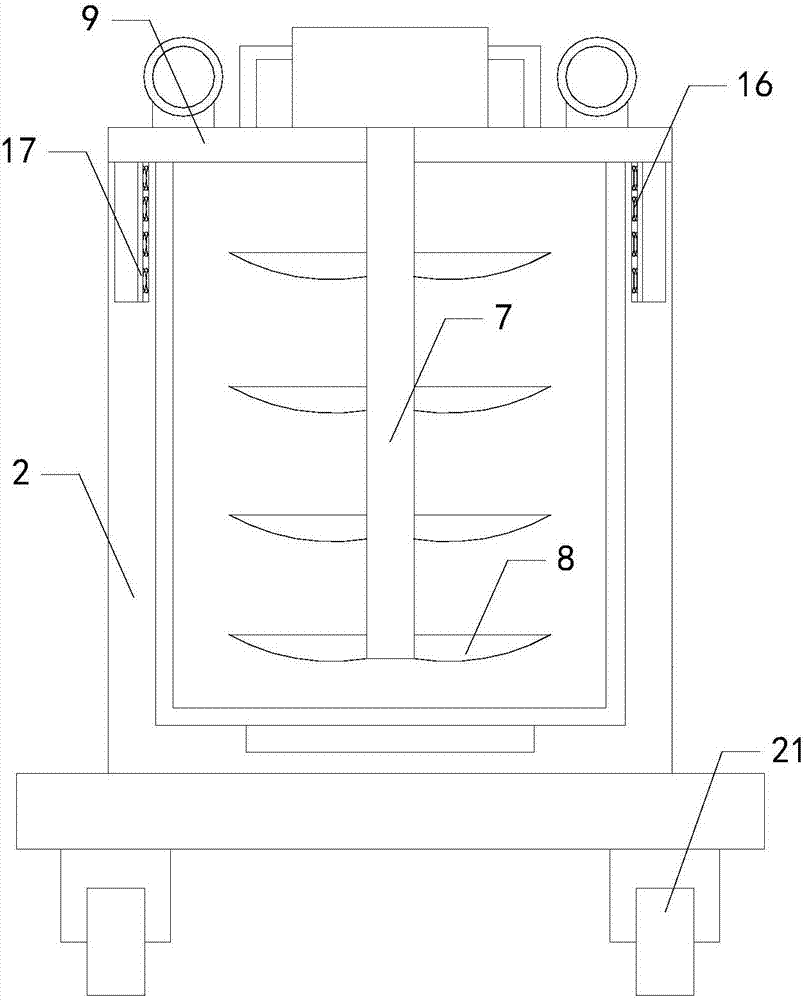

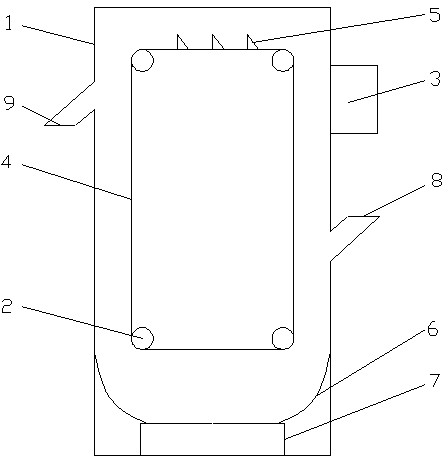

Household floor cleaning machine

ActiveCN103505157AReduce the amount of cleaningReduce volumeMachine detailsFloor-scrubbing machinesEngineeringAutomation

The invention belongs to a cleaning appliance and particularly relates to a household floor cleaning machine which is suitable for household use. The household floor cleaning machine is characterized by comprising a vehicle body, a towel box arranged at the bottom of the vehicle body, a transport component, a conveying and pushing part, a pushing component for pushing a towel transported by the transport component to the bottom of the vehicle body, and a dirty towel storage box for storing dirty towels, wherein the dirty towel storage box is provided with a dirty towel inlet and a dirty towel outlet, and a towel pushing outlet is formed in the position, corresponding to the lower part of the pushing component, at the bottom of the vehicle body. The cleaning machine cleans the ground by automatically transporting and pushing the towel, is in tight contact with the ground, has a good cleaning effect. The transport is convenient and smooth, and jamming is not likely to happen. The equipment cannot be easily damaged and is long in service life. The cleaning machine is simple in structure, low in cost, high in degree of automation and good in cleaning effect.

