Belt conveyors

A technology of belt conveyors and conveyor belts, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of heavy labor, low production efficiency, and the flat belt conveyor is easily affected by the external environment, so as to reduce the amount of cleaning and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

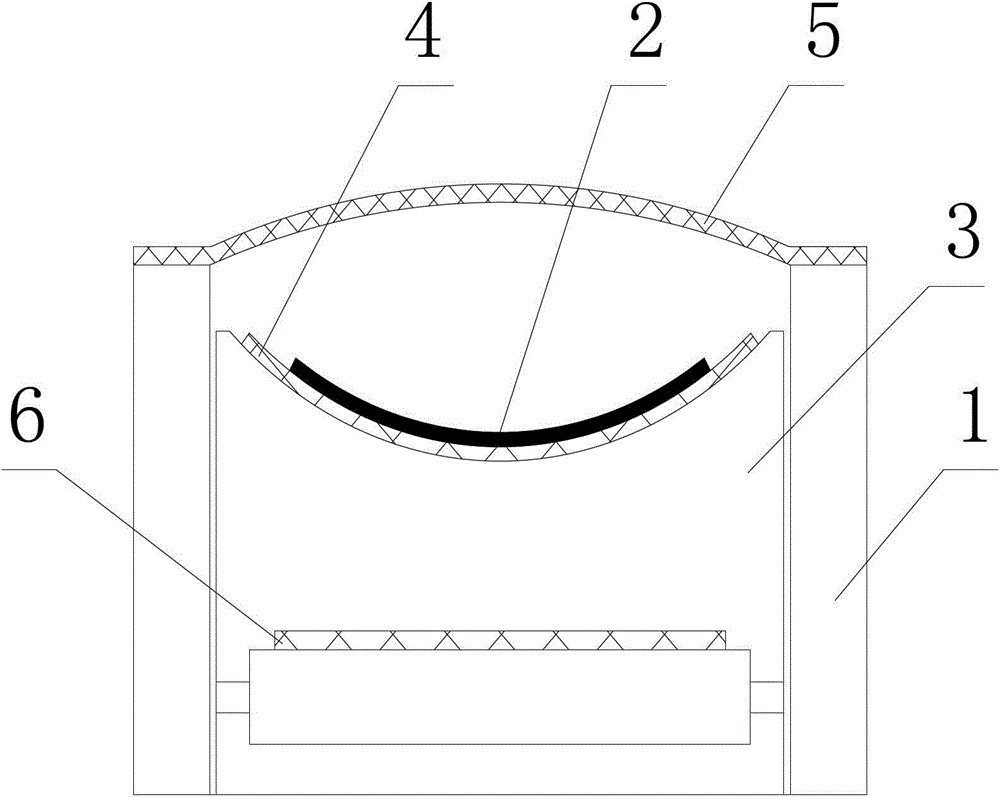

[0014] Such as figure 1 As shown, the belt conveyor includes a frame 1, a conveyor belt 2 arranged on the frame 1, a partition 3 is provided on the frame 1 below the conveyor belt 2, and the upper end cross section of the partition 3 is Arc-shaped, the middle part of the partition 3 is provided with a support portion 4 supported by the conveyor belt 2, and the frame 1 above the partition 3 is provided with an upper cover 5, between the upper cover 5 and the partition 3 Form a closed space, the frame 1 below the partition 3 is provided with a conveying device 6 for material return, the central angle corresponding to the circular arc is 120-150°, and the circular arc corresponding The radius is 80-100mm. When the material falls to both sides of the conveyor belt, the material automatically falls back to the conveyor belt through the support part 4, which reduces the accumulation of dust on the frame 1. The support part 4 is wear-resistant Sliding plate, the middle part of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com