A kind of production method of stainless steel clad plate

A technology of stainless steel plate and production method, which is applied in the field of metal pressure processing, to achieve the effects of avoiding defects and later repairing costs, preventing surface oxidation, and ensuring weld penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

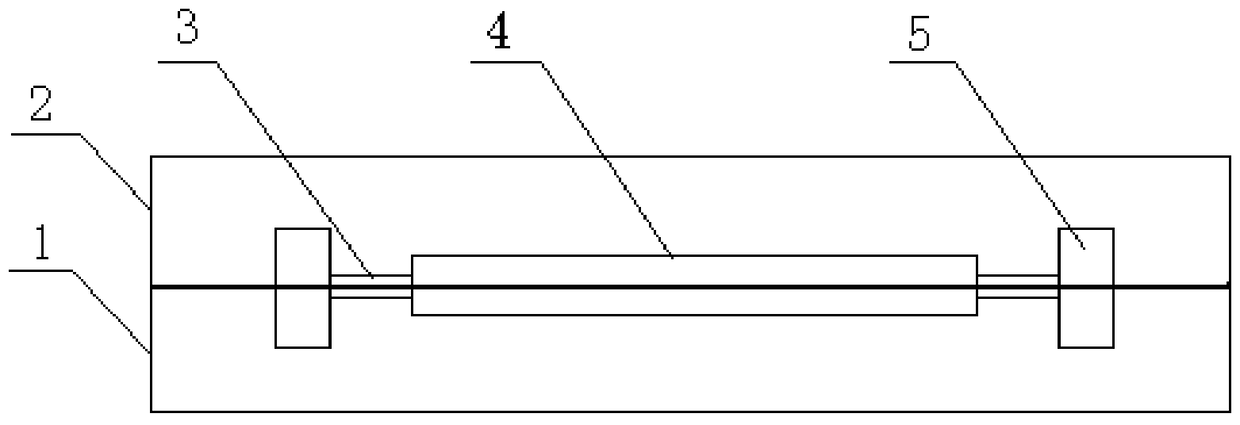

[0024] The size of the 316L stainless steel plate 4 is 2000×1400×13mm, and the dimensions of the Q370qE lower carbon steel base billet 1 and the upper carbon steel base billet 2 are 3756×1622×250mm.

[0025] 1. One side of the lower carbon steel base billet 1 and the upper carbon steel base billet 2 is used as a composite surface, and the composite surface is subjected to surface polishing treatment.

[0026] 2. Dig out an embedding groove in the middle of the base billet according to the size of the stainless steel plate 4. The depth of the embedding groove is 13mm, and the length and width are 2002×1402mm to ensure that the roughness of the composite surface of the billet should not be greater than 5mm per 1000mm. Then, a slit 3 and an exhaust chamber 5 communicating with it are respectively processed at both ends of the slot. The volume of the two exhaust chambers 5 is 800×100×40 mm. The exhaust chamber 5 is connected to the stainless steel plate 4 through the slit 3. bondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com