Owner:如东县东广物流有限公司

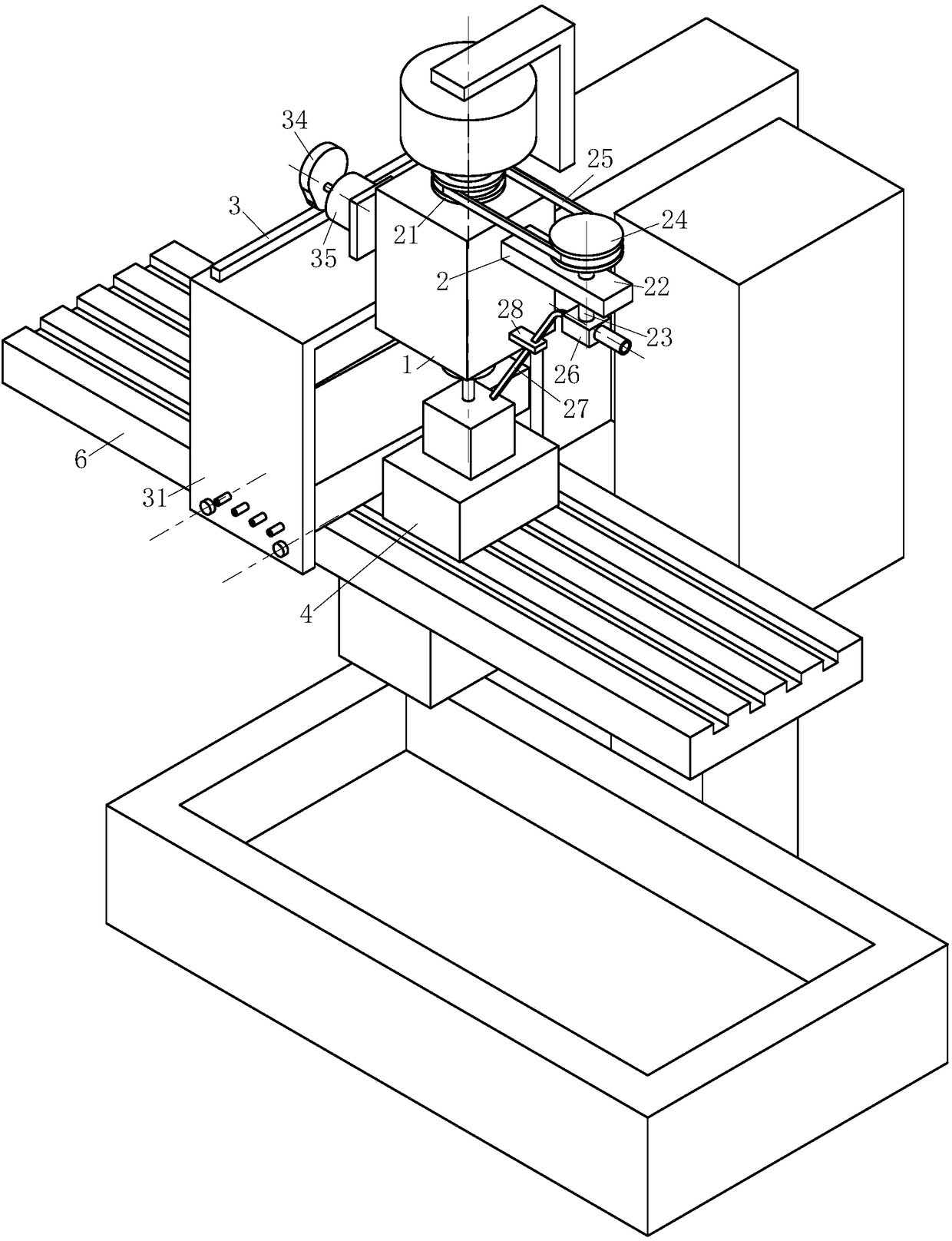

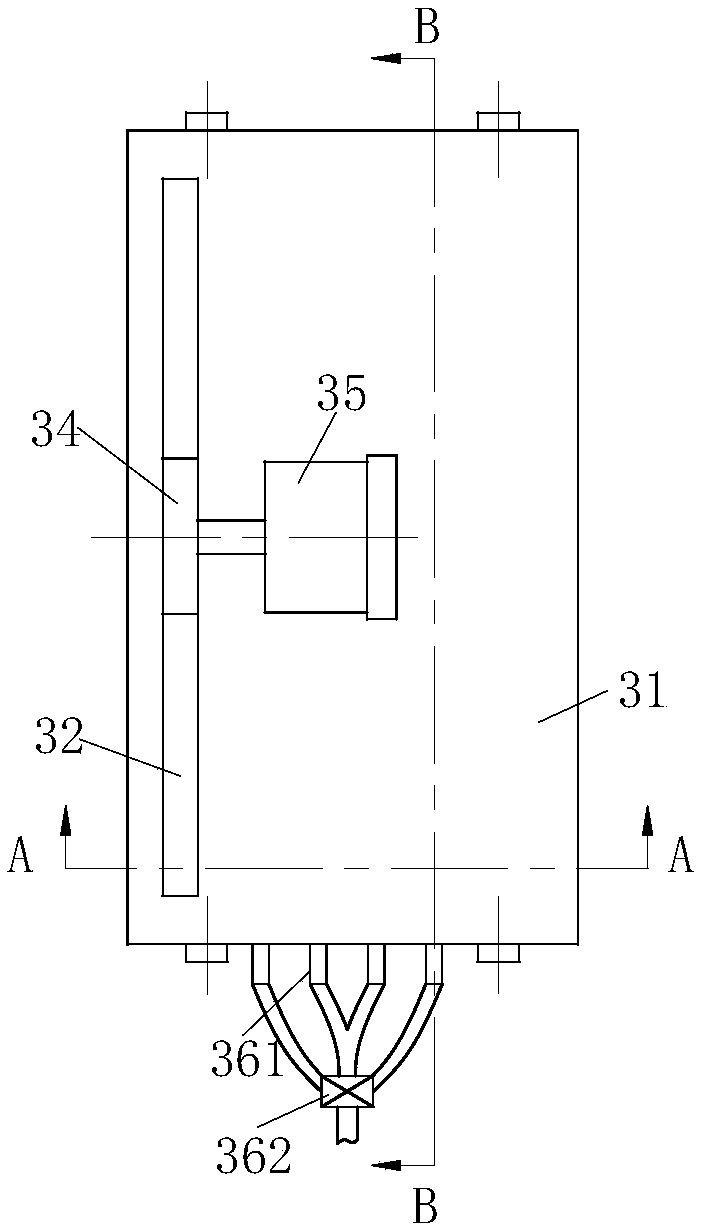

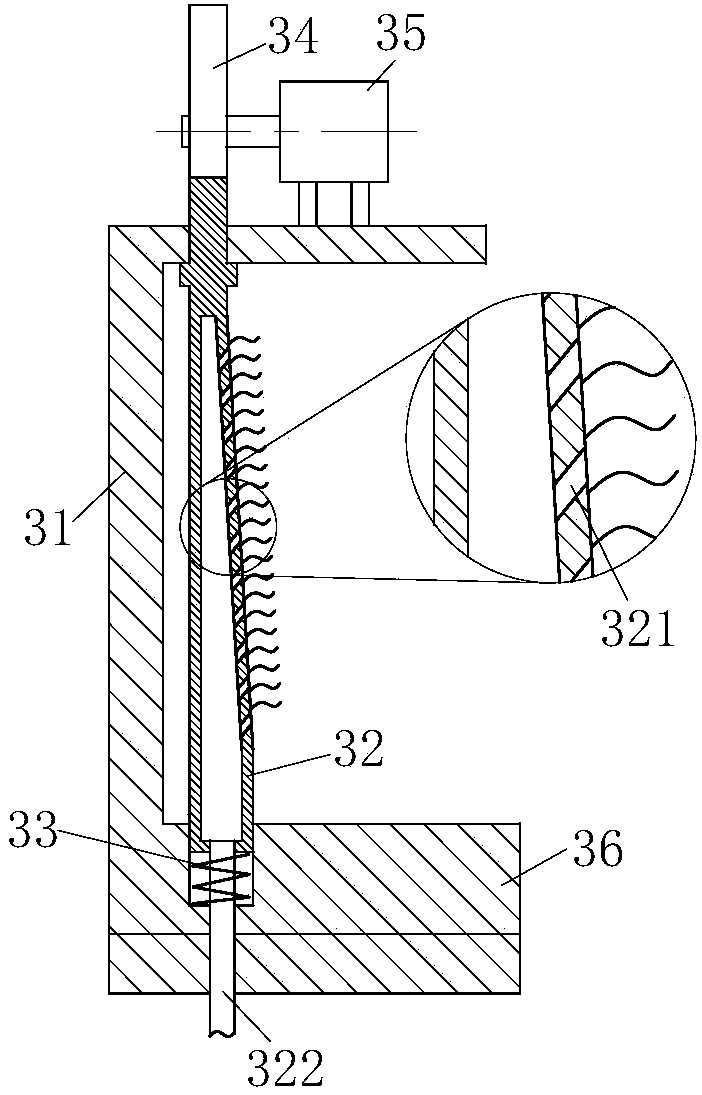

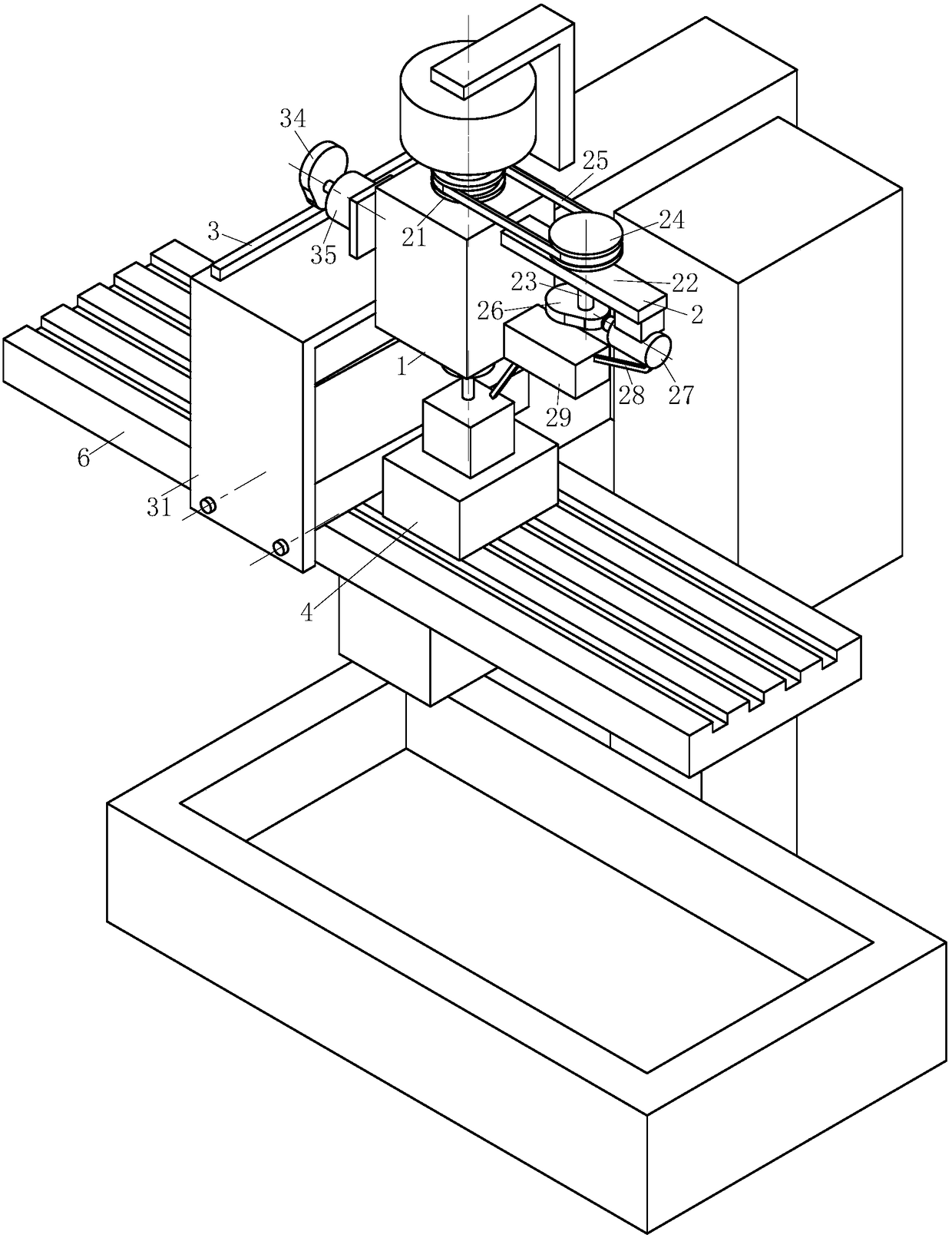

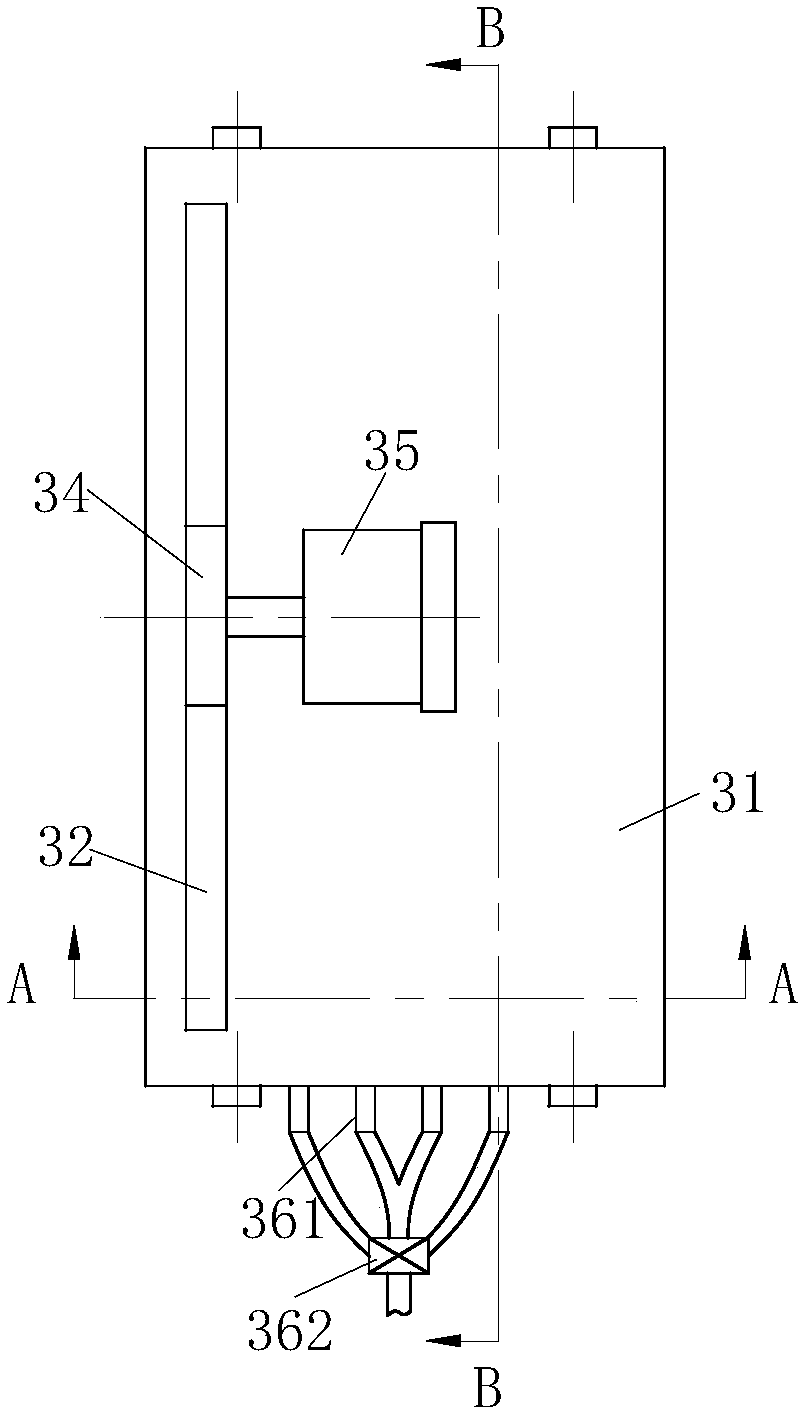

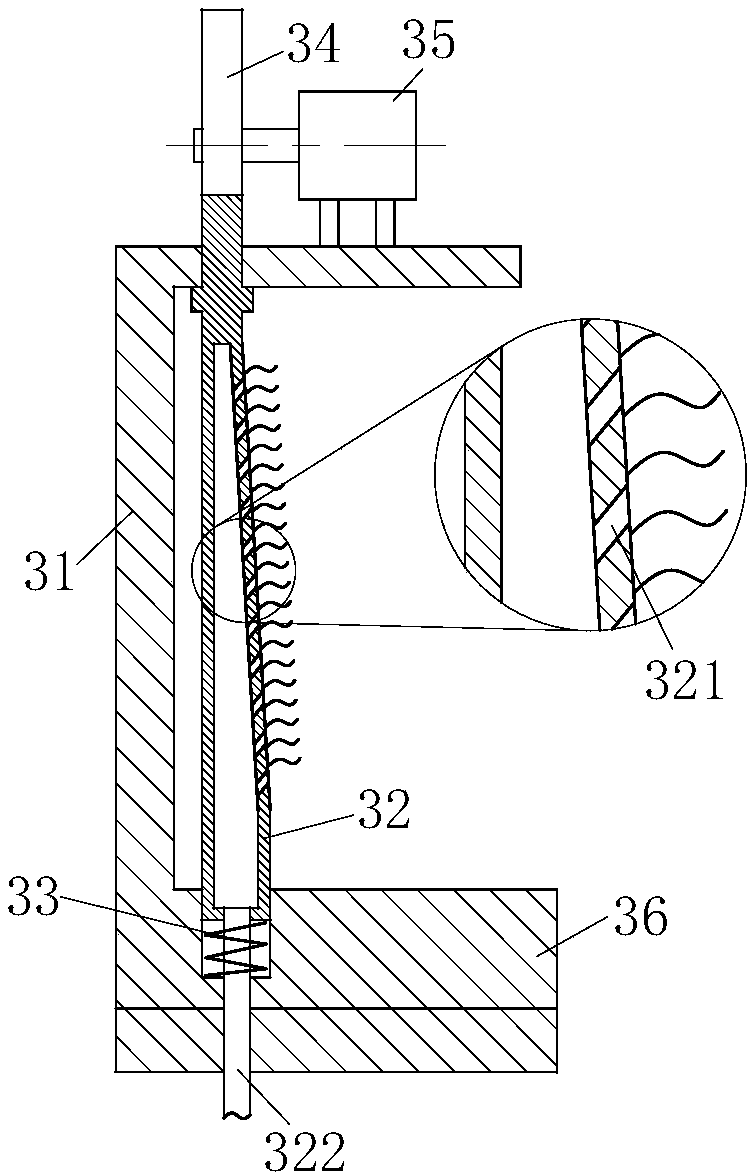

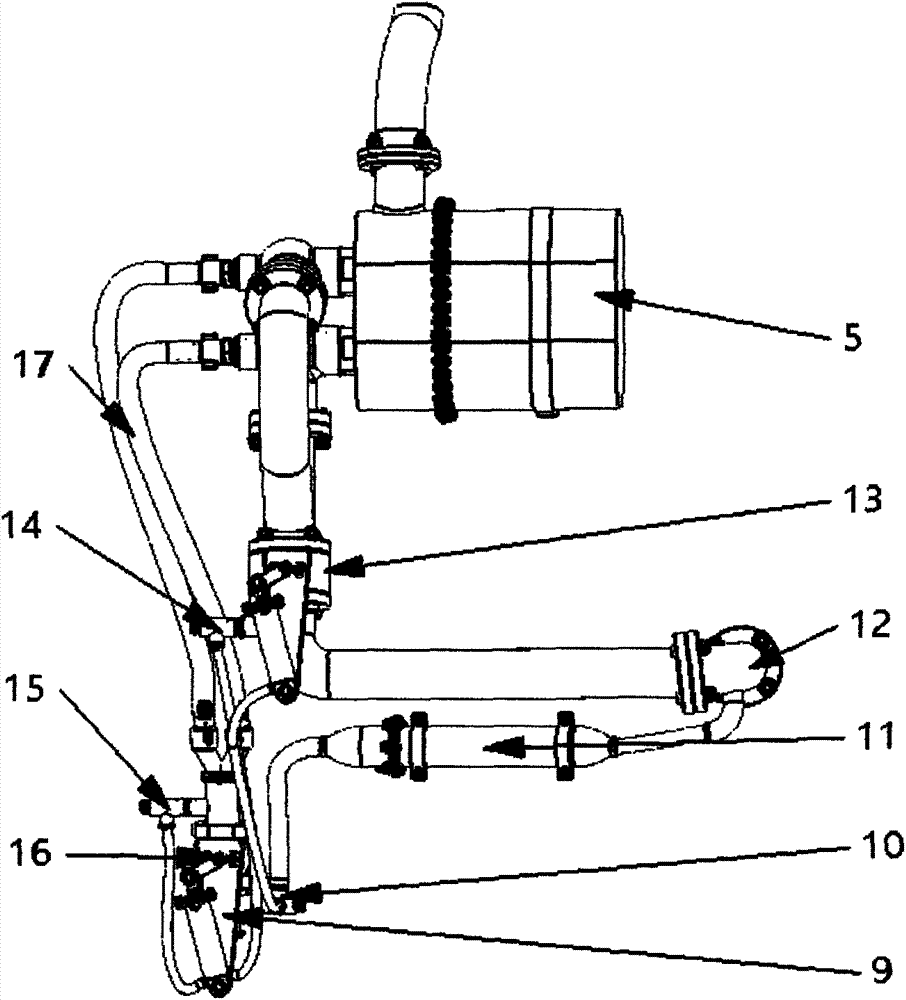

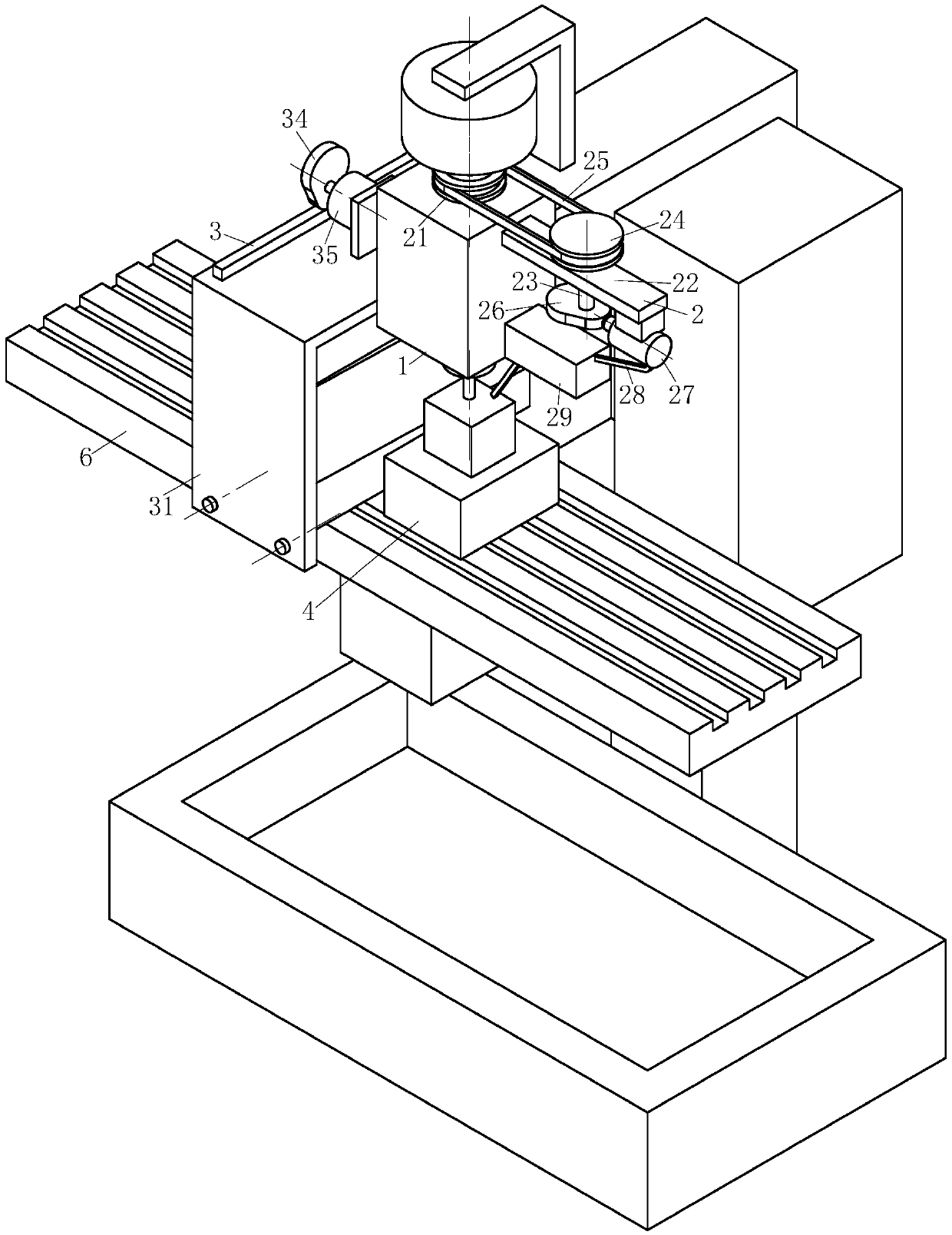

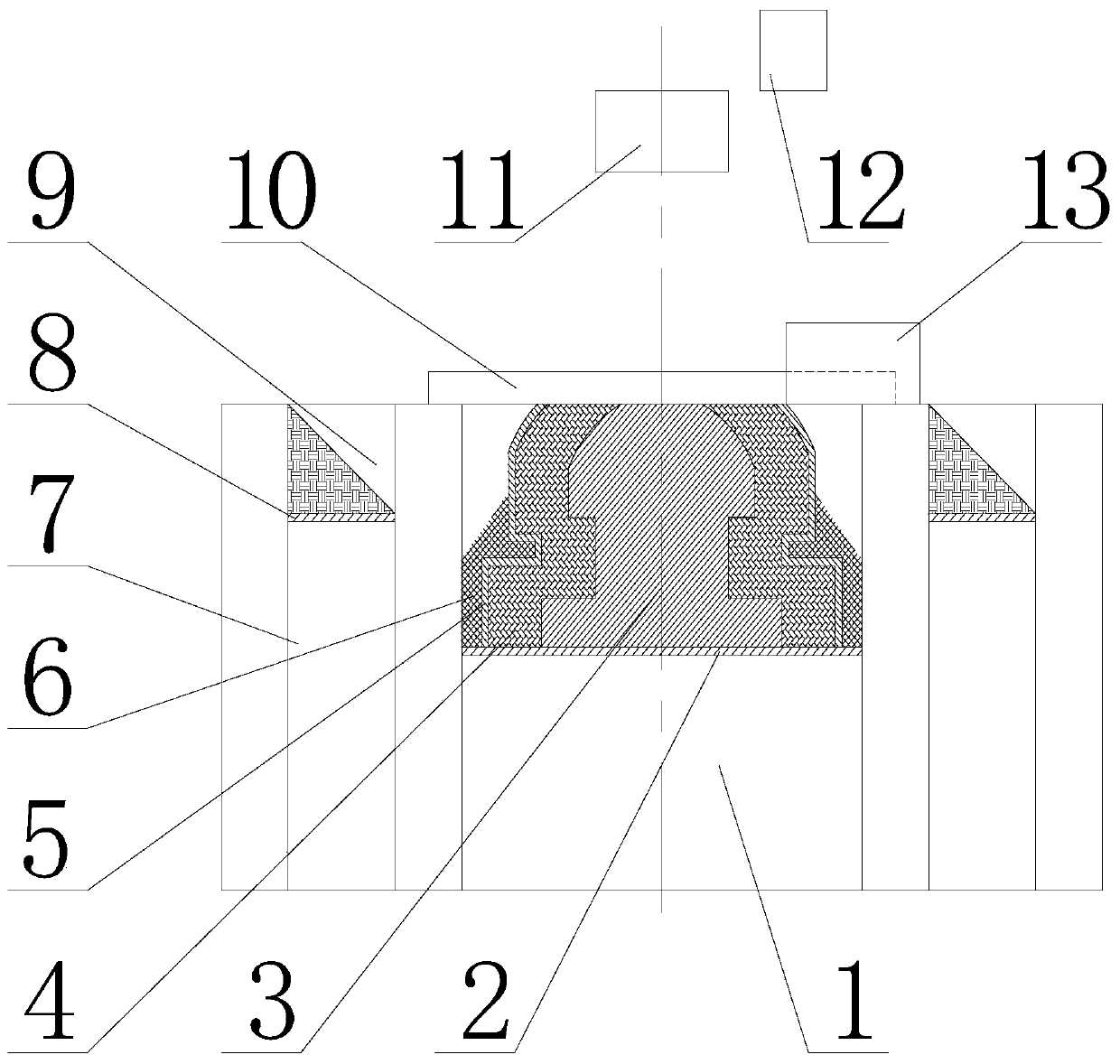

Processing chip treatment system for numerical controlled milling machine for brittle metal material cutting process

ActiveCN108115184APrevent splashImprove cleaning efficiencyMilling machinesMaintainance and safety accessoriesNumerical controlImpeller

The invention belongs to the technical field of machine processing equipment, and particularly relates to a processing chip treatment system for a numerical controlled milling machine for a brittle metal material cutting process. The system comprises a jet module, a chip stop module and a chip discharge pipe, wherein the jet module is arranged on one side of a main shaft tank of a milling machine,comprises a sleeve joint belt pulley, a mount rack, a rotating shaft, a connection belt pulley, a belt, an impeller casing, a pipeline and a support frame, and is used for blowing chips of a millingmachine to the chip stop module; the chip stop module comprises a tank body, a chip stop plate, a spring, a cam, a vibration motor and a guide plate, is arranged on one side of a chip-cutting platformof the milling machine, and is used for retaining chips blown by the jet module; and the chip discharge pipe is arranged at the lower end of one side of the chip stop module. The processing chip treatment system is especially suitable for cleaning broken chips of a brittle material, can generate high-pressure air flow through rotation of a main shaft; chips are intensively blown to the chip stopplate, are concentrated, and can avoid chip splashing, so that the cleaning workload of an operator can be reduced, and the work efficiency can be improved.

Owner:开平正霖卫浴实业有限公司

Anti-fusion-welding multi-procedure milling processing system for aluminum alloy

ActiveCN108274052AReduce wastePrevent splashWorkpiecesMilling equipment detailsKeroseneLiquid storage tank

The invention belongs to the technical field of common milling machines, and particularly relates to an anti-fusion-welding multi-procedure milling processing system for an aluminum alloy. The systemcomprises a jetting module, a chip blocking module and a chip removal pipe; the jetting module comprises a sleeving belt pulley, a mounting frame, a rotating shaft, a connecting belt pulley, a belt, afirst cam, a compressor, a pipeline and a liquid storage tank, is arranged on one side of a milling machine spindle box in a matched mode, can jet kerosene and is used for blowing milling machine chips away from the chip blocking module; and the chip blocking module comprises a box body, a chip blocking plate, a spring, a second cam, a vibration motor and a guide plate, is arranged on one side ofa milling machine chip platform and is used for blocking the chips blown away by the jetting module. The system is particularly suitable for aluminum alloy milling in a small processing plant, the chips can be blown away by jetting the kerosene, and a cutter can be lubricated; and the chips can be intensively blown to the chip blocking plate, so that the chips can be prevented from splashing, thecleaning workload of operators can be reduced, and the working efficiency can be improved.

Owner:唐山尚德门窗有限公司

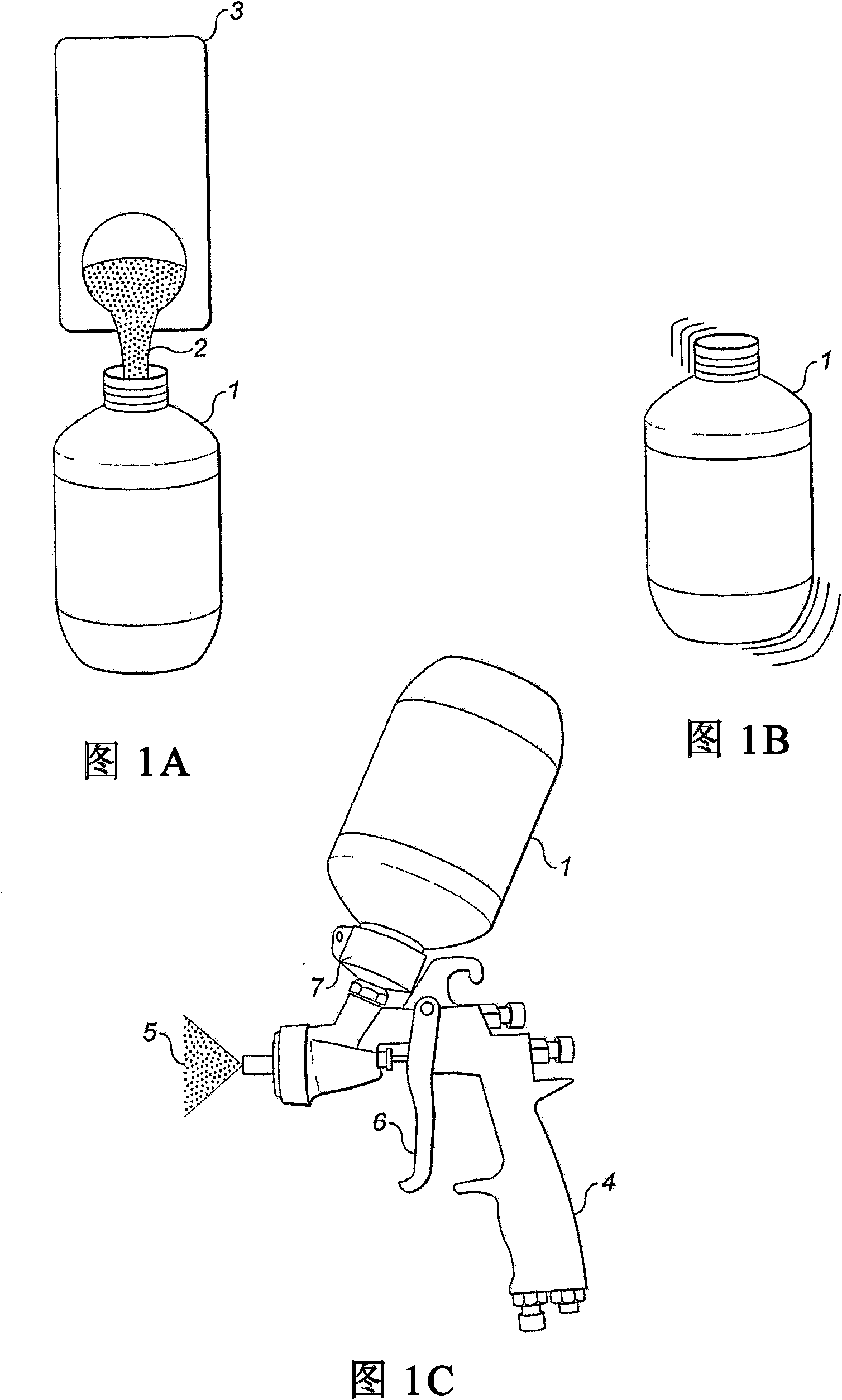

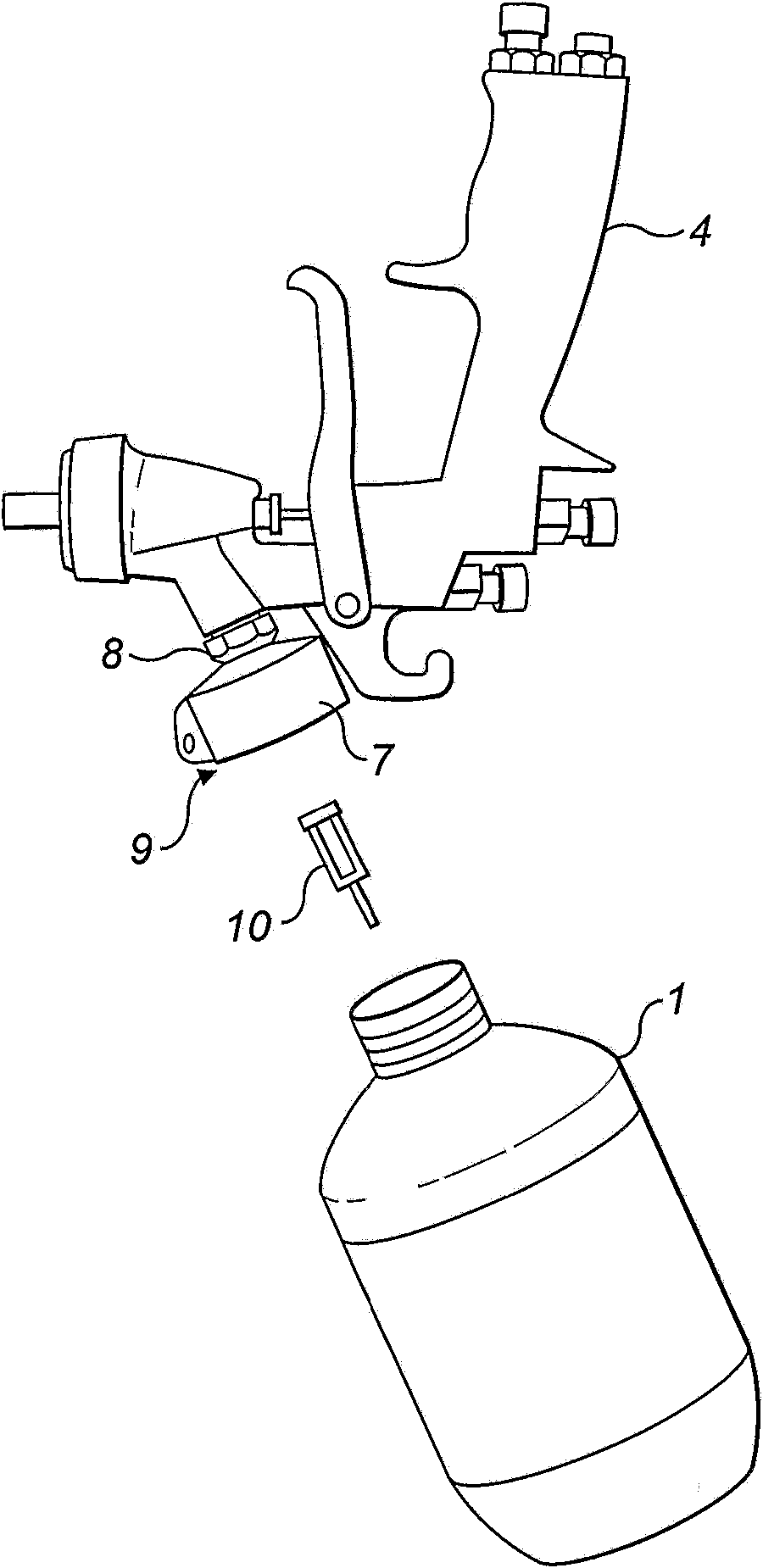

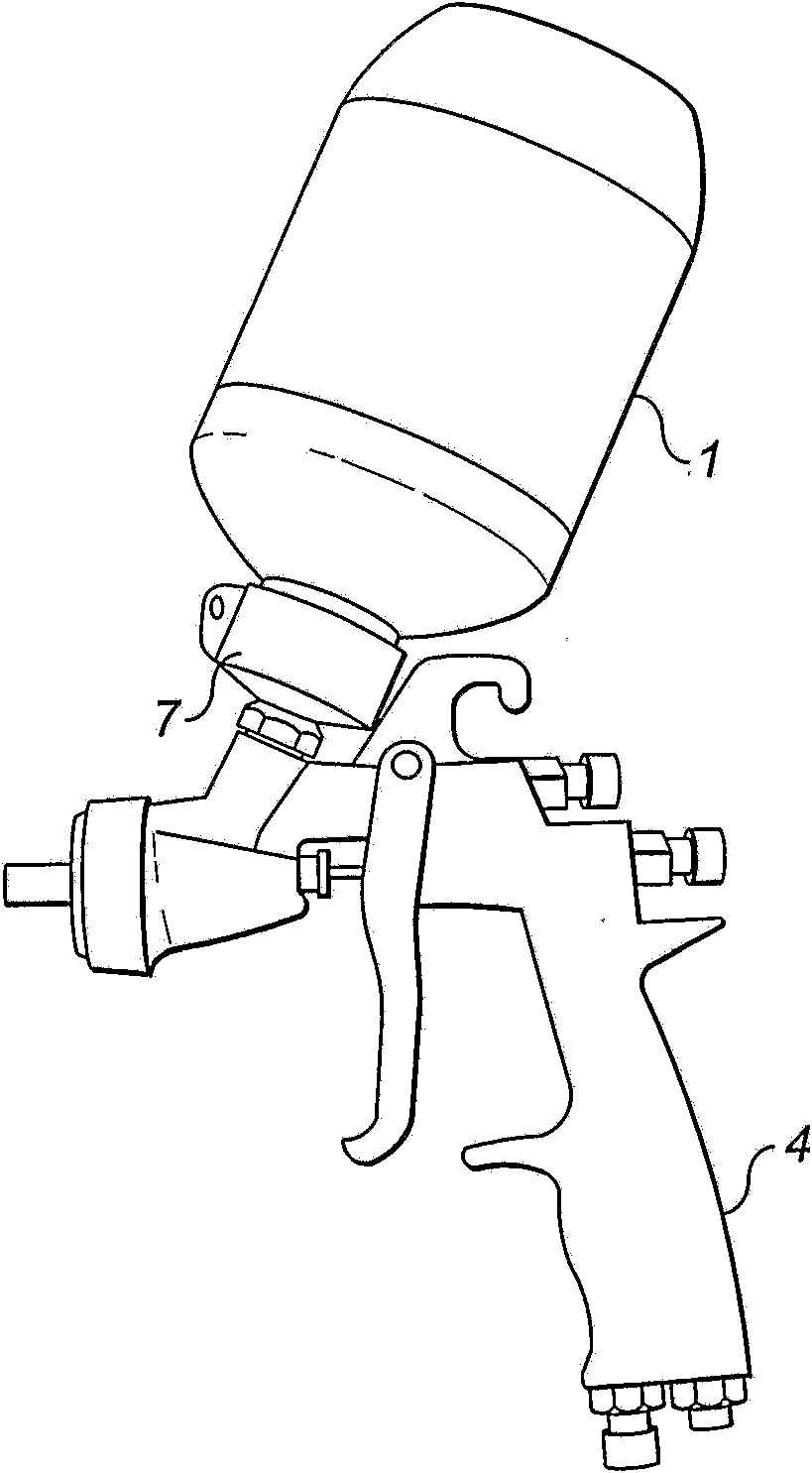

A connector for a gravity feed spray gun, a gravity feed spray gun and a method of preparing a spray paint

The present invention concerns a connector for connecting a paint container (1) having an aperture to a gravity feed spray paint gun. The connector comprises a coupling (7) for connection to the container's aperture and, in use, for mounting the container above the spray gun; a paint feed channel (10) for feeding paint from the container into the spray gun; and an air feed channel (13) for feeding air into the container as paint is fed into the spray gun.

Owner:U POL LTD

Glass rod polishing device

InactiveCN112692715ASmooth circulationBeautiful appearancePolishing machinesEngineeringStructural engineering

The invention discloses a glass rod polishing device which comprises a base, a moving plate capable of moving left and right along the base, a first bull gear, a second bull gear, a glass rod and a first rotating shaft, wherein the first bull gear and the second bull gear are arranged on the base; the glass rod is arranged in the first bull gear and the second bull gear in a penetrating mode; the first rotating shaft is arranged on the first bull gear; the glass rod is sleeved with a polishing device; and the polishing device comprises a polishing pressing head, a collecting box arranged outside the polishing pressing head in a sleeving mode, and a discharging box arranged on one side of the collecting box. According to the glass rod polishing device provided by the invention, the discharging box also synchronously moves in the same direction along with the polishing pressing head, so that a first pipeline and a second pipeline do not need to be arranged too long, the cost investment is reduced, liquid in the pipelines circulates more smoothly, and the appearance is more attractive; due to the effect of a first one-way valve, the flow direction of the liquid in the first pipeline and the second pipeline is more stable; and the first pipeline can also extract and recover the liquid collected in the collecting box into the discharging box, so that the waste of resources is reduced, and the recycling rate is increased.

Owner:浙江靖和光电科技股份有限公司

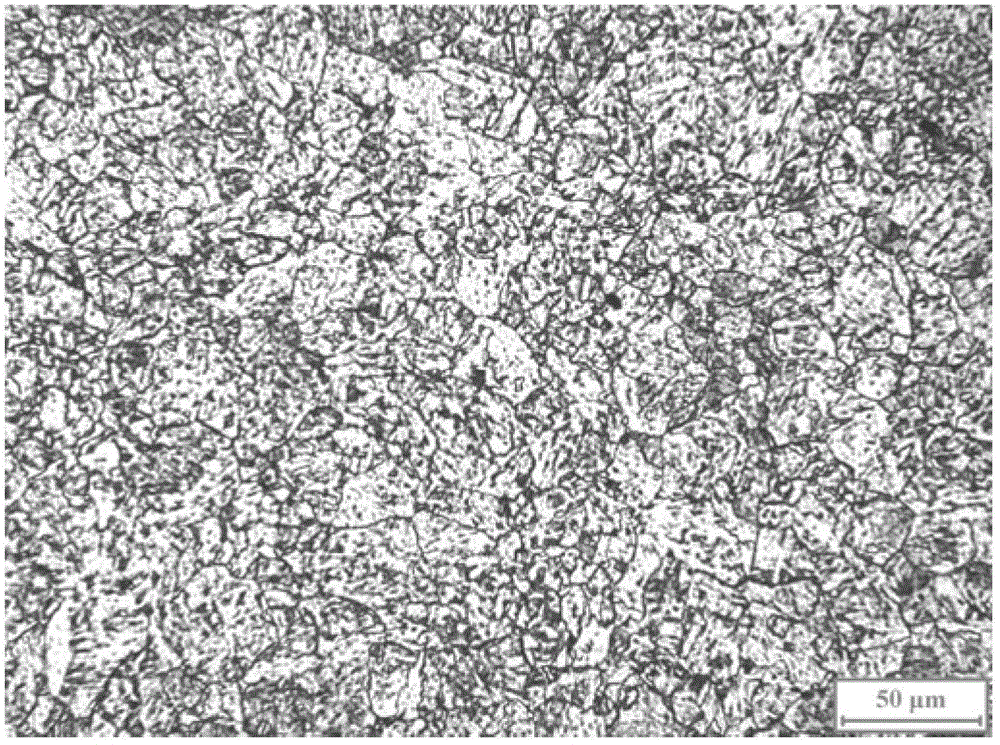

A kind of low-alloy high-strength steel plate for large-thickness boiler drum and its manufacturing method

The invention relates to a low-alloy high-strength steel plate for a big-thickness boiler drum and a manufacturing method of the low-alloy high-strength steel plate. The manufacturing method comprises the following steps: (1) carrying out smelting, external refining and vacuum degassing treatment on the following components in percentage by weight: 0.135-0.17% of C, 0.15-0.50% of Si, 1.20-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.002% of S, 0.10-0.30% of Cr, 0.10-0.30% of Mo, 0.40-0.70% of Ni, 0.008-0.018% of Nb, 0.020-0.040% of Al, less than or equal to 0.05% of Cu, less than or equal to 0.006% of N, less than or equal to 0.003% of O, less than or equal to 0.00018% of H, 0.004-0.010% of Ti and the balance of Fe and unavoidable impurities, wherein Ti / N is less than or equal to 2.74; (2) casting; (3) carrying out steel ingot and cogging; (4) carrying out steel plate rolling and finishing; (5) carrying out normalizing, wherein the normalizing temperature of the steel plate is 900-940 DEG C, the temperature maintaining time is not less than 30 minutes after a core part of the steel plate is heated to 900-940 DEG C; (6) carrying out accelerated cooling to guarantee the cooling speed of the core part of the steel plate to be not less than 1 DEG C / second; (7) tempering at the temperature of 640-690 DEG C, and carrying out air cooling until reaching the room temperature after the steel plate is discharged out of a furnace.

Owner:BAOSHAN IRON & STEEL CO LTD

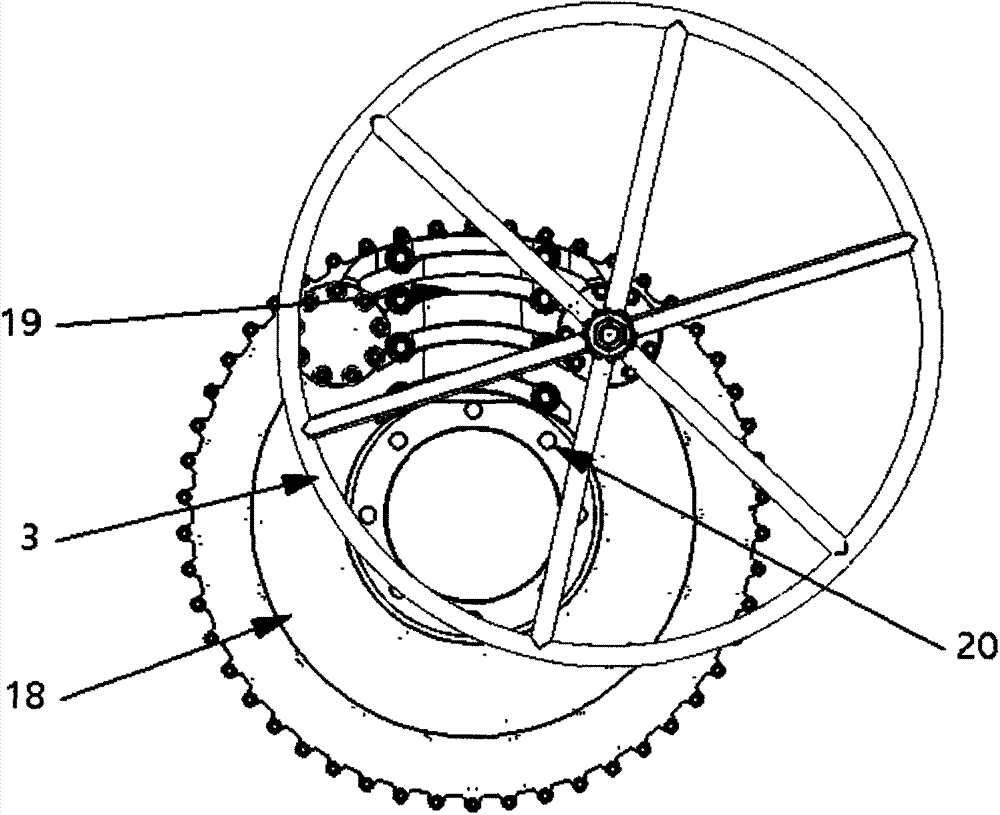

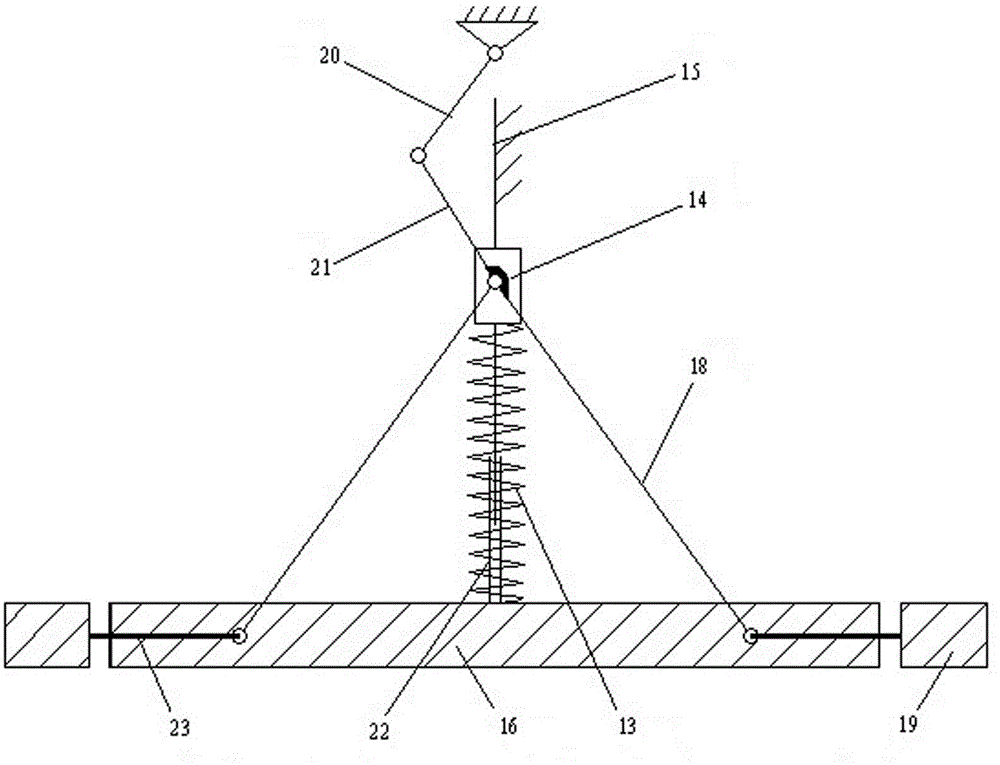

Equipment capable of improving laser selection melting and forming efficiency, and using method thereof

ActiveCN108188391AReduce running timeShorten exercise distanceAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceLaser

Equipment capable of improving the laser selection melting and forming efficiency comprises a forming unit, a powder supply unit, a powder recovery unit and a laser control unit; the forming unit is used for bearing a forming part (3), an unformed powder binding layer (5) and unformed powder; the powder recovery unit is used for spreading powder according to the section shape of the forming part (3) in a plane to be formed; meanwhile, the unformed powder binding layer (5) is formed; the powder recovery unit is used for bearing unformed powder; and the laser control unit is used for scanning powder in the plane to be formed according to a scanning path generated by the part section information of the forming part (3), so that the spread powder is melted into a part of the forming part (3).The invention further provides a using method of the equipment capable of improving the laser selection melting and forming efficiency.

Owner:XIAN SPACE ENGINE CO LTD

Vacuum ladle for aluminum electrolysis

InactiveCN103785821AExtended operating cycleReduce capacityMelt-holding vesselsAutomatic controlElectrolysis

The invention discloses a vacuum ladle for aluminum electrolysis. The vacuum ladle for aluminum electrolysis comprises an electrolysis discharging automatic control device and a vacuum ladle rotating and dumping device. The electrolysis discharging automatic control device is installed at a vacuum ladle vacuum discharge hole. The vacuum ladle rotating and dumping device is arranged between a vacuum ladle suspension arm and a vacuum ladle body. Through the vacuum ladle for aluminum electrolysis, the work efficiency and the quality of virgin aluminum are improved, and the production cost is reduced.

Owner:谷万铎

Method for controlling hypodermic bubble defect of wide and thick slab of medium carbon steel

The invention discloses a method for controlling hypodermic bubble defects of a wide and thick slab of medium carbon steel. In the casting process, crystallizer protecting slag with alkalinity of 1.0-1.1 is used; the cooling strength of the bent section is controlled between 0.18-0.23 kg / L; the deformation is controlled to be 0.60 mm / m-0.70 mm / m under light pressure. A solid stopper rod is used, the argon blowing pressure of the middle ladle circular seam is 0.20-0.30 MPa, and the argon blowing flow is 2-4 L / min. According to the invention, the hypodermic bubble defects of the wide and thick slab of medium carbon steel can be effectively controlled, the cleaning amount of the casting blank in the later stage is reduced, the cleaning-free is achieved, meanwhile, the rejection rate of the rolled material is reduced, and the production cost is reduced; the system has the advantages of completeness and strong operability, can be rapidly popularized and promoted in production lines, and hasremarkable benefits.

Owner:HEBEI IRON AND STEEL

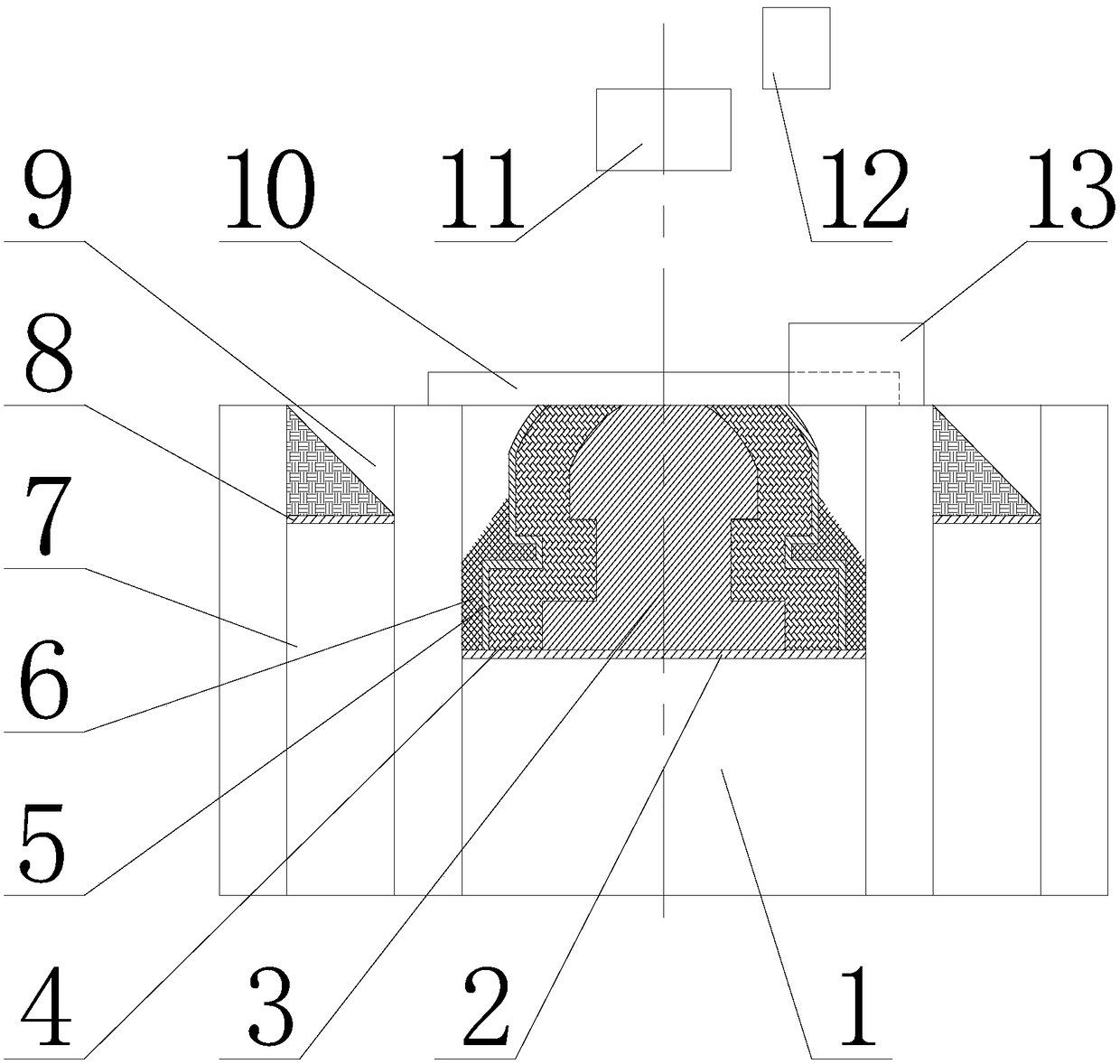

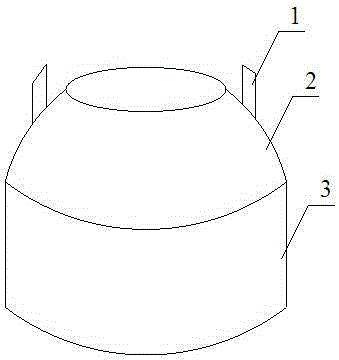

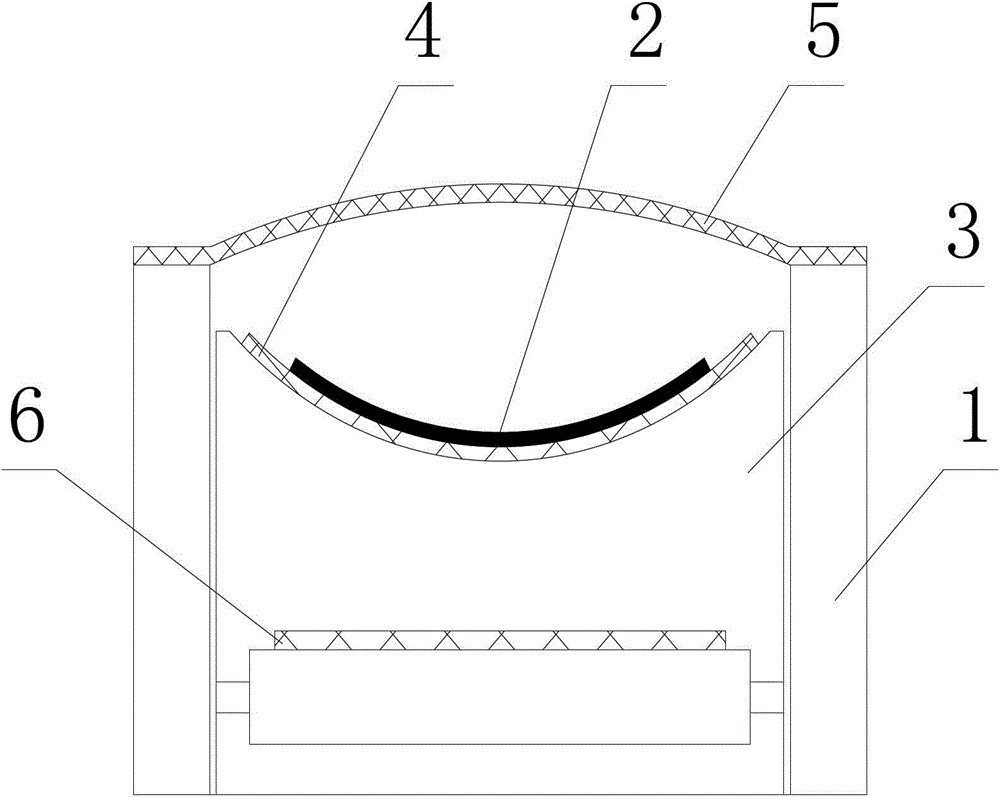

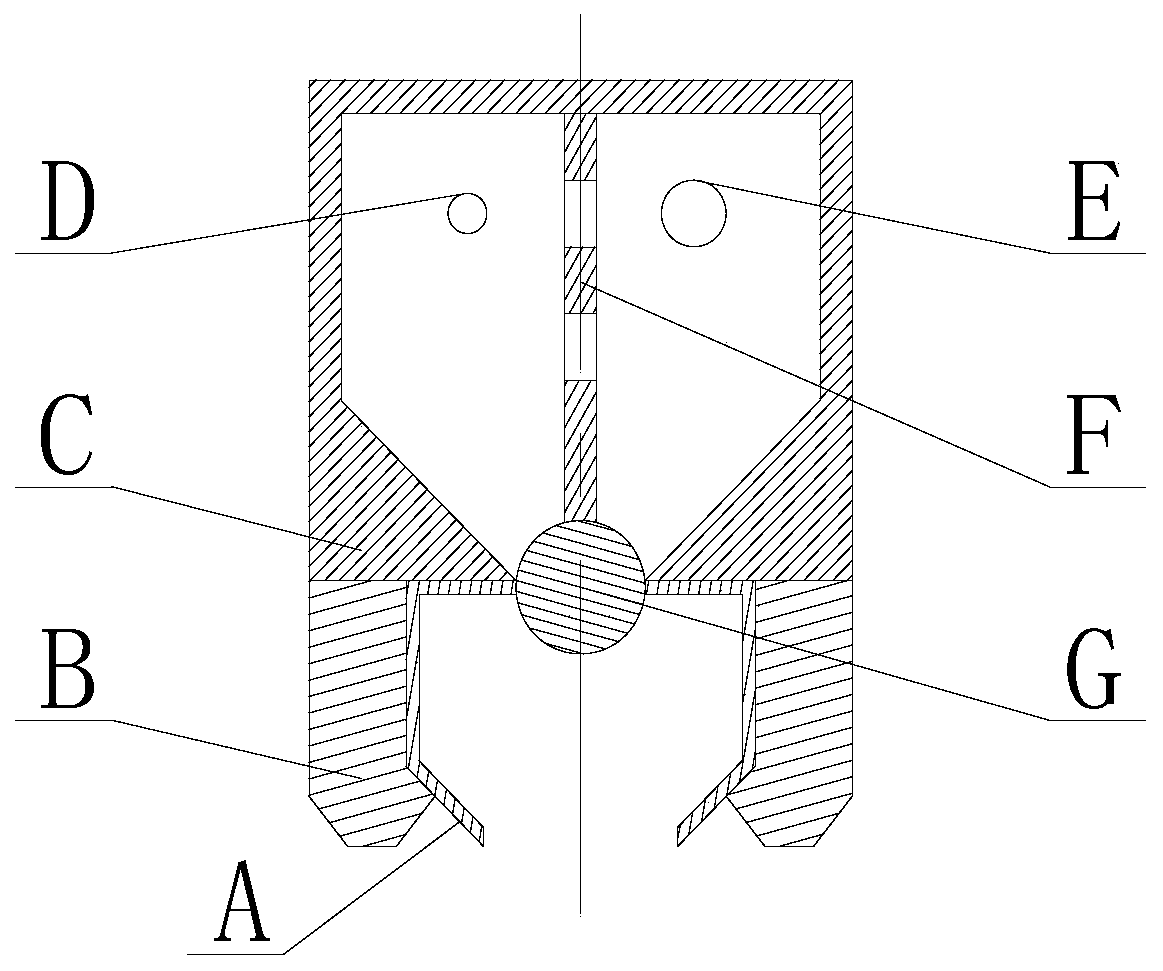

Tool for assisted construction of anti-subsidence manhole cover asphalt reinforcement layer

The invention discloses a tool for assisted construction of an anti-subsidence manhole cover asphalt reinforcement layer, and belongs to the field of municipal construction tools. The tool comprises a hollow cylinder part (3) and a hollow round table part (2), wherein the outer diameter of the bottom surface of the hollow round table part (2) is equal to the outer diameter of the top surface of the hollow cylinder part (3), the bottom surface of the hollow round table part (2) is connected to the top surface of the hollow cylinder part (3), the outer diameter of the top surface of the hollow cylinder part (3) is equal to the inner diameter of a pitshaft, and a handle (1) is fixedly arranged on the hollow round table part (2). According to the present invention, before the asphalt layer is paved, the bottom portion of the hollow cylinder part (3) is placed on the shaft mouth and then the asphalt is paved around the tool and compacted, the tool is pulled out after the asphalt is cooled to the temperature of about 60 DEG C and molded, and the lower portion of the manhole cover is inserted into the pitshaft to perform vibration rolling so as to make the manhole cover and the asphalt reinforcement layer tightly contact, such that the construction process for reinforcing the manhole cover through the asphalt is completed.

Owner:SHANDONG HUITONG CONSTR GRP CO LTD

A kind of production method of stainless steel clad plate

ActiveCN107009090BAvoid magnetic deflectionAvoid defectsLaminationLamination apparatusSS - Stainless steelComposite plate

The invention provides a production method of stainless steel composite plates. The production method comprises the steps that caulking grooves are dug in the middles of two carbon steel base blanks according to the size of stainless steel plates, and slots and exhaust chambers communicating with the slots are formed in the two ends of each caulking groove separately; the two stainless steel plates are embedded into the caulking grooves of the two base blanks in the mode that the surfaces where an isolating agent is spread face upwards, and the two base blanks are buckled together to form a composite blank; the composite blank is put into a vacuum chamber to be vacuumized, spot welding is conducted first and then continuous welding is conducted, vacuum breaking and cooling are conducted, and an anti-oxidation coating is sprayed on the surface; heating and heat preserving are conducted on the cooled welded blank in a heating furnace, wherein the initial rolling temperature ranges from 1,000 DEG C to 1,150 DEG C, the accumulated reduction rate of the first three passes is higher than or equal to 35%, and the finish rolling temperature ranges from 930 DEG C to 1,050 DEG C; edges are cut after rolling, and then two stainless steel composite plates are obtained. According to the method, the condition that a magnetic deflective blow phenomenon occurs between stainless steel and carbon steel due to magnetic influence can be avoided, effective compositing between the stainless steel and the carbon steel is achieved, the surface clearing and grinding amount is decreased, and the yield of the composite plates is increased.

Owner:ANGANG STEEL CO LTD

Construction Method of Hyperbolic Roof Structure with Random Oblique Mesh Tic-Tac Beams

ActiveCN103615110BImprove work efficiencyShorten the construction periodBuilding material handlingFalseworkSupporting system

An irregular oblique-crossing web-shaped grillage beam hyperbolic roof structure construction method comprises the steps of construction preparing, secondary conversion of design drawing, lofting grillage beam ground projection axis measuring, steel pipe buckling piece all-round scaffold supporting system erecting, grillage beam bottom wood ridge lower support horizontal rod elevation giving off, wood ridge binding and bottom plate paving on a supporting horizontal rod, given-off roof beam position measuring, bound grillage beam steel rib machining, grillage beam grillage side mould mounting and reinforcing, grillage beam top plate mounting and reinforcing, face plate steel rib binding and hyperbolic roof concrete pouring. Through a space three-dimensional technology, a reasonable supporting system and accurate location of a hyperbolic roof and a grillage beam, the concrete mixing proportion is optimized, the quality and the attractive degree of the hyperbolic roof can be improved, construction difficulty is lowered, and construction efficiency is improved.

Owner:广西建工第一建筑工程集团有限公司

Anti-sputtering concrete pouring auxiliary device and using method thereof

ActiveCN114658223AReduce inflowLower the volumeBuilding material handlingArchitectural engineeringPipe

The invention relates to the technical field of building construction, and discloses an anti-sputtering concrete pouring auxiliary device and a using method thereof, and the anti-sputtering concrete pouring auxiliary device comprises a left pouring auxiliary plate, a right pouring auxiliary plate and a connecting device. The left pouring auxiliary plate comprises a pouring auxiliary plate frame, and a galvanized steel plate, a hand pull ring, channel steel and an adjustable connecting piece which are connected to the pouring auxiliary plate, and the left pouring auxiliary plate is rectangular; the right pouring auxiliary plate comprises a pouring auxiliary plate frame, a galvanized steel plate, a hand pull ring, channel steel, an adjustable connecting piece and a pump pipe fixing device, wherein the galvanized steel plate, the hand pull ring, the channel steel, the adjustable connecting piece and the pump pipe fixing device are connected to the pouring auxiliary plate. The connecting devices are respectively hinged with the pouring auxiliary plates; the device is simple in structure, light, convenient to transport and capable of meeting the requirement of manual carrying on a construction site; the pouring auxiliary plate slows down the speed of concrete flowing into the formwork, the pouring auxiliary plate on the other side blocks sputtering of the concrete, the concrete falling outside the formwork is reduced, then the later construction waste cleaning amount is reduced, and economic benefits are achieved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Belt conveyors

The invention relates to a belt conveyor. The belt conveyor comprises a rack and a conveying belt arranged on the rack, a partition plate is arranged on the portion, below the conveying belt, of the rack, the cross section of the upper end of the partition plate is arc-shaped, the middle of the partition plate is provided with a supporting portion which is supported by the conveying belt, an upper cover is arranged on the portion, above the partition plate, of the rack, a closed space is formed between the upper cover and the partition plate, and a conveying device used for material return is arranged on the portion, below the partition plate, of the rack. Due to the fact that the conveying belt is arranged in the closed space formed between the upper cover and the partition plate, the belt conveyor has the advantages of guaranteeing that materials will not fly upward and scatter when being used, preventing outer-wall impurities from being mixed with the conveyed materials, and avoiding the situation that the materials are damaged when being exposed to the sun and rain. Due to the fact that the conveying device used for material return and the conveying belt are arranged in a separated mode, the belt conveyor further has the advantages of preventing a large number of dust adhered to the conveying belt from accumulating on the inner side of a box body. The belt conveyor has the advantages of guaranteeing that the conveying belt will not shift due to the fact that the supporting portion is in contact with the conveying belt, improving production efficiency, and reducing the cleaning workload.

Owner:平湖光明机械股份有限公司

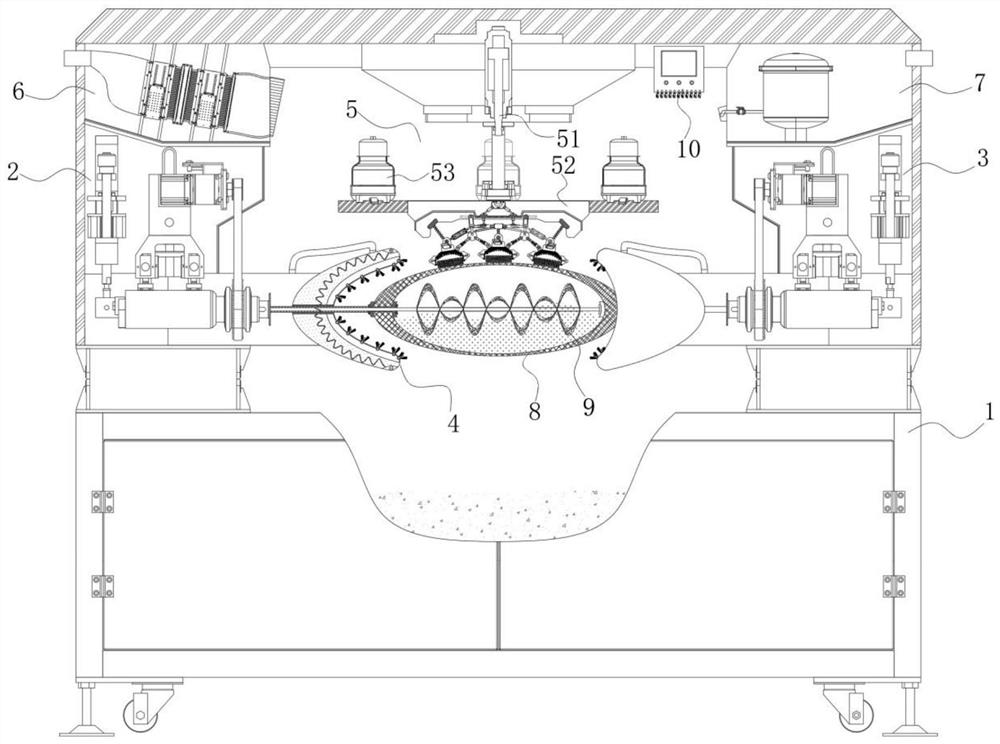

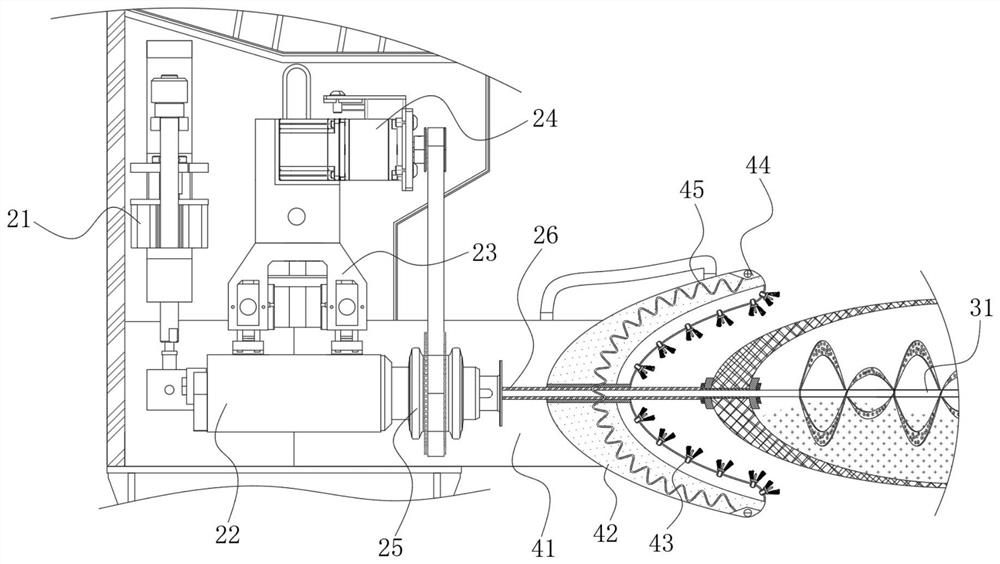

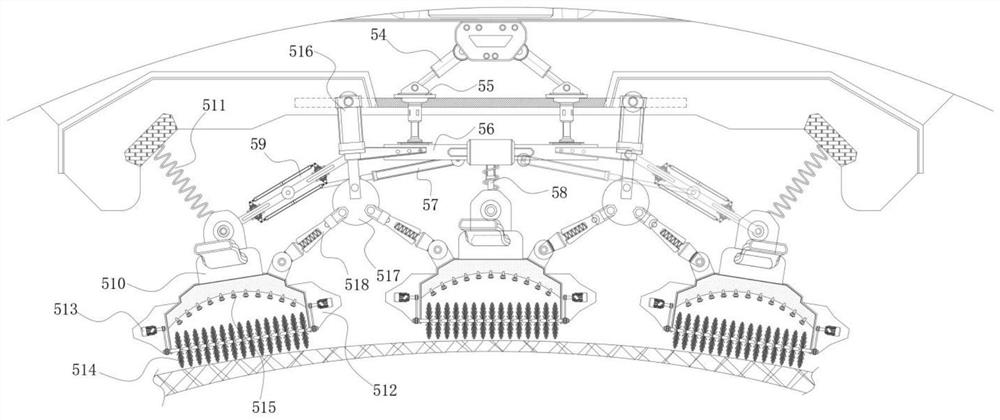

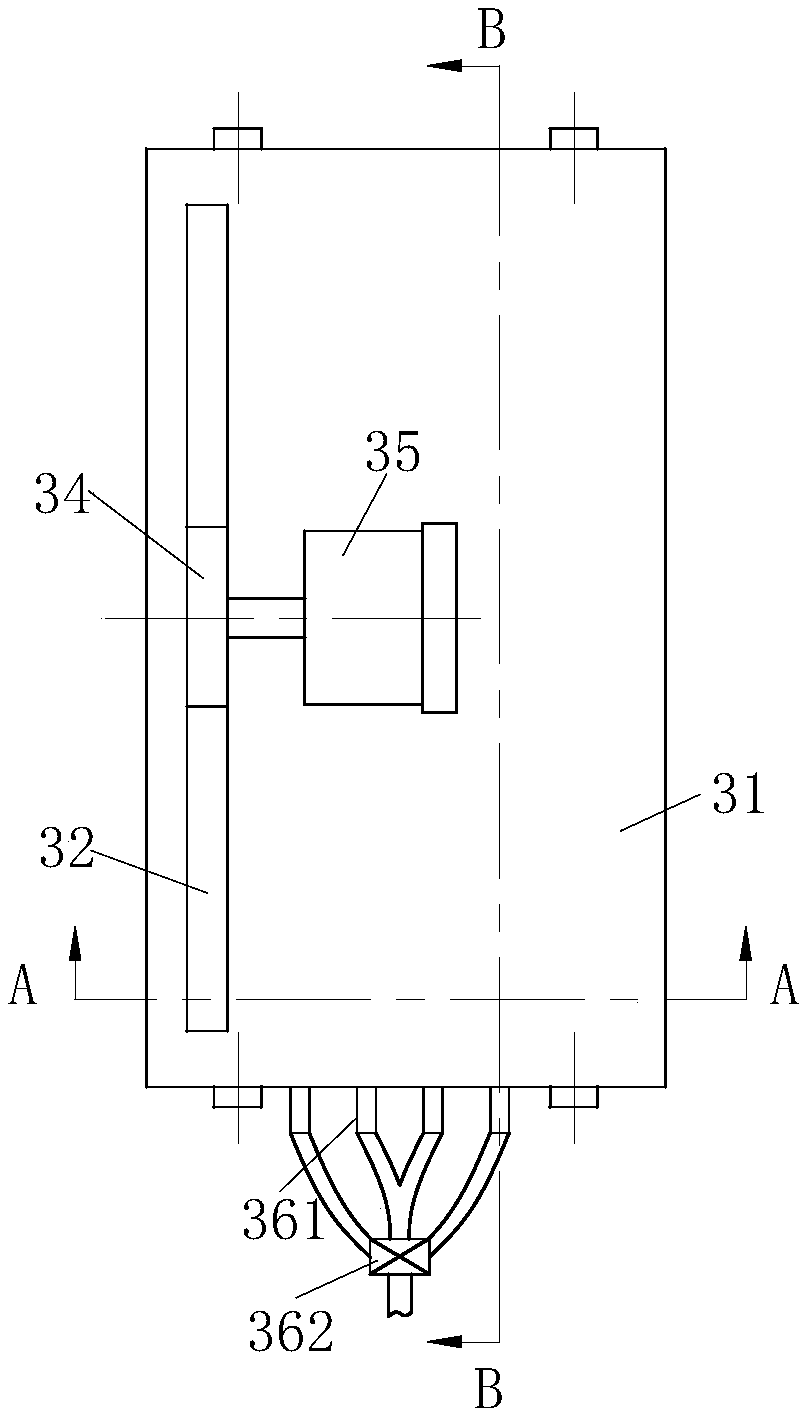

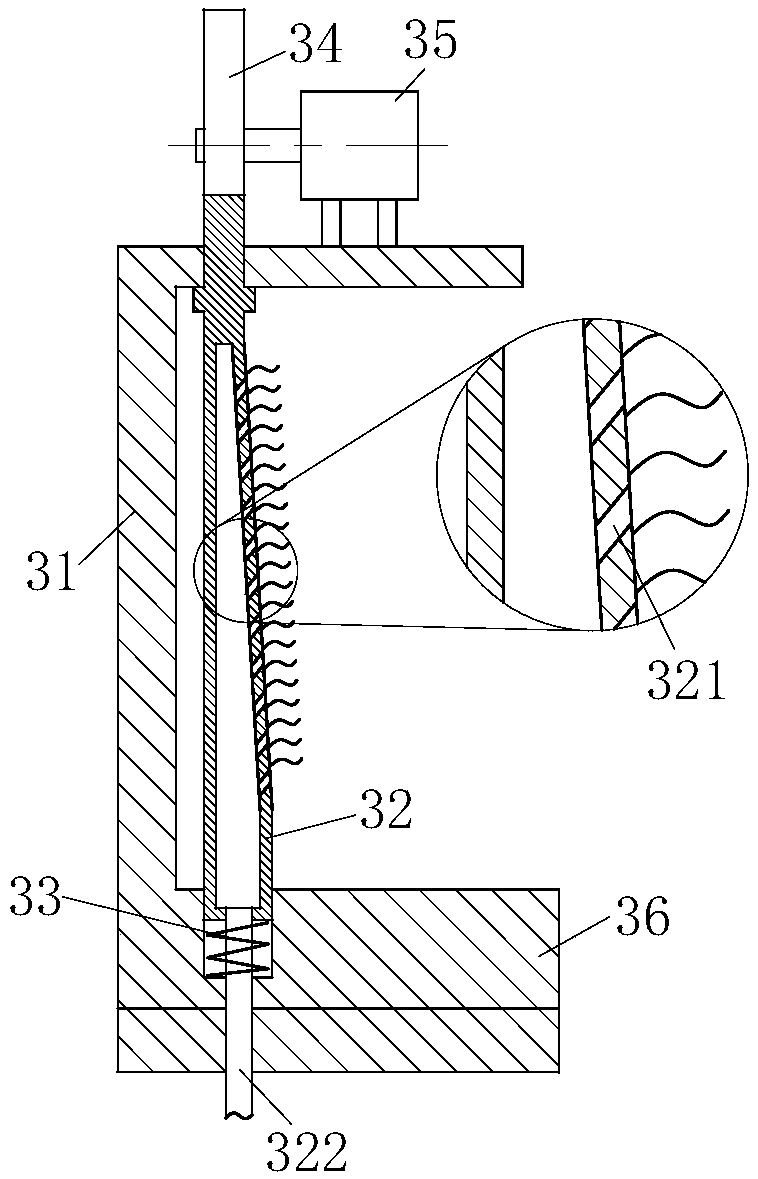

Raw material dissolving device and method for preparing porous inorganic material

ActiveCN113368715AImprove solubilityTumble fullRotating receptacle mixersTransportation and packagingEngineeringInorganic materials

The invention discloses a raw material dissolving device and method for preparing a porous inorganic material. The raw material dissolving device comprises a sealed cabinet, a left driving device, a right driving device, a spraying device, a cleaning device, a filter and a pressure supplementing device, the upper cavity and the square cavity in the sealed cabinet are respectively provided with a decomposition chamber and a collection chamber, and the center of the decomposition chamber is provided with a container. Stirring blades are arranged in the container, the left driving device drives the container to rotate along the transverse axis of the container, the right driving device drives the stirring blades to conduct rotary stirring and smashing in the container, spraying devices are installed on the left side and the right side of the container, and a cleaning device fixed to the center shell wall of the inner side of the sealed cabinet is arranged above the container. A pressure detector for monitoring the pressure intensity in the cavity is further installed on the right side of the sealing box cabinet, the filter is installed above the left driving device and filters generated gas, and the pressure supplementing device is installed above the right driving device and regulates and controls the pressure intensity in the sealed cabinet.

Owner:重庆新申世纪新材料科技有限公司

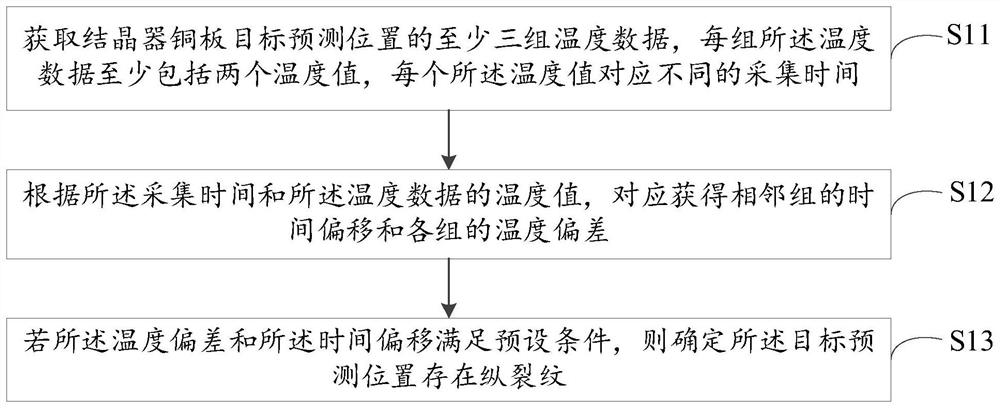

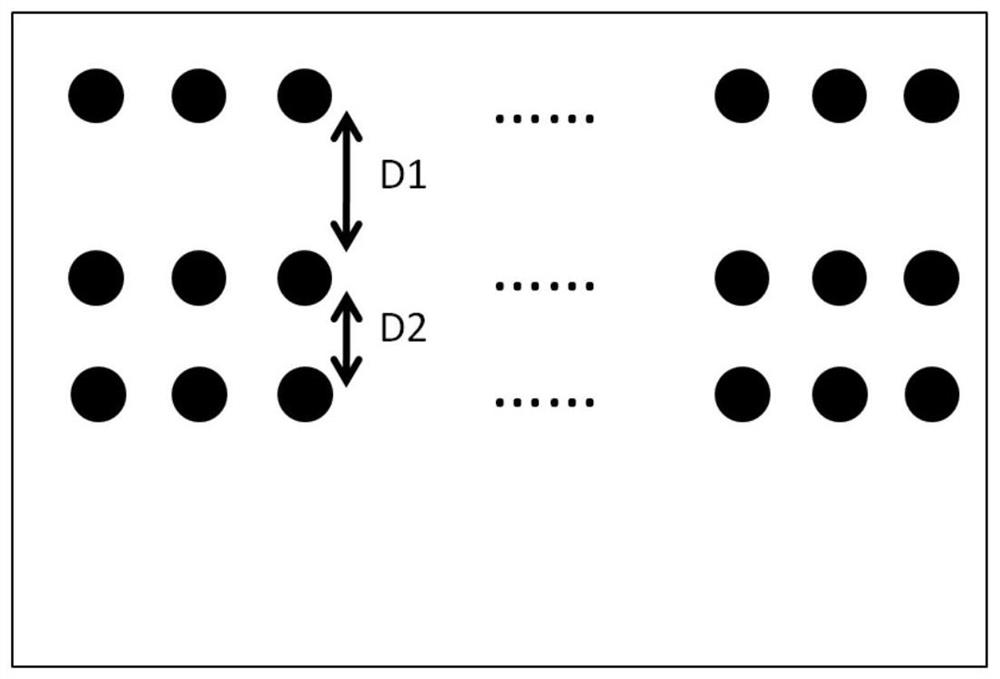

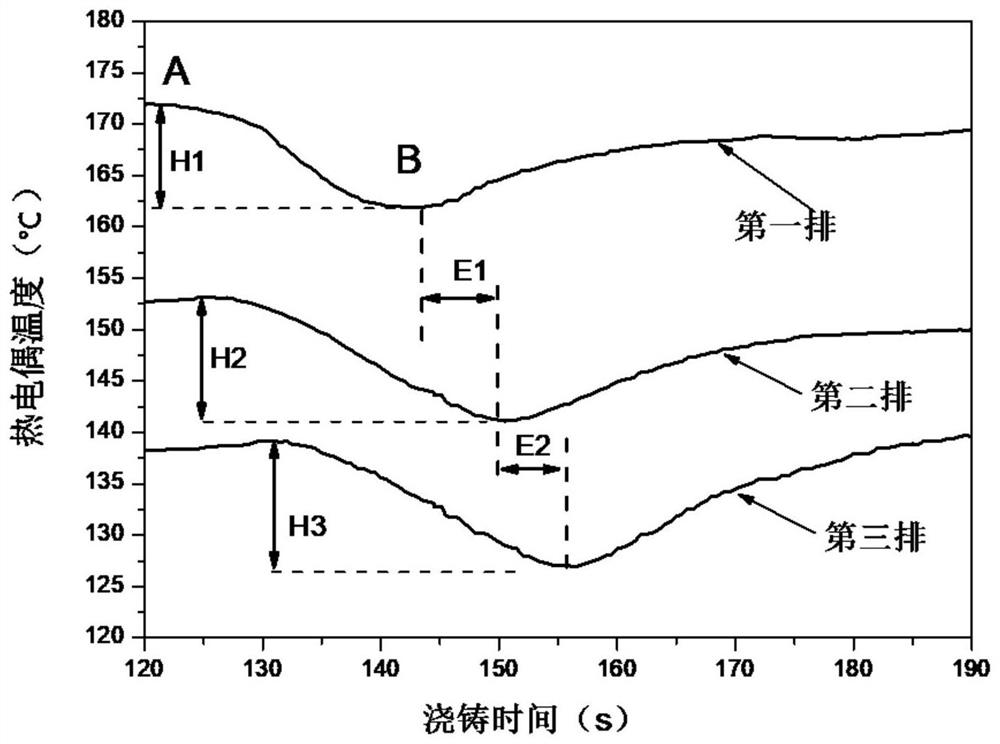

Method and device for predicting longitudinal crack of casting blank

PendingCN114850420AAccurate predictionEnables real-time forecastingManufacturing computing systemsComplex mathematical operationsThermodynamicsTwo temperature

Owner:SHOUGANG CORPORATION

A multi-process milling processing system for aluminum alloy anti-melting welding

ActiveCN108274052BReduce wastePrevent splashWorkpiecesMilling equipment detailsKeroseneLiquid storage tank

The invention belongs to the technical field of common milling machines, and particularly relates to an anti-fusion-welding multi-procedure milling processing system for an aluminum alloy. The systemcomprises a jetting module, a chip blocking module and a chip removal pipe; the jetting module comprises a sleeving belt pulley, a mounting frame, a rotating shaft, a connecting belt pulley, a belt, afirst cam, a compressor, a pipeline and a liquid storage tank, is arranged on one side of a milling machine spindle box in a matched mode, can jet kerosene and is used for blowing milling machine chips away from the chip blocking module; and the chip blocking module comprises a box body, a chip blocking plate, a spring, a second cam, a vibration motor and a guide plate, is arranged on one side ofa milling machine chip platform and is used for blocking the chips blown away by the jetting module. The system is particularly suitable for aluminum alloy milling in a small processing plant, the chips can be blown away by jetting the kerosene, and a cutter can be lubricated; and the chips can be intensively blown to the chip blocking plate, so that the chips can be prevented from splashing, thecleaning workload of operators can be reduced, and the working efficiency can be improved.

Owner:唐山尚德门窗有限公司

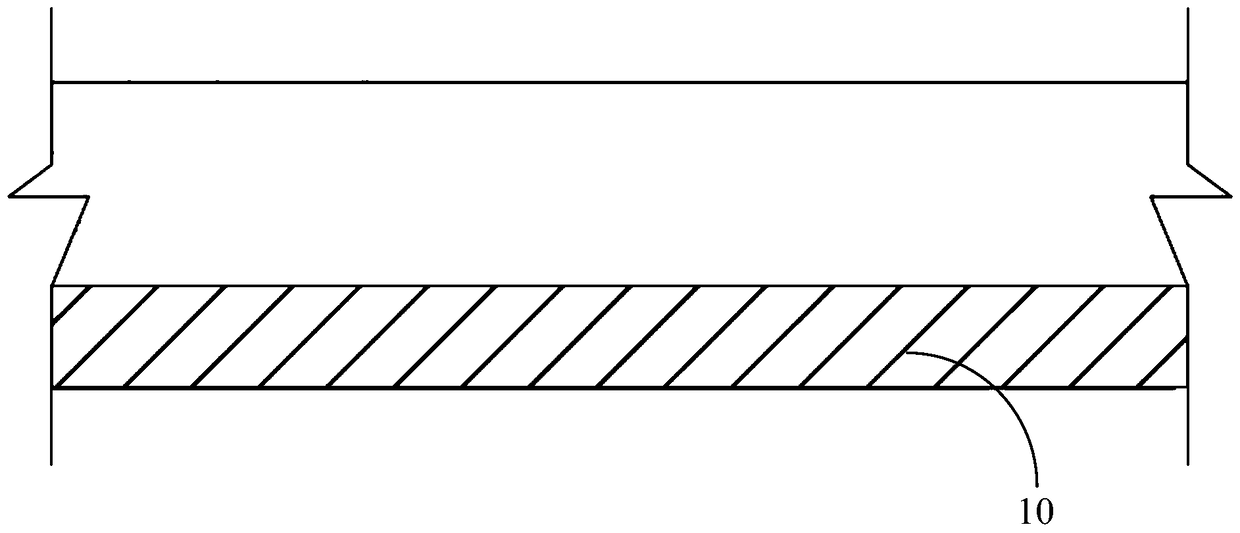

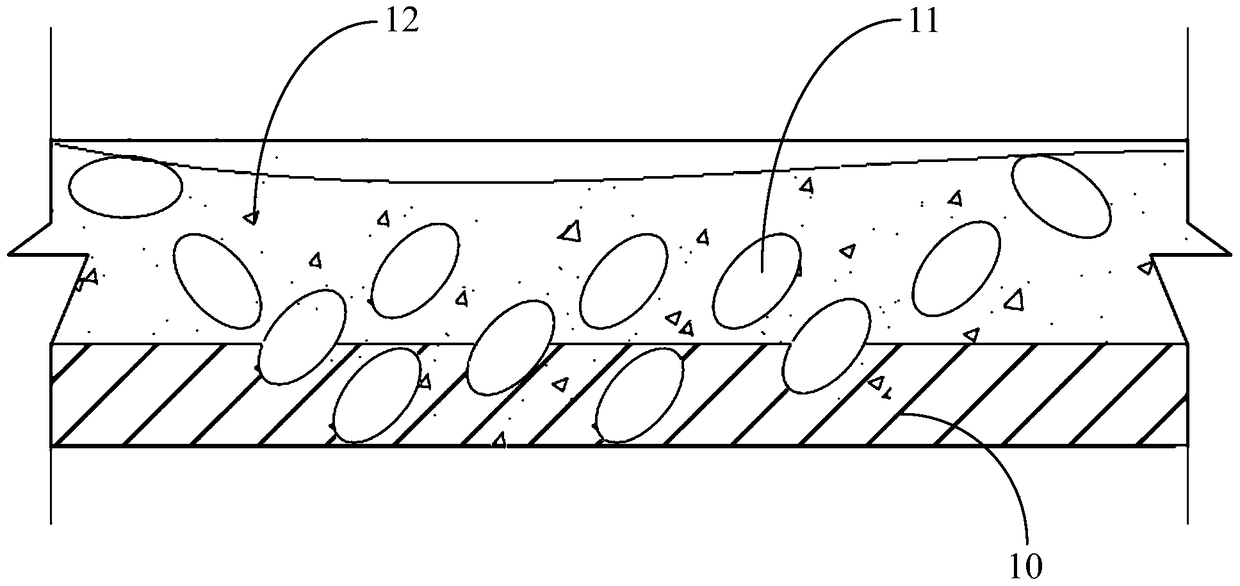

A kind of silt, quicksand ground treatment method

ActiveCN105297700BReduce the amount of cleaningGood adhesionSoil preservationActivated sludgeUltimate tensile strength

The invention discloses a method for treating silt and quicksand foundations, which comprises the steps of: removing a certain height of silt and quicksand in untreated silt and quicksand foundations to form cleaned silt and quicksand layers; Aggregate is backfilled in the quicksand layer to the design elevation, and the aggregate hits the silt and quicksand layer and integrates with the silt and quicksand layer to form a treated silt and quicksand foundation. The present invention adopts partial removal of silt and quicksand in the foundation to form silt and quicksand layers, and then smashes and backfills the aggregate into the silt and quicksand layers to integrate the aggregates with the silt and quicksand layers, which not only reduces the The cleaning amount of silt and quicksand reduces the input of labor and materials, and can also use the characteristics of the silt and quicksand layer itself to increase the bonding performance between aggregates, form a firm and stable whole, and improve the sludge after treatment. Structural strength of quicksand foundation.

Owner:SICHUAN TAILONG CONSTR GRP CO LTD

Method for Controlling Subcutaneous Bubble Defects of Medium Carbon Steel Wide and Thick Slabs

The invention discloses a method for controlling hypodermic bubble defects of a wide and thick slab of medium carbon steel. In the casting process, crystallizer protecting slag with alkalinity of 1.0-1.1 is used; the cooling strength of the bent section is controlled between 0.18-0.23 kg / L; the deformation is controlled to be 0.60 mm / m-0.70 mm / m under light pressure. A solid stopper rod is used, the argon blowing pressure of the middle ladle circular seam is 0.20-0.30 MPa, and the argon blowing flow is 2-4 L / min. According to the invention, the hypodermic bubble defects of the wide and thick slab of medium carbon steel can be effectively controlled, the cleaning amount of the casting blank in the later stage is reduced, the cleaning-free is achieved, meanwhile, the rejection rate of the rolled material is reduced, and the production cost is reduced; the system has the advantages of completeness and strong operability, can be rapidly popularized and promoted in production lines, and hasremarkable benefits.

Owner:HEBEI IRON AND STEEL

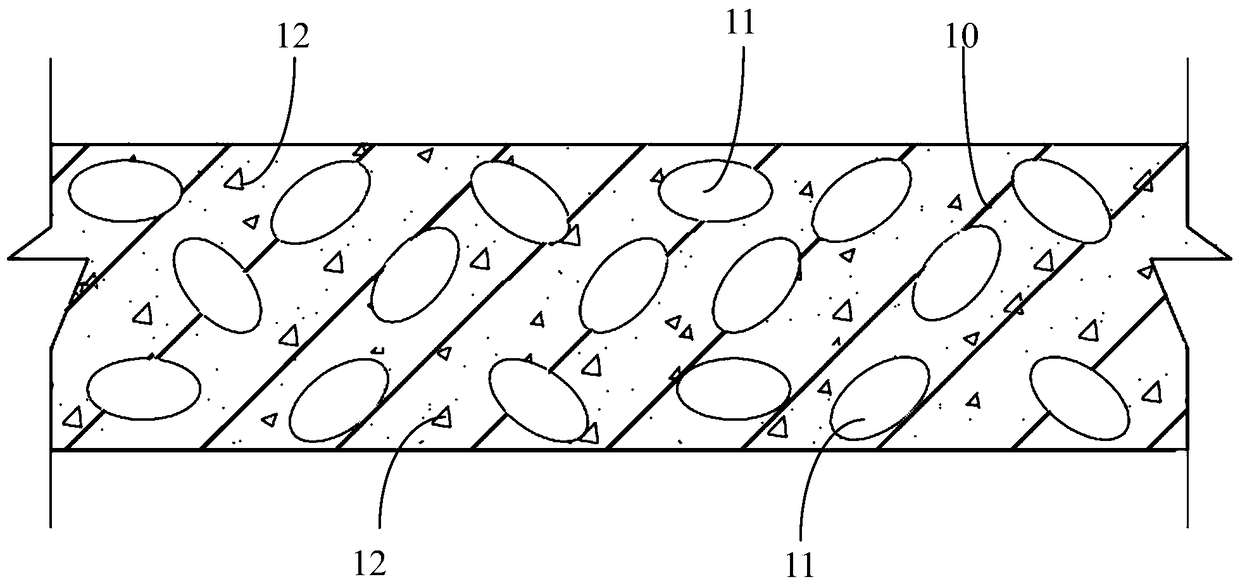

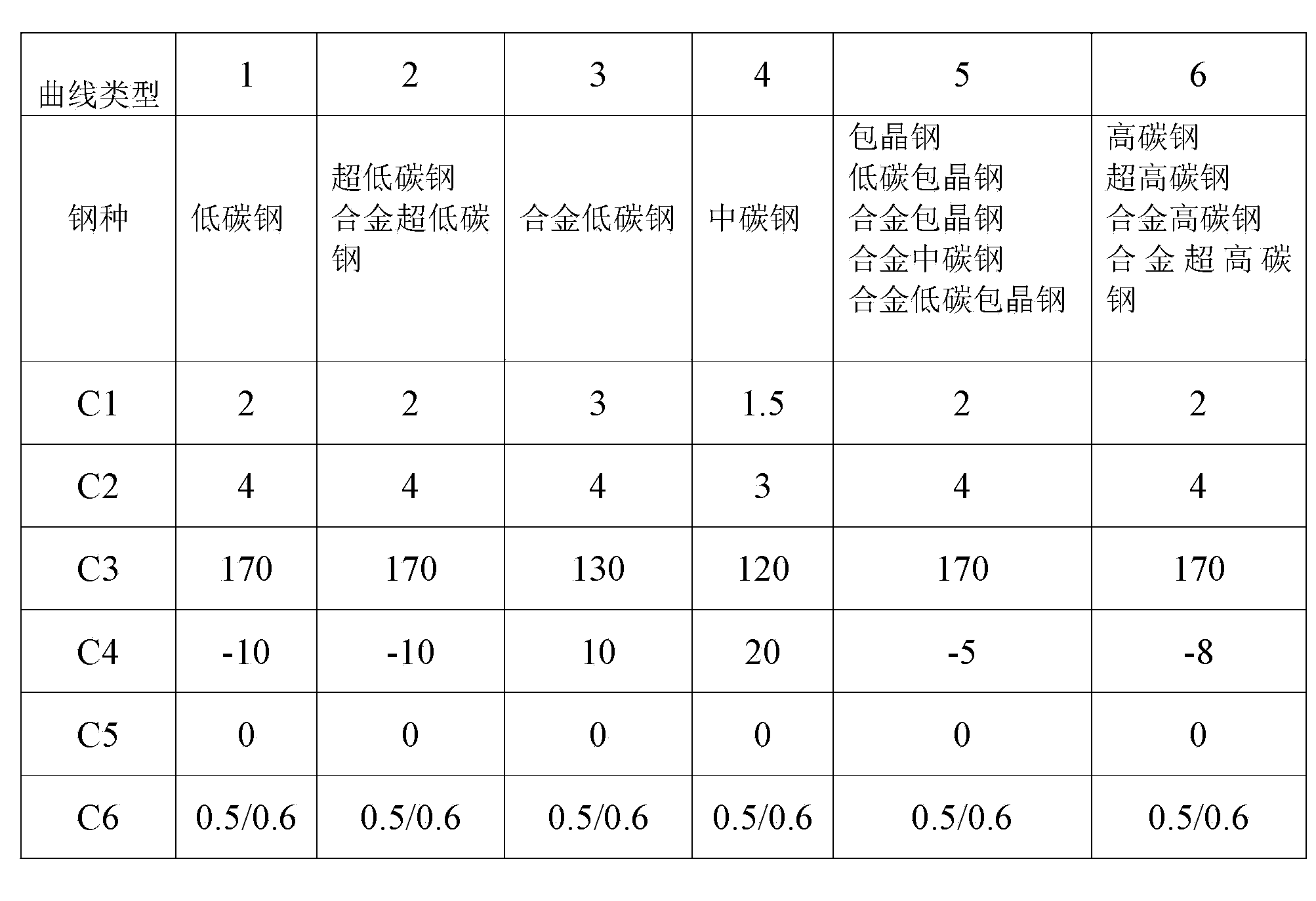

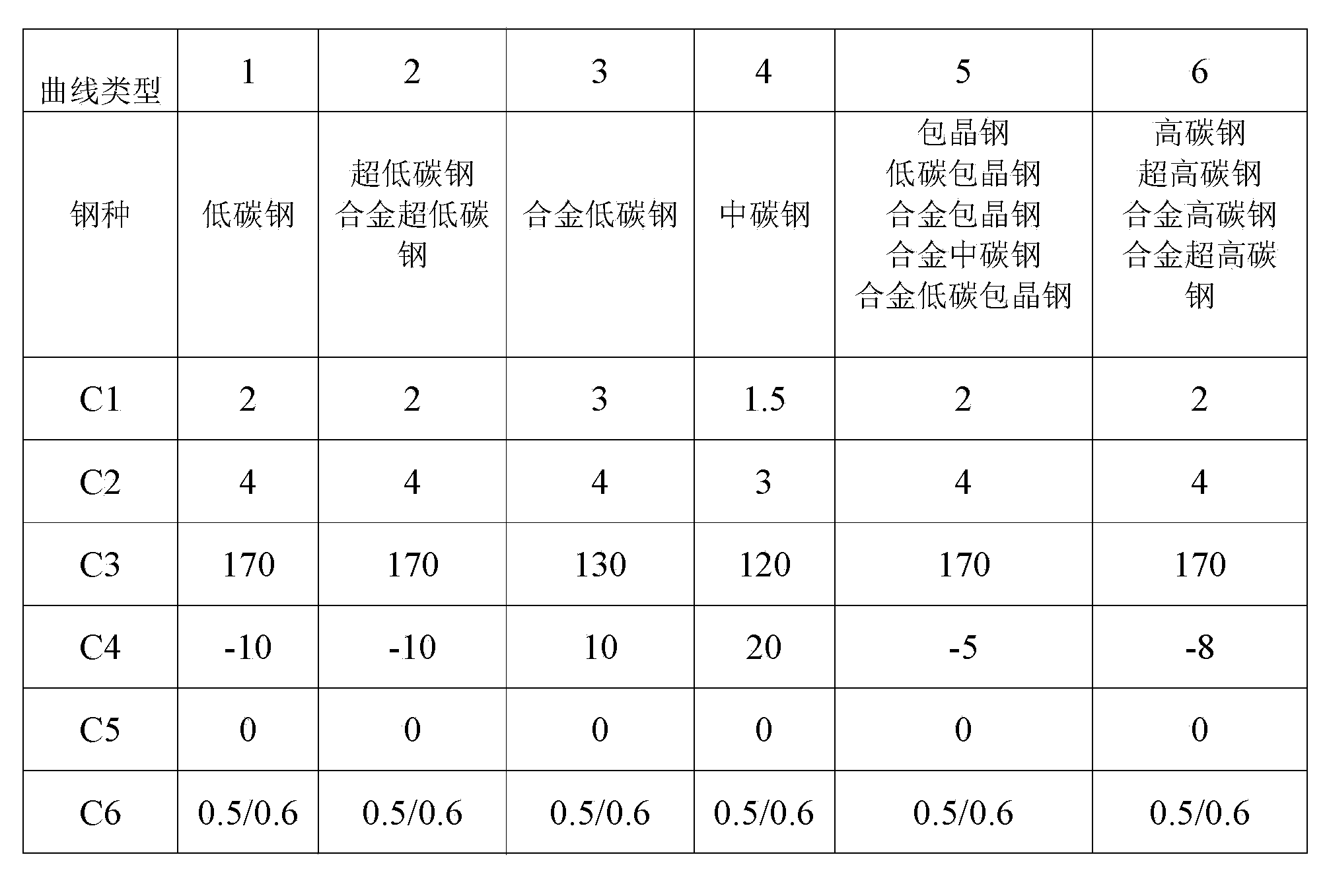

Parameter control method for vibrating table of continuous casting crystallizer

The invention provides a parameter control method for a vibrating table of a continuous casting crystallizer. The method comprises the following steps of: constructing an offline vibration waveform trigger according to a vibrating table waveform trigger model algorithm, and compiling a crystallizer vibration waveform generation program; setting sine and cosine vibration parameters according to different steel grades; writing the set vibration parameters into a data block of a vibration programmable logic controller (PLC) program of a primary control system, controlling a vibrator, and displaying waveforms, negative slip time and a vibration mark depth in real time by utilizing the waveform trigger; and determining a casting powder viscosity value of a corresponding steel grade. Therefore, sticking breakout accidents of the crystallizer and breakout early warning times can be effectively reduced; the surface quality of a casting blank is improved, the reject rate is lowered, and the metallic yield is improved; the cleaning capacity of a blank field is reduced, the casting blank cleaning cost is saved, and the labor intensity of flame cleaning personnel is reduced; and the risks of online thermal tests are reduced, and the viscosity applicability level of casting powder is improved.

Owner:ANGANG STEEL CO LTD

A stage performance prop table

Owner:伯希和户外运动集团股份有限公司

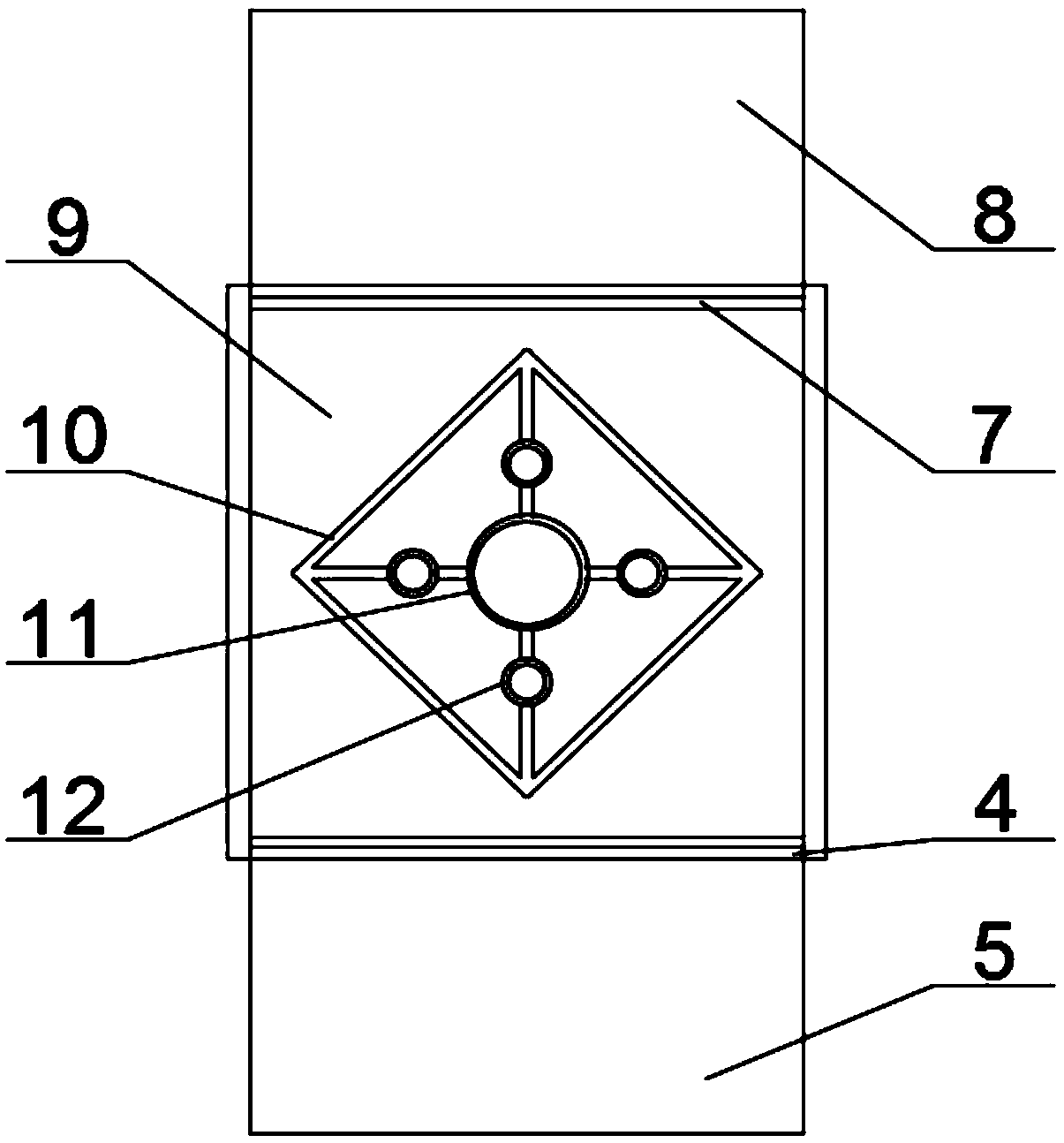

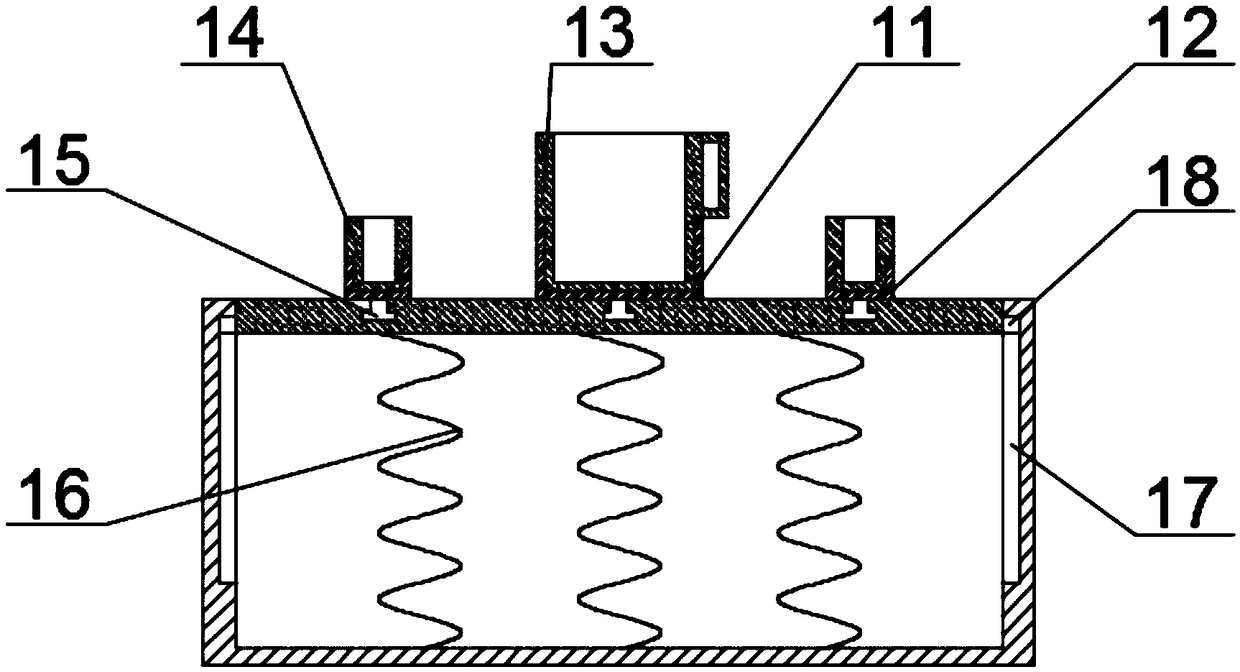

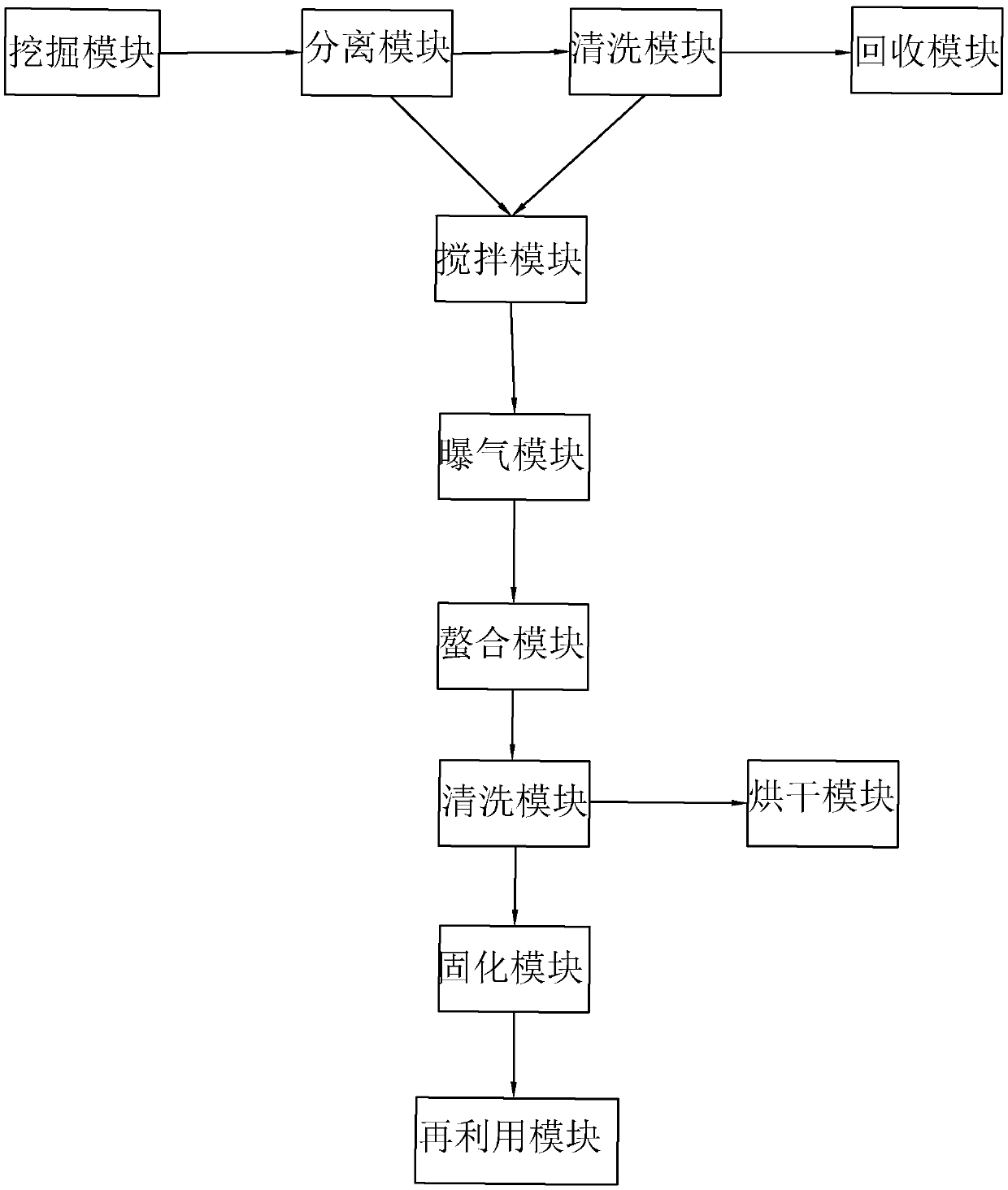

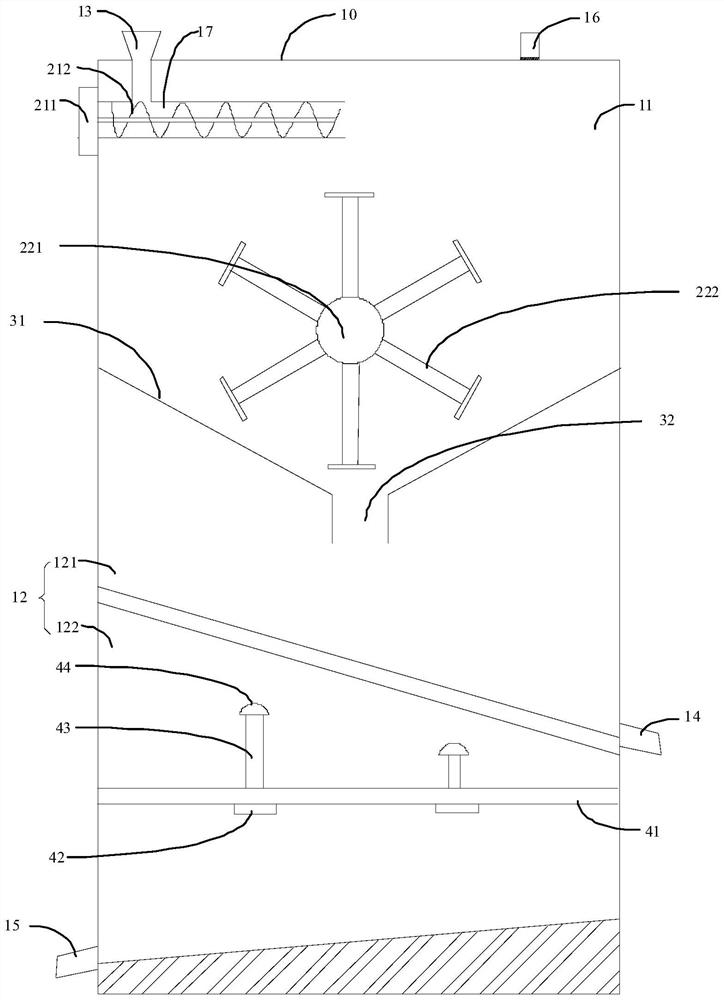

Treatment system and method for river pollution

InactiveCN109626770AAvoid secondary pollutionReduce the amount of cleaningSludge treatment by de-watering/drying/thickeningWater contaminantsAfter treatmentSludge

The invention discloses a treatment system and method for river pollution and relates to the technical field of river pollution treatment. The problem is solved that in the prior art, river bottom sludge cannot be treated. According to the technical scheme, the system is characterized by comprising a digging module, an aeration module, a chelation module, a cleaning module, a solidification moduleand a recycling module; the method comprises the following steps of sludge digging, separation, cleaning, recycling, stirring, aeration, chelation, cleaning, drying, solidification and recycling. Thebottom sludge in a river is drawn out from the river and then treated, pollutants in the bottom sludge are removed, the situation can be avoided that secondary pollution of water is caused by the bottom sludge, and the bottom sludge after treatment can also be recycled.

Owner:深圳市升源园林生态有限公司

A kind of equipment that can improve the efficiency of laser selective melting and forming and its application method

ActiveCN108188391BReduce running timeShorten exercise distanceAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceLaser

Owner:XIAN SPACE ENGINE CO LTD

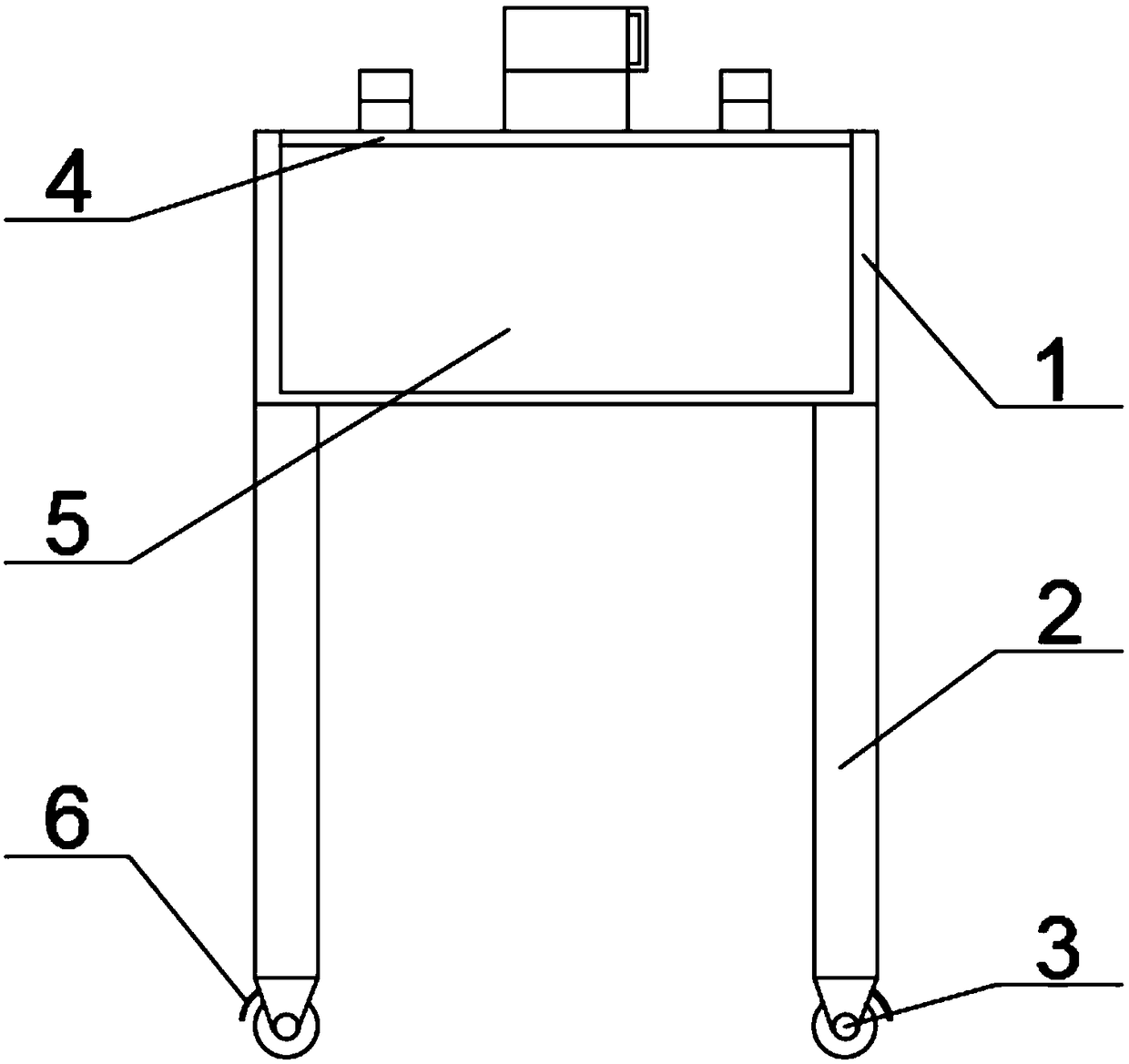

A household floor cleaning machine

ActiveCN103505157BReduce the amount of cleaningReduce volumeMachine detailsFloor-scrubbing machinesEngineeringIn degree

The invention belongs to a cleaning appliance and particularly relates to a household floor cleaning machine which is suitable for household use. The household floor cleaning machine is characterized by comprising a vehicle body, a towel box arranged at the bottom of the vehicle body, a transport component, a conveying and pushing part, a pushing component for pushing a towel transported by the transport component to the bottom of the vehicle body, and a dirty towel storage box for storing dirty towels, wherein the dirty towel storage box is provided with a dirty towel inlet and a dirty towel outlet, and a towel pushing outlet is formed in the position, corresponding to the lower part of the pushing component, at the bottom of the vehicle body. The cleaning machine cleans the ground by automatically transporting and pushing the towel, is in tight contact with the ground, has a good cleaning effect. The transport is convenient and smooth, and jamming is not likely to happen. The equipment cannot be easily damaged and is long in service life. The cleaning machine is simple in structure, low in cost, high in degree of automation and good in cleaning effect.

Owner:如东县东广物流有限公司

Barium sulfate stirring and filtering equipment

PendingCN114505220AReduce chance of blockageReduce the amount of cleaningSievingScreeningEngineeringMechanical engineering

The invention discloses stirring and filtering equipment for barium sulfate. The stirring and filtering equipment comprises a box body, a stirring assembly, a filtering plate and a vibration assembly, a feeding port is formed in the box body, a flow guide plate is arranged in the box body, a flow guide hole is formed in the flow guide plate, a heating cabin and a filtering cabin are formed in the box body through the flow guide plate, a plurality of heating pipes are evenly arranged in the heating cabin, the stirring assembly is installed in the heating cabin and opposite to the feeding port, and the filtering plate is installed in the filtering cabin and provided with a plurality of filtering holes. The filter plate and the flow guide hole are oppositely arranged, the vibration assembly comprises a mounting rod, a vibration piece and a driving piece connected with the vibration piece, the mounting rod is mounted in the box body and located on the side, away from the stirring assembly, of the filter plate, and the vibration piece is mounted on the mounting rod and located on the side, facing the filter plate, of the mounting rod; according to the technical scheme, the vibration assembly is arranged, so that materials are prevented from blocking the filtering plate, the filtering effect is improved, and the cleaning amount of the filtering plate is reduced.

Owner:深圳市锦昊辉实业发展有限公司

Spraying equipment for backlight component

InactiveCN107335557ANot easy to fallReduce the amount of cleaningLiquid spraying apparatusPalletLight source

The invention relates to the technical field of coating technologies, in particular to spraying equipment for a backlight component. Paint is not likely to fall to the portion outside a work box, and the cleaning amount of workers is reduced; meanwhile, the paint containing place is cleaned conveniently; the equipment comprises a base, the work box, a motor, a communicating pipe, a support and a spray gun, a rotating shaft is arranged at the output end of the bottom of the motor, stirring blades are arranged on the rotating shaft, and the spray gun is arranged on the top of the support; the equipment further comprises a cover plate and four fixed blocks, the cover plate is arranged on the top of the work box, the motor is arranged on the top of the cover plate, and the fixed blocks are arranged on the left side, the right side and the rear side of the cover plate respectively; the equipment further comprises a containing box, a left spring set, a left clamping plate, a right spring set and a right clamping plate, the containing box is arranged in a working chamber, the left end of the right clamping plate makes contact with the upper half area of the right side wall of the containing box, a through hole is formed in the lower side of the right end of the containing box, and a seal sleeve is arranged at the input end of the communicating pipe.

Owner:YANCHENG SANDING ELECTRONICS TECH CO LTD

Material return type bucket elevator

The invention discloses a material return type bucket elevator, which comprises a housing, chain wheel groups, a motor, and a transmission chain, wherein the motor drives the chain wheel groups; the transmission chain is mounted on the chain wheel groups in a matching manner; a plurality of hoppers are arranged on the transmission chain; guide plates are symmetrically arranged inside the housing; and a material return groove is arranged between the guide plates in a matching manner. Through the adoption of the structure, the material return type bucket elevator provided by the invention can reduce the waste of raw material, guarantees that an elevator body is clean and tidy, and reduces the cleaning load.

Owner:李严光

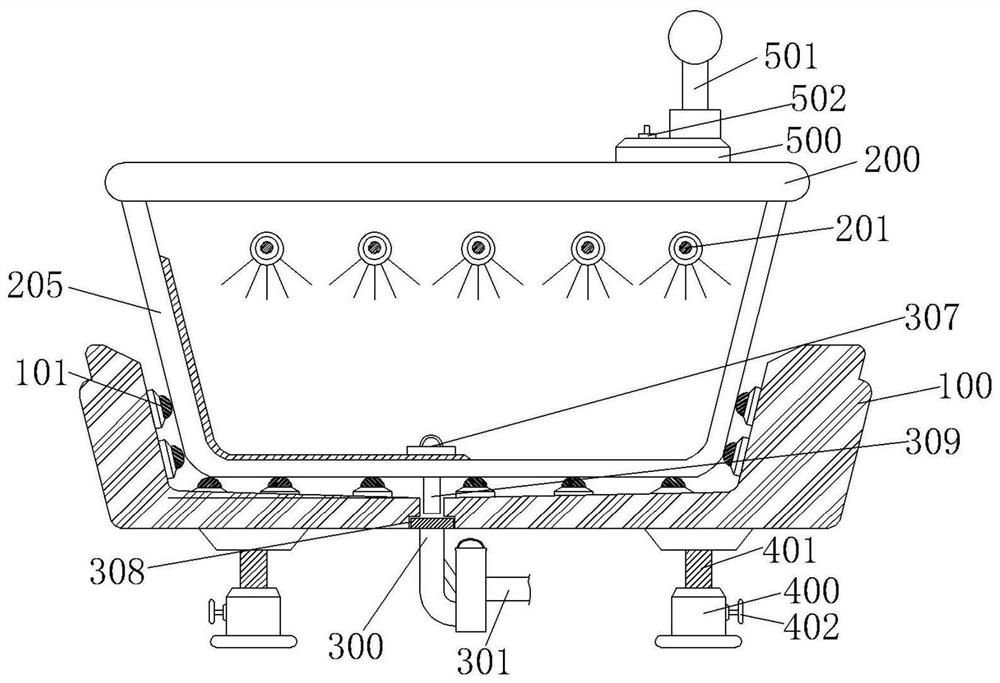

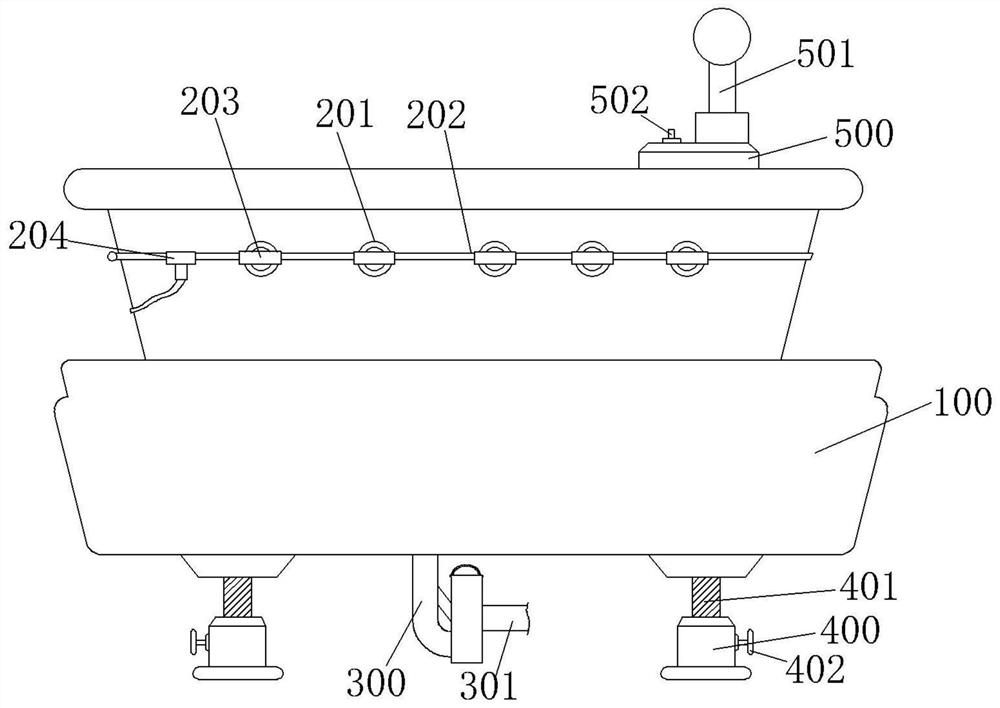

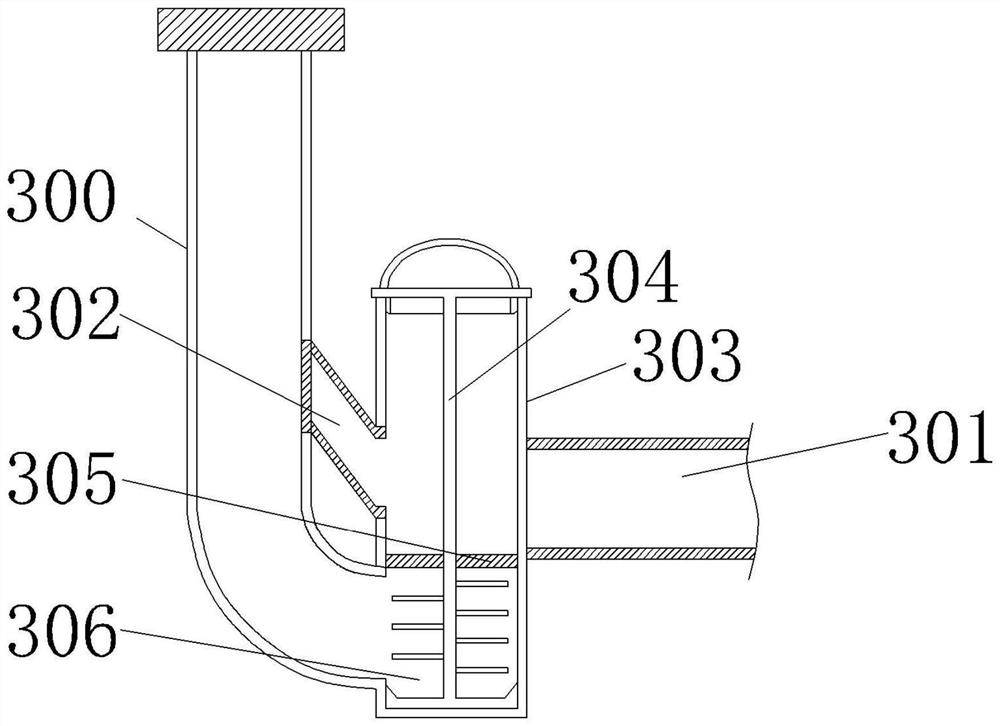

Electronic equipment for quickly cleaning bathtub

InactiveCN112545338AReduce the amount of cleaningAvoid cloggingBathsDouchesBathtubMechanical engineering

The invention relates to the technical field of cleaning and discloses an electronic device for quickly cleaning a bathtub. The cleaning mechanism comprises a mounting base, wherein buffer pads are uniformly arranged on the inner wall of the mounting base, the bathtub is placed in the mounting base, fan-shaped nozzles are uniformly and fixedly connected to the inner wall of the bathtub, the fan-shaped nozzles are fixedly connected to the outer wall of the mounting base, and one side of the fan nozzle is fixedly connected with a tee connector; According to the electronic equipment for rapidly cleaning the bathtub, water flow in the water passing pipeline is controlled by rotating the adjusting valve, the inner wall of the bathtub is cleaned by arranging the multiple sets of fan-shaped nozzles, and therefore waste adhering to the inner wall of the bathtub can flow to the treatment pipe; when a user enters the bathtub, overflowed water flows into the mounting base along with the outer wall of the bathtub and then flows into the collecting pipe, so the overflowed water can be quickly collected, the water is prevented from falling to the ground, and the cleaning amount of the user for abathroom is reduced.

Owner:杭州展虹科技有限公司

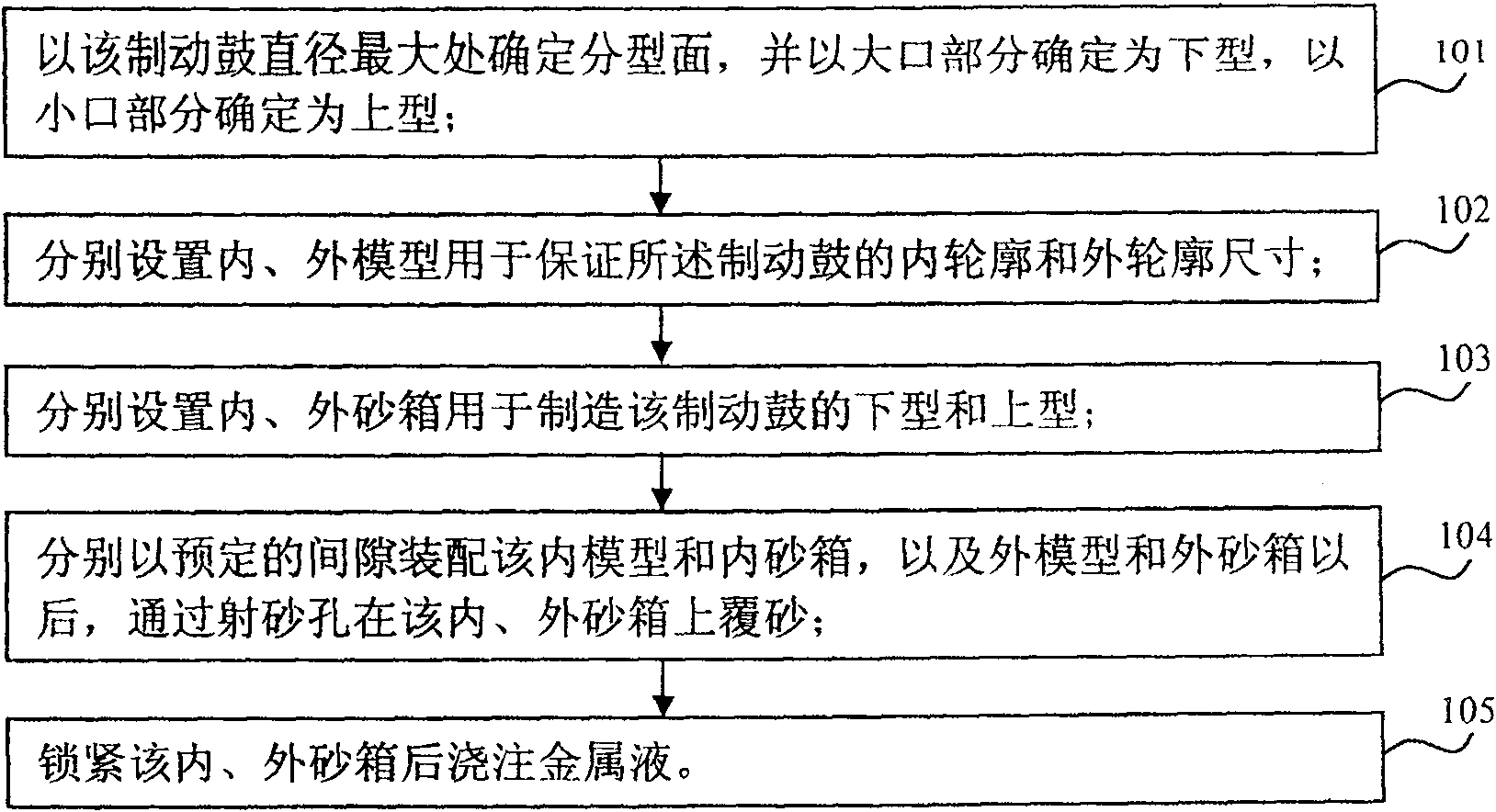

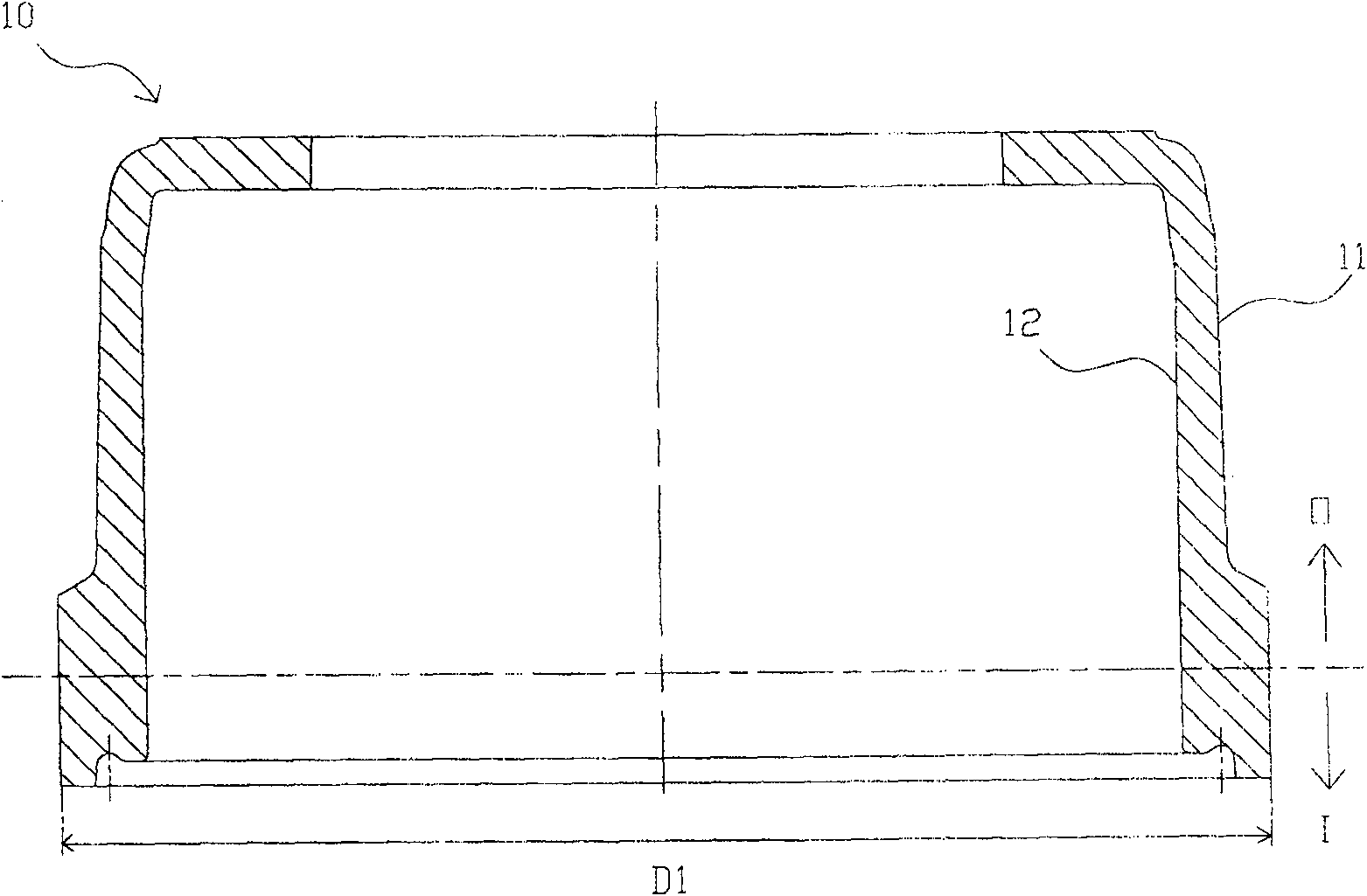

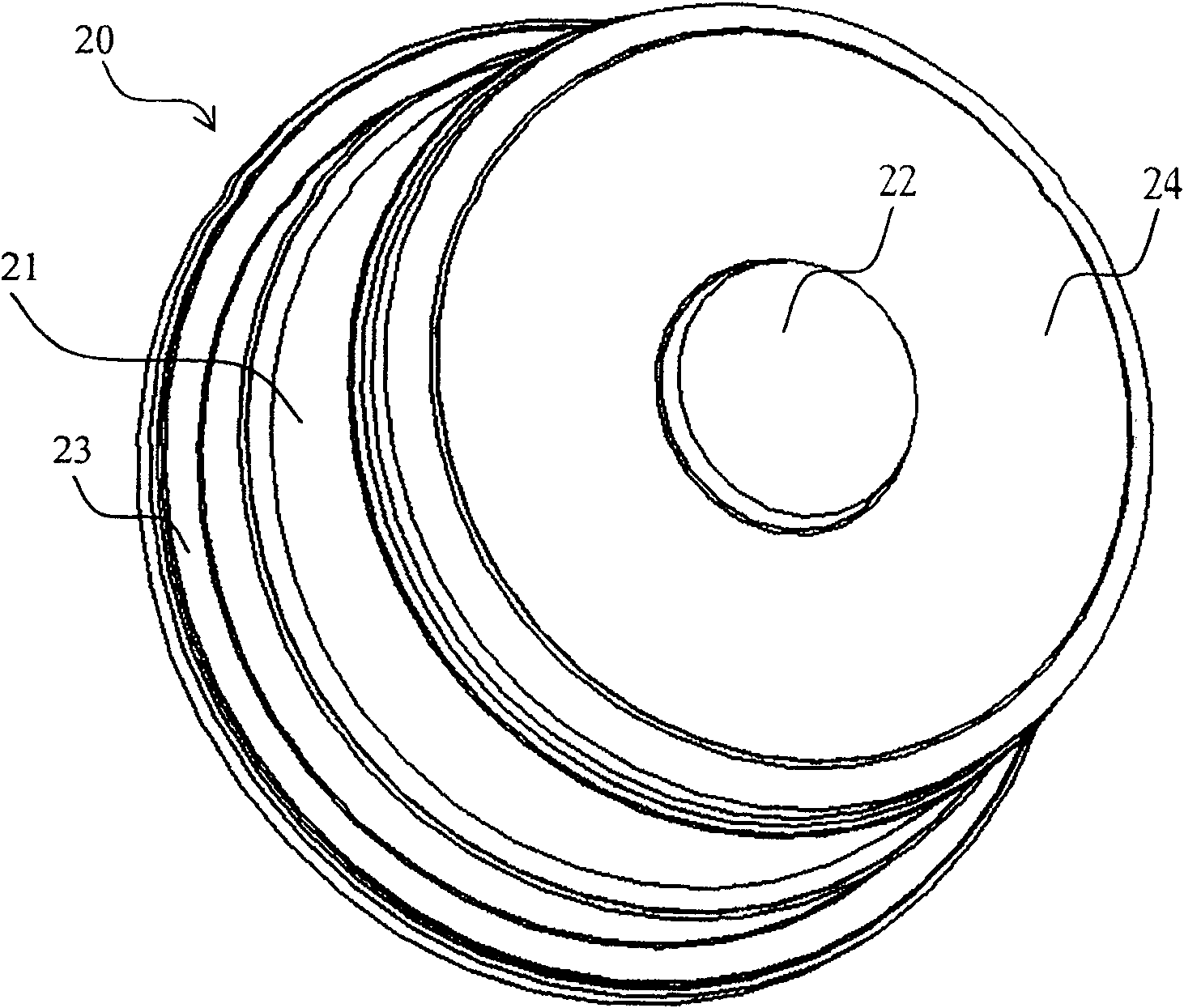

Method for using metal type sand-covering technique to manufacture brake drum

The invention relates to a method of manufacturing a brake drum by utilizing a metal-typed sand covering technique, comprising a die joint is determined by the maximum diameter position of the brake drum, a lower joint is determined by a large mouth part and an upper joint is determined by a small mouth part; an internal model and an external model are respectively arranged in order to ensure the internal profile dimension and the external profile dimension of the brake drum; an internal sand box and an external sand box are respectively arranged in order to manufacture the lower joint and the upper joint of the brake drum; after the internal model and the internal sand box, the external model and the external sand box are assembled according to prearranged clearances, the internal sand box and the external sand box are covered with sands through a sand injection hole; metal liquid is poured after the internal sand box and the external sand box with sand cover are tightly locked. The invention has the advantages of improving working environment, more precise dimension of the castings, better surface quality, higher yield, lower cost and higher production efficiency.

Owner:ZHUMADIAN ZHONGJI HUAJUN CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com